Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

03 2100 Reinforcement

Caricato da

Vaibhav ChowdharyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

03 2100 Reinforcement

Caricato da

Vaibhav ChowdharyCopyright:

Formati disponibili

Project Title Page 02/12 000101

Dhirubhai Ambani International Convention and Exhibition Centre

DHIRUBHAI AMBANI INTERNATIONAL CONVENTION

AND EXHIBITION CENTRE

AT BANDRA KURLA COMPLEX- MUMBAI, INDIA.

10107-D008-STR-CO000-0003_01

TECHNICAL SPECIFICATIONS

FOR

REINFORCEMENT

PREPARED BY

STRUCTURAL ENGINEERS

STERLING ENGINEERING CONSULTANCY SERVICES PVT.LTD.

Queens Mansion, Prescot Road, Fort, Mumbai - 400 001

Phones : 2073578, 2070582 Fax : 2073584

Sterling Engineering Consultancy Services Pvt. Ltd. Issued for Construction

September 26,2014

REINFORCEMENT SPECIFICATION 05/12 033000

Dhirubhai Ambani International Convention and Exhibition Centre

1. Standards

2.0 Applicable Codes :

The provisions of the latest Indian Standards listed below, but not restricted to, form part of these

specifications:

IS-1785 Cold Drawn Stress relieved wire (Part I).

IS-1786 Specification for Cold Twisted Steel Bars for Concrete Reinforcement.

IS-2751 Code of Practice for Welding of M.S.Bars.

IS-5525 Recommendation for detailing of Reinforcement in Reinforced Concrete Works.

IS-13920 Ductile detailing of reinforced concrete structure subjected to seismic force

3.0 STEEL REINFORCEMENT :

All reinforcement used in this work shall be preferred primary steel and confirm to I.S.1786 with

Fe 500 provided % elongation should be more than 14.5% and will be in the form of deformed

bars. Incase if any other option of recycled steel, it shall be comply with IS 1786. Use of Fe415

grade may be specified wherever applicable.

3.1 Bending of Reinforcement:

Reinforcing steel shall conform accurately to the dimensions shown on relevant drawings and

conforming to IS:2502.

Bars shall not be bent or straightened in a manner that will injure the material.

Bars bent during transport or handling shall be straightened before being used on work, they shall

not be heated to facilitate bending.

3.2 Placing of reinforcement.

All reinforcing bars shall be accurately placed in exact position shown on the drawings, and shall

be securely held in position during placing of concrete by annealed binding wire not less than 1

mm in size and conforming to IS:280, and by using stay blocks or metal chairs, spacers, metal

hangers, supporting wires or other approved devices at sufficiently close intervals. Bars will not be

allowed to sag between supports nor displaced during concreting or any other operation over the

work. All devices used for positioning shall be of non-corrodable material. Wooden and metal

supports will not extend to the surface of concrete, except where shown on the drawings. Placing

bars on layers of freshly laid concrete as the work progresses for adjusting bar spacing will not be

allowed. Pieces of broken stone or brick and wooden blocks shall not be used. Layers of bars

shall be separated by spacer bars, precast mortar blocks or other approved devices.

Spacer bars between two closely positioned layers of bars shall be placed not more than 1 m

apart. The diameter of the spaces shall be minimum 25 mm.

Chairs used to separate the two layers of slabs, walls etc. shall be spaced not more than 2 m

clear in all four directions. The ratio of the maximum horizontal length between the legs of the

chair to the diameter of the bars used in preparing chairs shall not be more than 100.

Spacing of cover blocks shall not exceed 1 m in any direction. The concrete grade of cover blocks

shall be same as that of concrete member.

Sterling Engineering Consultancy Services Pvt. Ltd Issued for Construction

September 26, 2014

REINFORCEMENT SPECIFICATION 05/12 033000

Dhirubhai Ambani International Convention and Exhibition Centre

Reinforcement after being placed in position shall be maintained in a clean condition until

completely embedded in concrete. Special care shall be exercised to prevent any displacement

of reinforcement in concrete already placed.

To protect reinforcement from corrosion, concrete cover shall be provided as indicated on the

drawings. All bars protruding from concrete and to which other bars are to be spliced and which

are likely to be exposed for an indefinite period (More than 2 months) shall be coated with

approved quality bitumen paint over and above the anti-corrosive treatment.

In the case of columns and walls, vertical bars shall be kept in normal position with timber

templates having slots accurately cut in for bar position. Such templates shall be removed after

the concreting has progressed upto a level. Bars crossing each other, where required, shall be

secured by binding wire(annealed) of size not less than 1 mm and conforming to IS:280 in such a

manner that they do not slip over each other at the time of fixing and concreting.

As far as possible, bars of full length shall be used. In case this is not possible, over lapping of

bars shall be done as directed by the Engineer. When practicable, overlapping bars shall not

touch each other, but be kept apart by 25 mm or 1.25 times the maximum size of the coarse

aggregate whichever is greater, by concrete between them, where this is not feasible, overlapping

bars shall be bound with annealed steel wire, not less than 1 mm thickness twisted tight. The

overlaps shall be staggered for different bars and located at points, along the span where neither

shear nor bending moment is maximum.

Dowels if provided for future lapping (up to 2 months ), shall be protected by a thick coat of neat

cement grout.

3.3 Welding of Bars.

Welding of HYSD reinforcement shall be carried out in accordance with IS:2571. When permitted

or specified on the drawing joints of reinforcement bars shall be butt-welded so as to transmit their

full strength. Welded joints shall preferably be located at points where steel will not be subject to

more than 75 percent of the maximum permissible stresses and welds so staggered that , at any

one section, not more than 33 percent of the rods are welded. Only electric are welding using a

process which excludes air from the molten metal and nonconforming to any or all other special

provisions for the work will be accepted. Suitable means shall be provided for holding the bars

securely in position during welding. It must be ensured that no voids are left in welding when

welding is done in 2 or 3 stages, previous surface shall be cleaned properly. Ends of the bars

shall be cleaned of all loose scale, rust, grease, paint and other foreign matter before welding.

Only competent welders shall be employed on the work. The M.S. electrodes used for welding

shall conform to IS:814. Welded pieces of reinforcement shall be treated. Specimens shall be

taken from the actual site and their number and frequency of tests shall be as directed by the

Engineer.

Sterling Engineering Consultancy Services Pvt. Ltd Issued for Construction

September 26, 2014

REINFORCEMENT SPECIFICATION 05/12 033000

Dhirubhai Ambani International Convention and Exhibition Centre

3.4 MECHANICAL COUPLERS

3.4.1 Reference Standards :

IS 456, 2000, Clause 12.4

BS 8110, Part 1, 1989, Clause 3.128.16.2

BS 5400, Part 4, 1990, Clause 5.8.6.6

BS 5400, Part 4, 1990, Clause 7.3.2.3

3.4.1.1 Mechanical couplers may be used for achieving continuity of reinforcing bars in reinforced

cement concrete construction. Mechanical couplers involve threading of bars, either

parallel threads or tapered threads.

3.4.1.2 Out of these, tapered threads are preferred in the compression members such as

individual bars of columns, as they can be easily aligned and possibility of loose screwing

is less. The threaded ends of bars may be joined by a coupler having left and right hand

threads.

3.4.1.3 Parallel threaded couplers are preferred in tension members and where splicing of the

bars is required to be done in-situ such as raft, column cages, beam cages etc.

3.4.1.4 Mechanical couplers with an anchor rod embedded in the concrete mass may be used to

facilitate doweling in case columns or shear walls are climbed in advance to the floors.

3.4.2 Mechanical couplers may replace the conventional laps and joints such as lapping of

bars, butt welding and sleeving.

Locations of mechanical couplers should be identical to the conventional splice locations

if they were used, i.e. such connections should occur away from points of high stress and

should be staggered appropriately. Standard structural drawings shall be followed for the

locations of the reinforcement joints.

3.4.2.1 Beams : In beams, the couplers may be used for the bottom bars within one fourth length

of the beam from the column supports. For the top reinforcing bars, the couplers shall be

used only in the middle third of the span of the beam.

3.4.2.2 Columns : In the columns, the couplers shall not be used in the end zone. In the middle

zone, at any level, only 50% of the bars shall be joined by couplers. Remaining 50% shall

be joined at a distance of least 40 times the diameter of the bar.

3.4.2.3 Dowels : Threaded coupler may be anchored into previously cast concrete unit to receive

the threaded end of reinforcement to be continued at a later date. Such couplers are

known as position couplers. In such cases, use of templates is mandatory in order to

maintain the relative position of the couplers with respect to the top, bottom and sides of

the structural members and with respect to other couplers in the group.

3.4.3 Purpose of using Couplers

3.4.3.1 They may be used in compression as well as tension. Although butt welding is possible in

case of compression jointing of bars, the only acceptable form of full strength butt joint for

a bar in tension comprises of mechanical coupler.

3.4.3.2 Couplers should not be used to join bars less than 2 m in length to make longer usable

bars, as such joints are likely to occur in high stress zones.

Sterling Engineering Consultancy Services Pvt. Ltd Issued for Construction

September 26, 2014

REINFORCEMENT SPECIFICATION 05/12 033000

Dhirubhai Ambani International Convention and Exhibition Centre

3.4.3.3 Use of couplers shall be authorized only at authorized lap locations as shown in the

structural drawings or described in the general specifications.

3.4.3.4 Attention must be given to the fact that usage of couplers helps in avoiding cranking of

bars at lap locations and also help in standardizing the cutting lengths of bars. Pre-

calculating the cutting lengths will lead to maximization of the utility of the couplers.

3.4.3.5 For all bars with diameter 20mm and above, its recommended to use mechanical coupler

to splice the bar. For bars with diameter 32mm and above, use of mechanical couplers

shall be made cumpelsory.

3.4.4 Acceptance Criteria

3.4.4.1 When a test is made on a representative gauge length assembly comprising

reinforcement of the size, grade and profile to be actually used in construction, and a

coupler of precise type to be used, the permanent elongation after loading to 0.6 Fy

should not exceed 0.1 mm.

3.4.4.2 The tensile strength of the coupled bar should exceed the following stress levels.

Design yield stress of Tensile strength of the

the reinforcement coupler assembly

(N/sq.mm) (N/sq.mm)

Fy = 250 275

Fy = 415 455

Fy = 500 550

3.4.4.3 The failure of the assembly may occur in any of the following ways :

a. Slippage of the threaded bars from the coupler

b. Necking and failure of the bars

c. Necking and failure of the coupler sleeve

3.4.4.4 In any of the cases above, the failure load shall not be less than corresponding to the

tensile strength of the coupler assembly as specified in 3.2 above.

3.4.4.5 At least 0.5% of the couplers and subject to minimum 2 Nos. in a project shall be tested

for each diameter of bar.

3.4.4.6 In case of failure of a test on a coupler, two additional tests of the same diameter shall be

tested. If both the additional tests prove to be satisfactory, the lot of the couplers may be

accepted for use in the construction. If any of the two additional tests fails to comply with

the elongation or strength criteria, the lot of couplers supplied by the vendor manufactured

in the same batch shall not be used in the construction. In such a case, couplers

manufactured in independent raw material batch shall be used after proper verification of

manufacturing records, and after testing the specimens once again for the new lot.

3.5 Measurement of Payment:

Sterling Engineering Consultancy Services Pvt. Ltd Issued for Construction

September 26, 2014

REINFORCEMENT SPECIFICATION 05/12 033000

Dhirubhai Ambani International Convention and Exhibition Centre

Reinforcement shall be measured in length separately for different diameters as actually used in

the work including overlaps. From the length so measured the weight of reinforcements shall be

calculated in Metric Tons on the same basis on which steel is supplied to the Contractor by the

Department or by the Employer, or from IS: 1735 if steel is arranged by the Contractor. Lengths

shall include bends at as shown in the approved reinforcement drawings. Wastage, overlaps not

shown on the drawings, cover blocks, spacers, chairs, couplings & welded joints, space bars and

annealed steel wire for binding shall not be measured and cost of these items shall be deemed to

be included in the rates for reinforcement. In case of couplers, the attention shall be specifically

given to the item description of the reinforcement item to understand whether the couplers are

part of the reinforcement item or are paid under separate item

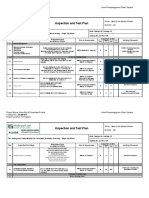

4.0 Inspection and Test Plan:

Format

Method Quantum Reference

Nature of Check/ Test of

of Check of Check Document

Record

Ensure Steel from Approved Source

Conduct the following Tests wherever

required and ensure that the material

is as per standard

A) For Fe500 Mild Steel Bars as per IS Review of

MTC

1786 MTC Every Lot

For Every

Third lot of 100

Chemical Analysis IS 1786 TPT

Party Test M.T., for

Every dia

For Every

Sterling

Third lot of 100

Elongation Specificatio TPT

Party Test M.T., for

n

Every dia

Tensile strength, Proof Stress For Every

Third lot of 100

IS 1786 TPT

Bend Party Test M.T., for

Rebend Every dia

*NOTE: Materials will be accepted based on Manufacturer test certificate (MTC). However

Reinforcement shall be used only after conforming lab results.

Sterling Engineering Consultancy Services Pvt. Ltd Issued for Construction

September 26, 2014

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Ashar Aji - Mechanical Construction EngineerDocumento14 pagineAshar Aji - Mechanical Construction EngineerNob Odyk NowsNessuna valutazione finora

- JRA-CDA-PL-071-REV-0 - Welding, Cutting and Grinding AFT Loading DeflectorDocumento4 pagineJRA-CDA-PL-071-REV-0 - Welding, Cutting and Grinding AFT Loading DeflectorMiller DutraNessuna valutazione finora

- ISSUE 367 QUIZ-Charpy Impact Test Reduction Temperature For CVN VIII.2-ANSWERDocumento9 pagineISSUE 367 QUIZ-Charpy Impact Test Reduction Temperature For CVN VIII.2-ANSWERcpchonburiNessuna valutazione finora

- Process Planning AssimentDocumento9 pagineProcess Planning Assimentዮሐንስ ታደሰNessuna valutazione finora

- Module 1 - Code Basics Review Questions & Answers: 1 © ASME 2014Documento2 pagineModule 1 - Code Basics Review Questions & Answers: 1 © ASME 2014aliNessuna valutazione finora

- 2 - Santiago Calatrava Outstanding Bridges and Special Structures PDFDocumento100 pagine2 - Santiago Calatrava Outstanding Bridges and Special Structures PDFnirvaangNessuna valutazione finora

- Ansi-Aws d1.2 PDFDocumento208 pagineAnsi-Aws d1.2 PDFzokytoNessuna valutazione finora

- ITP-3041 For PipeDocumento8 pagineITP-3041 For PipeSkinhead TvNessuna valutazione finora

- Welding Engineer Product Manager in Los Angeles CA Resume Jose PerezDocumento2 pagineWelding Engineer Product Manager in Los Angeles CA Resume Jose PerezJosePerez3Nessuna valutazione finora

- Selective Laser Should MeltingDocumento10 pagineSelective Laser Should MeltingAli MousaviNessuna valutazione finora

- Steel Plates For Offshore StructuresDocumento8 pagineSteel Plates For Offshore StructuresYiengeChanYeeNessuna valutazione finora

- BS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedDocumento24 pagineBS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedtienlamNessuna valutazione finora

- Cold Bonding LNG TanksDocumento4 pagineCold Bonding LNG TankskaybeeNessuna valutazione finora

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Documento28 pagine2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValenteNessuna valutazione finora

- 1221 Hot Gas and Extrusion Welding Jan 2016Documento2 pagine1221 Hot Gas and Extrusion Welding Jan 2016ibnu.asad984Nessuna valutazione finora

- Work Area For QCDocumento4 pagineWork Area For QCPankaj ShrivastvaNessuna valutazione finora

- Quantitative Wear Analysis of H13 Steel Tool During Friction Stir Welding of Cu-0.8%Cr-0.1%Zr AlloyDocumento9 pagineQuantitative Wear Analysis of H13 Steel Tool During Friction Stir Welding of Cu-0.8%Cr-0.1%Zr AlloyAnmol MalgotraNessuna valutazione finora

- 01-SAMSS-333-HF Welded Line Pipe PDFDocumento35 pagine01-SAMSS-333-HF Welded Line Pipe PDFmunnaNessuna valutazione finora

- Laser Welding Titanium-SSDocumento8 pagineLaser Welding Titanium-SSTayyab HussainNessuna valutazione finora

- Petronas Technical Standards: Pressure VesselsDocumento75 paginePetronas Technical Standards: Pressure VesselstestNessuna valutazione finora

- Omn Fac 317Documento12 pagineOmn Fac 317SaifullahNessuna valutazione finora

- Welding Steel and TankDocumento39 pagineWelding Steel and Tankprasanth bhadranNessuna valutazione finora

- The Relationship Between Boron Content and Crack Properties in FCAW Weld MetalDocumento6 pagineThe Relationship Between Boron Content and Crack Properties in FCAW Weld MetalVizay KumarNessuna valutazione finora

- Thermoplastic Polyolefin Based Sheet Roofing: Standard Specification ForDocumento3 pagineThermoplastic Polyolefin Based Sheet Roofing: Standard Specification Forasma hamzaNessuna valutazione finora

- Guidelines for Erection, Testing and Commissioning of Small Hydro Power PlantsDocumento73 pagineGuidelines for Erection, Testing and Commissioning of Small Hydro Power PlantsoctatheweelNessuna valutazione finora

- Vendor DocumentsDocumento24 pagineVendor DocumentsVictor Raul Falla FallaNessuna valutazione finora

- A Guide To Aluminum WeldingDocumento12 pagineA Guide To Aluminum Weldingnavalzero910100% (1)

- Arc Welding Electrodes (Product Catalogue)Documento28 pagineArc Welding Electrodes (Product Catalogue)ddprt123Nessuna valutazione finora

- Hot Tapping Scope of WorkDocumento3 pagineHot Tapping Scope of WorkSukhen Das50% (2)