Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Asset Management

Caricato da

Rahul JuwareDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Asset Management

Caricato da

Rahul JuwareCopyright:

Formati disponibili

Asset Management Service

A unique and customised service provided by Schneider Electric in order to help the customer to

manage and maintain his installations.

Q1. Content of Asset Management Program

Prevent contract with three offers which conceive Long Term Maintenance Contract (LTMC)

and Annual maintenance Contract (AMC) .

Customer criteria for Asset management program:

The entire electrical installation of a site from 250 kVA, 10 MVA.

Q2.What is LTMC/AMC ?

LTMC (Long Term Maintenance Contract) and AMC (Annual maintenance Contract) are

maintenance services offered, stretching over the period of 1 -5 years depending on type of

the contract.

Q3. Benefits to the Customer

A customised maintenance plan according to customer process and installation,

defined and scheduled according customer requirement.

Overview of budget to be set aside for maintenance.

Periodic diagnostic of installed equipments

Site intervention by Schneider Electric expert assuring high safety measures .

Reduced downtime .

Original manufacturer equipment guarantee.

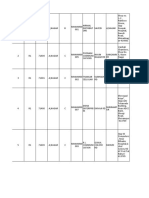

Q4.What are the different services provided under Prevent contract?

Prevent contract with three offers

NOTE:

‘24/7 Hotline’

‘24/7 Hotline’ provides exclusive access to group of experts in electrical distribution to satisfy

customer requirements during normal operation but especially in case of problem.

‘Emergency on site intervention’

Competent and responsive technical support intervention by a Schneider Electric expert on

customer site so asto make repairs as quick as possible.

‘Emergency Spare Parts Delivery’

SEI guarantee to deliver customer spare parts (agreed at the start of contract ) within a

contractual timescale which reduces the customer’s stoppage time.

‘Asset Online’

Online service which facilitates customer to view and keep track of maintenance operations

24/7 through Zen server.

Zen server is a repository to manage the assets data all along their life span.

Q5. How Prevent contract helps customer to control budget?

Emergency On-Site Intervention’ and ‘Emergency Spare Parts Delivery’ costs included

options provide formal statement of the financial resources set aside for carrying out

maintenance for a fiscal year .

Q6.Can customers go for customized Prevent?

Yes, but it is advisable to go for full offer as it results in cost optimisation.

Q7.Which services are outside the framework of Prevent contract?

The following services are not covered under Prevent Contract Proposal:

Equipment damage resulting from use that is not compliant with SEI's recommendations

Failure of equipment where SEI's recommendations for improvement and realignment with

specifications were not accepted;

Failure due to a lack of compliance with standard safety rules.

Incorrect operation of the equipment

Falling or shock

Force Majeure conditions.

Attempts to service or repair equipment without SEI's intervention or prior agreement

Failure of equipment not covered under Prevent Contract Proposal.

Action of non SEI authorized personal

Q8. What are the different levels of maintenance activities carried out under Prevent contract?

4 levels of maintenance are:

Level 1: Simple adjustments with no dismantling of equipment. Replacement of consumable

components that may be accessed with no safety risks

Level 2: Troubleshooting by standard replacement. Minor preventive maintenance operations,

such as greasing or checking of operation

Level 3: Operations requiring complex procedures and/or portable support equipment that is

complicated to use or implement.

Level 4: Operations whose procedures require comprehensive knowledge of a particular

technique or technology and/or the use of specialised support equipments.

Note: level 1 and 2 can be executed by the subcontractor but level 3 and 4 can be

executed by a Schneider Electric expert only.

Q9.Can Prevent contract be revised?

Yes, Prevent contract can be revised for further 2-10 years.

Q10.What is IB suite?

IB suite is an IT tool embedding specific modules related to maintenance intervention.

Q11.How IB suite helps in maintenance activities?

Schneider Electric engineer uses it to:

Create, Visualize and update equipment Tree view

Describe Equipment

Execute Manufacturer maintenance procedures

Collect Installed base data and equipment behavior

Generate Maintenance reports

Q12.What are Special services?

Special services comprise specific proprietary tools required for diagnostic work on electrical

distribution equipment. Special services include

ProSelect

ProDiag

ProCorona

Thermography

ProFusion

ProSelect

Q13. What is ProSelect?

Pro-Select is a test carried out to calculate tripping curve using Pro-Select software and to check

MV/LV and LV/MV discrimination.

Equipment Ranges- Masterpact M, Masterpact NT/NW, Compact C, CM, NS

Q14.What are the advantages of Pro-Select?

Detects a control unit failure

Detects a mechanical problem with the trip unit

Detects incorrect upstream/downstream (MV/LV and LV/LV) discrimination.

Q15. Execution steps for Pro-Select?

Shut down the equipment.

Current is injected from external source into the secondary coil and response time is measured.

Display of tripping curve for actual settings using the Pro-Select software.

ProFusion

Q16.What is Pro-Fusion?

It is a tool for analysis of possible drift on fuses due to overload and thermal capacity filament of the

fuses

• Equipment: MV fuses – all brands

• Job type: Intrusive (with shutdown)

• Tools : Pro-Fusion software

Q17.What are advantages of ProFusion ?

Avoids thermal runaway of fuses

Avoids fuse blowing following an overload

Q18.How Pro-Fusion works?

It works on the fact that if filament of fuse is destroyed, the resistance increases which results in

heating.

Shut down the equipment

Measure the resistance of an MV fuse using a milliohmeter.

Check this measurement with the ProFusion software.

ProDiag

Q19.What is ProDiag?

It is quality test performed by a specialist technician using a data acquisition suitcase and the

Pro-Diag expert software. It is performed on-site on a device that is operational and measures

equipment's dynamic characteristics throughout a full cycle(arming, closing, opening).

Q20.What are the measurements taken by ProDiag expert software?

Measurements taken are:

Arming time of control mechanism

Maximum current during arming

Opening and closing times

Opening and closing speeds

Simultaneousness of contacts at opening and closing

Bounce and over-travel

Wear of arcing contacts

Q21. What are advantages of ProDiag ?

Checks MV circuit breaker performance.

Evaluates equipment wear and tear.

Monitoring of performance deviations in order to anticipate failures

Target required maintenance actions

Help to plan and smooth out maintenance budgets

Anticipate a breakdown by identifying and planning preventative actions

Q22. How ProDiag works ?

ProDiag is executed in fallowing manner

Entry of data into Pro-Diag tool via an acquisition kit and sensors.

Analysis of data by a service expert.

Recommendation wit detailed report.

Thermography

Q23.What is Thermography?

It is a test which involves checking installations using a thermal imaging camera. It checks

measured temperatures with respect to normal operating temperatures.

Q24. What are advantages Thermography ?

Detect hot spots in a live electrical installation (due to a bad connection, harmonics, overloads,

unbalancing etc.)

Foresee risks of a fire and any other malfunction that could endanger people and equipment.

Q25. How Thermography works?

Thermal imaging cameras provide an image of what is happening in the form of a temperature

gradient. These images allow installation hot spots to be identified.

Checking measured temperatures with respect to normal operating temperatures.

Pro-Corona

Q26.What is Corona effect?

Corona is a type of localized emission resulting from transient gaseous ionization in an insulation

system when voltage gradient, exceeds a critical value. It also known as partial discharge.

Q27.What is ProCorona?

It is a test for detection of partial discharges using an ultrasonic sensor. It is carried out without

shutting down the equipment.

Q28. Operating principle of ProCorona?

Condensation is the major cause of surface discharges (corona effect). This is more likely to

occur if there are large variations in temperature. The effects and risks are amplified by other

phenomena such as: pollution, lightning etc. These lead to a fatal deterioration of equipment

over the long term.

This phenomenon can be detected sufficiently early on using ultrasonic means. If necessary, this

detection enables the required preventative and curative measures to be taken.

Q29. Advantages of ProCorona?

Detects conditions favorable to the creation of corona discharges

Prepare the implementation of solutions (installation of heating resistors, ventilation of the

substation, and replacement of insulation) in line with the conclusions of the expert assessment.

Potrebbero piacerti anche

- MANUAL For Wheat Flour Fortification - Technical GuidelinesDocumento46 pagineMANUAL For Wheat Flour Fortification - Technical GuidelinesRahul JuwareNessuna valutazione finora

- National Building Code 2005Documento1.161 pagineNational Building Code 2005api-2617216889% (47)

- Balbharti - KavitaDocumento266 pagineBalbharti - KavitaprasadkarkareNessuna valutazione finora

- My Idea OutletDocumento70 pagineMy Idea OutletRahul JuwareNessuna valutazione finora

- My Idea OutletDocumento70 pagineMy Idea OutletRahul JuwareNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Atmospheric Pressure Plasmas - A ReviewDocumento29 pagineAtmospheric Pressure Plasmas - A ReviewAntonio TakimiNessuna valutazione finora

- Ieee C57.152Documento5 pagineIeee C57.152The_EgyeptianNessuna valutazione finora

- Giacometti 1992Documento20 pagineGiacometti 1992SPMS_MELECNessuna valutazione finora

- HVDC - TutorialDocumento14 pagineHVDC - Tutorialrodrig15Nessuna valutazione finora

- Plasma Tweeter - Final PaperDocumento24 paginePlasma Tweeter - Final PaperZihan Zang100% (1)

- BE Electrical Engg. High Voltage Engg. MCQS: Test LinkDocumento17 pagineBE Electrical Engg. High Voltage Engg. MCQS: Test LinkSample UseNessuna valutazione finora

- Simulation of Electric Field Distribution Around Water Droplets On Outdoor Insulator SurfacesDocumento5 pagineSimulation of Electric Field Distribution Around Water Droplets On Outdoor Insulator Surfacesdemy antonyNessuna valutazione finora

- Condition Monitoring Inspection: Thermography / ThermoscanDocumento2 pagineCondition Monitoring Inspection: Thermography / Thermoscanvinil radhakrishnaNessuna valutazione finora

- Electrical Viva 100 QuestionDocumento63 pagineElectrical Viva 100 QuestionMd. Farhan ShahriorNessuna valutazione finora

- HV (M) STUDENT - Copy ..Bibhas MannaDocumento10 pagineHV (M) STUDENT - Copy ..Bibhas MannaBibhas MannaNessuna valutazione finora

- Experimental Studies On Corona Discharge Ionization: V. S. SawantDocumento5 pagineExperimental Studies On Corona Discharge Ionization: V. S. SawantInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- TrichelDocumento12 pagineTrichelafgaleanoNessuna valutazione finora

- Corona Loss in Power SystemsDocumento24 pagineCorona Loss in Power Systemssunny414Nessuna valutazione finora

- Gas Discharge Plasmas and Their ApplicationsDocumento50 pagineGas Discharge Plasmas and Their ApplicationsKonstantin Shalnov100% (1)

- Advantages of Bundled Conductors in Transmission LinesDocumento5 pagineAdvantages of Bundled Conductors in Transmission Linesf3ziii100% (1)

- CoronaShield® P 8001 SemiConductive Varnish Von RollDocumento3 pagineCoronaShield® P 8001 SemiConductive Varnish Von Rollyeprem82Nessuna valutazione finora

- Back Corona in ESPDocumento4 pagineBack Corona in ESPewfsd67% (3)

- 74276-Study On EseDocumento109 pagine74276-Study On Esestanjack99Nessuna valutazione finora

- Technical Article Polymeric Insulators - CFO and BILDocumento28 pagineTechnical Article Polymeric Insulators - CFO and BIL임광식Nessuna valutazione finora

- Maintain SF6 Circuit BreakersDocumento5 pagineMaintain SF6 Circuit BreakerskienNessuna valutazione finora

- VSH 10E+VSC 104E - CatalogDocumento2 pagineVSH 10E+VSC 104E - CatalogxeagonNessuna valutazione finora

- Lecture 10 - Corona Discharge LossDocumento12 pagineLecture 10 - Corona Discharge LossAbdul Hisham100% (1)

- Bapcon Plus ManualDocumento20 pagineBapcon Plus Manualsrinivas100% (5)

- 7065PCDocumento171 pagine7065PCNomer EvascoNessuna valutazione finora

- ps-II, IImidDocumento5 pagineps-II, IImidGopi Pavan JonnadulaNessuna valutazione finora

- 1998, IEEE EI Magazine, Ageing Tests of Polymeric Housing Materials For Non-Ceramic Insulators PDFDocumento8 pagine1998, IEEE EI Magazine, Ageing Tests of Polymeric Housing Materials For Non-Ceramic Insulators PDFMansoor AsifNessuna valutazione finora

- Unit III: Line InsulatorsDocumento48 pagineUnit III: Line InsulatorsVenkatesh KumarNessuna valutazione finora

- Corona DischargeDocumento16 pagineCorona DischargejuarozNessuna valutazione finora

- Surface Potential Decay of Low Density PolyethylenDocumento6 pagineSurface Potential Decay of Low Density Polyethylenlabiod sihamNessuna valutazione finora