Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

KQATEX1 Apparel Textile Requirements 150310

Caricato da

Ammar MaqsoodDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

KQATEX1 Apparel Textile Requirements 150310

Caricato da

Ammar MaqsoodCopyright:

Formati disponibili

KQATEX1 Apparel

Textile Requirements

March 2010

For clarification of any Kmart standard, contact:

Kmart Quality Team

L4, 690 Springvale Road

Mulgrave Victoria 3170 Australia

Tel: (03) 9902 2000

Table of contents

Introduction .................................................................................................................................... 2

Kmart Fabric Performance Compliance System ........................................................................ 3

Introduction

Vendor Responsibilities

Test Reports

Test Requirements

Apparel Fabric Performance Test Requirements ....................................................................... 6

Colourfastness Tests .................................................................................................................... 8

Physical Tests ................................................................................................................................ 9

Washing Methods to Determine Shrinkage & Spirallity Based on Fibre Types ...................... 10

Strength Requirement based on Garment Type ......................................................................... 11

Testing Laboratories ..................................................................................................................... 12

Kmart Test Methods—Apparel and Home Textiles .................................................................... 14

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

1

Introduction

Introduction

This document is for:

Kmart Quality Team team members

Kmart Buyers

Vendors

Manufacturers

Agents.

This document provides information about the Kmart textile requirements for Apparel products that

are ranged in Kmart.

Use this document in conjunction with the following standards:

Merchandise Quality Standards—Apparel Finished Measurements

Merchandise Quality Standards—Apparel Care Instructions

Merchandise Quality Standards—Apparel Workmanship

KQCS Kmart Quality Compliance Standard.

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

2

Kmart Fabric Performance Compliance System

Kmart Fabric Performance Compliance System

Introduction

All Kmart Apparel vendors must be familiar with and comply with the fabric performance requirements

within this standard.

This document contains:

Apparel Fabric Test Requirements Guidelines

Apparel Fabric Colourfastness and Physical Performance standards.

Vendor responsibilities

Understand Kmart requirements.

The fabric purchase orders must include the following:

Kmart requirements.

Indicate whether or not contrast trims/fabrics will be used on the garment, for example ―This fabric

will be trimmed with white binding‖.

Indicate whether further processing will take place, for example ―placement print‖, ―garment

washing‖.

Request a Test Report to be delivered with the production fabric.

Fabric to be tested by an independent laboratory and test reports received should be an original

PDF format.

Ensure all test reports conform to Kmart requirements prior to the commencement of production.

QTA1/contract details:

fabric details on the QTA1 and Kmart contracts must be correct. Any changes to these details

must be communicated to the Kmart Merchandise team to ensure all documentation is altered

to reflect the correct details.

the Fabric weight must not be stated as a range. It must be the single value specified by the

fabric manufacturer.

Exception Reporting

When a fabric/garment does not conform to Kmart requirements and could be considered commercially

viable to be sold in Kmart stores, refer to KQCS Part 3—Section E: Exception Reporting.

Query Form

Fabric Query Form.

Test reports

Laboratory test report application requirement includes:

Style name or number—where it is multiple styles, please list as many as possible to ensure all styles

are covered.

Kmart name as brand.

If fabric submitted—clear description of fabric type with correct fibre content. The tested colour names

must duplicate colourway names on the order.

If garment submitted—clear description of style name or number, garment type, fabric type and correct

fibre content.

Indicate if raw material ie: greige fabric or bulk production.

Indicate clearly each component if there is more than one component within the garment, for example

Pink cotton interlock top, Black Polyester/Cotton jersey pant and Black Nylon Lace trim for pant.

Give permission for the laboratory to post the test report on their internet database for easy access for

Kmart Merchandise and Quality teams.

Indicate the garment‘s nominated care instruction—this is particularly important for appearance after

washing test criteria.

Indicate if the test report is for a resubmission.

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

3

Kmart Fabric Performance Compliance System

It is the vendor‘s responsibility to ensure the following:

fabric conforms to all the details specified on the Kmart contract, for example Fabric weight,

construction, etc.

Test Reports conform to Kmart requirements prior to the commencement of production.

All test reports must be checked and approved by the Apparel vendor. All reports must be signed and

dated by the person responsible as designated on the Vendor Profile.

Vendors must:

e-mail electronic copies (original pdf format) of test reports to a Kmart Textiles Product Technologist

before pre production samples.

submit test reports for every Garment Style

Test reports must be no older than 12 months.

The e-mail shall contain garment style number(s), Kmart Department numbers, and completed QTA1(s)

and Query Form where required.

Test requirements

Multiple styles

Multiple colours of one fabric across one style or several styles from the same Mill/batch.

At least one colour to have the physical tests, except pilling.

Multiple styles

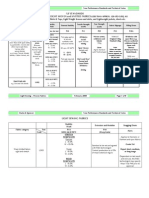

NUMBER OF SAMPLES FOR PHYSICAL

NUMBER OF COLOURS

TESTS

1–5 1

5–10 2

10–15 3

>20 4

If the same fabric is used in other styles, which have not been listed on the test report, we require a

declaration from the vendor. This declaration is to state the test report number of the fabric and the

additional style numbers that the fabric has been used in.

Pilling must be tested on all colours.

Multiple fabrics

Where there is more than one fabric used within a garment or style, all fabrics are to be:

tested

compatible with each other.

The style name, number and fabric type must be clearly listed and described within the test reports.

The QTA1 and contract must clearly specify all fabric types and where its position is within the garment.

Multiple components

All trims, linings, interlining, filling etc. should be tested to comply with the same characteristic of the shell

fabric.

All embellishments and trims must be tested for appearance after washing to ensure all components are

washable and maintain a satisfactory appearance after washing. The wash method is determined by the

garment‘s nominated care instruction. This can be tested in a garment form with trims and

embellishments attached as per bulk.

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

4

Kmart Fabric Performance Compliance System

Industrial garment washing/wash finishes

The supplier must submit a garment for testing that has undergone all intended washing finishes, for

example enzyme wash, stone wash. Perform both physical and colourfastness testing on the garment

after this final stage.

Print fastness

Assess print fastness or print quality after 3 washes with intermediary drying between washes using the

garments nominated care instruction. The quality of the print is assessed prior to and after washing, the

criteria to be checked includes fading, peeling, poor print registration, cracking, cross staining and general

appearance.

Colour matching

The supplier must ensure that all batches of fabric are shade colourmatched using the light source TL84.

The grey scale rating is to be a minimum of rating 4. All panels within a garment should be

colourmatched. All trims or accessories that have been agreed to be colourmatched must also follow this

standard.

Spirallity

Check garment spirallity prior to and after washing. Initially this is a visual inspection, if garment spirallity

is detected, by which the side seam is not ―in-line‖ with the garment side, (where the seam is not a design

feature), it is to be tested for spirallity. If no garment spirallity is found prior to washing, an after wash

result is still required. The percentage result is achieved by measuring the length and the side seam

movement. The calculation is:

X ÷ Length x 100/1

Where X = side movement.

Fabric Spirallity on knits is determined by the amount of variation from the right angle of the four corners

of the dimensional stability template, this is to be stated as a percentage. Assess the fabric prior to and

after washing by assessing the variation from right angles of the wales and courses.

Claims

When a claim is made, on packaging or point of sale (including catalogues), it must be substantiated

through documentation. Test reports and certificates are required for approval. Any claim associated with

raw material, for example Egyptian or Organic cotton, requires a documentation trail from the beginning

(grower) to the end of production showing batch coding and certification that the item went through each

process. The following are examples of claims:

Anti pilling

Egyptian cotton

Organic cotton

Anti bacterial

Moisture management

Visibility for work wear.

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

5

Apparel Fabric Performance Test Requirements

Apparel Fabric Performance Test Requirements

The performance and colourfastness requirements below are Kmart minimum. A tick () indicates that

this is a mandatory test.

Physical testing to be carried out on one colour at random, refer to ‗Test Requirements‘ section. All

colours to be tested according to table below.

Apparel Fabric Guidelines for Testing

TESTS WOVEN KNIT

COLOURFASTNESS TESTS

MEDIUM TO DARK SHADES

COLOURFASTNESS TO WASHING ALL MEDIUM TO DARK CONTRAST TRIM AND MAIN BODY

FABRICS

COLOURFASTNESS TO RUBBING MEDIUM TO DARK SHADES

MEDIUM TO DARK SHADES

COLOURFASTNESS TO WATER ALL MEDIUM TO DARK CONTRAST TRIM AND MAIN BODY

FABRICS

MEDIUM TO DARK SHADES OF SWIMWEAR, ACTIVE WEAR,

COLOURFASTNESS TO PERSPIRATION

UNDERWEAR AND LINGERIE

COLOURFASTNESS TO LIGHT SWIMWEAR, OUTDOOR WORK WEAR, SCHOOL WEAR

SWIMWEAR, BOARDSHORT AND ASSOCIATED APPAREL EG:

COLOURFASTNESS TO SEA WATER

SARONGS

SWIMWEAR, BOARDSHORT AND ASSOCIATED APPAREL EG:

COLOURFASTNESS TO CHLORINATED WATER

SARONGS

COLOURFASTNESS TO DRY CLEANING DRY CLEAN ONLY ITEMS

WHITE CORSETRY, WHITE SPORTS WEAR (FABRIC AND ALL

PHENOLIC YELLOWING

COMPONENTRY AND TRIMS)

PRINT FASTNESS (AFTER 3 WASHES) ALL PRINTS

DURABILITY OF ―GLOW IN THE DARK‖ (AFTER 5

A PRINTING PROCESS THAT GIVES A PHOSPHORESCENT FINISH AND

WASHES) THEREFORE ―GLOWS IN THE DARK‖ AFTER IT HAS BEEN EXPOSED TO LIGHT.

PHYSICAL TESTS

WOOL/WOOL BLEND WOOL/WOOL BLEND

FIBRE CONTENT OTHER FIBRES VERIFY % OTHER FIBRES VERIFY %

CLAIM CLAIM

FABRIC WEIGHT

VERIFY TO CONTRACT

GARMENT WEIGHT

WHERE REQUIRED

VERIFY TO CONTRACT VERIFY TO CONTRACT

CONSTRUCTION

(ENDS/PICKS) (WALES/COURSES)

VERIFY TO CONTRACT VERIFY TO CONTRACT

YARN COUNT

WHERE REQUIRED WHERE REQUIRED

DIMENSIONAL STABILITY (AS PER FIBRE TYPE)

ALL NATURAL FIBRE AND

NATURAL BLENDS:

SPIRALLITY/SKEW (AS PER FIBRE TYPE) DENIM JEANS

SINGLE KNIT AND PIQUE

TRADITIONAL KNIT

WASHABILITY OF ALL TRIMS, WASHABILITY OF ALL TRIMS,

APPEARANCE AFTER WASHING (AFTER 1 WASH

MULTIPLE FABRICS AND MULTIPLE FABRICS AND

AS PER CARE INSTRUCTION)

EMBELLISHMENTS EMBELLISHMENTS

DURABILITY OF GLITTER AND ―GLUED‖

TRIMS/EMBELLISHMENTS (AFTER 3 WASHES AS

PER CARE INSTRUCTION)

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

6

Apparel Fabric Guidelines for Testing

Apparel Fabric Performance Test Requirements

TESTS WOVEN KNIT

SYNTHETIC BLENDS FOR SYNTHETIC AND SYNTHETIC

JACKETS, PANTS AND BLENDED WEFT KNIT

PILLING (AFTER 1 WASH) SKIRTS FABRICS

WOOL/WOOL BLEND WORK WOOL/WOOL BLEND WORK

AND SCHOOL WEAR AND SCHOOL WEAR

ALL FABRICS BELOW

150GSM AND THE

FOLLOWING FABRICS:

SATIN, SATEEN,

SEAM SLIPPAGE —

GEORGETTE, FLANNELETTE

(OPEN WEAVE, LONG

FLOATS OR BRUSHED

FABRICS)

LOOSE/OPEN WEAVE

WASH TREATMENTS

OVERDYED

TEAR STRENGTH —

BRUSHED

WRINKLE RESISTANT

TREATED

FLANNELETTE

TENSILE STRENGTH (BREAKING FORCE) OVERDYED FABRIC —

IF TEAR STRENGTH FAILS

TIGHT FITTING ACTIVE

BURSTING PRESSURE

WEAR

FABRIC FOR UNDERWEAR

SWIM WEAR

STRETCH AND RECOVERY —

ACTIVE WEAR

RIB

CREASE RECOVERY WRINKLE RESISTANT TREATED VERIFY CLAIMS

WATER REPELLENCY WATER REPELLENCY CLAIMS

WATER PROOF WATER PROOF CLAIMS

MOISTURE MANAGEMENT (WICKING) VERIFY CLAIMS

UPF (ULTRA VIOLET PROTECTION FACTOR) VERIFY CLAIMS

HIGH VISIBILITY VERIFY CLAIMS

FLAMMABILITY ACCORDING TO AS/NZS 1249:2003

MICROBIOLOGICAL AND FUNGAL VERIFY CLAIMS

FORMALDEHYDE TO BE CONFIRMED

HEAVY METALS TO BE CONFIRMED

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

7

Colourfastness Test Requirements

Colourfastness Test Requirements

Colourfastness Test Requirements—Minimum Requirements

CORDUROY,

LIGHT

DENIM, CONTRAST

COLOUR**

FLANNELETTE, DARK MEDIUM FLUORESCENT COLOUR

<1/25

PIGMENT DYED, COLOUR COLOUR COLOUR WITHIN A

STANDARD

PIGMENT GARMENT

DEPTH

PRINTED

COLOURFASTNESS

TO WASHING

SHADE CHANGE 4 4 4 4 3/4 4

STAIN COTTON 3/4 4 4 4 3/4 4/5

STAIN NYLON 2/3 3 3/4 3/4 3 4/5

COLOURFASTNESS

TO RUBBING

DRY 3/4 3/4 4 4 4 4

WET 2* 2/3 3 3 3 3/4

COLOURFASTNESS

TO WATER

SHADE CHANGE 4 4 4 4 3/4 4

STAIN COTTON 4 4 4 4 3/4 4/5

STAIN NYLON 3/4 3/4 3/4 3/4 3 4/5

COLOURFASTNESS

TO PERSPIRATION

SHADE CHANGE 4 4 4 4 3/4 4

STAIN COTTON 4 4 4 4 3/4 4/5

STAIN NYLON 3/4 3/4 3/4 3/4 3 4/5

COLOURFASTNESS

TO LIGHT

SHADE CHANGE 4/5 4/5 3/4 3/4 2/3 4/5

COLOURFASTNESS

TO SEA WATER

SHADE CHANGE 4 4 4 4 2/3 4

COLOURFASTNESS

TO CHLORINATED

WATER

SHADE CHANGE 4 4 4 4 2/3 4

COLOURFASTNESS

TO DRY CLEANING

SHADE CHANGE 4 4 4 4

PHENOLIC

3/4

YELLOWING

PRINT FASTNESS SATISFACTORY

(AFTER 3 WASHES) NEGLIGIBLE CRACKING AND PEELING

DURABILITY OF

“GLOW IN THE

SATISFACTORY, STILL FUNCTIONAL. THE ―GLOW IN THE DARK‖ AREAS STILL GLOW IN THE DARK

DARK” (AFTER 5

WASHES)

COLOUR MATCHING 4

*COLOURFASTNESS

TO WET AND DRY

WHERE A GARMENT STATES IN THE CARE INSTRUCTIONS TO WASH BEFORE USE, IF THE

RUBBING FOR

COLOUR FAILS COLOURFAST TO RUBBING, THE GARMENT/FABRIC IS TO BE WASHED/DRIED

CORDUROY, DENIM,

ACCORDING TO THE CARE INSTRUCTIONS AND THEN TESTED AGAIN. BOTH RESULTS ARE TO

FLANNELETTE,

BE REPORTED.

PIGMENT DYED,

PIGMENT PRINTED

**LIGHT COLOUR LESS THAN 1/25 STANDARD DEPTH

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

8

Physical Tests

Physical Test Requirements

Physical Test Requirements

PROPERTY WOVEN FABRIC KNIT FABRIC

FIBRE CONTENT

FOR 100% CLAIMS 100% (MIN) 100% (MIN)

FOR BLENDS ONLY 5% (MAX) 5% (MAX)

FABRIC WEIGHT -5%~+10% -5%~+10%

GARMENT WEIGHT — 10%

CONSTRUCTION (SETT OR COURSE/WALE

3% 3%

DENSITY)

YARN COUNT (LINEAR DENSITY) 3% 3%

DIMENSIONAL STABILITY

L 5%

UNBRUSHED FABRIC 3%

W –5%~+2%

L 6%

BRUSHED FABRIC 5%

W –5%~+2%

L 5%

RIB

W –7%~+2%

SKEW/SPIRALLITY

GARMENT LENGTH LESS THAN 60CM 7% 7%

GARMENT LENGTH GREATER THAN 60CM 5% 5%

SATISFACTORY, MINIMAL CHANGE TO TRIMS, MINIMAL

APPEARANCE AFTER WASHING (AFTER 1 WASH DISTORTION DUE TO DIFFERENTIAL DIMENSIONAL STABILITY,

AS PER CARE INSTRUCTION) MINIMAL CHANGE TO EMBELLISHMENTS WHEN COMPARED TO

PRE-WASH SAMPLE.

DURABILITY OF GLITTER AND “GLUED”

SATISFACTORY, NO DETACHMENT OF GLUED TRIMS AND

TRIMS/EMBELLISHMENTS (AFTER 3 WASHES AS

EMBELLISHMENTS. NO DETERIORATION TO THE GLUE.

PER CARE INSTRUCTION)

PILL RESISTANCE

NORMAL FABRICS TESTED AFTER 1 WASH 3/4 3

LOW PILL FABRICS TESTED AFTER 1 WASH — 3/4

SEAM SLIPPAGE REFER TO STRENGTH REQUIREMENT BASED ON GARMENT TYPE

TEAR STRENGTH REFER TO STRENGTH REQUIREMENT BASED ON GARMENT TYPE

TENSILE STRENGTH (BREAKING FORCE) REFER TO STRENGTH REQUIREMENT BASED ON GARMENT TYPE

BURSTING PRESSURE REFER TO STRENGTH REQUIREMENT BASED ON GARMENT TYPE

UPON THE STYLE OF GARMENT

STRETCH RATES STRETCH RATE MUST THE SAME

AS FIT APPROVED SAMPLE.

RECOVERY RATES TO BE ADDED LATER.

BEFORE WASH 120 DEGREE

CREASE RECOVERY AFTER WASH (3 WASHES)

115 DEGREE

INITIAL: 3.5

STAIN RELEASE

AFTER WASH (5 WASHES): 3

BEFORE WASH 90

WATER REPELLENCY

AFTER WASH 80

BEFORE WASH 100

WATER PROOF

AFTER WASH 100

MOISTURE MANAGEMENT (WICKING) 7CM (MIN) BEFORE AND AFTER WASH

UPF (ULTRA VIOLET PROTECTION FACTOR) VERIFY CLAIM AS PER STANDARD

HIGH VISIBILITY VERIFY CLAIM AS PER STANDARD

FLAMMABILITY VERIFY CLAIM AS PER STANDARD

MICROBIOLOGICAL AND FUNGAL NO GROWTH

100PPM (MAX)

FORMALDEHYDE

CHILDREN UP TO 6 YEARS 30PPM (MAX)

HEAVY METALS AS PER AS/NZS ISO 8124.3

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

9

Washing Methods to Determine Shrinkage & Spirallity Based on Fibre Types

Washing Methods to Determine Shrinkage & Spirallity Based on Fibre Types

Washing Methods to Determine Shrinkage & Spirallity Based on Fibre Types

WASH METHOD FOR

FIBRES DRYING METHOD RESTORATION

SHRINKAGE

ACETATE WARM GENTLE MACHINE WASH LINE DRY COOL IRON

ACRYLIC—WOVEN WARM GENTLE MACHINE WASH LINE DRY DO NOT IRON

ACRYLIC—KNITS WARM GENTLE MACHINE WASH SCREEN DRY DO NOT IRON

COTTON—WOVEN WARM MACHINE WASH LINE DRY STEAM PRESSING

COTTON—KNITS WARM MACHINE WASH LINE DRY STEAM PRESSING

COTTON/POLYESTER WARM MACHINE WASH LINE DRY STEAM PRESSING

ELASTANE—WOVEN WARM GENTLE MACHINE WASH LINE DRY DO NOT IRON

ELASTANE—KNITS WARM GENTLE MACHINE WASH SCREEN DRY DO NOT IRON

FIBRE BATTING WARM GENTLE MACHINE WASH SCREEN DRY DO NOT IRON

FOAM PADDING WARM HAND WASH SCREEN DRY DO NOT IRON

HOLLOW FIBRE WARM MACHINE WASH TUMBLE DRY NO

MICRO FIBRE WARM MACHINE WASH TUMBLE DRY NO

LINEN WARM MACHINE WASH LINE DRY STEAM PRESSING

LEATHER WASHABLE WARM HAND WASH SCREEN DRY NO

NYLON WARM MACHINE WASH TUMBLE DRY NO

NYLON/COTTON WARM MACHINE WASH TUMBLE DRY NO

POLYESTER WARM MACHINE WASH TUMBLE DRY NO

POLYESTER/COTTON WARM MACHINE WASH TUMBLE DRY NO

POLYESTER/VISCOSE WARM GENTLE MACHINE WASH LINE DRY NO

POLYESTER/WOOL WARM GENTLE MACHINE WASH LINE DRY NO

POLYPROPYLENE WARM MACHINE WASH LINE DRY NO

POLYURETHANE WARM MACHINE WASH LINE DRY NO

PVC WARM MACHINE WASH LINE DRY NO

SILK WARM GENTLE MACHINE WASH LINE DRY WARM IRON

SUEDE WASHABLE WARM HAND WASH SCREEN DRY DO NOT IRON

VISCOSE WARM GENTLE MACHINE WASH LINE DRY COOL IRON

VISCOSE/POLYESTER WARM GENTLE MACHINE WASH LINE DRY COOL IRON

WOOL—KNITS WARM GENTLE MACHINE WASH SCREEN DRY HAND SMOOTH OUT

WOOL—WOVEN WARM GENTLE MACHINE WASH LINE DRY WARM SETTING IRON

WOOL BLENDED KNITS WARM GENTLE MACHINE WASH SCREEN DRY HAND SMOOTH OUT

WOOL BLENDED

WARM GENTLE MACHINE WASH LINE DRY WARM SETTING IRON

WOVEN

Washing Methods to Determine Shrinkage, Spirallity & Appearance after washing

Warm Hand Wash —AS2001.5.4 simulated hand wash, 40°C

Warm Gentle Wash —AS2001.5.4.7A gentle setting, 40°C front-loading machine

—AS2001.5.4.8B gentle setting, 40°C top loading machine

Warm Machine Wash —AS2001.5.4.5A normal setting, 40°C front loading machine

—AS2001.5.4.4B normal setting, 40°C top loading machine

Line Dry or Tumble-Dry is suggested according to above table

Screen Dry is recommended for Wool, Acrylic and/or Elastane blended Knits

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

10

Strength Requirement based on Garment Type

Strength Requirement based on Garment Type

Strength Requirement Based on Garment Type

PROPERTY FABRIC TEST METHOD LEVEL A LEVEL B LEVEL C LEVEL D

TENSILE STRENGTH

WOVEN AS2001.2.3.1 220 N 190 N 160 N 130 N

(BREAKING FORCE)

TEARING STRENGTH WOVEN AS2001.2.8 12 N 10 N 8N 6N

BURSTING PRESSURE KNIT AS2001.2.4 480 kPa 480 kPa 330 kPa 330 kPa

SEAM SLIPPAGE WOVEN AS2001.2.21 110 N 95 N 80 N 65 N

SEAM BREAKAGE GENERAL AS2001.2.20 110 N 95 N 80 N 65 N

Garment Type

GARMENT FITTING LEVEL GARMENT FITTING LEVEL

ANGEL SUITS NORMAL C

PYJAMA ALL C

(INFANTS) LOOSE D

NORMAL C ROMPER SUITS

BLOUSES ALL C

LOOSE D (INFANTS)

NORMAL B NORMAL B

COATS SHIRTS

LOOSE C LOOSE C

NORMAL A

CORSETRY & BRAS ALL C SHORTS

LOOSE B

NORMAL C NORMAL B

DRESS SKIRTS

LOOSE D LOOSE C

DRESSING GOWNS ALL C SKIVVIES ALL C

NORMAL A

GARMENT LINING ALL C SLACKS

LOOSE B

NORMAL B

JACKETS SLOPPY JOES ALL C

LOOSE C

NORMAL B

JEANS SLEEP SUITS (INFANTS) ALL C

LOOSE C

TOPS C NORMAL C

JOGGING SUITS SUN SUITS

BOTTOMS B LOOSE D

KNIT WEAR ALL C SWIMWEAR ALL C

LEOTARD ALL B TANK TOPS ALL C

TOPS C TOPS C

LOUNGE SUITS TRACKSUITS

BOTTOMS B BOTTOMS B

NORMAL C NORMAL A

NIGHT DRESS TROUSER/JEANS

LOOSE D LOOSE B

CHILDREN‘S

ALL A T-SHIRTS ALL C

OVERALLS

NORMAL

C

PILCHERS SETS NORMAL C LACE &

UNDER WEAR

(INFANTS) LOOSE D POINTELLE

D

STRUCTURES

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

11

Testing Laboratories for Textile, Clothing and Footwear

Testing Laboratories for Textile, Clothing and Footwear

Introduction

Laboratories may be used as long as they are NATA, SATRA or HOLKAS registered or have an equivalent

accreditation. Test reports from Government accredited laboratories are not acceptable.

International laboratories

Refer to the table below for testing laboratories overseas that are familiar with Kmart testing requirements.

International Laboratories

LOCATION LAB NAME

ITS (INTERTEK)

SGS

QUALSPEC

AWTA (JSIC)

BUREAU VERITAS

Australian laboratories

Refer to the table below for testing laboratories in Australia.

Australian Laboratories

CITY LAB NAME AND CONTACT DETAILS

info@arpansa.gov.au

http://www.arpansa.gov.au/

awtainfo@awta.com.au

http://www.awta.com.au/Contacts/Melbourne_Laoratory/Melbourne_Contacts.htm

Dale.Carroll@csiro.au

http://www.csiro.au/resources/Textile-Testing-Rates.html

dheffer@djha.com.au

trudie.orchard@rmit.edu.au

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

12

Australian Laboratories

CITY LAB NAME AND CONTACT DETAILS

Testing Laboratories for Textile, Clothing & Footwear

brian.mciver@target.com.au

graham_walters@bigpond.com

vviclabp@bigpond.net.au

qualspec@qualspec.com.au

info@qualspec.com.au

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

13

Kmart Test Methods

Kmart Test Methods—Apparel and Home Textiles

Kmart Test Methods

TEST ITEMS STANDARD STANDARD NAME

DIMENSIONAL CHANGE: DETERMINATION OF

DIMENSIONAL CHANGE IN LAUNDERING OF

VISUAL ASSESSMENT

TEXTILE FABRIC AND GARMENTS – AUTOMATIC

APPEARANCE AFTER WASHING AND DRY AFTER WASHING

WASHING METHOD.

CLEANING (AFTER 1 WASH) AS2001.5.4:2005

DIMENSIONAL CHANGE: ON DRY CLEANING IN

AS2001.5.7

PERCHLOROETHYLENE EXCLUDING FINISHING

– MACHINE METHOD.

DETERMINATION OF MAXIMUM FORCE AND

BREAKING FORCE AS2001.2.3.2 ELONGATION AT MAXIMUM FORCE USING THE

GRAB METHOD.

DETERMINATION OF BURSTING PRESSURE OF

BURSTING PRESSURE AS2001.2.4 TEXTILE FABRICS HYDRAULIC DIAPHRAGM

METHOD.

VISUAL

COLOUR MATCHING

COMPARISON/TL 84

COLOURFASTNESS TO CHLORINATED

DETERMINATION OF COLOURFASTNESS TO

WATER (AVAILABLE CHLORINE AS2001.4.5

CHLORINATED SWIMMING POOL WATER.

CONCENTRATION 20MG/L)

COLOURFASTNESS TO DRY CLEANING DETERMINATION OF COLOURFASTNESS OF

AS2001.4.16

SOLVENTS PERCHLOROETHYLENE TEXTILES TO DRY CLEANING SOLVENTS.

DETERMINATION OF COLOURFASTNESS TO

LIGHT USING AN ARTIFICIAL LIGHT SOURCE

(MERCURY VAPOUR – TUNGSTEN FILAMENT –

AS2001.4.21 60 HOURS

COLOURFASTNESS TO LIGHT INTERNALLY PHOSPHOR – COATED LAMP).

AS2001.4.B02 60 HOURS

DETERMINATION OF COLOURFASTNESS TO

ARTIFICIAL LIGHT: XENON ARC FADING LAMP

TEST.

COLOURFASTNESS TO PERSPIRATION DETERMINATION OF COLOURFASTNESS TO

AS2001.4.E04

(ALKALINE) PERSPIRATION.

DETERMINATION OF COLOURFASTNESS TO

COLOURFASTNESS TO RUBBING AS2001.4.3

RUBBING.

DETERMINATION OF COLOURFASTNESS TO

COLOURFASTNESS TO SEAWATER AS2001.4.E02

SEAWATER.

DETERMINATION OF COLOURFASTNESS TO

COLOURFASTNESS TO WASHING AS2001.4.15B

WASHING.

DETERMINATION OF COLOURFASTNESS TO

COLOURFASTNESS TO WATER AS2001.4.E01

WATER.

TEXTILE FABRIC – DETERMINATION OF THE

RECOVERY FROM CREASING OF A

CREASE RECOVERY BSEN22313

HORIZONTALLY FOLDED SPECIMEN BY

MEASURING THE ANGLE OF RECOVERY.

DIMENSIONAL CHANGE: ON DRY CLEANING IN

DIMENSIONAL STABILITY TO DRY AS2001.5.7

PERCHLOROETHYLENE EXCLUDING FINISHING

CLEANING (AFTER 1 CYCLE) METHOD A NORMAL

– MACHINE METHOD.

DIMENSIONAL CHANGE: DETERMINATION OF

DIMENSIONAL STABILITY TO WASHING

DIMENSIONAL CHANGE IN LAUNDERING OF

AS PER CARE INSTRUCTION (AFTER 1 AS2001.5.4:2005

TEXTILE FABRIC AND GARMENTS – AUTOMATIC

WASH)

WASHING METHOD.

DIMENSIONAL CHANGE: DETERMINATION OF

DURABILITY OF ―GLUED‖ TRIMS/

DIMENSIONAL CHANGE IN LAUNDERING OF

EMBELLISHMENTS (AFTER 3 WASHES) AS2001.5.4:2005

TEXTILE FABRIC AND GARMENTS – AUTOMATIC

AS PER CARE INSTRUCTION

WASHING METHOD.

FABRIC WEIGHT AS2001.2.13 DETERMINATION OF MASS PER UNIT AREA.

DOWN AND/OR FEATHER FILLING MATERIALS

FEATHER & DOWN AS2479:2007

AND FILLED PRODUCTS.

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

14

Kmart Test Methods

TEST ITEMS STANDARD STANDARD NAME

Kmart Test Methods

AS2001.7

FIBRE CONTENT AATCC TM20A FIBRE ANALYSIS SERIES.

ASTM D629

TEXTILE TEST METHODS – WOOL –

FIBRE DIAMETER ISO 137 DETERMINATION OF FIBRE DIAMETER –

PROJECTION MICROSCOPE METHOD.

TEXTILES – DETERMINATION OF

ISO 14184-1 (IF FAILURE FORMALDEHYDE – PART 1: FREE AND

FORMALDEHYDE

AFTER 1 WASH) HYDROLIZED FORMALDEHYDE (WATER

EXTRACTION METHOD).

HIGH VISIBILITY SAFETY GARMENTS.

RETROREFLECTIVE MATERIALS AND DEVICES

AS/NZS 4602

HIGH VISIBILITY FOR ROAD TRAFFIC CONTROL PURPOSES

AS/NZS 1906.4

PART 4: HIGH-VISIBILITY MATERIALS FOR

SAFETY GARMENTS.

WEIGHT CHECK

BEFORE AND AFTER

LINTING/PILE LOSS (AFTER 1 WASH) WASHING AND TUMBLE

DRYING CALCULATED

AS % LOSS

ANTIBACTERIAL ACTIVITY ASSESSMENT OF

TEXTILE MATERIALS: PARALLEL STREAK

AATCC TM147 METHOD.

MICROBIOLOGICAL/FUNGAL

AATCC TM30 ANTIFUNGAL ACTIVITY, ASSESSMENT ON

TEXTILE MATERIALS: MILDEW AND ROT

RESISTANCE OF TEXTILE MATERIALS.

TEXTILES – TESTS FOR COLOURFASTNESS –

PHENOLIC YELLOWING ISO 105-X18 PART X18: ASSESSMENT OF THE POTENTIAL

TO PHENOLIC YELLOWING OF MATERIALS.

TEXTILES. TERRY TOWELS AND TERRY

PILE RATIO EN 14697 TOWELS FABRICS. SPECIFICATIONS AND

METHODS OF TEST.

KNIT FABRICS: ISO

TEXTILES – DETERMINATION OF FABRIC

12945-1

PROPENSITY TO SURFACE FUZZING AND TO

PILL BOX 14,400

PILLING – PART 1: PILLING BOX METHOD.

REVOLUTIONS

PILLING WOVEN FABRICS: TWC

(IWS) 196

MARTINDALE PILLING MARTINDALE PILLING TEST METHOD.

TEST 1,000

REVOLUTIONS

DIMENSIONAL CHANGE: DETERMINATION OF

PRINT FASTNESS (AFTER 3 WASHES)

DIMENSIONAL CHANGE IN LAUNDERING OF

DURABILITY OF ―GLOW IN THE DARK‖ AS2001.5.4:2005

TEXTILE FABRIC AND GARMENTS – AUTOMATIC

(AFTER 5 WASHES)

WASHING METHOD.

DETERMINATION OF SEAM OPENING DUE TO

SEAM SLIPPAGE AS2001.2.21 THE APPLICATION OF FORCE IN THE

TRANSVERSE DIRECTION.

DIMENSIONAL CHANGE: DETERMINATION OF

AS2001.5.4

DIMENSIONAL CHANGE IN LAUNDERING OF

SPIRALLITY REF TO SPIRALITY

TEXTILE FABRIC AND GARMENTS – AUTOMATIC

KQCATEX

WASHING METHOD.

STAIN RELEASE AATCC TM 130 SOIL RELEASE: OILY STAIN RELEASE METHOD.

BS 4294 LOAD 3KgF

METHODS OF TEST FOR THE STRETCH AND

STRETCH AND RECOVERY SPORTSWEAR LOAD

RECOVERY OF PROPERTIES OF FABRICS.

6KgF

DETERMINATION OF TEAR FORCE OF FABRICS

TEAR STRENGTH AS2001.2.8 USING THE BALLISTIC PENDULUM METHOD

(ELMENDORF).

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

15

Kmart Test Methods

TEST ITEMS STANDARD STANDARD NAME

Kmart Test Methods

DETERMINATION OF MAXIMUM FORCE AND

TENSILE STRENGTH (BREAKING FORCE) AS2001.2.3.2 ELONGATION AT MAXIMUM FORCE USING THE

GRAB METHOD.

THERMAL INSULATION PERFORMANCE: DOMESTIC OVEN GLOVES – REQUIREMENTS

BS 6526

RATE OF THERMAL DIFFUSION ANNEX A AND TEST METHODS.

THERMAL RESISTANCE (WARMTH DETERMINATION OF THERMAL RESISTANCE

BS 5335-1

RATING) FOR QUILTS.

DETERMINATION OF THE NUMBER OF

THREAD PER UNIT LENGTH (ENDS &

THREADS PER UNIT LENGTH IN WOVEN

PICKS) AS2001.2.5

FABRIC.

THREAD PER UNIT LENGTH (WALES & AS2001.2.6

DETERMINATION OF THE NUMBER OF WALES

COURSES)

AND COURSES IN KNITTED FABRIC.

SAFETY OF TOYS PART 1: SAFETY ASPECTS

TRIM & ACCESSORIES: ATTACHMENT AS/NZS ISO 8124.1 RELATED TO MECHANICAL AND PHYSICAL

STRENGTH SECTION 5.24.6 PROPERTIES. REASONABLY FORESEEABLE

ABUSE TESTS – TENSION TEST.

SUN PROTECTIVE CLOTHING – EVALUATION

UPF AS/NZS 4399

AND CLASSIFICATION.

WATER ABSORBENCY (AFTER 1 WASH) TARGET TP 73

DETERMINATION OF RESISTANCE OF FABRICS

WATER PENETRATION-CONE TEST AS2001.2.18

TO WATER PENETRATION – CONE TEST.

DETERMINATION OF WATER REPELLENCY OF

WATER PROOF AS2001.2.16

TEXTILE SURFACES – SPRAY RATING TEST.

DETERMINATION OF WATER REPELLENCY OF

WATER REPELLENCY AS2001.2.16

TEXTILE SURFACES – SPRAY RATING TEST.

WETTABILITY (AFTER 1 WASH) AATCC79 ABSORBENCY OF TEXTILES.

WICKING (AFTER 1 WASH) TARGET TP 77

WRINKLE RESISTANCE

APPEARANCE OF FABRICS AFTER REPEATED

(APPEARANCE AFTER REPEATED HOME AATCC 124 5 CYCLES

HOME LAUNDERING.

LAUNDERING)

AS2001.2.23 OR DETERMINATION OF LINEAR DENSITY OF

YARN COUNT

ISO 7211/5 TEXTILE YARN FROM PACKAGES.

KQATEX1 Apparel Textile Requirements – Last Updated 15 March 2010

16

Potrebbero piacerti anche

- Carr and Latham's Technology of Clothing ManufactureDa EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerValutazione: 4 su 5 stelle4/5 (1)

- Travel Smith Fabric and Garment Testing ManualDocumento30 pagineTravel Smith Fabric and Garment Testing Manualard136011100% (1)

- Assignment On An Overview of Quality and Quality Control in Textile IndustryDocumento9 pagineAssignment On An Overview of Quality and Quality Control in Textile IndustryZAyedNessuna valutazione finora

- Global URBN Fabric and Apparel Testing Manual 2.25.2019Documento81 pagineGlobal URBN Fabric and Apparel Testing Manual 2.25.2019THYAGUNessuna valutazione finora

- Apparel - Fabric & Garment Test Procedures & Requirements ManualDocumento101 pagineApparel - Fabric & Garment Test Procedures & Requirements ManualNik ChaudharyNessuna valutazione finora

- Tesco Textile Performance Standards Fabric Testing RequirementsDocumento21 pagineTesco Textile Performance Standards Fabric Testing RequirementsRezoanul Haque100% (1)

- Soft Lines Technical Manual 2014Documento155 pagineSoft Lines Technical Manual 2014rhinorame6801Nessuna valutazione finora

- H&M QSR Part 01 - IntroductionDocumento7 pagineH&M QSR Part 01 - IntroductionRashedul AlamNessuna valutazione finora

- Testing procedures for fabrics and trims performanceDocumento48 pagineTesting procedures for fabrics and trims performanceshivanift100% (1)

- SM QA ChildrenswearDocumento58 pagineSM QA Childrenswearnaveenerotex100% (1)

- 10 Apparel QamanualDocumento44 pagine10 Apparel QamanualRanjeetKamatNessuna valutazione finora

- Care LabelDocumento21 pagineCare Labelmonisha100% (1)

- Santoni SeamlessDocumento2 pagineSantoni SeamlessSudheer SinghNessuna valutazione finora

- Fabric and Apparel Performance Testing ProtocolDocumento20 pagineFabric and Apparel Performance Testing Protocolbeeyesyem100% (1)

- H&M FABRIC SUPPLIER LAB GUIDELINE Jan 2014Documento7 pagineH&M FABRIC SUPPLIER LAB GUIDELINE Jan 2014Rashedul Alam100% (1)

- Cut Order PlanningDocumento12 pagineCut Order PlanningShirisha Bala100% (3)

- VM Section 6 Technical Design Sample & Fit RequirementsDocumento46 pagineVM Section 6 Technical Design Sample & Fit RequirementssuditiNessuna valutazione finora

- STDS'M&SDocumento8 pagineSTDS'M&SSazid Rahman100% (1)

- Fabric Inspection Process & Defect ClassificationsDocumento20 pagineFabric Inspection Process & Defect ClassificationsHarrison Kan100% (1)

- Apparel Quality Standard & Implementation PDFDocumento125 pagineApparel Quality Standard & Implementation PDFRommel Corpuz100% (1)

- Sample Room DepartmentDocumento5 pagineSample Room DepartmentRajib DasNessuna valutazione finora

- Automation in Garment ManufacturingDocumento43 pagineAutomation in Garment ManufacturingvagueNessuna valutazione finora

- Fabric Inspection and Shrinkage Testing ProceduresDocumento6 pagineFabric Inspection and Shrinkage Testing ProceduresMayan DynastyNessuna valutazione finora

- Fabrics Faults or DefectsDocumento13 pagineFabrics Faults or DefectsGopal KrishnanNessuna valutazione finora

- Processed Fabric InspectionDocumento5 pagineProcessed Fabric InspectionTamrat TesfayeNessuna valutazione finora

- Controlling and Check Points in Spinning ProcessDocumento10 pagineControlling and Check Points in Spinning ProcessBithy Paul100% (1)

- Quality Control of Lee JeansDocumento17 pagineQuality Control of Lee JeansLalit ChaudharyNessuna valutazione finora

- SCAP Session 10 Fabric LossesDocumento21 pagineSCAP Session 10 Fabric LossesReena VermaNessuna valutazione finora

- Analysis of Time StudyDocumento3 pagineAnalysis of Time StudyroshaeroNessuna valutazione finora

- Burberry - Fabric and Fabric TestingDocumento29 pagineBurberry - Fabric and Fabric Testingleo100% (1)

- Garment Washing Machine and EquipmentsDocumento22 pagineGarment Washing Machine and EquipmentsAman DeepNessuna valutazione finora

- Plant Layout - IDocumento16 paginePlant Layout - ITanya rajNessuna valutazione finora

- 1.2.1 - Triumph Global Quality Manual and Appendix - Edition Jan 2010Documento118 pagine1.2.1 - Triumph Global Quality Manual and Appendix - Edition Jan 2010LâmViên100% (1)

- Garment Defects .Documento24 pagineGarment Defects .Anmol JainNessuna valutazione finora

- Garment Cutting Room ActivitiesDocumento11 pagineGarment Cutting Room ActivitiesNaisargiNessuna valutazione finora

- Department of Fashion TechnologyDocumento22 pagineDepartment of Fashion TechnologyAbhishek YadavNessuna valutazione finora

- Best final inspection procedure checklistDocumento2 pagineBest final inspection procedure checklistSayed Aasim JawaidNessuna valutazione finora

- Fabric RelaxationDocumento2 pagineFabric RelaxationNahid67% (3)

- IoT Machine Maintenance Using SensorsDocumento20 pagineIoT Machine Maintenance Using SensorsGagan SinghviNessuna valutazione finora

- SpiralityDocumento9 pagineSpiralitySenthil KumarNessuna valutazione finora

- Dnls MMDocumento19 pagineDnls MMpriyal100% (1)

- Traffic Light System in Garment IndustryDocumento11 pagineTraffic Light System in Garment IndustryGopal Dixit0% (1)

- Buyer Manual Performance - Protocols - and - SpecificationsDocumento196 pagineBuyer Manual Performance - Protocols - and - Specificationsravikant100% (1)

- Soptextilefinishing 170316114830Documento73 pagineSoptextilefinishing 170316114830Mohammed Tanjil Morshed remonNessuna valutazione finora

- Apparel standards and quality control processesDocumento11 pagineApparel standards and quality control processesAman DeepNessuna valutazione finora

- QCM - Quality Control in Garments Industry by SatexDocumento21 pagineQCM - Quality Control in Garments Industry by Satexsatex100% (1)

- Materials GPQ PDFDocumento20 pagineMaterials GPQ PDFAmirul IslamNessuna valutazione finora

- TrousersDocumento6 pagineTrousersJeremy Charles100% (1)

- Spreading and Cutting of Apparel ProductsDocumento43 pagineSpreading and Cutting of Apparel ProductsDaniela JakimovaNessuna valutazione finora

- Fabric Finishing:: Finishing Faults/Defects - Different Types of Textile Finishing Faults/Defects With Their CausesDocumento31 pagineFabric Finishing:: Finishing Faults/Defects - Different Types of Textile Finishing Faults/Defects With Their CausesGemeda GebinoNessuna valutazione finora

- Objective of Marker Planning and Marker MakingDocumento4 pagineObjective of Marker Planning and Marker MakingSanthosh KannanNessuna valutazione finora

- Thread Consumption GuideDocumento6 pagineThread Consumption GuideMohammad Saleh MusaNessuna valutazione finora

- Production Planning and Control in the Garments IndustryDocumento2 pagineProduction Planning and Control in the Garments Industrykbalabala100% (1)

- Standardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Documento8 pagineStandardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Anish RajNessuna valutazione finora

- Thread ConsumptionDocumento4 pagineThread ConsumptionMd Mamun Hosain100% (1)

- 'How To Fill RMC Form' Guideline - UPDATED 14-3-23Documento15 pagine'How To Fill RMC Form' Guideline - UPDATED 14-3-23Sk SalimuzzamanNessuna valutazione finora

- Wheeled Loader L953F Specifications and DimensionsDocumento1 paginaWheeled Loader L953F Specifications and Dimensionssds khanhNessuna valutazione finora

- Equilibruim of Forces and How Three Forces Meet at A PointDocumento32 pagineEquilibruim of Forces and How Three Forces Meet at A PointSherif Yehia Al MaraghyNessuna valutazione finora

- Price List PPM TerbaruDocumento7 paginePrice List PPM TerbaruAvip HidayatNessuna valutazione finora

- Cableado de TermocuplasDocumento3 pagineCableado de TermocuplasRUBEN DARIO BUCHELLYNessuna valutazione finora

- Shopping Mall: Computer Application - IiiDocumento15 pagineShopping Mall: Computer Application - IiiShadowdare VirkNessuna valutazione finora

- Week 15 - Rams vs. VikingsDocumento175 pagineWeek 15 - Rams vs. VikingsJMOTTUTNNessuna valutazione finora

- Oxygen Cost and Energy Expenditure of RunningDocumento7 pagineOxygen Cost and Energy Expenditure of Runningnb22714Nessuna valutazione finora

- Link Ratio MethodDocumento18 pagineLink Ratio MethodLuis ChioNessuna valutazione finora

- An Introduction To Ecology and The BiosphereDocumento54 pagineAn Introduction To Ecology and The BiosphereAndrei VerdeanuNessuna valutazione finora

- Emergency Management of AnaphylaxisDocumento1 paginaEmergency Management of AnaphylaxisEugene SandhuNessuna valutazione finora

- Hi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!Documento8 pagineHi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!BS Central, Inc. "The Buzz"Nessuna valutazione finora

- France Winckler Final Rev 1Documento14 pagineFrance Winckler Final Rev 1Luciano Junior100% (1)

- Kalley Ltdn40k221twam Chassis msd6308 SM PDFDocumento49 pagineKalley Ltdn40k221twam Chassis msd6308 SM PDFjulio cesar calveteNessuna valutazione finora

- Weone ProfileDocumento10 pagineWeone ProfileOmair FarooqNessuna valutazione finora

- Prasads Pine Perks - Gift CardsDocumento10 paginePrasads Pine Perks - Gift CardsSusanth Kumar100% (1)

- Chapter 4 DeterminantsDocumento3 pagineChapter 4 Determinantssraj68Nessuna valutazione finora

- Special Power of Attorney: Benedict Joseph M. CruzDocumento1 paginaSpecial Power of Attorney: Benedict Joseph M. CruzJson GalvezNessuna valutazione finora

- PHY210 Mechanism Ii and Thermal Physics Lab Report: Faculty of Applied Sciences Uitm Pahang (Jengka Campus)Documento13 paginePHY210 Mechanism Ii and Thermal Physics Lab Report: Faculty of Applied Sciences Uitm Pahang (Jengka Campus)Arissa SyaminaNessuna valutazione finora

- Tutorial 1 Discussion Document - Batch 03Documento4 pagineTutorial 1 Discussion Document - Batch 03Anindya CostaNessuna valutazione finora

- H I ĐĂNG Assigment 3 1641Documento17 pagineH I ĐĂNG Assigment 3 1641Huynh Ngoc Hai Dang (FGW DN)Nessuna valutazione finora

- Qad Quick StartDocumento534 pagineQad Quick StartMahadev Subramani100% (1)

- Mutual Fund PDFDocumento22 pagineMutual Fund PDFRajNessuna valutazione finora

- List of Reactive Chemicals - Guardian Environmental TechnologiesDocumento69 pagineList of Reactive Chemicals - Guardian Environmental TechnologiesGuardian Environmental TechnologiesNessuna valutazione finora

- 7 Aleksandar VladimirovDocumento6 pagine7 Aleksandar VladimirovDante FilhoNessuna valutazione finora

- Inventory ControlDocumento26 pagineInventory ControlhajarawNessuna valutazione finora

- Be It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledDocumento2 pagineBe It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledCesar ValeraNessuna valutazione finora

- Analyze and Design Sewer and Stormwater Systems with SewerGEMSDocumento18 pagineAnalyze and Design Sewer and Stormwater Systems with SewerGEMSBoni ClydeNessuna valutazione finora

- Differential Pulse Code ModulationDocumento12 pagineDifferential Pulse Code ModulationNarasimhareddy MmkNessuna valutazione finora

- Public Private HEM Status AsOn2May2019 4 09pmDocumento24 paginePublic Private HEM Status AsOn2May2019 4 09pmVaibhav MahobiyaNessuna valutazione finora

- Use Visual Control So No Problems Are Hidden.: TPS Principle - 7Documento8 pagineUse Visual Control So No Problems Are Hidden.: TPS Principle - 7Oscar PinillosNessuna valutazione finora

- Bulletproof Seduction: How to Be the Man That Women Really WantDa EverandBulletproof Seduction: How to Be the Man That Women Really WantValutazione: 4.5 su 5 stelle4.5/5 (168)

- Fabric Manipulation: 150 Creative Sewing TechniquesDa EverandFabric Manipulation: 150 Creative Sewing TechniquesValutazione: 4.5 su 5 stelle4.5/5 (13)

- Playful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsDa EverandPlayful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Metric Pattern Cutting for Women's WearDa EverandMetric Pattern Cutting for Women's WearValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewDa EverandThe Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewValutazione: 4.5 su 5 stelle4.5/5 (25)

- Women's Work: The First 20,000 Years: Women, Cloth, and Society in Early TimesDa EverandWomen's Work: The First 20,000 Years: Women, Cloth, and Society in Early TimesValutazione: 4.5 su 5 stelle4.5/5 (190)

- The Basics of Corset Building: A Handbook for BeginnersDa EverandThe Basics of Corset Building: A Handbook for BeginnersValutazione: 4.5 su 5 stelle4.5/5 (17)

- Knitting for Anarchists: The What, Why and How of KnittingDa EverandKnitting for Anarchists: The What, Why and How of KnittingValutazione: 4 su 5 stelle4/5 (51)

- Strip Tees: A Memoir of Millennial Los AngelesDa EverandStrip Tees: A Memoir of Millennial Los AngelesValutazione: 4 su 5 stelle4/5 (24)

- Self-Care for Men: How to Look Good and Feel GreatDa EverandSelf-Care for Men: How to Look Good and Feel GreatValutazione: 4 su 5 stelle4/5 (4)

- DIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!Da EverandDIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!Valutazione: 3.5 su 5 stelle3.5/5 (7)

- A Victorian Lady's Guide to Fashion and BeautyDa EverandA Victorian Lady's Guide to Fashion and BeautyValutazione: 3.5 su 5 stelle3.5/5 (8)

- Famous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsDa EverandFamous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsValutazione: 4 su 5 stelle4/5 (4)

- 250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaDa Everand250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaValutazione: 5 su 5 stelle5/5 (7)

- How to Dress: Secret styling tips from a fashion insiderDa EverandHow to Dress: Secret styling tips from a fashion insiderValutazione: 4 su 5 stelle4/5 (1)

- Crystal Basics: The Energetic, Healing, and Spiritual Power of 200 GemstonesDa EverandCrystal Basics: The Energetic, Healing, and Spiritual Power of 200 GemstonesValutazione: 5 su 5 stelle5/5 (3)

- The Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewDa EverandThe Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewValutazione: 4 su 5 stelle4/5 (10)

- Soap Making Guide With Recipes: DIY Homemade Soapmaking Made Easy: DIY Homemade Soapmaking Made EasyDa EverandSoap Making Guide With Recipes: DIY Homemade Soapmaking Made Easy: DIY Homemade Soapmaking Made EasyValutazione: 4.5 su 5 stelle4.5/5 (17)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsDa EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsValutazione: 4.5 su 5 stelle4.5/5 (4)

- Modern Ladies' Tailoring: A basic guide to pattern draftingDa EverandModern Ladies' Tailoring: A basic guide to pattern draftingValutazione: 5 su 5 stelle5/5 (13)

- Emily Post's Etiquette in Society, in Business, in Politics, and at HomeDa EverandEmily Post's Etiquette in Society, in Business, in Politics, and at HomeValutazione: 4 su 5 stelle4/5 (59)