Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SE-400 Expansion Joint FOR KUHMARKHERA ROAD KHALWA DIST. KHANDWA, M.P

Caricato da

Ismail ShekhTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SE-400 Expansion Joint FOR KUHMARKHERA ROAD KHALWA DIST. KHANDWA, M.P

Caricato da

Ismail ShekhCopyright:

Formati disponibili

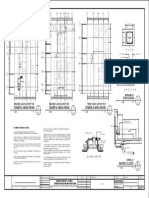

MATERIAL SPECIFICATION :

IN GENERAL, THE SPECIFICATIONS FOR MATERIALS, FABRICATION,

HANDLING, STORAGE, INSTALLATION, TEST AND STANDARDS SHALL

BE AS PER THE IRC SP - 69 (2011) ALONG WITH RIS OF 'MORTH '.

11000 BILL OF QUANTITY :-

THE STEEL OF EDGE BEAM CONFORMS TO STEEL GRADE IS 2062 Gr. B.

5500 5500 LENGTH OF EACH EXPANSION JOINT = 11.000 RM

THE PROPERTIES OF STRIP SEAL SHALL BE AS PER TABLE 7.4.2.2.1

SLOPE AS PER P&P No. OF JOINTS = 06 JOINTS

FOR CHLOROPRENE RUBBER OF IRC SP - 69 (2011)

TOTAL LENGTH OF EXPANSION JOINT = 11.000 RM x 06 JOINTS 1

FOR CORROSION PROTECTION, SHOT BLASTING TO SA 2 &

= 66.000 RM 2

DETAIL 'A'

EPOXY PAINT WITH A MINIMUM DFT OF 150 mic.

ELEVATION OF EXPANSION JOINT INSTALLATION PROCEDURE :

01. THE GAP BETWEEN THE STEEL EDGE MEMBERS SHALL BE ADJUSTED

DEPENDING ON THE TEMPERATURE AT THE TIME OF INSTALLATION OF

THE EXPANSION JOINT USING THE CLAMP PLATE ARRANGEMENT.

STRIP SEAL SE - 400 02. THE EXPANSION JOINT IS LOWERED IN POSITION INTO THE BLOCKOUT.

(CAPABLE OF TAKING 16 Ø 152 LG. ANCHOR STUDS

MOVEMENT UPTO 80 mm) STAGGERED AT 250 mm C/C 03. THE LEVEL AND GRADIENT IS ADJUSTED MATCHING WITH THE FINAL

250 Z FINISH LEVEL OF THE DECK SLAB AT THE CARRIAGE WAY .

04. THE ANCHOR STUDS ARE SECURED TO THE DECK REINFORCEMENT

ADEQUATELY BY WELDING.

05. ADDITIONAL STEEL BARS MAY ALSO BE USED TO ACHIEVE INTEGRITY

125

WITH THE DECK SLAB.

Z

PLAN OF EXPANSION JOINT 06. NECCESSARY FORM WORK IS INSTALLED.

07. CONCRETE OF DESIRED MIX IS POURED INTO THE BLOCKOUT ENSURING

PROPER COMPACTION.

08. THE CLAMP PLATES ARE REMOVED.

09. BLOCKOUTS ARE CURED SUFFICIENTLY.

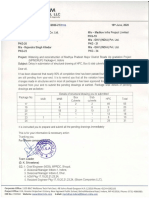

Expn. Gap Gap Opening

mm. INSTALLATION TEMPERATURE 10. TO MAINTAIN A UNIFORM JOINT OPENING AND EXTRUSION PARALLELISM,

mm MIN. MAX. 5°C 10°C 15°C 20°C 25°C 30°C 35°C 40°C 50°C

A STRING LINE SHALL BE USED.

"g" 5 50 80 71.1 62.2 53.3 44.4 35.56 26.7 17.78 8.89

11. FOR SMOOTH RIDING OPERATION, WE RECOMMEND INSTALLATION OF

THE EXPANSION JOINTS AFTER THE WEARING COAT

STEEL EDGE BEAM NOTE :

EDGE BEAM

WEARING COAT 300 "g" TRANSVERSE REINFORCEMENT BAR * ` g ' = EXPANSION JOINT GAP TO BE ADJUSTED AT THE TIME OF

(INDICATIVE) (NOT IN SANFIELD SCOPE) INSTALLATION DEPENDING ON THE AMBIENT TEMPERATURE.

( TO BE ADVISED BY THE ENGINEER - IN - CHARGE )

* LINK BARS OF VARIOUS SIZES DEPENDING UPON THE SITE

MAIN DECK CONDITIONS ARE USED TO FACILITATE CONNECTIVITY WITH

200

REINFORCEMENT

(INDICATIVE) MAIN DECK REINFORCEMENT. & TO BE PROVIDED BY MAIN

0

25 CONTRACTOR AT THE TIME OF INSTALLATION.

DECK SLAB

125 ANCHOR STUDS

STRIP SEAL

LINK BARS @ 250 mm C/C 16 Ø x 152 LG ANCHOR STUDS

STRIP SEAL

WELDED WITH THE DECK STAGGERED AT 250 mm C/C

REINFORCEMENT (ADJACENT STUDS @ 125 mm C/C)

(NOT IN SANFIELD SCOPE)

ISOMETRIC VIEW CROSS-SECTION AT ' Z - Z '

REVISION DESCRIPTION DATE

CL OF SYMMETRY 8 mm FILLET WELD

EDGE BEAM PROJECT :- KUHMARKHERA ROAD KHALWA DIST. KHANDWA, M.P

65

ELECTRIC ARC WELDING OF

LENGTH 200 mm (MINIMUM) CLIENT :-

WITH 4 mm ROD AT SITE

21

HEX BOLT

CONSULTANT :-

30 NUT FOR M12 BOLT

80

12Ø x 51LG.

76

CONTRACTOR :- M/s MADHAV INFRA PROJECT LTD

WASHER 12Ø LOCK WASHER 12Ø

TITLE :- STRIP SEAL EXPANSION JOINT SYSTEM

20

80 GUSSET PLATE DRG. NO. :- SIL /MIP/ 55(III) / 19 / 06 - 21567 DATE :- 22/06/2019

GUSSET PLATE 12 THK.

8 mm FILLET WELD SCALE :- REV. :- SHEET :- DRAWN BY :- CHECKED BY :-

12 THK. OF LENGTH 100 mm

NTS 00 1 OF 1 S.R.Q. F.S.

EDGE BEAM DETAILS SPLICING DETAILS AT `A'

THIS DESIGN OR DRAWING IS THE PROPERTY OF SANFIELD (INDIA)

LIMITED. IT IS SUBJECTED TO THEIR RECALL AND MUST NOT BE

LENT COPIED OR REPRODUCED WITHOUT THEIR WRITTEN PERMISSION.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Bloom: CompaniesDocumento1 paginaBloom: CompaniesIsmail ShekhNessuna valutazione finora

- 501 (Regarding Forest Area) PDFDocumento1 pagina501 (Regarding Forest Area) PDFIsmail ShekhNessuna valutazione finora

- Bloom: CompaniesDocumento1 paginaBloom: CompaniesIsmail ShekhNessuna valutazione finora

- 2624 P04 PDFDocumento1 pagina2624 P04 PDFIsmail ShekhNessuna valutazione finora

- Lt. No 484Documento1 paginaLt. No 484Ismail ShekhNessuna valutazione finora

- Bloom: CompaniesDocumento1 paginaBloom: CompaniesIsmail ShekhNessuna valutazione finora

- Bloom: CompaniesDocumento1 paginaBloom: CompaniesIsmail ShekhNessuna valutazione finora

- LT No. 430Documento6 pagineLT No. 430Ismail ShekhNessuna valutazione finora

- Bloom: CompaniesDocumento1 paginaBloom: CompaniesIsmail ShekhNessuna valutazione finora

- Bloom: CompaniesDocumento1 paginaBloom: CompaniesIsmail ShekhNessuna valutazione finora

- Project ReportDocumento14 pagineProject ReportIsmail ShekhNessuna valutazione finora

- Lt. No. 455 (Regarding Forest Area)Documento1 paginaLt. No. 455 (Regarding Forest Area)Ismail ShekhNessuna valutazione finora

- Demand Note: Pan of MPPKVVCL: Aadcm7397NDocumento2 pagineDemand Note: Pan of MPPKVVCL: Aadcm7397NIsmail ShekhNessuna valutazione finora

- Demand Note: Pan of MPPKVVCL: Aadcm7397NDocumento2 pagineDemand Note: Pan of MPPKVVCL: Aadcm7397NIsmail ShekhNessuna valutazione finora

- Letter No. 404Documento2 pagineLetter No. 404Ismail ShekhNessuna valutazione finora

- Structure List (Amravati EPC-8)Documento4 pagineStructure List (Amravati EPC-8)Ismail ShekhNessuna valutazione finora

- 16 - Chapter 5 PDFDocumento16 pagine16 - Chapter 5 PDFIsmail ShekhNessuna valutazione finora

- Project ReportDocumento16 pagineProject ReportIsmail ShekhNessuna valutazione finora

- 16 - Chapter 5 PDFDocumento16 pagine16 - Chapter 5 PDFIsmail ShekhNessuna valutazione finora

- Lab Organization ChartDocumento1 paginaLab Organization ChartIsmail ShekhNessuna valutazione finora

- M 233-86 (1996)Documento1 paginaM 233-86 (1996)Ismail ShekhNessuna valutazione finora

- AASTHO Test Method IndexDocumento7 pagineAASTHO Test Method IndexIsmail ShekhNessuna valutazione finora

- Vendor RegistrationDocumento1 paginaVendor RegistrationIsmail ShekhNessuna valutazione finora

- MPRDC Regarding RoyaltyDocumento12 pagineMPRDC Regarding RoyaltyIsmail ShekhNessuna valutazione finora

- Sign Board InventyDocumento49 pagineSign Board InventyIsmail ShekhNessuna valutazione finora

- Lab Equipments Calibrations (2018-19)Documento28 pagineLab Equipments Calibrations (2018-19)Ismail ShekhNessuna valutazione finora

- SP64Documento122 pagineSP64gyayakbhutaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Speed of Concrete MixerDocumento3 pagineSpeed of Concrete MixerAnonymous S94DOOkmeNessuna valutazione finora

- Vci MBDocumento23 pagineVci MBAyeshaNessuna valutazione finora

- 20141008composites Market Report GRPCRPDocumento44 pagine20141008composites Market Report GRPCRPMarina FungNessuna valutazione finora

- Indipco ManualDocumento53 pagineIndipco Manualنايفف بن عبداللهNessuna valutazione finora

- A Review On Investigation of Casting Defects With SimulationDocumento5 pagineA Review On Investigation of Casting Defects With SimulationInternational Journal of Innovations in Engineering and ScienceNessuna valutazione finora

- BS en 01519 1 2000 2002Documento34 pagineBS en 01519 1 2000 2002Attef BedawyNessuna valutazione finora

- Lab Report-1Documento5 pagineLab Report-1Raza AliNessuna valutazione finora

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 pagineInspection & Testing Requirements Scope:: Test and Inspection PerWael ChouchaniNessuna valutazione finora

- Pool Fittings LeafletDocumento20 paginePool Fittings LeafletmohammudaphNessuna valutazione finora

- Copper and Its AlloysDocumento4 pagineCopper and Its AlloysneilNessuna valutazione finora

- Cath Basin: Detailed ofDocumento1 paginaCath Basin: Detailed ofGwapo AkoNessuna valutazione finora

- Astm C 330Documento4 pagineAstm C 330Muhammad NaumanNessuna valutazione finora

- DBM PC SpecificationDocumento11 pagineDBM PC SpecificationkesharinareshNessuna valutazione finora

- Steel Joist System - Product ManualDocumento20 pagineSteel Joist System - Product Manual200365530Nessuna valutazione finora

- Why StainlessDocumento2 pagineWhy StainlessklopssNessuna valutazione finora

- Weekly Progress Report 23-10 PDFDocumento4 pagineWeekly Progress Report 23-10 PDFMohamed ArafaNessuna valutazione finora

- Astm C172Documento3 pagineAstm C172JojolasNessuna valutazione finora

- As10 Air ValveDocumento1 paginaAs10 Air ValveChris KNessuna valutazione finora

- Construction Work DMRCDocumento33 pagineConstruction Work DMRCRubeel NaqviNessuna valutazione finora

- 2010 NCCCarpentry Fact SheetDocumento2 pagine2010 NCCCarpentry Fact SheetWendy Rasmussen-GriggsNessuna valutazione finora

- BS 416-1.1990 PDFDocumento27 pagineBS 416-1.1990 PDFHaris KyriazisNessuna valutazione finora

- BS en 10090-1998Documento18 pagineBS en 10090-1998Martijn GrootNessuna valutazione finora

- Unit-V Investment Casting of SuperalloysDocumento36 pagineUnit-V Investment Casting of SuperalloysJ JhansibaiNessuna valutazione finora

- Cuestionario - Kalpakjian Ch13-16 Laminado Forjado Extrusión - Schey CH 9 Bulk Deformation Proccesses - Groover Ch19 Bulk Deformation - SOLVEDDocumento102 pagineCuestionario - Kalpakjian Ch13-16 Laminado Forjado Extrusión - Schey CH 9 Bulk Deformation Proccesses - Groover Ch19 Bulk Deformation - SOLVEDEdgar CaloNessuna valutazione finora

- 1.2842 enDocumento2 pagine1.2842 enCosmin IonutNessuna valutazione finora

- Schedule of Rates For Electrical Installation Works in Sarawak 2018Documento19 pagineSchedule of Rates For Electrical Installation Works in Sarawak 2018Yves L100% (3)

- Service RegisterDocumento60 pagineService RegisternikunjNessuna valutazione finora

- QAQCDocumento15 pagineQAQChaslinNessuna valutazione finora

- 10-Padalu (2020) - Cyclic Two-Way Out-Of-Plane Testing of URMDocumento24 pagine10-Padalu (2020) - Cyclic Two-Way Out-Of-Plane Testing of URMRolando AlvaradoNessuna valutazione finora