Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Guidance Note On Packaging Inks - Version 2018

Caricato da

Boonyarit LurdgrienggraiyingTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Guidance Note On Packaging Inks - Version 2018

Caricato da

Boonyarit LurdgrienggraiyingCopyright:

Formati disponibili

Page 1 of 7

Nestlé Guidance Note on Packaging Inks

October 2018

PURPOSE

This document is a part of the Nestlé Packaging Safety and Compliance Program and specifically

addresses inks used for the outside of Nestlé packaging materials.

This document equally applies to: printing inks, primers and overprint lacquers/coatings/varnishes

which are applied by conventional press or digital ink processes. These different ink designations will

be referred to as “ink” in this document.

This document must be shared with Nestlé vendors and upwards in the packaging value chain (i.e.

with ink makers, ink ingredient makers, ink coating and overprint varnish manufacturers).

CONTENTS

Page

General Requirements – Regulations 1

General Requirements – Sustainability and Recyclability 2

General Requirements – Exclusions 2

P I G M E N T S and Table 1: Exclusion list for Pigments 3

P H O T O I N I T I A T O R S and Table 2: Exclusion list for

4

Photoinitiators (energy cured printing)

P H O T O I N I T I A T O R S and Table 3: Minimize list for

4

Photoinitiators (energy cured printing)

A C R Y L A T E S and Table 4: Exclusion list for Acrylates

5

(energy cured printing)

A C R Y L A T E S and Table 5: Minimize list for Acrylates 5

S O L V E N T S and Table 6: Exclusion list for Solvents 6

S O L V E N T S and Table 7: Minimize list for Solvents 6

GENERAL REQUIREMENTS

Regulations:

Local legislation for food packaging inks must be followed where one exists. In addition, inks must

also be formulated to comply with other local regulations such as environmental laws (e.g. REACH,

California’s Proposition 65, US-EPA TOSCA, etc.).

In the absence of local legislation, Nestlé requires inks to be formulated using ingredients that are

listed in the Swiss Ink Ordinance on Materials and Articles and respect the migration limits contained

therein.

Published: Previous version:

October 2018 September 2016

Page 2 of 7

Summary of the Swiss Ordinance for food packaging inks requirements:

Part A lists chemical substances that have been toxicologically evaluated and a Specific Migration

Limit (SML) has been set for each substance.

Part B lists chemical substances which have not been toxicologically evaluated but are still allowed

to be used in ink formulations with the default migration limit set at 0.01 mg/kg (10 ppb) for food

or food simulant.

The applicable migration limits must be respected for substances in part A and part B in order to

fully comply with the Swiss Ink Ordinance requirements.

Substances not listed in the Swiss Ink Ordinance are not allowed to be used in any part of a food

packaging ink formulation.

Principally, the Swiss inks ordinance must be followed first and foremost. Exceptions may be granted

for ink chemicals used outside of Europe which are specifically permitted by local food packaging ink

regulations which include a toxicological evaluation (e.g. US-FDA FCN). These ink chemicals are

exceptionally allowed for use in Nestlé packaging provided these chemicals are not prohibited

elsewhere in this document. For these exceptions, the supplier must include a reference to the

specific regulation (e.g. FCN number) as a part of the compliance statement to the Nestlé

requirements.

Sustainability and Recyclability for inks:

Nestlé’s goals of sustainability and recyclability for food packaging must extend to inks. This means

going forward, ink manufacturers must take into consideration and start formulating inks using

components which are more environmentally and recyclability friendly.

General exclusions for ink formulations:

This Note has negative lists of components. The components below are allowed by the Swiss Ink

Ordinance, but are forbidden for Nestlé ink formulations due to quality and safety concerns.

Titanium Acetyl Acetonate (TAA) must not be used as an adhesion promoter.

ortho-Phthalate (commonly called phthalate) plasticizers must not be used.

Bisphenol A (BPA) and materials manufactured from or incorporating BPA in reacted form as

part of the chemical structure must not be used where safe suitable alternatives exist. Any BPA

residue/cross contamination must not be detected in food product from ink above 0.1 ppb.

SVHC must not be used where suitable alternatives exist.

Nitrocellulose resins must not be used for ovenable/microwavable packaging that is heated with

food prior to consumption due to decomposition concerns.

Vegetable oils/fatty acid esters with strong odours must not be used (for offset inks)

Heavy/Toxic metal restrictions and regulations must be followed:

o Migration limitations are listed in the Swiss inks ordinance for barium, cobalt, zinc,

arsenic, and other metals which must be respected.

o Regulations for metals where a product is sold must be followed and can be significantly

lower than 100ppm. Check local regulations to confirm compliance to limits for incidental

presence of lead, mercury, chromium +6, cadmium, and other metals.

Published: Previous version:

October 2018 September 2016

Page 3 of 7

Press washes and fountain solutions must not contain solvents and other chemicals which give

off-odour or taint to the food.

PIGMENTS

Rhodamine-based (“Fanal”) pigments may contain residual rhodamine, which is a suspected

carcinogenic substance. These pigments are generally less stable (visual aspect changes, migrations).

The prohibited pigments are listed in Table 1.

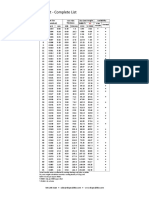

Table 1: Exclusion list for Pigments

Color CAS Swiss Ink

Pigments

index number Ordinance

Pigment Red 81 45160:1 12224-98-5 B

Pigment Red 81:1 45160:3 80083-40-5 B

Pigment Red 81:2 45161:1 75627-12-2 B

Pigment Red 81:3 45161:2 68310-07-6 B

Pigment Red 81:5 45160:4 63022-06-0 B

Pigment Red 169 45160:2 12237-63-7 B

Pigment Green 1 42040:1 1325-75-3 B

Pigment Blue 1 42595.2 1325-87-7 B

Pigment Blue 62 44084 57485-98-0 B

Pigment Violet 1 45170:2 1326-03-0 B

Pigment Violet 2 45175:1 1326-04-1 B

1325-82-2

Pigment Violet 3 42535:2 B

67989-22-4

Pigment Violet 27 42535:3 12237-62-6 B

Pigment Violet 39 42555:2 64070-98-0 B

Other Pigments that should be minimized* and phased-out where suitable alternatives exist:

Pigments that generate small amounts of polychlorobiphenyls (PCBs) or are manufactured from

3,3’-dichlorobenzidine with different couplers must be minimized or phased-out where suitable

alternatives exist.

* Minimized means to use the minimum quantity necessary to achieve expected technical effect.

Published: Previous version:

October 2018 September 2016

Page 4 of 7

PHOTOINITIATORS

Nestlé recommends the use of photo-initiators mentioned in List A of the Swiss Ink Ordinance, i.e.

those for which toxicological data exist. Additionally, there are photo-initiators listed in the Swiss Inks

Ordinance which Nestlé does not allow for its packaging due to negative odour/taint, migration

potential, or safety concerns. The prohibited photo-initiators are listed in Table 2.

Table 2: Exclusion list for Photo-Initiators

CAS Swiss Inks Reason to exclude

PhotoInitiator Name

Number Ordinance

Sensory impact Migration

2-Hydroxy 2-methyl propiophenone 7473-98-5 B

/contamination potential

Migration

2-(Dimethylamino)ethyl benzoate 2208-05-1 B

/contamination potential

Benzophenone types:

- Benzophenone 119-61-9 A

A Sensory impact Migration

- 2-Methyl benzophenone 131-58-8

/contamination potential

- 4-Methyl benzophenone 134-84-9 A

- 2,4,6-trimethylbenzo phenone 954-16-5 B

Sensory impact Migration

1-Hydroxycyclohexyl phenylketone 947-19-3 B

/contamination potential

2,2-Dimethoxy 2-phenyl Sensory impact Migration

24650-42-8 B

acetophenone /contamination potential

2-Methyl 4'-(methylthio)

71868-10-5 B Sensory impact

2-morpholino-propiophenone

2- and 4-Isopropyl 9H- thioxanthen-9-one 83846-86-0 A

Perceived safety issue

(2-ITX and 4-ITX) 5495-84-1 A

2,4-Diethyl 9H-thioxanthen-9-one 82799-44-8 B Questionable toxicology

Diphenyl (2,4,6-trimethyl benzoyl) Questionable toxicology

75980-60-8 A

phosphine oxide Perceived issue

Note: This exclusion list is not applicable to UV printing on metal substrates (cans, closures) which

undergo a thermal curing process (e.g. oven cured).

Table 3: Minimize list for Photo-Initiators

CAS Swiss Ink Reason to Minimize

PhotoInitiator Name

Number Ordinance

Irgacure/Omnirad 369 119313-12-1 A Questionable toxicology

Other monomeric Benzophenones (not

Various A/B Potential for migration

forbidden above)

* Minimize means to use the minimum quantity necessary to achieve an expected technical effect.

Published: Previous version:

October 2018 September 2016

Page 5 of 7

ACRYLATES

Nestlé recommends the use of acrylates mentioned in List A of the Swiss Ink Ordinance, i.e. those for

which toxicological data exist. Additionally, there are acrylates for UV and EB printing which Nestlé

does not allow for its packaging even though these are listed in the Swiss Ordinance. The prohibited

acrylates are listed in Table 4.

Table 4: Exclusion list for acrylates (must not be intentionally used)

CAS number Swiss Ink

Chemical name

Ordinance

Butanediol Diacrylate (BDDA) 1070-70-8 B

Diethylene glycol diacrylate (DEGDA) 4074-88-8 B

Isodecyl acrylate (IDA) 1330-61-6 B

Octyl acrylate (ODA) 2499-59-4 A

Phenoxy ethyl acrylate 48145-04-6 B

There are some acrylates which are allowed by the Swiss ink ordinance and the Nestlé requirements,

but have negative quality attributes. These must be minimized* in the ink and varnish formulations

so that their residual levels in foods (or food simulants) are below regulatory and sensory thresholds.

The acrylates to be minimized are listed in Table 5.

* Minimize means to use the minimum quantity necessary to achieve an expected technical effect.

Table 5: Minimize* list for Acrylates

Swiss Inks

Chemical name CAS number

Ordinance

Trimethylol propane triacrylate (TMPTA) 15625-89-5 A

Dipropylene glycol diacrylate (DPGDA) 57472-68-1 B

1, 6-Hexanediol diacrylate (HDDA) 13048-33-4 B

2-Ethyl hexyl acrylate (2EHA) 103-11-7 A

Mixtures of pentaerythritol tri- and tetra-

acrylates (PETA) 3524-68-3 B

Tetraethylene glycol diacrylate (TEGDA) 17831-71-9 B

* Minimize means to use the minimum quantity necessary to achieve an expected technical effect.

Published: Previous version:

October 2018 September 2016

Page 6 of 7

SOLVENTS

Table 6: Exclusion list of Solvents: must not be intentionally used in the ink formulation.

CAS Swiss Ink

Chemical name

number Ordinance

2-Methoxyethanol (methyl glycol) 109-86-4 Deleted from

Swiss Ord.

2-Ethoxyethanol (Ethyl glycol) 110-80-5 Deleted from

Swiss Ord.

Monochlorobenzene 108-90-7 A

Toluene 108-88-3 A

1-methyl-2-pyrrolidone/ 872-50-4 A

N-Methylpyrrolidone

Table 7: Minimize list for Solvents: must be minimized* in the ink formulation to reduce the risk of

off-odour and taint.

CAS Swiss Inks CAS Swiss Inks

Chemical name Chemical name

number Ordinance number Ordinance

Hexylene glycol/ 2-

Methanol 67-56-1 A Methyl-2,4- 107-41-5 A

penanediol

Cyclohexane 110-82-7 A Butoxypropanol 5131-66-8 A

Methyl ethyl ketone Butoxy propoxy

78-93-3 A 29911-28-2 A

(MEK) propanol

Methyl isobutyl

108-10-1 A Ethanediol 107-21-1 A

ketone (MiBK)

Hexanol 111-27-3 A Diethylene glycol 111-46-6 A

2-Ethyl-1-hexanol 104-76-7 A Triethylene glycol 112-27-6 A

Butyl glycol acetate /

n-octanol 111-87-5 A Ethyleneglycol butyl 112-07-2 A

ether acetate

1-methoxy-2-

propylacetate / 2-

Butyl glycol 111-76-2 A 108-65-6 A

propanol, 1-methoxy-,

acetate

Ethyl diglycol /

Diethyleneglycol ethyl 111-90-0 A Ethylbenzene 100-41-4 A

ether

Butyl diglycol 112-34-5 A 1-Pentanol 71-41-0 A

* Minimize means to use the minimum quantity necessary to achieve an expected technical effect.

Published: Previous version:

October 2018 September 2016

Page 7 of 7

LINKS TO SWISS INK ORDINANCE

ANNEX 6, RS817.023.21

https://www.blv.admin.ch/dam/blv/en/dokumente/gebrauchsgegenstaende/rechts-und-

vollzugsgrundlagen/anhang-6-sr-

bedarfsgegenstaende.pdf.download.pdf/130401%20Annex%206_en.pdf (in English)

ANNEX 10:

https://www.blv.admin.ch/dam/blv/en/dokumente/lebensmittel-und-ernaehrung/rechts-und-

vollzugsgrundlagen/lebensmittelrecht2017/anhang10-verordnung-materialien-kontakt-lm-

gg.pdf.download.pdf/Annex-10-ordinance-fdha-materials-and-articles-intended-to-come-into-

contact-with-food-stuffs.pdf (in English)

HOW WERE COMPONENTS IN THE TABLES SELECTED?

Components excluded from or minimized in food packaging inks because of:

• potential or adverse toxicity

• perceived risk by consumers, media, NGO, etc.

• demonstrated migration potential

• negative sensory impact on the packed food or in points of sale

CONTACT INFORMATION

Stephen Klump

Head of Global FCM-Safety & Compliance

Nestlé Research – FCM Department

809 Colins Avenue

Marysville Ohio USA

Phone: +1 937 645 21 37

e-mail: stephen.klump@rd.nestle.com

Published: Previous version:

October 2018 September 2016

Potrebbero piacerti anche

- The Identification of Vat Dyes on Cellulosic MaterialsDa EverandThe Identification of Vat Dyes on Cellulosic MaterialsNessuna valutazione finora

- Industrial Inorganic PigmentsDa EverandIndustrial Inorganic PigmentsGunter BuxbaumValutazione: 5 su 5 stelle5/5 (1)

- Nestle Guidance Note On Packaging Inks VersionDocumento5 pagineNestle Guidance Note On Packaging Inks VersionRizky DwinantoNessuna valutazione finora

- Boya, Vernik, Cila Katkı MaddeleriDocumento27 pagineBoya, Vernik, Cila Katkı MaddeleriYusuf ErtürkNessuna valutazione finora

- Exclusion List EuPIADocumento4 pagineExclusion List EuPIAsz01Nessuna valutazione finora

- ZDHC MRSLDocumento21 pagineZDHC MRSLSarker Choton100% (1)

- Free or Total Chlorine Test Kit: CN-66 (223101), CN-66F (223102) and CN-66T (223103)Documento3 pagineFree or Total Chlorine Test Kit: CN-66 (223101), CN-66F (223102) and CN-66T (223103)Edward MendezNessuna valutazione finora

- Mapping of Stain RemoversDocumento75 pagineMapping of Stain RemoversMohammad MariasaNessuna valutazione finora

- Clariant Brochure Colorants For The Coloration of Consumer Goods 201312 enDocumento84 pagineClariant Brochure Colorants For The Coloration of Consumer Goods 201312 enEudy CardozoNessuna valutazione finora

- Sds Derwent Academy Acrylic PaintsDocumento5 pagineSds Derwent Academy Acrylic PaintsTania NuñezNessuna valutazione finora

- Niir Complete Technology Book On Dyes Dye IntermediatesDocumento9 pagineNiir Complete Technology Book On Dyes Dye IntermediatesAmit Kanani100% (1)

- Ich Topic q3c (r5)Documento26 pagineIch Topic q3c (r5)lenanazarova1969Nessuna valutazione finora

- CRM - 69-December2021 PH in TobaccoDocumento7 pagineCRM - 69-December2021 PH in Tobaccofajar lestaryNessuna valutazione finora

- Colorants and Auxiliaries-Vol-2Documento455 pagineColorants and Auxiliaries-Vol-2ibayraktar775208Nessuna valutazione finora

- 901 10 Utrecht Acrylic Artists' Colors SDS 2017 03 08Documento10 pagine901 10 Utrecht Acrylic Artists' Colors SDS 2017 03 08Gordon FUNGNessuna valutazione finora

- Notice No 6 Rev 2008Documento14 pagineNotice No 6 Rev 2008RohitMishraNessuna valutazione finora

- Flame Retardants: Uses in The Supply ChainDocumento3 pagineFlame Retardants: Uses in The Supply ChainEMS 4AYDNessuna valutazione finora

- David Howard (UK) Ltd. - Safety Policy - PART2 Restricted & Banned Substances (Updated 10.01.2014)Documento17 pagineDavid Howard (UK) Ltd. - Safety Policy - PART2 Restricted & Banned Substances (Updated 10.01.2014)Faruque UddinNessuna valutazione finora

- Forms WCPDG Residual SolventDocumento53 pagineForms WCPDG Residual SolventJoe Luis Villa MedinaNessuna valutazione finora

- German Legislation On Azo DyesDocumento16 pagineGerman Legislation On Azo Dyesscribd_user2010Nessuna valutazione finora

- Textile Prods BookaaaaDocumento24 pagineTextile Prods BookaaaakamalkantmbbsNessuna valutazione finora

- Organic PigmentDocumento23 pagineOrganic Pigmentgalati12345Nessuna valutazione finora

- Residual SolventsDocumento23 pagineResidual SolventsakramuddaulaNessuna valutazione finora

- Colorants For Food ToysDocumento104 pagineColorants For Food ToysKonstantin Cherepanov100% (1)

- ResorcinolDocumento26 pagineResorcinolJoséNessuna valutazione finora

- Atlas Copco Group Prohibited ListDocumento12 pagineAtlas Copco Group Prohibited ListjhonyalfNessuna valutazione finora

- C&A Chemical ManualDocumento61 pagineC&A Chemical ManualFazle Riaz KhanNessuna valutazione finora

- CandA RSL and MRSL March 2019 Interim Update 29 10 2019Documento61 pagineCandA RSL and MRSL March 2019 Interim Update 29 10 2019AKHIL SHARMANessuna valutazione finora

- Hempel SilviumDocumento5 pagineHempel SilviumJennylyn DañoNessuna valutazione finora

- Patagonia RSL Manual 2020 FebDocumento52 paginePatagonia RSL Manual 2020 Febphan khánh đường100% (1)

- 1453183734FSC P5 M18 E-TextDocumento9 pagine1453183734FSC P5 M18 E-Textshafana fatimaNessuna valutazione finora

- Cosmetic Sampling MethodsDocumento11 pagineCosmetic Sampling MethodssilentluciditysfNessuna valutazione finora

- Analytical Notice Lovi 04 16 GBDocumento2 pagineAnalytical Notice Lovi 04 16 GBJocilene Dantas Torres NascimentoNessuna valutazione finora

- Manufacturing Restricted Substances List (MRSL)Documento21 pagineManufacturing Restricted Substances List (MRSL)Sajjad AhmedNessuna valutazione finora

- GUID - 8 en-USDocumento23 pagineGUID - 8 en-USHammam HafidzurahmanNessuna valutazione finora

- Chronicle Jan09Documento28 pagineChronicle Jan09rauftextileNessuna valutazione finora

- Clariant Brochure Sales Range Printing Ink Paints Plastics Industries 201503 ENDocumento100 pagineClariant Brochure Sales Range Printing Ink Paints Plastics Industries 201503 ENJari Rene BrazNessuna valutazione finora

- 5600 - OrganofosforadosDocumento22 pagine5600 - OrganofosforadosDanilo CostaNessuna valutazione finora

- SCCP o 120Documento23 pagineSCCP o 120fauzNessuna valutazione finora

- Solv Residuales en FarmacosDocumento12 pagineSolv Residuales en FarmacoslizlescNessuna valutazione finora

- Bestseller Restricted Substances List 2018Documento22 pagineBestseller Restricted Substances List 2018Maksud Ahmed ShajibNessuna valutazione finora

- PH Adjustment in Pharmaceutical Production: InfopointDocumento2 paginePH Adjustment in Pharmaceutical Production: Infopointmaikel marten-borisNessuna valutazione finora

- IP 346 (Report by Institute of Petroleum)Documento24 pagineIP 346 (Report by Institute of Petroleum)Hida Al-FithriNessuna valutazione finora

- BFR IX Colorants For Plastics and Other Polymers Used in CommoditiesDocumento2 pagineBFR IX Colorants For Plastics and Other Polymers Used in CommoditiesRoshni PattanayakNessuna valutazione finora

- IKEA Restricted Substance ListDocumento21 pagineIKEA Restricted Substance ListPedro RYNessuna valutazione finora

- Studies Towards The Substitution of Ortho-Phthalates in PlastisolsDocumento18 pagineStudies Towards The Substitution of Ortho-Phthalates in PlastisolsEMS 4AYDNessuna valutazione finora

- Permatex Anti Seize LubricantDocumento9 paginePermatex Anti Seize LubricantPubcrawlNessuna valutazione finora

- GB 4806.6-2016 National Food Safety Standard - Food Contact Plastic Resi...Documento20 pagineGB 4806.6-2016 National Food Safety Standard - Food Contact Plastic Resi...Nguyễn Tiến Dũng100% (2)

- Annex 10 Ordinance Fdha Materials and Articles Intended To Come Into Contact With Food StuffsDocumento202 pagineAnnex 10 Ordinance Fdha Materials and Articles Intended To Come Into Contact With Food Stuffsjai soniNessuna valutazione finora

- Ag25 SpectraDocumento2 pagineAg25 SpectraDHRUVNessuna valutazione finora

- Attachment 0Documento10 pagineAttachment 0Buyung MaulanaNessuna valutazione finora

- Risk Assessment Paper Food Contact StarchesDocumento16 pagineRisk Assessment Paper Food Contact Starchesbernard6812Nessuna valutazione finora

- Polymer Additive Reference StandardsDocumento36 paginePolymer Additive Reference Standardsvasucristal100% (1)

- 09 - Carbon Dioxide - G71143R04Documento5 pagine09 - Carbon Dioxide - G71143R04chem.rajavithiNessuna valutazione finora

- Chlorine and PH Test Kit: Description Unit Item NoDocumento2 pagineChlorine and PH Test Kit: Description Unit Item NoDavita CaliNessuna valutazione finora

- Mono Antidandruff-Products EnglishDocumento9 pagineMono Antidandruff-Products EnglishTom DelongeNessuna valutazione finora

- F D & C Red 40 Powder: Technical Data SheetDocumento2 pagineF D & C Red 40 Powder: Technical Data SheetDHRUVNessuna valutazione finora

- GB 4806.7-2016 National Food Safety Standard - Food Contact Plastic Mat...Documento4 pagineGB 4806.7-2016 National Food Safety Standard - Food Contact Plastic Mat...Nguyễn Tiến Dũng100% (1)

- The Power of Functional Resins in Organic SynthesisDa EverandThe Power of Functional Resins in Organic SynthesisFernando AlbericioNessuna valutazione finora

- High Performance PigmentsDa EverandHigh Performance PigmentsEdwin B. FaulknerNessuna valutazione finora

- TDS SR 168Documento1 paginaTDS SR 168Boonyarit LurdgrienggraiyingNessuna valutazione finora

- Colors and Effects - PSG Pigment Preparations PolyolefinsDocumento24 pagineColors and Effects - PSG Pigment Preparations PolyolefinsBoonyarit LurdgrienggraiyingNessuna valutazione finora

- RDS Size Selection Chart WebDocumento1 paginaRDS Size Selection Chart WebBoonyarit LurdgrienggraiyingNessuna valutazione finora

- Solar Heat Management Building and Construction Plastics Value CardDocumento2 pagineSolar Heat Management Building and Construction Plastics Value CardBoonyarit LurdgrienggraiyingNessuna valutazione finora

- Input Industries Industrial DownloadDocumento6 pagineInput Industries Industrial DownloadBoonyarit LurdgrienggraiyingNessuna valutazione finora

- Mitsu Carbon BlackDocumento1 paginaMitsu Carbon BlackBoonyarit LurdgrienggraiyingNessuna valutazione finora

- Paint It Cool! Pigments For Solar Heat Management in Paints PDFDocumento12 paginePaint It Cool! Pigments For Solar Heat Management in Paints PDFBoonyarit LurdgrienggraiyingNessuna valutazione finora

- Pigment Vs DyeDocumento3 paginePigment Vs DyeBoonyarit LurdgrienggraiyingNessuna valutazione finora

- Carbon BlackDocumento15 pagineCarbon BlackBoonyarit Lurdgrienggraiying100% (1)

- Guide Formulation For Road Marking PaintDocumento1 paginaGuide Formulation For Road Marking PaintBoonyarit Lurdgrienggraiying100% (2)

- Difference Between SolventsDocumento3 pagineDifference Between SolventsBoonyarit LurdgrienggraiyingNessuna valutazione finora

- Functions of Dispersing Additives in Ink: By: Adesh Katariya Manager-R&D, Tirupati Inks LTDDocumento71 pagineFunctions of Dispersing Additives in Ink: By: Adesh Katariya Manager-R&D, Tirupati Inks LTDBoonyarit LurdgrienggraiyingNessuna valutazione finora

- Printing InksDocumento28 paginePrinting InksBoonyarit Lurdgrienggraiying100% (3)

- High Density Polyethylene HC7260LS-L: DescriptionDocumento1 paginaHigh Density Polyethylene HC7260LS-L: DescriptionJaime222Nessuna valutazione finora

- China BPA 2012Documento3 pagineChina BPA 2012Anusha RajagopalanNessuna valutazione finora

- JP Vol.16 09-13 PDFDocumento5 pagineJP Vol.16 09-13 PDFAndres J AndradeNessuna valutazione finora

- Plastic Pollution - WikipediaDocumento32 paginePlastic Pollution - WikipediaTahafanMaggedonNessuna valutazione finora

- 1957 Digest - Summer 2012Documento116 pagine1957 Digest - Summer 2012SandraDojčinovićNessuna valutazione finora

- PROJECT REPORT On Domestic Plastic pollution-DESKTOP-LDFLDU3Documento10 paginePROJECT REPORT On Domestic Plastic pollution-DESKTOP-LDFLDU3imtiaz khanNessuna valutazione finora

- Revisions To The 22nd Edition of The OMADocumento6 pagineRevisions To The 22nd Edition of The OMAravi haNessuna valutazione finora

- The Environmental Impacts of The Disposal of Plastic Bags and Water Bottles in Tigray, Northern EthiopiaDocumento15 pagineThe Environmental Impacts of The Disposal of Plastic Bags and Water Bottles in Tigray, Northern EthiopiaAbu EnsahNessuna valutazione finora

- Epocast 50a1-9816Documento22 pagineEpocast 50a1-9816NICKYNessuna valutazione finora

- Product Selection Guide: To Corrosion Resistant Vipel ResinsDocumento6 pagineProduct Selection Guide: To Corrosion Resistant Vipel ResinsChristian HinostrozaNessuna valutazione finora

- Cumene - Final Yeat Project 2019 - Final FormatingDocumento188 pagineCumene - Final Yeat Project 2019 - Final FormatingTalha IshaqNessuna valutazione finora

- Bestseller Restricted Substances List 2018Documento22 pagineBestseller Restricted Substances List 2018Maksud Ahmed ShajibNessuna valutazione finora

- Commercial Application of CumeneDocumento1 paginaCommercial Application of CumenegermaineNessuna valutazione finora

- 27 Anxiety-Busting Strategies: HealthmeansDocumento26 pagine27 Anxiety-Busting Strategies: HealthmeansLekshmi20140% (1)

- 9 Disturbing Side Effects of SodaDocumento3 pagine9 Disturbing Side Effects of SodapabloituNessuna valutazione finora

- KONES ComplaintDocumento3 pagineKONES ComplaintJustin RohrlichNessuna valutazione finora

- Hempadur Quattro Base 1763650630 En-UsDocumento12 pagineHempadur Quattro Base 1763650630 En-UsBill MillNessuna valutazione finora

- Jalal 2018Documento9 pagineJalal 2018AbeiasaNessuna valutazione finora

- (American Scientist) American Scientist Magazine (BookFi) PDFDocumento84 pagine(American Scientist) American Scientist Magazine (BookFi) PDFKarthikeya100% (1)

- History of PlasticsDocumento3 pagineHistory of PlasticsSwapnil BhatagalikarNessuna valutazione finora

- JJMLL: Translation Strategies in The English-Arabic E-Brochures of Baby Care ProductsDocumento24 pagineJJMLL: Translation Strategies in The English-Arabic E-Brochures of Baby Care ProductsRiya alwajeeNessuna valutazione finora

- Technip Energies Technology HandbookDocumento120 pagineTechnip Energies Technology HandbookLokesh Ravichandran100% (1)

- LOVE From The Heart HHI MagazineDocumento35 pagineLOVE From The Heart HHI MagazineCristina SarbuNessuna valutazione finora

- Public and Environmental HealthDocumento13 paginePublic and Environmental HealthOlohuntoyin Olamide YusufNessuna valutazione finora

- PLASTICDocumento25 paginePLASTICosho risqatNessuna valutazione finora

- Essay On Plastic PollutionDocumento16 pagineEssay On Plastic PollutionRUSHIKESH SAWANT100% (1)

- 3450 Resin MsdsDocumento6 pagine3450 Resin MsdsAhmed Emad AhmedNessuna valutazione finora

- Safe Handling and Storage of ResinsDocumento49 pagineSafe Handling and Storage of Resinsrenjith2017Nessuna valutazione finora

- Water StructuringDocumento22 pagineWater StructuringBlack Hat100% (11)

- CS - Flipcaps CS0270-01Documento23 pagineCS - Flipcaps CS0270-01Birol ErgenNessuna valutazione finora