Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Giám sát độ rơ lỏng Bulong đai ốc BoltSafe-Brochure-1

Caricato da

lampfievCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Giám sát độ rơ lỏng Bulong đai ốc BoltSafe-Brochure-1

Caricato da

lampfievCopyright:

Formati disponibili

BoltSafe product line overview

The problem

The problem with bolted joints has always been; how can you be sure your threaded assemblies have

achieved and/or have kept the required bolt load? Unequal and insufficient bolt load is in most cases

reason for gasket joints to start leaking. During assembly gaskets get an overload to compensate later

relaxation, especially with hydraulic tensioners. It remains unclear what the relaxation will be over time.

Other bolting insecurities are:

• Bolts break due to fatigue issues. But when?

• During operation bolt loads may vary. But how much?

• Bolts become loose. But why?

• How can maintenance costs on bolting be reduced?

• What is the coefficient of friction?

• What is the right tool setting, or best bolting procedure?

This resulted in expensive check ups and re-tightening procedures to become common for high loaded

bolts in (steel) constructions such as cranes and wind turbines.

The solution

Place a BoltSafe washer between the nut/bolt head and the flange surface, and measure the actual bolt

load during the assembly. This way the correct residual bolt load is ensured. After assembly, the actual

bolt load can be monitored, so under-/overload and expensive check ups can be avoided. With a simple

test the coefficient of friction can be determined rather than assumed or guessed. The same test shows

you the exact tool settings to reach the desired bolt load.

This leads to enhanced safety, dependable joints, better control and improved cost benefit both during

installation and throughout the joint’s service life.

To avoid bolting related failures has never been this easy.

Measuring bolt load accurately

Ways to visualise boltload

Handheld Reader

The SM-200 Handheld Reader is a handheld instrument which has the function to read and store

data from both the CMS (Continuous Monitoring Sensor) and PMS (Periodic Monitoring Sen-

sor) BoltSafe washers. The user can monitor the residual bolt load directly on the instrument.

With the PC connection cable you can send the measured bolt load data to a PC afterwards. You

can analyze this measured bolt load data with the special software called “BS Report Generator”.

Wireless in combination with the Handheld Reader

BoltSafe can also be used in small spaces where cables do not fit. Narrow spaces happen to be the

speciality of the PMS washer. BoltSafe Sensors PMS have a non-contacting interface and require

no cable connections. During service, the unit is powered over an inductive interface connected to

a Handheld Reader. The BoltSafe Sensor PMS can be read by the Handheld Reader in combination

with a PMS-probe. The user can monitor the residual bolt load directly on the instrument.

Measuring bolt load accurately

Network with PDI

With the PDI box and a network of CM-1000 boxes, you can visualize the bolt load continuous.

You can connect up to eight BoltSafe sensors to one CM-1000 box and you can use up to 31

CM-1000 boxes in a network to one PDI box in combination with a PC. You can analyze the

continuous bolt load data with the special software called “BS2000 Network Monitoring”.

Network with PDI-NT

With the PDI-NT box, you can visualize the bolt load on the BoltSafe sensors continuous. The

difference with the PDI box mentioned earlier, is that with the PDI-NT no PC is needed because

it has a HMI Display and the PDI-NT can provide various output signals, like 4-20 mA or serial

data. Other functions are:

• Generating alarm at too high or too low bolt load

• Trending the bolt load during a predefined period

• Creating custom-made applications

• Connect the BoltSafe washers to other platforms

Measuring bolt load accurately

The new RS-232 and Analog converter

With the BoltSafe RS-232 and Analog converter it is easy to connect a BoltSafe CMS sensor (Con-

tinuous Monitoring System) directly to any Data acquisition system, computer or PLC. The free

Windows-based software allows users to easily readout the load that is applied to the sensor.

The software can also be used to adjust the moment when the BoltSafe RS-232 and Analog

converter has to switch a relay on or off (in kN or as percentage of full scale). This makes it possible

to use the converter standalone; to activate an alarm or warning light.

The RS-232 and Analog converter can also be used to switch off a remote control or even a

complete pump or (electric) torque tool. The complete serial communication protocol will be pro-

vided, which also enables users to use their own software and adjust settings via their computer or

PLC.

• Digital readout in RS-232

• Analog readout: 0-5Vdc, 0-10Vdc, 0-20mA and 4-20mA

Alarming

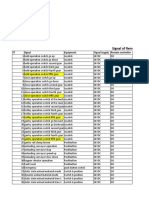

This graph shows the measured results. Alarming

too low or too high can be adjusted with a network

interface.

It is possible to set an alarm with a PDI-NT box and

the RS-232 and Analog converter.

+31 246790797 www.boltsafe.com info@boltsafe.com

Ver.11-02-19

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Power Management 01740Documento138 paginePower Management 01740lampfievNessuna valutazione finora

- Basic Software Testing Skills: Logigear Certified Test Professional IDocumento264 pagineBasic Software Testing Skills: Logigear Certified Test Professional Imrlam90100% (1)

- Efive VPN Server - SetupDocumento43 pagineEfive VPN Server - SetuplampfievNessuna valutazione finora

- SU List Signal Rev1.0Documento8 pagineSU List Signal Rev1.0lampfievNessuna valutazione finora

- How PLC Reads The Data From Field TransmittersDocumento5 pagineHow PLC Reads The Data From Field TransmitterslampfievNessuna valutazione finora

- How Do You Establish Modbus-Rtu Communication?: SIMATIC S7-1200 FW V4.2 / STEP 7 V14 (TIA Portal)Documento10 pagineHow Do You Establish Modbus-Rtu Communication?: SIMATIC S7-1200 FW V4.2 / STEP 7 V14 (TIA Portal)lampfievNessuna valutazione finora

- Tram Lang Them Che Do 1 BomDocumento16 pagineTram Lang Them Che Do 1 BomlampfievNessuna valutazione finora

- Using SD Card PDFDocumento17 pagineUsing SD Card PDFlampfievNessuna valutazione finora

- Cantier Profile With MES - Industry 4.0 (Partners)Documento28 pagineCantier Profile With MES - Industry 4.0 (Partners)lampfievNessuna valutazione finora

- Cantier Profile With MES - Industry 4.0 (Partners)Documento28 pagineCantier Profile With MES - Industry 4.0 (Partners)lampfievNessuna valutazione finora

- Anybus WirelessDocumento46 pagineAnybus WirelesslampfievNessuna valutazione finora

- Difference Between Fieldbus, Profibus and HART ProtocolsDocumento6 pagineDifference Between Fieldbus, Profibus and HART ProtocolslampfievNessuna valutazione finora

- LMR 400 Type Cables DatasheetDocumento2 pagineLMR 400 Type Cables DatasheetlampfievNessuna valutazione finora

- Airline Reservation System SynopsisDocumento18 pagineAirline Reservation System SynopsissudarshanNessuna valutazione finora

- MagicSoft Playout HelpDocumento28 pagineMagicSoft Playout HelpJorge RiveraNessuna valutazione finora

- 057-350 G0123 OpsDocumento14 pagine057-350 G0123 OpsArsen SemenystyyNessuna valutazione finora

- HPE MSA Gen6 Virtual Storage Technical Reference Guide-A00103247enwDocumento32 pagineHPE MSA Gen6 Virtual Storage Technical Reference Guide-A00103247enwHernan HerreraNessuna valutazione finora

- Clickshare Barco R5900025 - 06 - UserGuideDocumento52 pagineClickshare Barco R5900025 - 06 - UserGuideJeromeNessuna valutazione finora

- Página 1 de 2 928G Wheel Loader and IT28G Integrated Toolcarrier DJD00001-UP (MACHINE) PO..Documento2 paginePágina 1 de 2 928G Wheel Loader and IT28G Integrated Toolcarrier DJD00001-UP (MACHINE) PO..David MusanNessuna valutazione finora

- Data Mining Lab ManualDocumento44 pagineData Mining Lab ManualAmanpreet Kaur33% (3)

- Compact DiscDocumento7 pagineCompact DiscDan ConstantinNessuna valutazione finora

- 100 TOP COMPUTER NETWORKS Multiple Choice Questions and Answers COMPUTER NETWORKS Questions and Answers PDFDocumento21 pagine100 TOP COMPUTER NETWORKS Multiple Choice Questions and Answers COMPUTER NETWORKS Questions and Answers PDFvaraprasad_ganjiNessuna valutazione finora

- Cisco SPA 502G 1-Line IP PhoneDocumento5 pagineCisco SPA 502G 1-Line IP PhonemastrNessuna valutazione finora

- User Satisfaction in Mobile ApplicationsDocumento10 pagineUser Satisfaction in Mobile ApplicationsNirianNessuna valutazione finora

- Huawei BTS Field Commissioning GuideDocumento78 pagineHuawei BTS Field Commissioning GuideKumar Yuv100% (6)

- Pulse Ramping Automation InterfaceDocumento82 paginePulse Ramping Automation InterfaceAEE PC UdumalpetNessuna valutazione finora

- Special ALT CharactersDocumento2 pagineSpecial ALT CharactersYervant ArabianNessuna valutazione finora

- MCQ On MS WordDocumento13 pagineMCQ On MS WordAbby DukeworthNessuna valutazione finora

- FJ 310Documento2 pagineFJ 310shalarthiNessuna valutazione finora

- MM TAXBRA Migracao BatchDocumento3 pagineMM TAXBRA Migracao BatchMárcio NascimentoNessuna valutazione finora

- Lollipop ManualDocumento59 pagineLollipop ManualVafaKhalighiNessuna valutazione finora

- Interview FaqsDocumento100 pagineInterview FaqsKumar Perabattula100% (1)

- Courier Fonts: Everything You Ever Wanted To Know About Courier - . - and Then SomeDocumento9 pagineCourier Fonts: Everything You Ever Wanted To Know About Courier - . - and Then SomehsdvbvhlsdaNessuna valutazione finora

- HP 477dw Web ServerDocumento53 pagineHP 477dw Web Servercovenant660Nessuna valutazione finora

- OTC FS 4.7.2 ENH0689 EU Ehancements For Seeburger MapsDocumento12 pagineOTC FS 4.7.2 ENH0689 EU Ehancements For Seeburger MapsdarapuNessuna valutazione finora

- Experience With An IT Asset Management SystemDocumento23 pagineExperience With An IT Asset Management SystemCA Ghanathe RamakrishnaNessuna valutazione finora

- Sixth Sense Technology Shows That We Stepped To A New GenerationDocumento10 pagineSixth Sense Technology Shows That We Stepped To A New GenerationVijila PoojaNessuna valutazione finora

- Dostackbufferoverflowgood TutorialDocumento69 pagineDostackbufferoverflowgood TutorialtimmNessuna valutazione finora

- PresentCh03 - Decision and Repetition StatementsDocumento16 paginePresentCh03 - Decision and Repetition StatementsGebreigziabher M. AbNessuna valutazione finora

- Isabela State University: ISUR-IICT-SQA-089Documento13 pagineIsabela State University: ISUR-IICT-SQA-089Emelita Valdez LealNessuna valutazione finora

- Coding File InventoryDocumento10 pagineCoding File Inventorymaintenance cwaNessuna valutazione finora

- D1 IHC Training Simulators For Dredging and OffshoreDocumento3 pagineD1 IHC Training Simulators For Dredging and OffshoreSig Baha100% (1)