Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

30 Manual Nissan Sentra 2013

Caricato da

DavidTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

30 Manual Nissan Sentra 2013

Caricato da

DavidCopyright:

Formati disponibili

ENGINE

ENGINE LUBRICATION SYSTEM

SECTION LU LU

E

CONTENTS

MRA8DE OIL FILTER ....................................................... 10 F

Removal and Installation .........................................10

PRECAUTION ............................................... 2 Inspection ................................................................11

G

PRECAUTIONS ................................................... 2 REMOVAL AND INSTALLATION ............... 12

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- OIL COOLER .................................................... 12

SIONER" ................................................................... 2 Exploded View .........................................................12 H

Precaution for Liquid Gasket ..................................... 2 Removal and Installation .........................................13

Inspection ................................................................14

PREPARATION ............................................ 4 I

UNIT DISASSEMBLY AND ASSEMBLY ... 15

PREPARATION ................................................... 4

Special Service Tools ................................................ 4 OIL PUMP ......................................................... 15

Commercial Service Tools ........................................ 4 .................................................................................15 J

Removal and Installation .........................................15

SYSTEM DESCRIPTION .............................. 6 Inspection ................................................................16

K

DESCRIPTION .................................................... 6 SERVICE DATA AND SPECIFICATIONS

Engine Lubrication System Schematic ...................... 6 (SDS) ............................................................ 17

PERIODIC MAINTENANCE .......................... 7 SERVICE DATA AND SPECIFICATIONS L

ENGINE OIL ........................................................ 7 (SDS) ................................................................. 17

Inspection .................................................................. 7 Oil Pressure .............................................................17

Oil Capacity .............................................................17 M

Draining ..................................................................... 8

Refilling ..................................................................... 9

Revision: October 2012 LU-1 2013 Sentra NAM

PRECAUTIONS

< PRECAUTION > [MRA8DE]

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000008837248

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least 3 minutes before performing any service.

Precaution for Liquid Gasket INFOID:0000000008971156

REMOVAL OF LIQUID GASKET

• After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket.

Tool number : KV10111100 (J-37228)

CAUTION:

Be careful not to damage the mating surfaces.

• Tap (1) Tool to insert it, and then slide it (2) by tapping on the side

as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly

tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces. WBIA0566E

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica-

tion surface and the mating surface, using scraper.

• Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign materials.

PBIC0003E

Revision: October 2012 LU-2 2013 Sentra NAM

PRECAUTIONS

< PRECAUTION > [MRA8DE]

3. Attach liquid gasket tube to Tool.

A

Tool number : WS39930000 ( — )

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-21, "Recommended Chemical Products and Sealants". LU

4. Apply liquid gasket without breaks to the specified location with

the specified dimensions.

• If there is a groove for the liquid gasket application, apply liq- C

uid gasket to the groove.

D

WBIA0567E

• As for the bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes. E

Make sure to read the text of service manual.

• Within five minutes of liquid gasket application, install the mat-

ing component. F

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten nuts or bolts after the installation.

• After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant. G

SEM159F

H

CAUTION:

If there are more specific instructions in the procedures contained in this manual concerning liquid

gasket application, observe them. I

Revision: October 2012 LU-3 2013 Sentra NAM

PREPARATION

< PREPARATION > [MRA8DE]

PREPARATION

PREPARATION

Special Service Tools INFOID:0000000008767829

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number Description

(Kent-Moore No.)

Tool name

ST25051001 Measuring oil pressure

(J-25695-1) Maximum measuring range: 2,452 kPa (25

Oil pressure gauge kg-cm2, 356 psi)

NT050

ST25052000 Adapting oil pressure gauge to upper oil pan

(J-25695-2)

Hose

S-NT559

KV10115801 Removing and installing oil filter

(J-38956)

Oil filter wrench

S-NT772

KV10111100 Removing oil pan (lower) etc.

(J-37228)

Seal cutter

S-NT046

WS39930000 Pressing the tube of liquid gasket

( — )

Tube presser

NT052

Commercial Service Tools INFOID:0000000008767830

Revision: October 2012 LU-4 2013 Sentra NAM

PREPARATION

< PREPARATION > [MRA8DE]

Tool name Description

A

Deep socket Removing and installing oil pressure sensor

27 mm (1.06 in)

LU

C

PBIC4066E

Revision: October 2012 LU-5 2013 Sentra NAM

DESCRIPTION

< SYSTEM DESCRIPTION > [MRA8DE]

SYSTEM DESCRIPTION

DESCRIPTION

Engine Lubrication System Schematic INFOID:0000000008767831

JSBIA2841GB

Revision: October 2012 LU-6 2013 Sentra NAM

ENGINE OIL

< PERIODIC MAINTENANCE > [MRA8DE]

PERIODIC MAINTENANCE A

ENGINE OIL

Inspection INFOID:0000000008767832

LU

ENGINE OIL LEVEL

NOTE: C

Before starting engine, put vehicle horizontally and check the engine oil level. If engine is already started, stop

it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

D

2. Insert oil level gauge and check that the engine oil level is within

the range (A) shown.

3. If engine oil is out of range, adjust it. E

G

PBIC3309J

ENGINE OIL APPEARANCE

• Check engine oil for white turbidity or heavy contamination. H

• If engine oil becomes turbid and white, it is highly probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKAGE I

Check for engine oil leaks around the following areas.

• Oil cooler

• Oil temperature sensor J

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure sensor

• Oil filter K

• Valve timing control cover

• Valve timing control solenoid valve (intake and exhaust)

• Front cover L

• Mating surface between cylinder head and camshaft bracket

• Mating surface between cylinder block and cylinder head

• Mating surface between camshaft bracket and rocker cover

M

• Crankshaft oil seals (front and rear)

OIL PRESSURE CHECK

WARNING: N

• Be careful not to get burned, as engine oil may be hot.

• When checking engine oil pressure, shift position should be “P” (CVT models) or “N” (M/T models),

and apply parking brake securely.

O

1. Check engine oil level.

Revision: October 2012 LU-7 2013 Sentra NAM

ENGINE OIL

< PERIODIC MAINTENANCE > [MRA8DE]

2. Disconnect harness connector at oil pressure sensor (1), and

remove oil pressure sensor using a suitable tool.

(2) : Starter motor

: Engine front

CAUTION:

Do not drop or shock oil pressure sensor.

JPBIA4449ZZ

3. Install Tools (A) and (B).

Tool number (A) : ST25051001 (J-25695-1)

Tool number (B) : ST25052000 (J-25695-2)

JPBIA0074ZZ

4. Start engine and warm it up to normal operating temperature.

5. Check engine oil pressure with engine running under no-load.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

Engine oil pressure : Refer to LU-17, "Oil Pressure".

CAUTION:

If difference is extreme, check oil passage and oil pump for oil leaks.

6. After the inspections, install oil pressure sensor as follows:

a. Remove old liquid gasket adhering to oil pressure sensor and engine.

b. Apply liquid gasket and tighten oil pressure sensor to specification.

Use Genuine RTV Silicon Sealant or equivalent.

Tightening torque : Refer to EM-94, "Exploded View".

c. Check engine oil level.

d. After warming up engine, check that there are no leaks of engine oil with engine running.

Draining INFOID:0000000008767833

WARNING:

• Be careful not to get burned, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Warm up the engine, and check for engine oil leaks from engine components. Refer to LU-7, "Inspection".

2. Stop the engine and wait for 10 minutes.

3. Loosen oil filler cap.

4. Remove drain plug and then drain engine oil.

Revision: October 2012 LU-8 2013 Sentra NAM

ENGINE OIL

< PERIODIC MAINTENANCE > [MRA8DE]

Refilling INFOID:0000000008767834

A

1. Install drain plug with new drain plug washer. Refer to EM-33, "Exploded View".

CAUTION:

Be sure to clean drain plug and install with new drain plug washer. LU

Tightening torque : 34.3 N·m (3.5 kg-m, 25 ft-lb).

2. Refill with new engine oil. C

• Engine oil specification and viscosity: Refer to MA-12, "Engine Oil Recommendation".

• Engine oil capacity : Refer to LU-17, "Oil Capacity".

CAUTION: D

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

• Always use oil level gauge to determine the proper amount of engine oil in the engine.

E

3. Warm up engine and check area around drain plug and oil filter for engine oil leaks.

4. Stop engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-7, "Inspection". F

Revision: October 2012 LU-9 2013 Sentra NAM

OIL FILTER

< PERIODIC MAINTENANCE > [MRA8DE]

OIL FILTER

Removal and Installation INFOID:0000000008767835

REMOVAL

1. Remove engine under cover. Refer to EXT-16, "Exploded View".

2. Drain engine oil. Refer to LU-8, "Draining".

3. Remove the oil filter using Tool (A) as shown.

: Front

Tool number : KV10115801 (J-38956)

WARNING:

Be careful not to burn yourself, as the engine oil may be

hot.

CAUTION:

• When removing, prepare a shop cloth to absorb any oil

leaks or spills. JPBIA4450ZZ

• Do not allow engine oil to adhere to the drive belts.

• Completely wipe off any oil that adheres to the engine and the vehicle.

• The oil filter is provided with a relief valve. Use a Genuine

NISSAN oil filter or equivalent.

ALC094

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

SMA010

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn (A), or tighten to specification.

Oil filter : 18.0 N·m (1.8 kg-m, 13 ft-lb)

Tool number : KV10115801 (J-38956)

JPBIA0077ZZ

Revision: October 2012 LU-10 2013 Sentra NAM

OIL FILTER

< PERIODIC MAINTENANCE > [MRA8DE]

4. Refill engine with new engine oil. Refer to LU-9, "Refilling".

5. Install engine under cover. Refer to EXT-16, "Exploded View". A

Inspection INFOID:0000000008767836

LU

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-7, "Inspection".

2. Start the engine, and check that there are no leaks of engine oil. C

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level, and adjust the level. Refer to LU-7, "Inspection".

D

Revision: October 2012 LU-11 2013 Sentra NAM

OIL COOLER

< REMOVAL AND INSTALLATION > [MRA8DE]

REMOVAL AND INSTALLATION

OIL COOLER

Exploded View INFOID:0000000008767837

M/T models

JSBIA2840ZZ

1. Clamp 2. Water hose 3. Clamp

4. Water hose 5. Oil cooler 6. O-rings

Revision: October 2012 LU-12 2013 Sentra NAM

OIL COOLER

< REMOVAL AND INSTALLATION > [MRA8DE]

CVT models

A

LU

I

JSBIA2839ZZ

1. Clamp 2. Water hose 3. Clamp

J

4. Water hose 5. Water hose clip 6. Oil cooler

7. Clamp 8. Water hose 9. O-rings

A. To CVT oil warmer

K

Removal and Installation INFOID:0000000008767838

REMOVAL L

1. Remove engine under cover. Refer to EXT-16, "Exploded View".

2. Drain engine coolant. Refer to CO-12, "Changing Engine Coolant".

CAUTION: M

Perform when engine is cold.

3. Remove water hoses.

4. Remove bolts, oil cooler and O-rings. N

CAUTION:

• Be careful not to get burned when engine and engine oil may be hot.

• When removing, prepare a shop cloth to absorb any engine oil leaks or spills. O

• Completely wipe off any engine oil that adheres to engine and vehicle.

INSTALLATION

Installation is in the reverse order of removal. P

CAUTION:

Do not reuse O-rings.

NOTE:

Revision: October 2012 LU-13 2013 Sentra NAM

OIL COOLER

< REMOVAL AND INSTALLATION > [MRA8DE]

Tighten the oil cooler bolts in order as shown to specification.

ALBIA0969ZZ

Inspection INFOID:0000000008767839

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary,

replace oil cooler assembly.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and the engine coolant level and add engine oil and engine coolant. Refer to

LU-7, "Inspection" and CO-11, "System Inspection".

2. Start the engine, and check that there are no leaks of engine oil or engine coolant.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and the engine coolant level again. Refer to LU-7, "Inspection" and CO-11,

"System Inspection".

Revision: October 2012 LU-14 2013 Sentra NAM

OIL PUMP

< UNIT DISASSEMBLY AND ASSEMBLY > [MRA8DE]

UNIT DISASSEMBLY AND ASSEMBLY A

OIL PUMP

INFOID:0000000008767840

LU

JSBIA2753GB

M

1. O-ring 2. Oil pan (upper) 3. Oil level gauge guide

4. O-ring 5. Oil level gauge 6. Oil pump chain tensioner

N

7. Oil pump drive chain 8. Crankshaft sprocket 9. Oil pump sprocket

10. Oil pump 11. Drain plug washer 12. Drain plug

13. Oil pan (lower) 14. Oil filter 15. Connector bolt

O

16. Crankshaft position sensor 17. Rear oil seal

A. Refer to LU-10, "Removal and Instal- B. Oil pan side

lation"

P

Removal and Installation INFOID:0000000008767841

REMOVAL

1. Remove engine under cover. Refer to EXT-16, "Exploded View".

2. Remove air cleaner and air duct. Refer toEM-25, "Removal and Installation".

Revision: October 2012 LU-15 2013 Sentra NAM

OIL PUMP

< UNIT DISASSEMBLY AND ASSEMBLY > [MRA8DE]

3. Remove fender protector. Refer to EXT-28, "FENDER PROTECTOR : Removal and Installation - Front

Fender Protector".

4. Remove timing chain. Refer to EM-49, "Removal and Installation".

5. Remove oil pump.

• Loosen bolts in reverse order as shown.

(1) : Oil pump

(2) : Oil pan (upper)

: Engine front

JPBIA4451ZZ

INSTALLATION

CAUTION:

Do not reuse O-rings or washers.

Installation is in the reverse order of removal.

Oil Pump

• Tighten bolts in numerical order as shown.

(1) : Oil pump

(2) : Oil pan (upper)

: Engine front

JPBIA4451ZZ

Inspection INFOID:0000000008767842

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-7, "Inspection".

2. Start the engine, and check that there are no leaks of engine oil.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level, and adjust the level. Refer to LU-7, "Inspection".

Revision: October 2012 LU-16 2013 Sentra NAM

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS) [MRA8DE]

SERVICE DATA AND SPECIFICATIONS (SDS) A

SERVICE DATA AND SPECIFICATIONS (SDS)

Oil Pressure INFOID:0000000008767844

LU

Unit: kPa (kg/cm2, psi)

Engine speed Approximate discharge oil pressure* C

Idle speed 71 (0.72, 10.3)

2,000 rpm 200 (2.04, 29.0)

D

*: Engine oil temperature at 80°C (176°F)

Oil Capacity INFOID:0000000008767843

E

Unit: (US qt, lmp qt)

With oil filter change 4.0 (4-1/4, 3-1/2)

Drain and refill

Without oil filter change 3.8 (4, 3-3/8) F

Dry engine (Overhaul) 4.8 (5-1/8, 4-1/4)

Revision: October 2012 LU-17 2013 Sentra NAM

Potrebbero piacerti anche

- 49 Manual Nissan Sentra 2013Documento32 pagine49 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 44 Manual Nissan Sentra 2013Documento195 pagine44 Manual Nissan Sentra 2013David100% (1)

- 50 Manual Nissan Sentra 2013Documento276 pagine50 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 52 Manual Nissan Sentra 2013Documento52 pagine52 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 51 Manual Nissan Sentra 2013Documento11 pagine51 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- Car Service Manuals Honda 2016 CRV PDFDocumento541 pagineCar Service Manuals Honda 2016 CRV PDFDavid0% (1)

- 46 Manual Nissan Sentra 2013Documento106 pagine46 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 48 Manual Nissan Sentra 2013Documento39 pagine48 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 45 Manual Nissan Sentra 2013Documento33 pagine45 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 36 Manual Nissan Sentra 2013Documento54 pagine36 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- Pwcpower WindowsDocumento72 paginePwcpower WindowsgabyNessuna valutazione finora

- 39 Manual Nissan Sentra 2013Documento9 pagine39 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 2013 NISSAN Sentra PWO PDFDocumento6 pagine2013 NISSAN Sentra PWO PDFFSR1407Nessuna valutazione finora

- 43 Manual Nissan Sentra 2013Documento49 pagine43 Manual Nissan Sentra 2013David100% (1)

- 34 Manual Nissan Sentra 2013Documento13 pagine34 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 41 Manual Nissan Sentra 2013Documento16 pagine41 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 35 Manual Nissan Sentra 2013Documento102 pagine35 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 47 Manual Nissan Sentra 2013Documento21 pagine47 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 32 Manual Nissan Sentra 2013Documento21 pagine32 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 42 Manual Nissan Sentra 2013Documento14 pagine42 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 40 Manual Nissan Sentra 2013Documento54 pagine40 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 33 Manual Nissan Sentra 2013Documento80 pagine33 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 53 Manual Nissan Sentra 2013Documento64 pagine53 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 26 Manual Nissan Sentra 2013Documento58 pagine26 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 31 Manual Nissan Sentra 2013Documento38 pagine31 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- Hac PDFDocumento194 pagineHac PDFDavidNessuna valutazione finora

- 2013 Nissan Sentra LanDocumento128 pagine2013 Nissan Sentra LanFSR1407100% (1)

- 25 Manual Nissan Sentra 2013Documento6 pagine25 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- 28 Manual Nissan Sentra 2013Documento24 pagine28 Manual Nissan Sentra 2013DavidNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Revised+MRP+16th+April+2021 UpdatedDocumento8 pagineRevised+MRP+16th+April+2021 Updatedgokul saravananNessuna valutazione finora

- Bosch Motorsport ECU MS 15 Sport Calibration GuideDocumento107 pagineBosch Motorsport ECU MS 15 Sport Calibration GuideMauricio Navarro santanaNessuna valutazione finora

- 16V 4000 P83 2240 1800 3,6Documento1 pagina16V 4000 P83 2240 1800 3,6Amir Asyraf SuhailiNessuna valutazione finora

- Ca 50 50Documento2 pagineCa 50 50Adrian MartinNessuna valutazione finora

- C11 Valve Lash Settings (Tappet Settings)Documento6 pagineC11 Valve Lash Settings (Tappet Settings)Hari Hara Suthan100% (3)

- DPWH Price QuotationDocumento1 paginaDPWH Price QuotationRonaldo B VillaromanNessuna valutazione finora

- '09 '11 VN1700 B9F/BAF/BBF Title: This Catalog Covers: Grid No. This Grid CoversDocumento124 pagine'09 '11 VN1700 B9F/BAF/BBF Title: This Catalog Covers: Grid No. This Grid CoversDaniel MartínNessuna valutazione finora

- ECU Pinout AWP Vs AZGDocumento8 pagineECU Pinout AWP Vs AZGB-ertNessuna valutazione finora

- Hoja Tecnica Caterpillar CM25 50 HZDocumento2 pagineHoja Tecnica Caterpillar CM25 50 HZEdutamNessuna valutazione finora

- Engine Components IDocumento33 pagineEngine Components IParbat ShresthaNessuna valutazione finora

- Audi Service Training 4 2 v8 Fsi EngineDocumento4 pagineAudi Service Training 4 2 v8 Fsi Enginesamantha100% (60)

- Continental TSIO-470 Operator's ManualDocumento40 pagineContinental TSIO-470 Operator's Manuallegoulu21100% (2)

- Kirloskar 4R1040 Engine PDFDocumento94 pagineKirloskar 4R1040 Engine PDFSakthi Aravind91% (11)

- Lecture 4 PDFDocumento42 pagineLecture 4 PDFFelipe Barsanufio PereiraNessuna valutazione finora

- Dokumen - Tips - Manual Motor Perkins 1104d Euro 3Documento236 pagineDokumen - Tips - Manual Motor Perkins 1104d Euro 3Marianny MedinaNessuna valutazione finora

- Mikuni Carburetor TuningDocumento3 pagineMikuni Carburetor TuningGeorgeNessuna valutazione finora

- Parts Catalog: 2008/7 (Jul.) PublishedDocumento16 pagineParts Catalog: 2008/7 (Jul.) Publishedmiguel sousaNessuna valutazione finora

- Sterndrive Apps Manual Dec 2009 PDFDocumento386 pagineSterndrive Apps Manual Dec 2009 PDFViktor100% (1)

- Manufacturer: Peugeot Model: 206 1,4 Engine Code: TU3JP (KFW) Output: 55 (75) 5500 Tuned For: R-Cat Year: 2002-09 © Autodata Limited 2008 26.05.2010Documento4 pagineManufacturer: Peugeot Model: 206 1,4 Engine Code: TU3JP (KFW) Output: 55 (75) 5500 Tuned For: R-Cat Year: 2002-09 © Autodata Limited 2008 26.05.2010Алексей СмогуновNessuna valutazione finora

- 1GD - 2GD Engine Mechanical PDFDocumento326 pagine1GD - 2GD Engine Mechanical PDFCarlos Omar Zarate Yataco95% (57)

- YD25DDTi and ZD30DDT Engines in NISSAN Repair ManualsDocumento19 pagineYD25DDTi and ZD30DDT Engines in NISSAN Repair ManualsMoaed Kanbar91% (105)

- S14 SR20DET ECU PinoutDocumento1 paginaS14 SR20DET ECU Pinoutpedda meierNessuna valutazione finora

- Parts Catalog For Engine 150 HP - Sea Pro SN 2b482084 - 2b482085 - BakamlaDocumento115 pagineParts Catalog For Engine 150 HP - Sea Pro SN 2b482084 - 2b482085 - BakamlaPussarpras KamlaNessuna valutazione finora

- 2010 EMP Full Marine CatalogDocumento538 pagine2010 EMP Full Marine CatalogFstaRockr BurnsNessuna valutazione finora

- Slant Six Racing ManualDocumento51 pagineSlant Six Racing ManualNorEaster1100% (1)

- 5.1. Carburetors and Their SystemsDocumento48 pagine5.1. Carburetors and Their SystemsGODNessuna valutazione finora

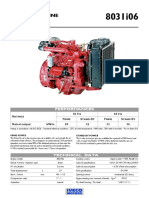

- 8031 I06 DS P4A048001EDocumento2 pagine8031 I06 DS P4A048001EAlan VeizagaNessuna valutazione finora

- Hyundai: Group Engine Year No. Displace No. Model Cyl. Ment G G4Aj G G4Dj G 4G15Documento2 pagineHyundai: Group Engine Year No. Displace No. Model Cyl. Ment G G4Aj G G4Dj G 4G15Евгений ДынникNessuna valutazione finora

- Madza Service Manual DensoDocumento1.000 pagineMadza Service Manual Densojermaine tobanNessuna valutazione finora

- 【EN】Maxxforce3.2 Engine Workshop Manual PDFDocumento322 pagine【EN】Maxxforce3.2 Engine Workshop Manual PDFsamuel ortega100% (4)