Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Application of Chemical (03-11) PDF

Caricato da

Erik SarastyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Application of Chemical (03-11) PDF

Caricato da

Erik SarastyCopyright:

Formati disponibili

The wide range of possible envrionmental factors a food we collect data during a storage period for some mode

some mode of de-

could be exposed to brings . up . several verv important con- terioration or chemical reaction, how can these data be used

sidw;~tionsin setting up a kinetic study o f f d q u a l i t y lms. to make projections about longer storage periods or other

For example, should the food product under study he stored storage conditions such as higher or lower temperature.

in a contrhled environmentaichamber in the package typi- The first attempts to linearize data (i.e., drawing the

cally used for distribution, or should it be stored sealed off straight line as suggested above) were made when chemists

from light and moisture exchange by putting it in a can or jar? began to study the mechanisms of various reactions; their

As an example of the problems inherent in this decision, let approaches have developed over the years into elaborate or

us consider a dehydrated or baked cereal product that would simple models, depending on the degree of sophistication used

be distributed in a semipermeable pouch. Using the typical to detect the various reactants and end products.

synthetic polymer material as the package during the kinetic For example, suppose we have the reaction

study will give the shelf life of the foodlpackage system, not

the food itself. This could confound the data if the moisture AZC (2)

gainhoss effects on the rate,of loss of quality cannot be sepa-

rated f r m other environmental factors. For example, one where A is a reactant; C, the product; and kf, the forward rate

might store the pruduct in an abuse condition at 40°C and 10mo constant. If we use more sophisticated analytical tools we

R H usinv the tvoiral nanrrhuard hox. In this condition the might find out, in fact, that the reaction is really much more

product will d r G u t and there will be a possibility of an in- complex, possibly

creased rate of rancidity development. On the other hand,

room temperature data (e.g., 23% 50%RH) might not show

t instead pick UD moisture.

anv ranciditv since the ~ r o d u cwill

and the powihle development of nonenzymatic browning will In this case A reacts with B to form two products, C and D,

he thc limitinr factor. If the food were stored in iars instead. which can also hack react with a rate constant of kb. The lower

moisture exchgnge would not occur, and the shelf life of the case letters indicate that more than one molecule of each

food at constant reaction phase conditions (e.a.. constant a,) .

com~onentis ~articinatine. The standard eauation defining-

woulci br rlrtermined. ohe ever, the jar could ;etain oil-odors the rate of loss of the reactants or gain of any component (e.g.,

that were developed hut which, if the distribution package see Benson (13)) is

wcrr used, might bass through the parkageur he ahsorbed by

thr r~arkurinrmaterial itself. Thus, storarr in a iar could evrn

lead to a cow& predicted shelf life. such probiems are more

difficult to deal with in practice than in theory. This problem

is eliminated with canned foods since moistu~eexchangedoes

not occur. Moisture loss for frozen foods is more of a problem T o solve the above equation,.which predicts the change in

in the defrost cycle when package ice forms. concentration of any component with time, one needs to know

Another consideration arises from the fact that, in the high the concentrations-of each component as a function of time.

abuse temperature studies, secondary chemical reactions that If this were possible, we would still have only one equation

would occur only slowly at the lower temperatures might now with six un!&owns (kf, kb, a, b , c, d). Thus the situation is

proceed at significant rates. This, of course, could compromise technically impossible to solve. Most kinetics or physical

the predictive power of the data since a different mode of chemistry books such as Benson (13), Wallas (16),or Amdur

deterioration might now become the controlling one. Thus, (17) suggest methods to get around this problem. Basically

one should not decide to test only for one chemical index if one needs to choose conditions such that either the forward

there

~~~-~~

~~ ~~

.

is a notential for multinle reactions to occur. This would

~~~

be true for any dry or semimoist food containing unsaturated

or backward reaction predominates andlor the concentrations

of several species such as B are so high that their change in

l i ~ i d sreducine

. suears. and protein. For example. dehvdrated concentration with time is negligible. Thus, if kb <<< k f and

pbtatbes go r&cG hklow '30-32'~ and de;eldp browning [B] is very large, the loss in [A] or gain in either [C] or [Dl is

(through NEB) above this temperature (I). In cases such as

this, it would he impossible to extrapolate shelf-life data ac-

curatelv from hieh temperature to low temperature unless the

specific effects on the kinetics of the reactibn are understood.

Finally, we have the question of cycling storage temperatures where k / is the ~ s e u d forward

o rate constant. Obviouslv this

versus constant temperature. Foods do not experience con- form of the equation ignores the true mechanism of theieac-

stant temperature during distribution. Should we thus study tion but is useful from a practical standpoint. as we will

the kinetics under variable conditions, or can constant tem- see.

perature conditions he used t o make predictions for variable A food system is very complex. Assuming that, for a given

conditions? Does the temperature cycling itself cause new mode of deterioration, the above assumptions hold, one can

reactions that would introduce errors in identifying the main simply write for the rate of gain of an undesirable quality

factor in deterioration, sometimes called a ''history effect" factor [B] or loss of a desirable quality factor [A] the following

(14)? equations

General Approach to Kinetics of Food Deterioration loss of quality -

Basic Mathematical Approach to the Kinetics gain of undesirable factor

of Deterioration of Food

There once was a chemist from Latta

Who couldn't interpret his data, where k is the pseudo rate constant, n is the order of the re-

So he drew a straight line, action (a curve-fitting parameter), and [A] or [B] are the

Now everything's fine, quality factors measured (e.g., a sensory value such as a he-

Except for the damnable scatter.

donic score).

The ahove limmerirk from Leffler and Grunwald (15) con- The above forms of the equations are used only for curve

cisely states the panicular prohlem facing chemists, especially fitting of the data (as defined by our Latta chemist) and in fact

those who have studied food deterioration for many years. 1f may have nothing to do with the true mechanistic steps in the

350 Journal of Chemical Education

degradation. For example, this simple form has been found 1for up to 50% loss (if this were as far as one collected data)

to apply to the growth or death of microorganisms, a process one would find it hard to distinguish between zero- and

which must proceed by a very complex set of steps. The major first-order. The poorer the analytical precision the greater

caveats in usine these eouations are that the above assumo- would he the chance of error in deciding on reaction order

tions must h o l i (i.e., the back reaction is negligible, and the unless the study were carried out far enough. Fortunately,

concentrations of other species are not limiting) and that all although food quality loss is slow a t room temperature, many

reaction phase condition; (pH, water activity, itemperatwe, food products become unacceptable with only a 20-30%

redox potential, concentration of all other species) must re- change from the initial value. Thus, it may not &en he nec-

main ~ o n s t a n t . ~ a s i c athis

l l ~ means that ihe pseudo rate essary to decide on thr reaction order and the simpler zero-

constant h is varticular to a given food system. order model could he chosen. It should be noted that in~ Firmre

~~ ~

~~~~~~ - ~~~ -

Labuza (1)has outlined in detail the Hpp~icationof these 1the slope of the line is the zero-order rate constant ho {hie

mathematics to the shelf-life testing of foods based on both in Figure 2, using loglo for the ordinate,

temperature and humidity abuse, and Labuza and Kamman

(18) have reviewed some of the computer solutions for analysis

of shelf-life data. Only a brief review of the critical parameters

can he presented here. What should be made clear is that there Thus to get h l one should multiply the value of the slope by

are two general ways to approach shelf-life testing. The most

common method is to select some single abuse condition such

as high temperature, analyze the product two or three times

during some specified storage period, and then extrapolate

the results to normal storage conditions by using some "fudge

factor," perhapsgained by experience with similar foods. The

..

better annroach is to assume that certain nrinci~lesof

r

chemical kinetics apply with respect to temperatureacceler- 0

ation.. ex..

- . the Arrhenius rrlationshiu. ..and w h r e kinetir de- 6 so-

sign to produce a more accurate prediction. a

Y

Reaction Order > 'O-

k

Fortunately, from a data manipulation standpoint, most 2 60-

3

literature data for change in food quality (based either on 0

some chemical reaction, microbial growth, death, or sensory Y

0

value) follow a zero-order (n = 0) or first-order (n = 1) reac-

tion model. Thus integrating eqns. (7) and (8)gives +

Z

40-

3

0

Zero Order L 30-

loss: [A1 = [Aol - kot (9) 4

gain: [Bl = [Bolt kot (10) 20-

First Order 10-

loss: In[A]/[Aol = -kit

or [A] = [A~le-~l'

(11)

(12) 0

I 1

50

I

m e4 200 250 3bo

gain: In[B]/[Bo]=+kit (13) TIME IN DAYS

01 [B] = [ B ~ ] e + ~ l ' (14) Figure 1. Loss of fwd quality as a function of time showing difference between

r e r p and firstkxder reaction. End of shelf life time (t,) occurs when quality

reaches maximum allowable loss value [A,].

If the data are plotted with quality factor on the y-axis versus

time on the x-axis, the above equations determine that the

reaction is zero-order when a straieht line is produced on linear

coordinates and first-order when a straight line is obtained

on semilon -paver.

. . It is possible to determine other orders if

the mechanism is known and the experimental procedure is

very precise. For example, a plot of 1/[A] or .l/[B] versus time

will give a straight line for a second-order reaction such as the

initial vitamin C loss in milk products or infant formula liquid.

Thus, if the order is known, one can extrapolate to the value

of A, or B, (subscripts denotes value at end of shelf life) on

the appropriate plot from only a few data points. Of course

doing this can result in a large error if there is error in the

values of [A] or [B]. Since a straight line can always be drawn

between two points, as we add more data we increase our

ability to predict both outside as well as inside the range of the

data points.

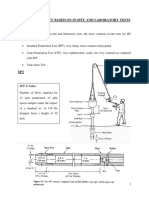

Thus, in Figure 1,a linear plot of quality versus time for a

loss in quality of a food would allow easy extrapolation to the

end of shelf life (t.) since the zero-order data fit a gwd straight

line. However, the first-order data on the same coordinates *:

would be more difficult to extrapolate because of the curvature 10

80 00 1% 00 110

k

300

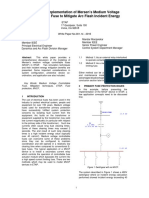

of the graph. Plotting the first-order data ss in Figure 2 solves TIME H DAYS

this extrapolation problem since it gives us thedesired straight F i w e 2. Loss of fwd quality factor f a a firstqder reaction pldted on semilog

line. w.End of shelf lifetims (ao c m when qualily reaches maximwmallowable

Interestingly, in looking a t the loss-of-quality data in Figure loss value [A.].

Volume 61 Number 4 April 1984 351

2.3. If the actual natural log, of the value of [A] or [B] is least-squares method or a modified-least-squares method

plotted on linear coordinates, then the slope is kl. One simple which is used for loearithmic data (first order) to eliminate

mathematical tool for first-order reactions is to use the time sume of the bias of he log function. In thew a;proaches the

at which the quality decreases to 50% (tllz), then measure of how well the dnta fit a straieht line is r2, the coef-

-1" 501100 =-t0.623 ficient of determination, where r 2 = 1represents a perfect fit.

k l= (16) It should he noted, however, that the r 2 of two points will al-

t ,I2 t112 ways be l, yet one could he far off in any prediction either

An illustration of the use of these eauations and the dif- outside or inside that range. The more data points the greater

ference in zero- versus first-order is shown in Table 1where is the confidence in using the r2 value as a statistical tool. Thii

the losses are calculated based onlv on a zero time value and regression analysis could he used to decide between zero- and

on the point at which there was 50% loss of quality. Thus, first-order.

- ~ ~ - -~ ~

~ ~ ~ -

using eqn. (9) for zero order, The next step then in this approach is to get an estimate of

[Ao] - [A] = -100 - 50 = -

50 quality unit the error ink from these regression calculations. Basically the

ko = - =1 true slope (8) is the measured slope (k) f the confidence

t 50 50 d limits

For a first-order reaction (eqn. (16)) the same data give

where 8 = true slope of regression line, t,lz = Student t value

Here one should note that the units of k for zero order are a t given degree of confidence desired (e.g., 90,95,99%) at

amountltime while that for first order is reciprocal time. One = n - 2 degrees of freedom, n = number of data points, t =

should not mix these k's or compare them absolutely as they time for each data point and

are different. As seen in Table 1, if the analytical error were

f5% one could not really distinguish between the orders using S. = standard error of [A] versus time

data for less than 50% loss.

Statistical Evaluation of Rate of Loss of OUaliW

Many different statistical mathematical approaches can These euuations illustrate that the more data points, esoe-

be used to evaluate the soundness of the amount of quality and cially at longer times which produre prater changes of quality

time data and to get an estimate of the error in the prediction . the smaller will be S, and the smaller the confidenre

from IAol.

o f t , (13, 19, 20). As noted by Lund (21), "Reporting data limits on the right.hand side of eqn. (1:). For n = 3 samples,

without an indication of error is one of the most common oc- the deeree of freedom is @ = 3 - 2 = I and thus the t . . . value

~

currences in the scientific literature today.. . investigators a t 95%confidenceis large (=12.71). If aminimum of 8 samples

have ignorrd the error assoriatrd with a parameter because are taken as suggested by Labuza and Kamman (18), then t,/z

the error is so large that it is meaningless to discuss the mean = 2.45 which gives a reasonable confidence in k and is still

valueof the parameter." What Lund says is quite true and is within practical and economic limits of most experimentation.

an indication of the problrm the "l.atta" rhemist would have Benson (13) has used this analysis to illustrate the effect of

with moat food deterioration data. The prohkm exists because precision on percent error in k (see Table 2). The hetter the

it is not always rronomirally frasihle or physically possible analytical precision and the greater the extent t o which the

to rollect enmgh data to satisfy some statistical model. As- reaction is studied the hetter is the estimate of k. If the pre-

suredly. appliration of statistics is most drsirahle and gives cision is only f5% and the reaction is carried out to only 20%,

one thk fekiing that the data are more useful, but those data the error in k is f35%.

without statistics should not be deemed useless. Prior A serond approarh, which was suggested by Lund (21) as

knowledge of the statistical requirements of a kinetic study wellas being il11atrau.d in kineticstexthx,ks.is t assume that

should help in the experimental design. Modern calculators each data point is an independent experiment with respect

and computer programs make the calculations easy once the to zero time. This is sometimes called point-by-point analysis.

data are collected. Thus

A review of statistical analysis of food deterioration data Xk i -

f l = havg195%confidence limits = - t./zo

(19)

has been made hy Labuza and Kamman (181, Lund (211, n 6

Saguy and Karel (22), Lenz and Lund (23), and Hill and

Griep-er-Block (24),and the reader is referred to these for in- where o is the standard deviation of all nk values and each k

depth analysis. Hasicall" two approarhes ran he used to get is determined using the zero value l&l (or IRol) and the ap-

an twimate of the error in the ratr ronswnt k. which is the key orooriateeuuations (10-15).'l'his method wndsto reduce the

factor used in making predictions for other conditions. ial;e of the 95% confidence limits making one feel that the

The first approach is to use some standard method of linear data are better than they may really be. The value of o comes

regression o n quality versus time data, for example the from the errors in evaluating quality and decreases as the

~rocedure'snrecision aets hetter, The confidence limits also

decrease as ihe numb& of data points is inrreased (propor-

Table 1. Experlrnental Data Manipulation tional t o n - ' % The choire of using this method versus using

Basis:A=IOOatt= Od

A = 50att=50d Table 2. Estlrnate of Percent Error In Reactlon Rate Constant, k

Calculated QualityValues ~.

Analvtical

~~

Time (d) Zero Order First Order Precision -Change in reactant species monitored.-,

(%) 1% 5% 10% 20% 30% 40% 50%

352 Journal of Chemical Education

least sauares is a matter of the oersonal oreference of there- Kinetic Approach to Accelerating Shelf-Life Deterioration

searcher and the statistical c o n h a n t . E'igure 3 shows a plot

of some actual data for the browning reaction during storage Introduction

of nonhygroscopic whey powder (25) illustrating thevisualiy In order to accelerate a shelf-life study of food deterioration

good fit to zero-order kinetics, whereas Figure 4 shows the as well as to get data which can he applied over a broader range

poor fit to first-order kinetics for the 35'C data. In using hoth of conditions, as noted, certain chemical laws can be used.

statistical methods as well as a visually drawn line to statis- With foods, however, there are limits to use of accelerated test

tically analyze the data a t 35°C the following would he conditions. Generally three approaches have been taken: (1)

found concentration acceleration, (2) moisture or humidity accel-

Zero Order: (35W eration iinrreased a,), and (3) temperature arreleration.

Regression analysis r2 = 0.994 With concentration accelsratirm Le., increasing the amount

S. = 0.79 of a reactant) other changes in the reactant phase or other

t & = 2.2 @ 95% CL *=9

6 = (0.288 i 0.017) X 10V unitlday

mechanisms may occur such that one could not use the data

t o predict for the normal concentration range. For example,

Point-by-point 6 = (0.305 -L. 0.015) X 10V unitlday with lipid oxidation of dry food products there is no change

Visual k = 0.3 X in rate above 10%oxygen in the headspace (26). Below this

oxygen level other reaction steps begin to predominate and

Thus, if the initial browning value were 0.01 and the product the rate decreases exponentially as 0 2 decreases.

hecame unacceotable at a value of 0.5. then we would find that The second test acceleration is to increase the wapr content

the time requiied to attain this value would he: of a food which in turn increases its water activitv. This is a

Average Minimum Maximum

well-known phenomenon which can he applied dry foods to

and has been studied in deoth for manv deterioration reac-

Regression 170 d 161d 181d tions (27,28). Generally, wkat is found is that betkeen the

Point-by-point 161 153 169

Visual 163 ... .. . moisture content corres~ondineto the monolaver (a, of about

0.2-0.4) and the moistire content at an a, of"arouid 0.60.8

(about 15-30 g H20/100 g solids) a plot of the rate constant

These results show that the standard linear remession (usine or shelf-life time (t.) on a log scale versus a, gives a straight

95% confidence limits) gives us a range for the end of shelf li& line, as in Figure 5. No mathematical model exists for this

that is not verv different from the ranee that the ~oint-hv- although several have been attempted (29).Thus for each food

point method gives. In addition, the visual average value is a t each temverature a different curve will he found, although,

within the limits of hoth statistical methods. This is auite a in general, the slope of the line shows about a two- to threefold

good fit to the data since t h ~I~rowning

. precision is generally increase in rate for evew 0.1 a, unit increase over the normal

less than f 2%. In the same study the results for loss of the 2040°C range. Of importance, however, is the observation

nutririmal quality of the protein (a first-order reaction) were that as the a, is increased certain reactions that do not occur

not as good because of the method orecision rf 1590).althouah at lower a,'s will predominate, thus giving results that cannot

eight sampling times were take; and the experiment was

carried out to 60%loss. For example, plotting the lysine data

a t 35°C gave a visual prediction of 65 days to reach 50%loss.

The linear regression value r 2 was only 0.89, and the time to

50% loss predicted by linear regression had a range of 48-56

d (average of 52 d). In this case, it should he noted that the

eyeball plot gave a shelf-life time outside of the calculated

regression range.

I . m . 3 . n . a . &

-0 O

. 110 180 0 20 40 60 80 100

D% DAYS

Figure 3. Zerwrder plot of extent of browningof nanhygr-plc whey powder F i w e 4. Firstader plot of extent of bmwning of omhygroscopicwhey powder

held at water activity of 0.44 for three temperawes. held at 35% and a water activw of 0.44 (data from Fig. 3.)

Volume 61 Number 4 April 1984 353

be projected to other conditions. In addition, some reactions, constant k increases. A plot of In k or k on a semilog plot

such as lipid oxidation, increase in rate as one decreases the versus 1IT should yield a straight line, as in Figure 6, since

moisture content below the monolayer due to changes in the

controlline kinetic mechanisms (29).

'~'hegel;bral method toaccelerate ihe riite of deterioratim

of foci1 IS to increase the tenmerature at which thc ~ r o d u r is

i The larger the value of EA,the steeper the slope. Thus, data

stored. Both theoretical andkmpirical models ( I ) have been from studies a t several high temperatures can be used to

used to extrapolate the high temperature data to shelf life at project the shelf life a t lower temperature, subject, of course,

low temperature. These techniques are also common in the to the errors in evaluating k previously discussed. Even though

testing of the shelf life of biologics and other drugs (30-36). the r 2 is usually high, if standard linear regression methods

The difference, however, is that with drugs the extrapolations were applied to the typical three-temperature study, the 95%

are generally easy because only one reaction is occurring, confidence limits of the slope ( E d R ) , and, thus, the error in

whereas with foods there is always the problem that, at higher EA, could still be quite high. For the browning data a t the

temperatures, the reactions which are the limiting mode of three temperatures shown earlier, we would find

deterioration may be different from those a t lower tempera-

tures. Visual plot

Temperature Acceleration for Shelf-Life Testing of a Food: Linear regression r2 = 0.999

Arrhenius Model (Ink versus 11T) +

EA = 29.68 11.48 kcallmole

Studies of the effects of temperature on the increase in In ko = 47.38 + 18.8

chemical reaction rate was first published in the late 1800's Point-by-paint analysis E A = 30.79 + 1.93kcallmale

(37). One of the most accepted models is that of Arrhenius in

which the temperature effect is incorporated into an expo-

*

In ko = 49.24 3.15

nential model of the rate constant in the form

k = hoe-EdRT (20) From this we see that although the three EA'S are close in

value, the linear regression method produces a very large

where ko = pre-exponential factor, E A = activation energy in confidence level for both E Aand ko. NOwonder this kind of

callmole, R = gas constant = 1.987 calloK mole, and T = ah- information is not included in the literature, as Lund has

solute temperature in OK. The theoretical basis for this stated (21). I t has been suggested that one should use the

equation can be found in some of the physical chemistry point-by-point method to get an E, from each individual k

textbooks mentioned previously. The value of E A (activation (18,21). As seen above, this gives an E Asimilar to that pro-

energy) is a measure of the temperature sensitivity of the re- duced by linear regression and reduces the confidence interval

action.. i.e... how much faster it will ao if the temnerature is significantly. This, in turn, would reduce the error limits on

raisrd. Mwt simplr hydrolysis renrtims have a value of 10-20 the value of k projected for a lower temperature. Of course,

krnllmole, lipid oxidatiun hy a free radical mechanism has an the better solution would be to do studies a t several more

E A = 15-25 kcallmole, nonenzymatic bruwning about 20-40 temperatures or even at the desired temperature, but this is

kcallmole. and enzvme and microhiill destruction from 50 to usually not possible with foods both because of cost and time.

150 kcal/&ole. ~ h e b a l u eof EAis very specific for each system With drugs and simple chemical solutions, another approach

and can vary with water activity. Basically, this model suggests is to do a study on a sample which is put through a sequence

that if a molecule has a total energy E 2 EA,then i t has a po- of continuously increasing temperature in some prescribed

tential for reactina which is controlled bv the value of ko. manner (linear or exponential). Many samples are taken over

sometimes called the collision factor. As the temperature in- time, and, with the correct mathematical model, the E Acan

creases, k~ and E A theoretically remain constant, but the

fraction of molecules with E 2 E A increases, thus the rate

I -1

0.

0.2 0.4 0.6 0.11 1.0 es so 3.1 3.2 3.3 M

W01.r AcIIYII~ I/T * K X 103

Figure 5. lilustratiMl of the ettect on increasing water activity (a,) on the shelf Figure 6 . Typical Arrhenius plot of log k versus inverse absolute temperature

life of a food at three differem temperatures ( T , < <

T2 T3). showing projection to lower temperature.

354 Journal of Chemical Education

he determined (30,38). This is usually not possible for food Then, substituting into eqn. (23) for shelf life a t T and T +

shelf-life studies because the temperatures required are 1O0C,we get

usually too high and the physical size of the sample causes heat

transfer limitations. This also would he almost impossible or

illogical to do with the 200-300 lh of food that might he needed and

for a sensory study. It should also be noted that several other

statistical models are available to evaluate the confidence

limits on E A such as a weighted-least-squares (39) and a

nonlinear simplex procedure for least squares (40). where T is in OK.

A convenient tool in transforming the Arrhenius plot is to Thus, the Qlo or slope b of the shelf-life plot will depend on

plot t , rather than k on the y-axis, as shown in Figure la. As the value of the activation energy. Qlo values range from 1.5

was shown by Lahuza (41 ),this derives simply from mathe- to 2 for sensory quality loss in canned foods, 1.5-3 for rau-

matical manipulation of the reaction equations and the cidity, 6 1 0 for browning reactions, and 20-40 for quality loss

Arrhenius relationship for any order. I n addition, since most of some frozen fruit and vegetables ( I ).

food studies are done over a rather narrow temperature range

(20-30°C), a simplification can he made in which log t , is Limitations of the Arrhenius Model

plotted directly against temperature rather than 1/T. Typical Based on the above discussions. it can he seen that there

"shelf-life plots" for over 400 different foods and modes of c(1~1~1 he many limitations besides s~atisticalr r n m in using

deterioration have been made ( I ) . either the Arrhenius ulut or shelf-life nlot to ~ r e d i c shelf t life

Instead of the activation enerm concept, manv researchers a t some lower tempeiature. ~enerall; the prbhlems exist he-

in the food lield have used the d;oapprdach for;ernperature cause somethinz occurs a t hieher temDeratures which does not

acceleration u,here ihe 0," is ihe derreme in shelf life (increase occur a t lower temperatures . . (14). ~ h e s limitations

e include

in rate) for a 1O0C temperature increase. the following

In fact, many have assumed the Qlo to he equal to a factor

1) At high temperatures (235°C) phase changes such as melting

of 2. However, this is erroneous and would apply only to re- of fats might occur. The liquid-phase fat can a d as a reaction

actions a t a certain temperature and E A value. T h e relation- medium or react itself where it would not at the lower temper-

ship is derived directly from the Arrhenius equation where ature.

2) During freezing, reactants are concentrated in the unfrozen

water. This concentration is temperature-dependentand not

accounted for in the typical reaction kinetic approach. The

By using O°C as an arbitrary reference temperature the major effectwould be seen just below the thaw point for frozen

equation for the shelf-life plot may he written foods.

3) Carbohydrates that might he inan amorphous physical state

t8 = t,ere-b(~-~mr)

= toe-br (23) at room temDerature and available for chemical reaction could

crystallize out at higher temperatuw and tht~etorenot react.

where b =slope in ADC,T = "C, t,.f = shelf life a t reference Thia uwld leml ttn ~ ~ ~ e r p r ~ d ~t.frhelf

c t i o ulife at nwm tpmper-

temperature T,.f, and to = shelf life a t 0°C.

4) Generally, many reactions are possible in any given fwd to cause

its deterioration. It may he possible that above some tempera-

ture a reaction with a higher En will .

~~

vredominate while below

that temperature a diffe;ent reaction will lead to loss of shelf

life. Thus, studying only one reaction will lead to significant

error in oredictions.

5) The untrr art~\,itv of a dehydrated loud at constant moisture

rmrent incrcares wirh Wrnprrature. Since some reacrron rates

are a, dependent, the acceleration of deterioration at higher

temperature would be larger than predicted solely hy~the

109 Arrhenius model. This would lead to overprediction of the shelf

life at room temperature. Many models exist for incorporating

Shelf moisture change and temperature change (22) but will not be

L~fe discussed here.

8 Since the solubility of gas decreases as T increases, oxidation

readions might became oxygen limiting. Several test procedures

for shelf life of oils get around this by using oxygen pressures

of 5&200 psi (26).

Other factors causing difficulties in making accurate predic-

tions could include change in paktitioning between the

aqueous and lipid phase, change in pH, protein conformation

changes, and moisture loss. Thus, there generally is an upper

limit of temperature that can he used f& accelkrating &c-

tious; this temperature is about 40% for canned foods (due

in part to possible thermophilic growth which begins a t 40-

109 45'C), 35-45°C for dry foods, 7-10°C for refrigerated products

Shelf and -5'C for frozen foods. Of importance here is that these

Life possible changes suggest that more than three temperatures

he used if one wants to find out if there is a shift in the kinetic

mode of deterioration with temperature, i.e., is the Arrhenius

or shelf-life plot truly linear?

Shelf-Llfe Predictions

Introduction

Figure 7.A, hansfwmed Anhenius plat of lag of shelf-lifeversus inverse tem-

Peralm. 6, a psedPtransformationof log of shelf life versus temperature for Once data are collected to prepare an Arrhenius or shelf-life

narrow temperature ranges. plot, one can then use this information to project the shelf life

Volume 61 Number 4 April 1984 355

a t some other temperature. The question, of course, is "what additive model called the Time/Temperature/Tolerance

temperature?" In fact, in the real world food products go (TTT) method or (2) a kinetic model based on the earlier

through rather variable temperature distrihutions (especially theoretical publications of Hicks (53) and Schwimmer et al.

canned and dry goods) and those distributions will each de- (54). Neither of these models considered the order of the re-

pend on the time of year the product is manufactured, the action, thus implying zero order. Lahnza (41) showed how each

physical position of the package (i.e., in the case, in the pallet, of these models could he derived solely from the kinetics

and where the pallet is in the warehouse, truck, rail car, or presented earlier and developed the equations for hothfirst-

shelf) and, of course, the peculiarities of the weather. In fact, and zero-order reactions.

the true shelf life of a particular food package which exits a The hasic tenet of any model is knowledge of the tempera-

food plant is unknown. It can only he "guesstimated" for a ture distrihution as a functiun of rime whirh is inserted into

particular temperature or temperature distrihution. either a zero- or first-order reaction equation in differential

Even if these things were taken into consideration, i t is form where

possible that temperature fluctuations themselves would

cause a "history" effect in which the rate of deterioration is

a function of the timeltemperature of prior storage. Little is

known about the magnitude of the history effect. Quast and The rate constant for each order takes the form

Karel(42) have found this for rancidity development in potato

Zero

Rate = k = ([A01 - [%I)

chi'pg, and some shelf-life studies of this phenomenon have

been conducted with pasta (43,44,45). In these latter studies, (27)

the question asked was whether one could predict the shelf

life of a product undergoing a knowri temperature fluctuation First

if one knew the temperature distrihution and had data at

constant temperatures in the form of a shelf-life plot. I t had

been the prejudice in the food research field that a product Inserting into eqn. (26) and solving for a single temperature

undergoing a reguldr temperature fluctuation, such as a 251 (Ti), i.e., k is constant then for a given time t

45°C sine wave, deteriorated more rapidly than if stored at Zero

the mean temperature (see Fig. 8) due to some "unknown

mechanism," and thus shelf life studies required this tern:

perature cycling. Most large f o d companies, from the 1950's

through the 1970's, in fact creavd weather rooms which cycled

over various extremes. What was not understood was that the First

increased rate could he merely due to the logrithmic in-

creaseldecrease in reaction rate constant due to a temperature

change. Thus, in fact, if the theoretical k were calculated and

compared to an actual k , one'could get a measure of the For zero order, the ratio of the time a t some given temperature

magnitude of the "history" effect. (t) to the total time the product could last if i t were always at

Fluctuating Temperature Kinetic Modeb that temperature (t.) gives the fraction of shelf life consumed

(f,,) since it is equal to [An] - [A], the amount of the mea-

Early storage studies of the effects of temperature cycling sured quality which has been used up, divided by [Ao] - [&I,

were done on food quality loss in frozen foods (46-48) and on the amount of that aualitv which could he used up. However,

ascorhic acid loss, microbial growth, and enzyme destruction for first order, sinceit involves a log function, the ratio is not

(4Wi2). These studies used one of two models: (1)a simplistic the fraction of shelf life consumed as was erroneously assumed

in the early research. In these studies, i t was assumed that a

distrihution could he divided into a set of constant tempera-

ture regions, and then the fraction consumed was summed up

for each time period.

The early work presented no hard data comparing theory to

actual results, and no statistics or estimates of the errors were

included in the studies. This T T T method became the ac-

cepted practice in the frozen food field, perhaps because of its

simplicity. I t should he noted that, perhaps fortuitously,

frozen foods were used which generally follow zero-order-loss

kinetics and unacceptahility occurs with only a 20-30s change

in some related chemical index (I).

A group at the University of Georgia followed up on the

T T T studies by applying a more elegant model to ascorbic

acid loss, microhial death, and heat denaturation of enzymes.

This work demonstrated that the reaction was faster for a sine

or square wave temperature periodicity than at the time av-

erage temperature; however, they found errors of from 10 to

60% in comparing theoretical rates to actual loss rates. This

was attributed partially to analytical error and in part to a

possible change in Qlo with temperature (they did not use E d .

- 0 The main errors, however, arose from the use of a zero-order

8 (days) mathematical model for first-order reactions. In addition, heat

Figure 8. Comparison between rate of quality 10% for a f w d held at constant transfer limitations were not taken into account when rapid

temperature of 25.35, and 45% and one undergoinga sine wave temperature cycling of temperature was done.

cycle of 25145°C. The food kinetics group at the University of Minnesota has

356 Journal of Chemical Education

Table 3. Results of Universitv of Minnesota Shelf-Life Studies

Actual Rate Predicted Rate

F w d Product Reference Condition Constant Constant

W g o s c o p i c whey P o d r

Nonenzymatic browning

(25) square wave 25/4S°C

a. = 0.44 *

0.019 0.0004 ODld 0.015 ODId

6-DNP lysine loss a, = 0.44 0.018 f 0.001 d-' 0.026 d-'

Relative nuhitianal valve a, = 0.44 0.0123 f 0.0004 d-' 0.0155 d-'

Nonhyqoscopic Whey P O W (25)

Nonenzymatic browning a. = 0.44 0.0069 f 0.0002 ODld 0.0076 OD/d

a. = 0.44 0.0189 f 0.004 dC' 0.0223 d-'

6DNP lysine

Relative nuiritionai value a,= 0.44 0.0116 *

0.001 d-' 0.0153 d-'

pasta

Thiamin (43 square wave 25145'C

a, = 0.44 0.0012 f 0.0002 d-' 0.0016 d-'

a. = 0.54 0.0019 f 0.0003 d-' 0.0023 d-'

a, = 0.65 0.0028 f 0.0002 d-' 0.0037 d-'

Thiamin ( 45) sine wave 25145°C

a, = 0.49 0.0016 f 0.0003 d-' 0.0013 d-'

Lysine Iwslprotein quality 144) square wave 35/55-C

a. = 0.44 0.033 f 0.006 wk-' 0.022 wk-'

a. = 0.65 0.063 f 0.012 wk-' 0.063 wk-'

Browning Square wave 35155°C

a, = 0.44 2.69 f 0.7 ODldl100g 2.15

a. = 0.65 4.00 f 0.8 O D / d / 1 0 0 g 2.93

a-ONP lysine loss* I55) sine wave 25145'C

a, = 0.49 0.0104 wk-' 0.0073 wk-'

Relative nutritional value 0.0118 f 0.0013 wk-' 0.0093 f 0.0013 wk-'

potato chips 15s) sine wave 25145%

peroxide iormatlon a,= 0.11 0.115 f 0.006 PVW 0.1 19 f 0.002 PVld

conducted studies of quality loss for a series of different food In some cases, the actual rate was faster than the predicted

oroducts stored for uo to one vear under square wave and sine rate indicating a positive-historyeffect while in other cases the

wave temperature distributions. Integrated mathematical opposite was true. These studies illustrated that, although one

models based on the Arrhenius eauation were used and the may be able to develop elegant mathematical models based

equations were corrected for reaction order. In addition, sta- on kinetics and may use elegant statistical models to get

tistics were applied to some of the results of these studies straight line ~ l o t sthe

, errors involved in analysis plus the

where enough data were available. The actual measured k was possi%le changes in mechanism with changingtemperature

compared to the predicted k based on constant temperature may preclude one from accurately predicting the quality loss

studies from a t least three temperatures. of a food undergoing a temperature distribution. This does

Using eqn. (26) as the basis, the group developed the fol- not mean we should not utilize kinetic principles nor apply

lowing equations for the theoretical rate constants. statistics, rather these results indicate the need for better

analytical tools and better experimental design, including

Square waue more temnerature measures and samoline times. and the need

toexamiie the Arrhenius plot (or s h h k to determine

if a chanee in kinetics occurs with temoerature. As our "Latta

chemist"may have found, sometimesone should not draw a

Sine waue straight line.

Acknowledgment

This project was supported in part by the University of

Spike w o w Minnesota Agricultural Experiment Station Grant No. 18-78

and NSF Grant No. 7910370.

where k ~ is, the rate constant a t the mean temperature of the

cycle (T, = (T,,,,,, + T1~~~.)12), Z = (Tm+ lO)I(T, + ad in Literature Cited

OK, 2' = (T, +

10)l(T, - no) in O K , a. = amplitude magni- (11 Labuza, T P., "Shelf Life Dating of Foods." Fwd and Nutrition Press, Westpart, CT,

tude =, ,T( - Tol ,J/2, and b = slope of shelf life plot from 1982.

eqn. (25). Thus, for a reaction undergoing cycling for some (2) Waller, G. R.. and Feather. M. S.. (Editor*), "The Maillard Reaction in Fmds and

Nulrition,"Ameriran Chemical Society, Washington. DC. 1983.

given condition, one can use eqns. (10)-(15) by substituting (3) Erikson, C.. (Editor). "Maillard Reactions in Foods." Pelgsmon Press, New Yark.

in them one of the above rate constants (k,, k.i.., ksd fork. 1982.

(4) Friedman, M.. (Editor). "Protein Crm~linking-Nutritional and Medical Conse-

If the cycling pattern is not regular, then eqn. (26) should be quences." Plenum Prees, New Yark, 1977.

used, and the quality loss summed up for each timeltemper- (5) Labuza, T. P., and Saltmarch, M., in "Water Activity: lnfluenee~on Fwd Quality,"

iEdilars: Rakland, L. and Steward, G I AcadernicPrens, New York, 1981.

ature segment as in the T T T method. (61 Labu2a.T. P., C r i l ReuFoad Technol.2.335 (1971).

Table 3 is a summary of the kinetic studies done a t the (71 Gseuls,M. C.. Jr., J. FaodSci.,40,399 (1975).

Universitv of Minnesota. A wide variety of reactions were 181 Gacula. M. C.. Jr.. and Kubsla. J. J.. J. FoodSci.. 40.404 119751.

studied mid both sine wave and square wa;e rycling were used.

The differenct between the predicted and actual reaction rare

chap. 6, p. 173.

constant ranged from as small as 3.5% for lipid oxidation to (12) Meisner,D. F.. BokwsDige~t.27,lW (19531.

as high as 30-44% for lysine loss in pasta and whey powder. (13) Benson. S. W., "Foundstionsaf Chemical Kinelia." McGraw-Hill, New York, 1960.

Volume 61 Number 4 Aoril 1984 357

(34) Wm1fe.A. J.,and Worthingfon,H. E. C.,DrugDeud Comm., 1131,185(1974).

(35) Kirkwmd, T. B. L.. Biamstrics. 33.736 (1977).

(36) Pop8.D. G.,DrvgCosm. lnd., 127151.54 (19301.

(371 Bunker,D.,Acrts. Chem. lies.,?. 195 (19751.

1281 Rnmrr.A. R.. J. Phorm. Pharmacol. 16. l 0 l T 119631.

(17) Amdur, L a n d Hsmmes, G., "Chemieal Kinetics," McCraw-HiU. New York, 1966.

(18) Lab3~za.T.P..and Kammsn, J.,in"ApplieationsofComputerliinFmdResesrchand

Fmd Industry: (Edilac Saguy, I.), Marcel Dekker, N w York. 1983, p.71.

(19) Cochrsn, W. G., and Cox. G. M.. "Experimental Dosigns:2nd ed., J. W h y & Son& (421 Quast, D.,and Karel, M., J. Food Sei., 37,584 11970).

Ine.. NwYork, 1957. (43) Ksmman, J. F , Labuza, T. P.. and Warthesen, J . J., J. FoedSci.. 46,1457 (1981).

(20) h u n d , J., "Modern Elementary Statistics," 3rd ed., Pmnti~e-HallN w York. (44) Labuza,T. P., Bohnrsck, K., and Kim, M. N., C w d Chem., 59,142 (19821.

,007 (45) Riboh.D. L.,and Labula,T.P..JFodPIoe. Preseru. 6.253(1982).

1211 Lund. D..Faod Technol.. 37111.92 119631. (46) GuUchmidt.J.,Lebmam. Wiss. u-Techno1.,7.137 11974).

i22i saw;, 1.i-d K ~ ~ I , M . , F ~ ~ ~ 34121.78

' T ~ c ~(1980).

~~I.. (47) Ysn Arsdel, W. B.. Food Tmhnol., 11.26 (1957).

(23) Lanz, M. K., and Lund, D. B.,Faod Technol., 34[2],51l1980). (48) Olson, R. L., in '"Low Temprature Biology of Foodstuffs," (Editor HaMharne, J.)

(24) Hill. C. G., and Griegcr-Bld, R. A.,Food Technol., 31121.56 (1980) Pergsmon Press. New York, 1968.

(25) Labuza, T. P., and Saltmarch, M., J. Food S c i , 47.92 (19611. (49) Powers, J. J., Lukasziwin, W., Wheeler, R.,snd Dorn%ettc.,T. P.,J FodSci.30.520

1261 Raenanaon. J.0.ar.d Labua.T. P..FoodChern..2. W1 119771. (19651.

(50) Wu, A. C. M., Eitenmiller, R. R., and Vowers, J. J., J. Food Sci., 39,1179 (19741.

(51) Wu, A. C. M., Eitenmiller, R. R., and Powers, J . J., J Food Sci. 40,840 (1975).

(52) Wu,A. C. M.,Eitenmiller,R. %and Powem, J . J., J. FoodSci.,40,1171i1975).

(63) Hicks, E. W., J. Covn Sic. Ind. Re$. iAu3trtralial. 17,111 (19441.

(29) Labuza, T. P., Food Teehnal., 34141.36 (19801. (641 Schwimmer, S., Ingraham, L. L., and Hughes, H. M., Ind. En& Chsm., 27, 1149

(30)Yang, W.,and Roy, S.,Drug Deud Ind. Phorm., 6[6],591(19801. ~.""",.

/IQSiJ

(31) Dauies, 0. L., and Budgeti, D. A., J Phorrn. Phormocol., 82,155 (1980) (55) Chen, J. Y., Bohnsack. K., and Labuza,T. P., J F w d Sci, 48,460 (19831.

(321 Co1e.B. R.,andLasdbsfer,L., J. Phorm.Phormocol.,18.101(1966). (56) Lsbula,T.P.,and Bergguiat, S., J FoodSci,48,712 (19831.

I331 Garrett, E. R., J Amen Phorm. Asaoc., 45Bl,171i1956).

358 Journal of Chemical Education

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grove Music Online: ConsonanceDocumento10 pagineGrove Music Online: Consonanceedition58Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Design of Concrete Airport PavementDocumento64 pagineDesign of Concrete Airport Pavementaeroalan100% (4)

- Beginner Ansys TutorialDocumento114 pagineBeginner Ansys TutorialNGUYEN92% (12)

- Sample Problem #6Documento4 pagineSample Problem #6Dozdi100% (2)

- Heat Transfer RadiationDocumento7 pagineHeat Transfer RadiationJerico MikesellNessuna valutazione finora

- Calculus Ibsl QsDocumento7 pagineCalculus Ibsl QsfarahNessuna valutazione finora

- EGR250HW No.3Documento12 pagineEGR250HW No.3homNessuna valutazione finora

- Identification of Acrylate Copolymers Using Pyrolysis and Gas ChromatographyDocumento5 pagineIdentification of Acrylate Copolymers Using Pyrolysis and Gas ChromatographyKate KlopfensteinNessuna valutazione finora

- Problems and Solutions To The MIChO Selection Camp 2015: Third PhaseDocumento38 pagineProblems and Solutions To The MIChO Selection Camp 2015: Third PhaseYau Ching Koon100% (1)

- Schrodinger Equation DerivationDocumento12 pagineSchrodinger Equation DerivationAndrés López Martínez100% (1)

- Real-Time Control of Microstructure in Laser Additive ManufacturingDocumento15 pagineReal-Time Control of Microstructure in Laser Additive ManufacturingkishoreNessuna valutazione finora

- A Proposal For Asphalt Wearing Course Specification in PalestineDocumento142 pagineA Proposal For Asphalt Wearing Course Specification in PalestineYasser AlghrafyNessuna valutazione finora

- Molecular Energy Levels NotesDocumento5 pagineMolecular Energy Levels Notesskrim2Nessuna valutazione finora

- What Isa Laya CentreDocumento9 pagineWhat Isa Laya CentreJohn SkybirdwalkingbearNessuna valutazione finora

- 5.soil Physic - Mechanical Properties TableDocumento8 pagine5.soil Physic - Mechanical Properties TablebsavaticNessuna valutazione finora

- Audit Energi Dalam Pengolahan KaretDocumento15 pagineAudit Energi Dalam Pengolahan KaretDamayanti HaetamiNessuna valutazione finora

- Introduction To EtabsDocumento23 pagineIntroduction To EtabsPraveen Biradar100% (1)

- Me3t3 Fluid Mechanics and Hydraulic MachinesDocumento3 pagineMe3t3 Fluid Mechanics and Hydraulic MachinesRavi Kumar0% (1)

- Delta Asda A2 M en 20130415Documento783 pagineDelta Asda A2 M en 20130415Joao RobertoNessuna valutazione finora

- Suspended Sediment SamplingDocumento46 pagineSuspended Sediment SamplingŔaɓiɳ ṨhtNessuna valutazione finora

- Lateral Stiffness Characteristics of Tall PDFDocumento19 pagineLateral Stiffness Characteristics of Tall PDFLaila Monteiro A MeloNessuna valutazione finora

- 11 HeatDocumento11 pagine11 Heatapi-185034533Nessuna valutazione finora

- Natural RubberDocumento16 pagineNatural RubberQoe IooNkNessuna valutazione finora

- Bearing Capacity From Other Methods-KFCDocumento14 pagineBearing Capacity From Other Methods-KFCmazharNessuna valutazione finora

- Product Safety Commission (Afps) : Management: Federal Institute For Occupational Safety and HealthDocumento12 pagineProduct Safety Commission (Afps) : Management: Federal Institute For Occupational Safety and HealthFabricio AmorimNessuna valutazione finora

- 2.3.6 Geometry Menu: Menu Item Description ShortcutDocumento9 pagine2.3.6 Geometry Menu: Menu Item Description Shortcutpraj24083302Nessuna valutazione finora

- Fuse CalculationDocumento5 pagineFuse CalculationVishnu ShankerNessuna valutazione finora

- 2010 YJC H2 Phy Paper1 QN AnsDocumento21 pagine2010 YJC H2 Phy Paper1 QN AnscjcsucksNessuna valutazione finora

- Canon IR3225 Trouble Error CodesDocumento30 pagineCanon IR3225 Trouble Error Codesnafees80% (10)

- Calculus of Variations CDocumento22 pagineCalculus of Variations Chungbkpro90100% (1)