Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

If It Ever Happens Eat Cockroach

Caricato da

aRTTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

If It Ever Happens Eat Cockroach

Caricato da

aRTCopyright:

Formati disponibili

1/2

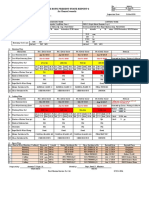

No. 003

DAMAGE REPORT RECTIFIED

Master: Capt. Leo A. Aparicio

Ship’s name: M/V ORION OCEAN

C.Engr. Marjoe A. Rendaje

Date of trouble: 03rd Dec. 2019 ☐ At sea ☒In port or Dock

Machinery or Device: Maker & Type: Unit&Parts:

Deck

Main Crane

engine No.1

stop: Mitsubishi Heavy

Cargo handling stop: Industries Working

Hydraulic Vane

hour forPump Unit

repairing:

1. Outline of trouble:

(Write in Addition, If necessary, sketches, Conditions before trouble, Appearances of

maintenance etc.)

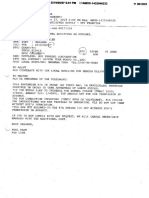

On 03rd December 2019 discharging at Kandla, India around 2015 hrs. While discharging in

progress the deck watch informed Engineers that the crane operator complaining on No.1

Deck crane slewing and luffing is very slow, engineers checked the possible cause and

carried troubleshooting work following makers recommendation and suspect hydraulic oil

pump not functioning well .

2. Probable cause:

Lack of hydraulic oil pressure causing luffing up not working, hydraulic oil pump

performance is decline due to hydraulic pump parts wear down parts.

3. Repair works / Emergency measures:

Checked Items:

1. Checked limit switches and micro switch condition for break release, replaced with

new spare

for luffing up.

2. Checked hydraulic & gear oil condition visually if there is discoloration

3. Cleaned hydraulic filter unit.

4. Checked the following pressure of hydraulic pump, hoisting, slewing luffing for

confirmation

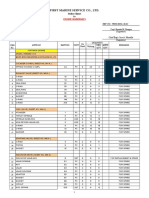

FIRST MARINE SERVICE CO., LTD. 0702010 R04

2/2

including break release pressure.

5. Checked Luffing control condition if move smoothly with full stroke

6. Checked the condition of relay for break release.

7. Checked the condition of solenoid valve power source measured normal and lamp

indicator.

5th December 2019 after departure work done.

1. Pulled out hydraulic pump assembly on deck crane No.1

6th December 2019 Underway to Mina Saqr.

1. Pulled out hydraulic pump on No.2 deck crane and installed to no.1 deck crane for

confirmation of oil pump working condition as per maker recommendation.

2. Drain all oil in the hydraulic system and cleaned hydraulic oil tank, oil cooler and filter

unit

and flushed with oil.

3. Hydraulic system unit oil renewed about 160 ltrs.

4. Tested deck crane after work done completed then found in satisfactorily in good

working condition after replaced hydraulic pump unit.

8th December 2019 at port of Mina Saqr.

1. Installed new received vane pump to No.2 Deck Crane then after completion of work,

tested and found satisfactory in good condition.

(No. 2 Deck Crane Replenished new hydraulic oil about 75 ltrs.)

4. Consumed spare parts or stores:

1. Micro switch of lever control for break release 1 pc.

2. Oil Pump assembly 1 Set.

5. Shore based support:

☐ Request ☒Not necessary (completed repairing on board)

Company’s action

FIRST MARINE SERVICE CO., LTD. 0702010 R04

3/2

6. Company’s repair plan if necessary:

Provided maker’s troubleshooting inspection.

Arranged to supply new hyd. Pump for replacement.

7. Shore based works / Ship’s work in accordance with repair plan by SI:

Received new hyd. pump and installed by ships hands.

8. Comments by SI:

Carry out regular inspection of oil condition and periodical cleaning and checking of

filter for metal particles. Inform to us if unusual condition is found so that proper

countermeasure and assistance can be done at earlier stage.

Date of Closing (Repairing) above trouble: Superintendent Signature:

th

08 Dec.2019 – Received new hyd. Pump

and installed to Deck crane no.2

After closing, SI shall send this report with signature to the ship.

The Master shall file this closing report to individual file for each damage.

FIRST MARINE SERVICE CO., LTD. 0702010 R04

Potrebbero piacerti anche

- Evu Karo Toh Kem ChaleDocumento1 paginaEvu Karo Toh Kem ChaleaRTNessuna valutazione finora

- It Never Happens To MeDocumento1 paginaIt Never Happens To MeaRTNessuna valutazione finora

- ORION OCEAN Visiting Report ContentDocumento1 paginaORION OCEAN Visiting Report ContentaRTNessuna valutazione finora

- Em No Hale Bhaila Devu To PadeDocumento1 paginaEm No Hale Bhaila Devu To PadeaRTNessuna valutazione finora

- Morality of Statistics Boolean LogicDocumento9 pagineMorality of Statistics Boolean LogicaRTNessuna valutazione finora

- How To Juice Onion SugarDocumento3 pagineHow To Juice Onion SugaraRTNessuna valutazione finora

- If It Happens So Be ItDocumento76 pagineIf It Happens So Be ItaRTNessuna valutazione finora

- Open House Tournament in Peach Tree BeesDocumento3 pagineOpen House Tournament in Peach Tree BeesaRTNessuna valutazione finora

- Peter Is in EnglandDocumento8 paginePeter Is in EnglandaRTNessuna valutazione finora

- When It Happens It StaysDocumento4 pagineWhen It Happens It StaysaRTNessuna valutazione finora

- Hitman and Papa TsangoDocumento1 paginaHitman and Papa TsangoaRTNessuna valutazione finora

- Open House Tournament in Peach Tree BeesDocumento3 pagineOpen House Tournament in Peach Tree BeesaRTNessuna valutazione finora

- Shop in The ViolenceDocumento1 paginaShop in The ViolenceaRTNessuna valutazione finora

- Hitman and Papa TsangoDocumento1 paginaHitman and Papa TsangoaRTNessuna valutazione finora

- Mail 27.09.2019Documento1 paginaMail 27.09.2019aRTNessuna valutazione finora

- Evu Hatu Ke Tevu HatuDocumento10 pagineEvu Hatu Ke Tevu HatuaRTNessuna valutazione finora

- I Could Eat Burger For BreakfastDocumento2 pagineI Could Eat Burger For BreakfastaRTNessuna valutazione finora

- We Want CorrosionDocumento4 pagineWe Want CorrosionaRTNessuna valutazione finora

- FaswebDocumento1 paginaFaswebaRTNessuna valutazione finora

- PN Junction Polarity Based IndexDocumento3 paginePN Junction Polarity Based IndexaRTNessuna valutazione finora

- Antibiotic RoboticDocumento1 paginaAntibiotic RoboticaRTNessuna valutazione finora

- Hello How Are You DoingDocumento10 pagineHello How Are You DoingaRTNessuna valutazione finora

- Stats On Rice in Different Regions of CambodiaDocumento2 pagineStats On Rice in Different Regions of CambodiaaRTNessuna valutazione finora

- Downloader5 LogDocumento16 pagineDownloader5 LogaRTNessuna valutazione finora

- Never Before Happen On TernDocumento25 pagineNever Before Happen On TernaRTNessuna valutazione finora

- Never Before Happen On TernDocumento25 pagineNever Before Happen On TernaRTNessuna valutazione finora

- Statistics of Bees in Subterranean HypocrisyDocumento14 pagineStatistics of Bees in Subterranean HypocrisyaRTNessuna valutazione finora

- Phobia of Poor People For MoneyDocumento1 paginaPhobia of Poor People For MoneyaRTNessuna valutazione finora

- Security of Giants in Ford LibertyDocumento3 pagineSecurity of Giants in Ford LibertyaRTNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Roads of Enlightenment GuideDocumento5 pagineRoads of Enlightenment GuideMicNessuna valutazione finora

- Wrongful ForeclosureDocumento8 pagineWrongful Foreclosurefaceoneoneoneone100% (2)

- Aaron VanneyDocumento48 pagineAaron VanneyIvan KelamNessuna valutazione finora

- Colville GenealogyDocumento7 pagineColville GenealogyJeff MartinNessuna valutazione finora

- Swot MerckDocumento3 pagineSwot Mercktomassetya0% (1)

- Chapter 1 Basic-Concepts-Of-EconomicsDocumento30 pagineChapter 1 Basic-Concepts-Of-EconomicsNAZMULNessuna valutazione finora

- UntitledDocumento18 pagineUntitledjake ruthNessuna valutazione finora

- Sales Channel: ABB Limited, BangladeshDocumento4 pagineSales Channel: ABB Limited, BangladeshMehedyNessuna valutazione finora

- Historein11 (2011)Documento242 pagineHistorein11 (2011)Dimitris Plantzos100% (1)

- Titman - PPT - CH11 Investment Decision Criteria STUDENTSDocumento86 pagineTitman - PPT - CH11 Investment Decision Criteria STUDENTSMia JironNessuna valutazione finora

- Can God Intervene$Documento245 pagineCan God Intervene$cemoara100% (1)

- The State of Iowa Resists Anna Richter Motion To Expunge Search Warrant and Review Evidence in ChambersDocumento259 pagineThe State of Iowa Resists Anna Richter Motion To Expunge Search Warrant and Review Evidence in ChambersthesacnewsNessuna valutazione finora

- About ArevaDocumento86 pagineAbout ArevaAbhinav TyagiNessuna valutazione finora

- Mental Health EssayDocumento4 pagineMental Health Essayapi-608901660Nessuna valutazione finora

- Civics: Our Local GovernmentDocumento24 pagineCivics: Our Local GovernmentMahesh GavasaneNessuna valutazione finora

- The Irish Chocolate CompanyDocumento7 pagineThe Irish Chocolate CompanyMaeveOSullivanNessuna valutazione finora

- Welcome To The Falcons School For GirlsDocumento6 pagineWelcome To The Falcons School For GirlsSowmiyiaNessuna valutazione finora

- Ais CH5Documento30 pagineAis CH5MosabAbuKhater100% (1)

- TolemicaDocumento101 pagineTolemicaPrashanth KumarNessuna valutazione finora

- Ia Prompt 12 Theme: Knowledge and Knower "Is Bias Inevitable in The Production of Knowledge?"Documento2 pagineIa Prompt 12 Theme: Knowledge and Knower "Is Bias Inevitable in The Production of Knowledge?"Arham ShahNessuna valutazione finora

- EREMES KOOKOORITCHKIN v. SOLICITOR GENERALDocumento8 pagineEREMES KOOKOORITCHKIN v. SOLICITOR GENERALjake31Nessuna valutazione finora

- Carl Rogers Written ReportsDocumento3 pagineCarl Rogers Written Reportskyla elpedangNessuna valutazione finora

- Web DesignDocumento2 pagineWeb DesignCSETUBENessuna valutazione finora

- Swepp 1Documento11 pagineSwepp 1Augusta Altobar100% (2)

- Ground Floor Plan Second Floor Plan: Bedroom 1 T & B Service Area Closet T & BDocumento1 paginaGround Floor Plan Second Floor Plan: Bedroom 1 T & B Service Area Closet T & BAbegail Dela CruzNessuna valutazione finora

- Mboce - Enforcement of International Arbitral Awards - Public Policy Limitation in KenyaDocumento100 pagineMboce - Enforcement of International Arbitral Awards - Public Policy Limitation in KenyaIbrahim Abdi AdanNessuna valutazione finora

- Government Arsenal Safety and Security OfficeDocumento5 pagineGovernment Arsenal Safety and Security OfficeMark Alfred MungcalNessuna valutazione finora

- Ethiopia Pulp & Paper SC: Notice NoticeDocumento1 paginaEthiopia Pulp & Paper SC: Notice NoticeWedi FitwiNessuna valutazione finora

- Module 4 - Starting Your BusinessDocumento8 pagineModule 4 - Starting Your BusinessJHERICA SURELLNessuna valutazione finora

- StarbucksDocumento19 pagineStarbucksPraveen KumarNessuna valutazione finora