Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

B - Boehler FOX EV 60 - Se - en - 5

Caricato da

Juan Bedolla FloresTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

B - Boehler FOX EV 60 - Se - en - 5

Caricato da

Juan Bedolla FloresCopyright:

Formati disponibili

BÖHLER FOX EV 60

Basic stick electrode, low-alloyed, high strength

Classifications

EN ISO 2560-A EN ISO 2560-B AWS A5.5 AWS A5.5M

E 46 6 1Ni B 4 2 H5 E 5518-N2 A U H5 E8018-C3H4R E5518-C3H4R

Characteristics and typical fields of application

Basic Ni- alloyed electrode with excellent mechanical properties, particularly high toughness and

crack resistance. For higher strength fine- grained constructional steels.

Suitable for service temperatures at -60°C to +350°C. Very good impact strength in aged condition.

Metal recovery about 115 %. Easily weld ability in all positions except vertical-down.

Very low hydrogen content (acc. AWS condition HD < 4 ml/100 g weld metal). Test values for SSC-

test are available.

Base materials

Constructional steels, pipe- and vessel steels, cryogenic fine-grained steels and special grades

S275N-S460N, S275NL-S460NL, S275M-S460M, S275ML-S460ML, P355N, P355NH, P460N,

P460NH, P275NL1-P460NL1, P275NL2-P460NL2, L360NB, L415NB, L360MB-L450MB, L360QB-

L450QB

ASTM A 203 Gr. D, E; A 350 Gr. LF1, LF2, LF3; A 420 Gr. WPL3, WPL6; A 516 Gr. 60, 65, 70; A

572 Gr. 42, 50, 55, 60, 65; A 633 Gr. A, D, E; A 662 Gr. A, B, C; A 707 Gr. L1, L2, L3; A 738 Gr. A;

A 841 A, B, C; API 5 L X52, X60, X65, X52Q, X60Q, X65Q

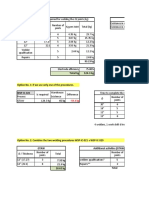

Typical analysis of all-weld metal (wt.-%)

C Si Mn Ni

wt.-% 0.07 0.4 1.15 0.9

Mechanical properties of all-weld metal

Condition Yield strength Tensile strength Elongation Impact work

Rp0,2 Rm A (L0=5d0) ISO-V KV J

MPa MPa % +20°C -60°C

u 510 (≥ 460) 610 (580 – 740) 27 (≥ 20) 180 110 (≥ 47)

s 480 580 27 160

u untreated, as welded

s stress relieved 580°C/2h / furnace down to 300°C / air

Operating data

Polarity: Redrying if Electrode ø (mm) L mm Amps A

DC ( + ) necessary: identification: 2.5 350 80 – 100

300 – 350°C, FOX EV 60 8018-C3 3.2 350 110 – 140

min. 2 h E 46 6 1Ni B

4.0 450 140 – 180

5.0 450 190 – 230

Approvals

TÜV (1524.), DNV (3 YHH), RMR (3 YHH), Statoil, LTSS, SEPROZ, CRS (3YH5), VG 95132, CE,

ABS

All information provided is based upon careful investigation and intensive research. 11/2014

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

Potrebbero piacerti anche

- 02112015000000B - Boehler FOX EV 70 - CeDocumento1 pagina02112015000000B - Boehler FOX EV 70 - CeOPAZOSCNessuna valutazione finora

- 02112015000000B - Boehler FOX EV 65 - CeDocumento1 pagina02112015000000B - Boehler FOX EV 65 - CeMohamed AdelNessuna valutazione finora

- B Boehler FOX EV 50-A Se en 5Documento1 paginaB Boehler FOX EV 50-A Se en 5Sun SunNessuna valutazione finora

- Böhler Fox Ohv: Rutile-Cellulosic Stick Electrode, UnalloyedDocumento1 paginaBöhler Fox Ohv: Rutile-Cellulosic Stick Electrode, UnalloyedMiroslav MiladinovićNessuna valutazione finora

- B - Boehler FOX SPE - Se - en - 5Documento1 paginaB - Boehler FOX SPE - Se - en - 5panait trofinNessuna valutazione finora

- Datasheet BOHLER AWS E7018-1 Stick ElectrodeDocumento1 paginaDatasheet BOHLER AWS E7018-1 Stick ElectrodeArhamNessuna valutazione finora

- 02112015000000B - Boehler FOX EV 50 - CeDocumento2 pagine02112015000000B - Boehler FOX EV 50 - Cejlamba26Nessuna valutazione finora

- Böhler Fox Eti: Rutile Stick Electrode, UnalloyedDocumento1 paginaBöhler Fox Eti: Rutile Stick Electrode, UnalloyedMiroslav MiladinovićNessuna valutazione finora

- Böhler Fox Cel 85: Cellulosic Stick Electrode, For Vertical-Down Welding, Pipe WeldingDocumento1 paginaBöhler Fox Cel 85: Cellulosic Stick Electrode, For Vertical-Down Welding, Pipe WeldingAndreeNessuna valutazione finora

- L1 34454 en B Boehler Aws E6013 Se en v1Documento1 paginaL1 34454 en B Boehler Aws E6013 Se en v1brayanNessuna valutazione finora

- FPO22001 ASME Filer Metal Data SheetDocumento5 pagineFPO22001 ASME Filer Metal Data Sheetyousab creator2Nessuna valutazione finora

- B - Boehler Fox Cel 70-P PDFDocumento1 paginaB - Boehler Fox Cel 70-P PDFrombi aritonangNessuna valutazione finora

- 01112015000000B - Boehler FOX CEL - CeDocumento1 pagina01112015000000B - Boehler FOX CEL - Cekapster KannourNessuna valutazione finora

- B Boehler-Fox-Cel Se en v1Documento1 paginaB Boehler-Fox-Cel Se en v1tacosanchezbrayanNessuna valutazione finora

- B Boehler-Fox-Cel Se en v1Documento1 paginaB Boehler-Fox-Cel Se en v1tacosanchezbrayanNessuna valutazione finora

- B Boehler-Fox-Cel Se en v1Documento1 paginaB Boehler-Fox-Cel Se en v1tacosanchezbrayanNessuna valutazione finora

- Katalog BelerDocumento1 paginaKatalog BelerСтефан АнтонићNessuna valutazione finora

- 02112015000000B - Boehler FOX CM 5 KB - CeDocumento1 pagina02112015000000B - Boehler FOX CM 5 KB - CejaroNessuna valutazione finora

- 03112015000000B - Boehler FOX SUM - CeDocumento1 pagina03112015000000B - Boehler FOX SUM - Cekapster KannourNessuna valutazione finora

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocumento1 paginaB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNessuna valutazione finora

- 02112015000000B - Boehler FOX DCMS Ti - CeDocumento1 pagina02112015000000B - Boehler FOX DCMS Ti - CeparbinaNessuna valutazione finora

- WELDING SPREADER Electrode KALMAR PDFDocumento1 paginaWELDING SPREADER Electrode KALMAR PDFArtin HykoNessuna valutazione finora

- 055 PDFDocumento1 pagina055 PDFantonio111aNessuna valutazione finora

- Supercito (E 42 5 B 32 h5)Documento1 paginaSupercito (E 42 5 B 32 h5)brunizzaNessuna valutazione finora

- 03112015000000B - Boehler FOX NiCr 70 NB - CeDocumento1 pagina03112015000000B - Boehler FOX NiCr 70 NB - CeFlori MovNessuna valutazione finora

- Böhler Fox Ev 50: &odvvlàfdwlrqvDocumento1 paginaBöhler Fox Ev 50: &odvvlàfdwlrqvHAMITOUCHENessuna valutazione finora

- 01112015000000B - Boehler EMK 8 - Solid WireDocumento2 pagine01112015000000B - Boehler EMK 8 - Solid WirePopa RobertNessuna valutazione finora

- B - Boehler FOX CM 9 KB - Se - en - 5Documento1 paginaB - Boehler FOX CM 9 KB - Se - en - 5misthahNessuna valutazione finora

- L1 34264 en T Thermanit MTS 3 Se en v2Documento1 paginaL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNessuna valutazione finora

- Bohler Fox S Ev 50: Stick Electrode, Unalloyed BasicDocumento1 paginaBohler Fox S Ev 50: Stick Electrode, Unalloyed Basickiki270977Nessuna valutazione finora

- Avesta 316L-SKRDocumento1 paginaAvesta 316L-SKRIuliu HurducaciNessuna valutazione finora

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Documento1 paginaL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouNessuna valutazione finora

- Tenacito 70Documento1 paginaTenacito 70Luis Angel Unocc FernandezNessuna valutazione finora

- T Thermanit GEW 316L-17 Se en 5Documento1 paginaT Thermanit GEW 316L-17 Se en 5PubcrawlNessuna valutazione finora

- Boehler CM2-UPDocumento1 paginaBoehler CM2-UPdiahNessuna valutazione finora

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocumento1 paginaThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNessuna valutazione finora

- Product Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocumento3 pagineProduct Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNessuna valutazione finora

- Electrodos-Revestidos KiswellDocumento116 pagineElectrodos-Revestidos KiswellJoel FloresNessuna valutazione finora

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocumento1 paginaOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNessuna valutazione finora

- 02112015000000B - Boehler FOX CEL Mo - CeDocumento1 pagina02112015000000B - Boehler FOX CEL Mo - CeOPAZOSCNessuna valutazione finora

- B - Boehler DMO-IG - Ss - en - 5 PDFDocumento1 paginaB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNessuna valutazione finora

- Utp 068 HHDocumento1 paginaUtp 068 HHRoberto_PrrNessuna valutazione finora

- SmawDocumento56 pagineSmawFakhar WindratamaNessuna valutazione finora

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Documento2 pagineProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNessuna valutazione finora

- Böhler Er 70 S-2Documento1 paginaBöhler Er 70 S-2brayanNessuna valutazione finora

- Standar Elektroda PDFDocumento182 pagineStandar Elektroda PDFFakhar WindratamaNessuna valutazione finora

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocumento1 paginaSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNessuna valutazione finora

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Documento1 paginaL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuNessuna valutazione finora

- Boehler FOX CN 25 9 CuT - CeDocumento1 paginaBoehler FOX CN 25 9 CuT - CeNiranjan Fakirchand YadavNessuna valutazione finora

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Documento2 pagineProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNessuna valutazione finora

- Acfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmDocumento1 paginaAcfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmdodoNessuna valutazione finora

- Boehler 2.5 Ni-Ig Ss en 5Documento1 paginaBoehler 2.5 Ni-Ig Ss en 5Valentin Hernández TrianoNessuna valutazione finora

- Groupe Automobile Jeandot - Wrangler-448Documento1 paginaGroupe Automobile Jeandot - Wrangler-448DarkedgeNessuna valutazione finora

- Böhler Fox S EV 50-1 - DatasheetDocumento1 paginaBöhler Fox S EV 50-1 - DatasheetKrishna Vacha100% (1)

- Utp 7015Documento1 paginaUtp 7015cesarlopezpolysiusNessuna valutazione finora

- 04042016000000A Avesta 2205 Covered ElectrodesDocumento1 pagina04042016000000A Avesta 2205 Covered Electrodesmeckup123Nessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesDa EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesValutazione: 4.5 su 5 stelle4.5/5 (7)

- Physical Electronics: Handbook of Vacuum PhysicsDa EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNessuna valutazione finora

- ESP - DE PINTURA Rev. H Paint and Coating SpecDocumento33 pagineESP - DE PINTURA Rev. H Paint and Coating SpecJuan Bedolla FloresNessuna valutazione finora

- Coke Drum SpecDocumento33 pagineCoke Drum SpecMahendra Rathore100% (1)

- Coke Drum SpecDocumento33 pagineCoke Drum SpecMahendra Rathore100% (1)

- Coke Drum SpecDocumento33 pagineCoke Drum SpecMahendra Rathore100% (1)

- API-650 Preguntas y Respuestas ImpresoDocumento49 pagineAPI-650 Preguntas y Respuestas ImpresoJuan Bedolla FloresNessuna valutazione finora

- Api 575Documento37 pagineApi 575Sakthi Pk100% (3)

- SSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDocumento11 pagineSSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDavid Aliaga Sayas100% (1)

- SalesOrd 7946351Documento1 paginaSalesOrd 7946351Juan Bedolla FloresNessuna valutazione finora

- Calculo Soldadura (Copia en Conflicto de Alejandro Arce Terrazas 2016-09-08)Documento6 pagineCalculo Soldadura (Copia en Conflicto de Alejandro Arce Terrazas 2016-09-08)Juan Bedolla FloresNessuna valutazione finora

- Technology Guide No. 12: SSPC: The Society For Protective Coatings Guide To Illumination of Industrial Coating ProjectsDocumento6 pagineTechnology Guide No. 12: SSPC: The Society For Protective Coatings Guide To Illumination of Industrial Coating ProjectsJuan Bedolla FloresNessuna valutazione finora

- Technology Guide No. 12: SSPC: The Society For Protective Coatings Guide To Illumination of Industrial Coating ProjectsDocumento6 pagineTechnology Guide No. 12: SSPC: The Society For Protective Coatings Guide To Illumination of Industrial Coating ProjectsJuan Bedolla FloresNessuna valutazione finora

- Agudeza VisualDocumento1 paginaAgudeza VisualJuan Bedolla FloresNessuna valutazione finora

- Cip Level 2 - Quiz 1Documento6 pagineCip Level 2 - Quiz 1David Hortas CasasNessuna valutazione finora

- Cip Level 2 - Quiz 1Documento6 pagineCip Level 2 - Quiz 1David Hortas CasasNessuna valutazione finora

- Nivel III Jesus Coronilla ValdezDocumento1 paginaNivel III Jesus Coronilla ValdezJuan Bedolla FloresNessuna valutazione finora

- Cip Level 2 - Quiz 1Documento6 pagineCip Level 2 - Quiz 1David Hortas CasasNessuna valutazione finora

- Quizlet CIP 1 CAP 21 12 PREGUNTAS PDFDocumento1 paginaQuizlet CIP 1 CAP 21 12 PREGUNTAS PDFJuan Bedolla FloresNessuna valutazione finora

- Docshare - Tips Cwi-ToolsDocumento5 pagineDocshare - Tips Cwi-ToolsJuan Bedolla FloresNessuna valutazione finora

- PTFE Cap1Documento6 paginePTFE Cap1RajanSharmaNessuna valutazione finora

- Classical ExperimentsDocumento2 pagineClassical ExperimentsShane Cagas AcaoNessuna valutazione finora

- Comparative Assessment of The Stabilization of Lime-Stabilized Lateritic Soil As Subbase Material Using Coconut Shell Ash and Coconut Husk AshDocumento12 pagineComparative Assessment of The Stabilization of Lime-Stabilized Lateritic Soil As Subbase Material Using Coconut Shell Ash and Coconut Husk AshEdem CHABINessuna valutazione finora

- Exp1 Sic180033 PDFDocumento6 pagineExp1 Sic180033 PDFfara basar100% (1)

- Science Notes KS3 Part 2Documento8 pagineScience Notes KS3 Part 2lamcass37Nessuna valutazione finora

- The Mole ConceptDocumento2 pagineThe Mole ConceptJay DansNessuna valutazione finora

- DAQ Destroyer Hybrid RocketDocumento48 pagineDAQ Destroyer Hybrid Rocketprakulmittal2100% (1)

- PSS Ebook 2 GPC SEC ColumnsDocumento30 paginePSS Ebook 2 GPC SEC ColumnselenitabastosNessuna valutazione finora

- Summer Training ProgramDocumento21 pagineSummer Training ProgramAyan BorgohainNessuna valutazione finora

- Fundamentals of Machine Design 2, Orlov (OCR, BM) PDFDocumento207 pagineFundamentals of Machine Design 2, Orlov (OCR, BM) PDFarcelitas75% (4)

- Environmental Studies: by Prof. Sanjukta MistriDocumento10 pagineEnvironmental Studies: by Prof. Sanjukta MistriramNessuna valutazione finora

- Yunus 2014Documento10 pagineYunus 2014La Ode Muhamad RusliNessuna valutazione finora

- Final Exam 3 - MEEN 2300 - Spring 2014Documento13 pagineFinal Exam 3 - MEEN 2300 - Spring 2014MichaelNessuna valutazione finora

- Indian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionDocumento7 pagineIndian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionAlok DoshiNessuna valutazione finora

- Nutritional Requirements of BacteriaDocumento25 pagineNutritional Requirements of BacteriaAira MiyaNessuna valutazione finora

- WellLock Resin Rigless Micro Channel Remediation H011331Documento1 paginaWellLock Resin Rigless Micro Channel Remediation H011331bagus918Nessuna valutazione finora

- Experiment 1: Determination of Corrosion Rate of Metals: ObjectiveDocumento3 pagineExperiment 1: Determination of Corrosion Rate of Metals: Objective041Mir QazimNessuna valutazione finora

- A Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowDocumento19 pagineA Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowPeerasak ArunNessuna valutazione finora

- CH 301 Unit 2 Exam-SolutionsDocumento9 pagineCH 301 Unit 2 Exam-SolutionsbrunosipodNessuna valutazione finora

- Catalogue CSM PDFDocumento4 pagineCatalogue CSM PDFFran IgledominguezNessuna valutazione finora

- Density of Cargoes: Name Equivalent Cor. Fact. Sp. Grav IMO UN Poll. Com Stow Cat. PT For 1 C at 30 CDocumento4 pagineDensity of Cargoes: Name Equivalent Cor. Fact. Sp. Grav IMO UN Poll. Com Stow Cat. PT For 1 C at 30 CJeet SinghNessuna valutazione finora

- M1 Part3Documento88 pagineM1 Part3Mohamed YahiaNessuna valutazione finora

- Modeling Ozone Generators by Using SIMULINKDocumento5 pagineModeling Ozone Generators by Using SIMULINKGOGONessuna valutazione finora

- Producing Malonate in Saccharomyces Cerevisiae Via The Alanine Pathwaysystems Microbiology and BiomanufacturingDocumento11 pagineProducing Malonate in Saccharomyces Cerevisiae Via The Alanine Pathwaysystems Microbiology and BiomanufacturingWendy SarmientoNessuna valutazione finora

- Electrochemical Synthesis of Ammonia As ADocumento4 pagineElectrochemical Synthesis of Ammonia As ADung Phan Thị ThùyNessuna valutazione finora

- Evaluation of Predicted Equations For Swelling PotentialDocumento6 pagineEvaluation of Predicted Equations For Swelling PotentialGonzalo100% (1)

- Corrosion Control - Jack-Up - SP-CO-ENG-CON-06-01Documento37 pagineCorrosion Control - Jack-Up - SP-CO-ENG-CON-06-01evenNessuna valutazione finora

- Centrifugal Compressor BasicsDocumento45 pagineCentrifugal Compressor BasicsAnkit Gandhi100% (1)

- Chemistry For Changing Times 14th Edition Hill Test Bank DownloadDocumento28 pagineChemistry For Changing Times 14th Edition Hill Test Bank DownloadJoey Dorman100% (21)