Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FPI Marine Brochure

Caricato da

Ashraf Gomah Mohamed ElshamandyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FPI Marine Brochure

Caricato da

Ashraf Gomah Mohamed ElshamandyCopyright:

Formati disponibili

MARINE

Glassfiber Reinforced Epoxy Pipe Systems (GRE) Version 02

• Sea water bilge and ballast

water (incl. BWT systems)

• Sea water cooling lines

• Black and grey water lines

• Condensate lines

• Sounding en ventilation lines

• Tank cleaning lines

• Potable water lines

• Jet-water lines

• Gland & flushing lines

• Heeling lines

• Scrubber lines

It’s designed to last the lifetime of the ship. the design of

PRODUCTS

this economic pipe system is in full compliance with the

IMO Resolution A.753 (18) and has been type approved by

various leading classifications societies.

For Marine application Future Pipe Industries has two product series available:

Fibermar®, for in-tank applications with exposure to external pressure and

Wavistrong® for systems not exposed to external pressure.

Fibermar® and Wavistrong® are type approved in the diameters from 25mm

(1”) to 900mm (36”). When using larger diameters, special project approvals can

be obtained.

Jointing of the system is achieved by adhesive bonding, rubber sealing (either tensile

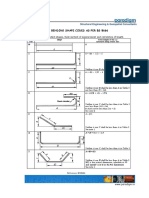

or non-tensile), lamination, flanges or by using mechanical couplings.

A complete fitting programme for adhesive joints for loose delivery is available for

pipe sizes up to 400mm. for larger diameters, fittings will be prefabricated in our

factory or by qualified installation companies.

Wavistrong® is available in various internal design pressure and suitable for systems

not exposed to vacuum. Fibermar® has been designed for internal design pressures

of 10 and 16 bar and external pressure to 10, 20, 30, 40 and 50 meters water column

and full vacuum.

When piping crosses hazardous areas, static build-up needs to be avoided. in this

Glassfiber Reinforced Epoxy (GRE) Pipe Systems case Wavistrong® and Fibermar® in the electrical conductive series should

be used. Possible accumulated charges will be drained via grounding saddles

Onboard Ships connected to the ship’s structure or by flanges connected to the bulkheads

The marine environment is one of the most corrosive environments. Dry

docking for maintenance is costly matter for shipping companies.

Replacement of corroded steel pipe is a common thing with every dry docking. Why does the

industry accept corroded steel any longer?

Glassfiber reinforced Epoxy (GRE) pipe systems are the sole solution against corrosion. Exhibiting

excellent corrosion resistance against seawater, various solvents and chemicals, together

with a low weight and favorable cost compared to steel alloys it’s the material of choice for

onboard ships.

It’s designed to last the lifetime of the ship. the design of this economic pipe system is in full

compliance with the IMO Resolution A.753 (18) and has been type approved by various leading

classifications societies.

MARINE Glassfiber Reinforced Epoxy Pipe Systems (GRE) Page 2 of 10

Applications Both Fibermar® and

Prefabrication

Wavistrong® pipe systems can

Summary of main applications: be supplied as prefabricated

spools.

• Sea water bilge and ballast water

(incl. BWT systems)

These pipe sections are tailor-made to

• Black & Grey water lines

customer’s requirements and have the

• Condensate lines

additional benefits of easier and quicker

• Sounding en ventilation lines

• Tank cleaning lines installation. When standard fittings can not

• Potable water lines be used, tailor-made fittings can be designed

• Jet-water lines and manufactured to meet the specific

• Gland & flushing lines requirements. Prefabrication can be carried out

• Heeling lines in our factory, at the shipyard’s location or in a

• Scrubber lines workshop by one of our preferred and qualified

• Sea water cooling contractors worldwide.

FIRE ENDURANCE Project SERVICES

Fibermar® and Wavistrong® can To ensure successful design, delivery and

be applied onboard ships as per IMO installation, Future pipe Industries offers the

Resolution A.753 (18) fire endurance matrix following services:

(See page 8 of this brochure) and meet

the following standards: • Project Management

• Assistance in system design:

• FTP code for Fire Test Procedures - Pipe support detailing

• Fire Endurance L3 according to IMO Resolution - Stress analysis

A.753 (18)

- Surge analysis

• Flame spread according to ASTM D635

- Isometrics and spool drawings

• Flame spread according to IMO Resolution A.653 (16)

- Material take-off

• Smoke and Toxicity test undertaken by QinetiQ

- Design of special items

- Onboard survey

- Installation training

- Supervision during installation

MARINE Glassfiber Reinforced Epoxy Pipe Systems (GRE) Page 4 of 10

Retrofits

SCRUBBER UNITS

During the lifetime of the ship, the corroded steel pipes

need to be replaced 2 or 3 times. This is costly and

undesirable.

Fibermar® and Wavistrong® are the ideal replacements for conventional steel

pipe systems. GRE’s non corrosive characteristics, easy jointing methods and

lightweight ensure this. it is simply just “Fit & Forget”.

Our International network of preferred and qualified contractors is able to

provide retrofit services worldwide. The International Maritime Organization (IMO) and US Coast

Guard (USCG) put together in place a legislation for the

cleaning of exhaust gases of ships. many ships need to be

equipped with scrubber units to ensure cleaner air and a

greener future.

The non-corrosive and light-weight properties of GRE have made it the material of choice

for the connecting piping for many suppliers of scrubber equipment and shipowners.

Besides the standard GRE piping, Future Pipe Industries designs and manufactures also

special items in GRE like tailor made drain pots, strainers, etc

BALLAST WATER TREATMENT

International Maritime Organization

(IMO) adopted the International

Convention for the control and

management of ships’ Ballast

Water and Sediments (BWMC),

which address the transportation

of potentially harmful organism

through ballast water.

Therefore many ships’ need to be equipped

with Ballast Water Treatment units. Also for this

corrosive application GRE is the right solution for

the connecting pipe systems.

MARINE Glassfiber Reinforced Epoxy Pipe Systems (GRE) Page 6 of 10

Pipe system locations in accordance with the fire endurance matrix according to IMO A. 753 (18) regulations

Naval SHIPS

Other machinery

Cofferdams, void

Accommodation,

Other dry cargo

tunnel & ducts

control spaces

Fuel oil tanks

Cargo pump

Ballast water

spaces, pipe

Open decks

Pump rooms

Cargo tanks

Ro-ro cargo

category A.

spaces and

Machinery

service and

PIPING SYSTEM

spaces of

Rigorously and successfully tested

rooms

holds

holds

tanks

for use onboard naval vessels, GRE not applicable GRE from FPI allowed GRE not allowed

both Wavistrong & Fibermar Cargo (flammable cargoes f.p. < 60°C

are suited to many applications Cargo lines 9

Crude oil washing lines 9

onboard both future and current Vent lines 9

generations of warships and Inert gas

submarines in service throughout Water seal effluent lines 1 1 1 1

the world. Besides the already Scrubber effluent lines 1 1 1 1

highlighted material, advantages

Main lines

Distribution lines

of GRE has proven to be noise Flammable liquids (f.p. > 60°C)

reducing. Cargo lines 3 9

Fuel oil 3

Specially for Naval applications, our products

Lubricating

have been tested and approved to:

Hydraulic oil

• Shock test

Seawater

• Smoke and Toxicity

• safety Case compliant with UK MoD DEFSTAN Bilge main and branches

00-56 & JSP430 FIre main and water spray

Foam system

Sprinkler system

Ballast

Besides the applications as per the IMO Matrix,

Cooling water, essential services

DREDGING

Tank cleaning services fixed machines 3 2

Wavistrong ® is the right solution for jet-water, Non essential systems

gland and flushing systems on-board dredgers. Fresh water

Cooling water, essential services

Wavistrong has been widely applied on-board new dredgers,

®

Condensate return

contributing to more durability. Another advantages of GRE on-board Non essential systems

dredgers is the weight saving, allowing for more dredge materials Sanitary/Drains/Scuppers

on-board. A special product developed by Future Pipe Industries for the Deck drains (internal) 4 4 4

dredging industry is the fall-pipe” for sub-sea rock installation in deep Sanitary drains (internal)

waters. the special Wavistrong® fall-pipes offer an enormous weight Scuppers and dischargers (overboard) 1 7 1 7 1 7 1 7 1 7 1 7

saving making operation on deeper sea-bottoms possible. Sounding/Air

Water tanks/dry spaces 9

Oil tanks (f.p. > 60°C) 9 9

Miscellaneous

Control air 5 5 5 5 5 5 5

Service air (non essential)

Brine

Auxiliary low pressure steam (7 bar) 8 8 8 8 8

Notes

1. Where non-metallic piping is used, remotely controlled 7. Scuppers serving open decks in positions 1 and

valves to be proved at ship’s side (valve is to be 2, as defined in regulation 13 of the International

controlled from outside space) Convention on Load Lines 1966, should be

2. Remote closing vales to be provided at the cargo tanks throughout unless fitted at the upper end with the

3. When cargo tanks contain flammable liquids with f.p. > means of closing capable of being operated from a

60°C may replace or position above the freeboard deck in order to prevent

4. For drains serving only the space concerned down flooding

my replace 8. For essential services such as fuel oil tank heating and

5. When controlling functions are not required by ship’s whistle is to replace

statutory requirements or guidelines 9. For tankers where compliance with paragraph 3(f) of

MARINE Glassfiber Reinforced Epoxy Pipe Systems (GRE)

may replace

6. For pipe between machinery space and deck water

seal may replace

regulations 13F of Annex 1 of MARPOL 73/78 is required

is to replace Page 8 of 10

Cost SAVINGS Wavistrong ® & Fibermar ®

AT THE GLANCE

Fibermar ® and Wavistrong ®

have proven to be cost • Long service life because of the non corrosive characteristics.

• Low installation costs due to the light-weight

effective solutions for many • Weight saving allows for more cargo on-board and reduce fuel consumption

applications on-board ships. • Easy to repair

Although the GRE material cost might be higher Summarizing, using GRE on-board is resulting in Lower Life Cycle Costs

than steel materials, the total installed costs are

mostly lower due to reduced fabrication and

installation time. Besides this, GRE contributes

to the lower total life cycle costs, because of

no maintenance during the life time of the

ship. Actually, the bigger the pipe size, the

bigger the cost savings. The low weight is further

contributing to a reduced fuel consumption

thus reducing the overall operational cost.

Type Approvals &

Other Certifications

FPI is committed to ISO 9001:2015 and ISO 14001-2015 to ensure

highest standards of quality and environment management.

Fibermar® and Wavistrong® are type approved by the major Classification Societies as:

• D.N.V./GL

• L.R.

• A.B.S.

• B.V.

• RINA

• R.M.R.S

• U.S.C.G.

MARINE Glassfiber Reinforced Epoxy Pipe Systems (GRE) Page 10 of 10

Potrebbero piacerti anche

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- Glassfiber Reinforced Epoxy Pipe Systems (GRE)Documento12 pagineGlassfiber Reinforced Epoxy Pipe Systems (GRE)Sivaram SivaNessuna valutazione finora

- Bondstrand Glassfiber Reinforced Epoxy Piping Systems For Offshore Applications BrochureDocumento8 pagineBondstrand Glassfiber Reinforced Epoxy Piping Systems For Offshore Applications BrochureLuis GuillermoNessuna valutazione finora

- Pipe ManualDocumento17 paginePipe Manualnaseer lateeNessuna valutazione finora

- GRP Pipe Systems: For Water, Sewage and Industrial ApplicationsDocumento6 pagineGRP Pipe Systems: For Water, Sewage and Industrial ApplicationsMuhammad Hussain BilalNessuna valutazione finora

- Crystic-Chemical Resistance Guide Page - 4Documento1 paginaCrystic-Chemical Resistance Guide Page - 4KiranNessuna valutazione finora

- Mar Download 5Documento6 pagineMar Download 5MeirinaDiahPuspitaIINessuna valutazione finora

- Bondstrand GRPDocumento6 pagineBondstrand GRPChokchai JitmonmanaNessuna valutazione finora

- ORI Catalogue - PipeDocumento18 pagineORI Catalogue - PipeMuhammad Aidil FitrahNessuna valutazione finora

- Perma Bond BrochureDocumento4 paginePerma Bond BrochureAmro Metwally El HendawyNessuna valutazione finora

- Conpipe Company BrochurefDocumento16 pagineConpipe Company BrochurefDURGAPRASAD JANYAVULANessuna valutazione finora

- Product Overview For Structural Waterproofing 2021 - ScreenDocumento68 pagineProduct Overview For Structural Waterproofing 2021 - ScreenterateoNessuna valutazione finora

- Aquagrip VJ Bro Issue-6 0320 EngDocumento11 pagineAquagrip VJ Bro Issue-6 0320 EngENTREGA RUBIALESNessuna valutazione finora

- Brands You Trust.: Industrial Diaphragm ValvesDocumento20 pagineBrands You Trust.: Industrial Diaphragm ValvesShayan Hasan KhanNessuna valutazione finora

- PE Aquagrip VJ BroDocumento9 paginePE Aquagrip VJ Brojorge71Nessuna valutazione finora

- 12 Column Pipe For Submersible PumpsDocumento4 pagine12 Column Pipe For Submersible PumpsEmac AutomationNessuna valutazione finora

- PDF Version!: GRP Pipe SystemsDocumento6 paginePDF Version!: GRP Pipe Systemstruss85Nessuna valutazione finora

- Kwc-Citadel Info English PDFDocumento48 pagineKwc-Citadel Info English PDFRiankwnNessuna valutazione finora

- GRP Pipes Fittings CatalogDocumento8 pagineGRP Pipes Fittings CatalogFaseen ibnu Ameer Ahasen0% (1)

- Industrial Hoses BrochureDocumento7 pagineIndustrial Hoses BrochureDaniel MarNessuna valutazione finora

- DEMISTERDocumento6 pagineDEMISTERNguyen ChuyenNessuna valutazione finora

- AVK Service Connection System BrochureDocumento20 pagineAVK Service Connection System BrochureAhlan kpNessuna valutazione finora

- Escaleras MarinasDocumento12 pagineEscaleras MarinasEduardo ArrietaNessuna valutazione finora

- Barriers of Protections BrochureDocumento8 pagineBarriers of Protections BrochureJaime Rousseau TNessuna valutazione finora

- PARKER Legris Tubing 2Documento8 paginePARKER Legris Tubing 2Rocio GremyosNessuna valutazione finora

- Osma Osmadrain BG Pim Od107 Feb 2017pdfDocumento58 pagineOsma Osmadrain BG Pim Od107 Feb 2017pdfDeepakkumarNessuna valutazione finora

- PP Pipe - TDSDocumento40 paginePP Pipe - TDSHue Trang Nguyen ThiNessuna valutazione finora

- CRANEChemPharmaIntro To Chlor-Alkali3Documento18 pagineCRANEChemPharmaIntro To Chlor-Alkali3Yamil Diaz SantosNessuna valutazione finora

- Gas and water drainageDocumento1 paginaGas and water drainageRolando CostaNessuna valutazione finora

- Valve Solutions For Drilling BRDocumento8 pagineValve Solutions For Drilling BRshamekhalmaamariNessuna valutazione finora

- SARAMET Austenitic Stainless SteelDocumento2 pagineSARAMET Austenitic Stainless Steelgabriel_127971761Nessuna valutazione finora

- Astral PVC SWR Pipes CatalogueDocumento15 pagineAstral PVC SWR Pipes CatalogueMALAY MRIDHANessuna valutazione finora

- Nilex Fabriform BrochureDocumento4 pagineNilex Fabriform BrochureApurba haldarNessuna valutazione finora

- No Dig, No Doubt: GRP Jacking Pipes: Trenchless Installation With Customized System SolutionsDocumento16 pagineNo Dig, No Doubt: GRP Jacking Pipes: Trenchless Installation With Customized System SolutionsHuy ChungNessuna valutazione finora

- DrainLining Product Info en 3-2-2020Documento9 pagineDrainLining Product Info en 3-2-2020MR seaNessuna valutazione finora

- Corrosion Resistant Fiberglass Piping Systems BrochureDocumento6 pagineCorrosion Resistant Fiberglass Piping Systems BrochureDavid MayNessuna valutazione finora

- MasterBrace LAM - Updated.1 2Documento2 pagineMasterBrace LAM - Updated.1 2Obrobb 92Nessuna valutazione finora

- Parker Hose Technical Handbook PDFDocumento63 pagineParker Hose Technical Handbook PDFAnonymous HvDSpkgV100% (1)

- Wellbore Integrity Restoration Services Brochure PDFDocumento8 pagineWellbore Integrity Restoration Services Brochure PDFDavid LuhetoNessuna valutazione finora

- VIKING JOHNSON - MaxiFit, MaxiStep y MaxiAdaptadoresDocumento19 pagineVIKING JOHNSON - MaxiFit, MaxiStep y MaxiAdaptadoresop.im.bkp.1Nessuna valutazione finora

- Catalog Fabricante TechnipDocumento9 pagineCatalog Fabricante Technipjimy GutiérrezNessuna valutazione finora

- MYK - Arment-Product-CatalystDocumento92 pagineMYK - Arment-Product-CatalystG.RameshNessuna valutazione finora

- Water Wastewater Treatment Application SheetDocumento2 pagineWater Wastewater Treatment Application SheetJULIONessuna valutazione finora

- HTTP WWW - FibrexDocumento6 pagineHTTP WWW - FibrexVinod Varadan SNessuna valutazione finora

- Master Catalog-AeroquipDocumento388 pagineMaster Catalog-AeroquipCOM GRAVENessuna valutazione finora

- Fiberglass Pipes For OilDocumento6 pagineFiberglass Pipes For Oilvuqar0979Nessuna valutazione finora

- Aeroquip - A-HOOV-MC001-E1 - Overview - LRDocumento6 pagineAeroquip - A-HOOV-MC001-E1 - Overview - LRMarcelo MalagoNessuna valutazione finora

- Serving The World in Pneumatic and Vacuum Conveying ProductsDocumento8 pagineServing The World in Pneumatic and Vacuum Conveying ProductsoganuluNessuna valutazione finora

- Demister (Vapor)Documento6 pagineDemister (Vapor)Nguyen ChuyenNessuna valutazione finora

- Brochure Waterstop - Reprint - WEB - LowDocumento52 pagineBrochure Waterstop - Reprint - WEB - LowIbrahim KhanNessuna valutazione finora

- Preprufe 300R & 160R PDFDocumento6 paginePreprufe 300R & 160R PDForlandomcortezNessuna valutazione finora

- GRP Pipes & Fitting SDocumento57 pagineGRP Pipes & Fitting Stahor jaborNessuna valutazione finora

- All Product Eng RevDocumento24 pagineAll Product Eng RevZuzer FakhriNessuna valutazione finora

- Dresser Water Steel ProductsDocumento24 pagineDresser Water Steel Productsclaimc100% (1)

- Sclairpipe: Versatile High Density Hdpe PipeDocumento10 pagineSclairpipe: Versatile High Density Hdpe PipeMOSHITOMOSHITANessuna valutazione finora

- FRP GratingDocumento20 pagineFRP Gratingmike maxwellNessuna valutazione finora

- Sliding Disc Valve CatalogDocumento13 pagineSliding Disc Valve Catalogsumanta_2008dredifmaNessuna valutazione finora

- Pvcbasicline: PVC System For SewersDocumento12 paginePvcbasicline: PVC System For SewersDo BuiNessuna valutazione finora

- Geotextiles and Geomembranes HandbookDa EverandGeotextiles and Geomembranes HandbookT.S. IngoldValutazione: 5 su 5 stelle5/5 (1)

- Abs Submersible Sewage Pump XFP 80C - 151e (GB)Documento2 pagineAbs Submersible Sewage Pump XFP 80C - 151e (GB)Ashraf Gomah Mohamed ElshamandyNessuna valutazione finora

- 9 Fully Welded Splice 9.1 Description of ConnectionDocumento7 pagine9 Fully Welded Splice 9.1 Description of ConnectionAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- EPM-DEM 2.0: Safety InstructionsDocumento1 paginaEPM-DEM 2.0: Safety InstructionsAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Optimize submersible sewage pump XFP 100J-501U titleDocumento2 pagineOptimize submersible sewage pump XFP 100J-501U titleAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Novo BPTDocumento11 pagineNovo BPTAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Mat Foundations Using STAADDocumento5 pagineMat Foundations Using STAADSha Mas ShaNessuna valutazione finora

- 2014-2015 3rd Year Civil - Seepage Analysis in SoilsDocumento30 pagine2014-2015 3rd Year Civil - Seepage Analysis in SoilsAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Group Presentation 2008 (GB)Documento23 pagineGroup Presentation 2008 (GB)Ashraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Manufacturing Units: We Know How Water WorksDocumento12 pagineManufacturing Units: We Know How Water WorksAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Hyperstatic Effects PDFDocumento13 pagineHyperstatic Effects PDFAnonymous 0tT3SeNessuna valutazione finora

- CDS-101 C-001 Architectural Room Programme March 2015Documento6 pagineCDS-101 C-001 Architectural Room Programme March 2015naveen_86Nessuna valutazione finora

- Tank Foundation New IdeaDocumento9 pagineTank Foundation New IdeaAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Norsok L-004 Piping Fabrication 2010 PDFDocumento30 pagineNorsok L-004 Piping Fabrication 2010 PDFarifin rizal100% (1)

- Piping Design Layout and Stress AnalysisDocumento19 paginePiping Design Layout and Stress AnalysisSolomon EmavwodiaNessuna valutazione finora

- Tapered Beam and Column Elements in Unbraced Framed StructuresDocumento15 pagineTapered Beam and Column Elements in Unbraced Framed StructuresAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- General Method For Determining Bearing Capacity of Domes With Radial Girders and Circular Elements On Circular Base, With Different Stiffening - 2016Documento7 pagineGeneral Method For Determining Bearing Capacity of Domes With Radial Girders and Circular Elements On Circular Base, With Different Stiffening - 2016Ashraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Seismic Isolation in South AmericaDocumento8 pagineSeismic Isolation in South AmericaAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- DIS 3D Isolation Systems PDFDocumento1 paginaDIS 3D Isolation Systems PDFAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- D9. Pisos AisladoresDocumento1 paginaD9. Pisos AisladoresJ RCNessuna valutazione finora

- Comparative Study of Seismic Analysis of Existing Elevated Reinforced Concrete Intze Water Tank Supported On Frame StagingDocumento12 pagineComparative Study of Seismic Analysis of Existing Elevated Reinforced Concrete Intze Water Tank Supported On Frame Stagingmailmaverick8167Nessuna valutazione finora

- BS-EN1992-1-1 - E - 2014 What Is NewDocumento1 paginaBS-EN1992-1-1 - E - 2014 What Is NewAshraf Gomah Mohamed Elshamandy0% (1)

- D9. Pisos AisladoresDocumento1 paginaD9. Pisos AisladoresJ RCNessuna valutazione finora

- Comparison For Steel TanksDocumento19 pagineComparison For Steel TanksAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Comparison Between Standards For Seismic Design of Liquid Storage Tanks With Respect To Soil-Foundation-Structure Interaction and Uplift 2012 PDFDocumento7 pagineComparison Between Standards For Seismic Design of Liquid Storage Tanks With Respect To Soil-Foundation-Structure Interaction and Uplift 2012 PDFAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- InstallGuide 4.5Documento4 pagineInstallGuide 4.5Ashraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Mpact of 2015 Earthquakes On A Local Hospital in NepalDocumento16 pagineMpact of 2015 Earthquakes On A Local Hospital in NepalAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Service Life Assessment of Concrete Structures in The GCC CountriesDocumento41 pagineService Life Assessment of Concrete Structures in The GCC CountriesAshraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Bar Bending Shape Codes per British Standard BS 8666Documento7 pagineBar Bending Shape Codes per British Standard BS 8666Ashraf Gomah Mohamed ElshamandyNessuna valutazione finora

- 3bar Shapes As Per BS8666Documento9 pagine3bar Shapes As Per BS8666Ashraf Gomah Mohamed ElshamandyNessuna valutazione finora

- Ceilcote 180 Flakeline+ds+engDocumento4 pagineCeilcote 180 Flakeline+ds+englivefreakNessuna valutazione finora

- The Wafflemat™ Foundation Forming System: On-Grade Mat Foundation For Expansive, Collapsible and Rocky SoilsDocumento25 pagineThe Wafflemat™ Foundation Forming System: On-Grade Mat Foundation For Expansive, Collapsible and Rocky Soilshumbert14000100% (1)

- FEA Tutorials NL4Documento29 pagineFEA Tutorials NL4Tran Tien Dung100% (1)

- PETRONAS Distributor Price List - W.E.F 10-10-23Documento2 paginePETRONAS Distributor Price List - W.E.F 10-10-23Mujeeb SiddiqueNessuna valutazione finora

- ASTM E 165 - 2012 (Standard Practice For Liquid Penetrant Examination For General Industry) - 2012Documento18 pagineASTM E 165 - 2012 (Standard Practice For Liquid Penetrant Examination For General Industry) - 2012omar quiñonesNessuna valutazione finora

- @unacademyplusdiscounts Arihant BITSAT Prep Guide 2020Documento1.367 pagine@unacademyplusdiscounts Arihant BITSAT Prep Guide 2020Ritviz AggarwalNessuna valutazione finora

- Groove Boards by Jaali in PDFDocumento44 pagineGroove Boards by Jaali in PDFGunjan ShahNessuna valutazione finora

- NC-559-ASM Rev 0510Documento2 pagineNC-559-ASM Rev 0510electrosysro8560Nessuna valutazione finora

- DR. BABASAHEB AMBEDKAR TECHNOLOGICAL UNIVERSITY MID SEMESTER EXAMDocumento2 pagineDR. BABASAHEB AMBEDKAR TECHNOLOGICAL UNIVERSITY MID SEMESTER EXAMdhiraj patilNessuna valutazione finora

- Metallurgical Failure AnalysisDocumento182 pagineMetallurgical Failure AnalysisJuan AsarcadoNessuna valutazione finora

- 1 Laboratory Procedures RPDDocumento30 pagine1 Laboratory Procedures RPDJASPREETKAUR0410100% (4)

- Allied Dyna-Flow PipeDocumento1 paginaAllied Dyna-Flow PipeMendoza Martinez GustaNessuna valutazione finora

- HVOF Processed CoCrFeMnNiDocumento11 pagineHVOF Processed CoCrFeMnNiRafael RiveraNessuna valutazione finora

- ABRIVATIONSDocumento14 pagineABRIVATIONSRoshan de SilvaNessuna valutazione finora

- Customer Price List: Certified Code Compliant Steel Stud Manufacturer Manufacturer of Supreme Framing SystemsDocumento5 pagineCustomer Price List: Certified Code Compliant Steel Stud Manufacturer Manufacturer of Supreme Framing SystemsRamonNessuna valutazione finora

- Feasibility Study of Hydrogen Chloride ProductionDocumento4 pagineFeasibility Study of Hydrogen Chloride ProductionIntratec SolutionsNessuna valutazione finora

- Cotton ListDocumento22 pagineCotton ListL.N.CHEMICAL INDUSTRYNessuna valutazione finora

- Performance Materials: Polyurethane SystemsDocumento51 paginePerformance Materials: Polyurethane SystemscaioltbgNessuna valutazione finora

- 5 SLS RequiermentsDocumento13 pagine5 SLS RequiermentssuniljayaNessuna valutazione finora

- Characterization of Municipal Solid Waste in Yenagoa Metropolis and Its Associated Management Problems, NigeriaDocumento9 pagineCharacterization of Municipal Solid Waste in Yenagoa Metropolis and Its Associated Management Problems, NigeriaIJRASETPublicationsNessuna valutazione finora

- Naclar Natural: Surface DisinfectantDocumento4 pagineNaclar Natural: Surface DisinfectantMarkus PerrevoortNessuna valutazione finora

- Sandwitched Fly Ash PanelDocumento33 pagineSandwitched Fly Ash PanelEdeeksha Shekhawat100% (1)

- Marine Bilge Water Treatment SystemDocumento11 pagineMarine Bilge Water Treatment Systemrobjsimon100% (3)

- Acetic-Acid MOCDocumento2 pagineAcetic-Acid MOCtopivNessuna valutazione finora

- P Block Elements DPP 07 Extra DPP Yakeen 20 2023 PW StarDocumento3 pagineP Block Elements DPP 07 Extra DPP Yakeen 20 2023 PW StarAgnibha MaitiNessuna valutazione finora

- Effects of Heat Treatments On Steels For Bearing ApplicationsDocumento7 pagineEffects of Heat Treatments On Steels For Bearing ApplicationsAshwani KansaraNessuna valutazione finora

- Data Sheet Schott® Borofloat: Chemical PropertiesDocumento2 pagineData Sheet Schott® Borofloat: Chemical PropertiesDiego SaenzNessuna valutazione finora

- All Cable Lugs and Connectors CatalogDocumento28 pagineAll Cable Lugs and Connectors CatalogTaufiq HidayatNessuna valutazione finora

- MINIMUM TESTING REQUIREMENTS FOR CONSTRUCTION PROJECTSDocumento17 pagineMINIMUM TESTING REQUIREMENTS FOR CONSTRUCTION PROJECTSAris TesoroNessuna valutazione finora

- The Essential Ingredients in A PVC Formulation AreDocumento7 pagineThe Essential Ingredients in A PVC Formulation AreRicky DavisNessuna valutazione finora