Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mini Excavator PDF

Caricato da

Edo SyawaludinTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mini Excavator PDF

Caricato da

Edo SyawaludinCopyright:

Formati disponibili

Safe Operating Procedure

Mini Excavator

The instructions recommended within this document apply to normal risk conditions. If the Mini

Excavator is to be operated in a dangerous or hostile environment, the user/client is responsible for

conducting an appropriate risk analysis and applying suitable controls to mitigate those additional

risks.

This instruction should be read in conjunction with the Risk Assessment.

GENERAL SAFETY

• This excavator can only be operated if it is a safe and sound operating condition by a

competent operator.

• No drugs, alcohol or smoking is permitted

• Operator must comply with all load limits

• Ensure all beacons, alarms, brakes are working prior to use

• Operator to wear seat belt at all times

• Operator to wear appropriate PPE (safety footwear and Hi-Vis jacket)

• Restrain loads correctly

• USE APPROVED LIFTING AND TIE DOWN POINTS, CHAINS AND STRAPS

OPERATING CONDITIONS

• Carry out a visual inspection for tracks, brakes, lights, mirrors, beacon, radiator, bucket

attachment, hoses

• Ensure you receive basic instruction on starting & braking

• When excavating ensure machine is on level ground

• Prior to excavating extend tracks to maximum that is compatible with available working

space.

• If possible, align the machine so that any long jerk actions will be in line with the tracks

• DO NOT OVERLOAD

• If possible carry out a stability test by gradually extending a filled bucket to maximum reach

in a safe location

• Look in the direction you are travelling and watch out for other people and obey

• Use the mirrors and look behind when reversing

• Use care when working near other machinery

• DRIVE UP AND DOWN INCLINES AND NEVER ACROSS. AVOID TURNING TRUCK ON

A SLOPE

• Exercise care when maneuvering on sloping ground

• Be aware of wet, soft or loose edges and don’t operate close to open or uncompacted

trenches or other excavations

• Refer to operator’s manual for all other requirements

• Load and unload on a flat level surface only

PARKING

• Park where there will be no obstruction to vehicles, site personnel or access ways

• Do not impede road traffic and post reflective warning signs

• Apply brake

• Remove ignition key for safe keeping

INSPECTION AND MAINTENANCE

• Excavator and mechanisms to be inspected and maintained regular in accordance with

manufacturer instructions

• Operator to carry out daily inspections of fuel, tyres, brakes, lights, mirrors, beacon and

radiator

• Carry out any necessary service and maintenance

The above instructions must be followed at all times If any of the instructions are not

possible, contact the site supervisor for an assessment of any safety requirements

SOP-0040 Version 1.0

Page 1 of 1 Approval Date August 2018

Mini Excavator Risk Assessment

Likely Risk Who/ What What is the Rate What Risk Control Actions Needs to Be Taken? Time

Issue may be Level? (What needs to be considered so that the risks are identified and effectively Frame

harmed? (Rate risk as Low, controlled)

(Specific Persons) Medium or High)

Crushing Operator Severity of Risk (S)- 3 • Assess ground conditions prior to commencing work to ensure stability Every hire

Spectator Likelihood of Risk (L)- 2 • Ensure that the capacity of the machine is not exceeded

Overall Risk (S x L)= 6 • Set up an exclusion zone to keep spectators out of work area

MEDIUM • Caution to be exercised in wet conditions

• Operate machine in a smooth manner avoiding jerky movements

• Always wear seatbelt and ensure flashing light and reverse alarm working

Striking Operator Severity of Risk (S)- 3 • Ensure spectators remain out of exclusion zone Every hire

Spectator Likelihood of Risk (L)- 2 • Only competent people to operate the machine

Overall Risk (S x L)= 6 • Ensure all machine alarms are in working order

MEDIUM

Electrical Operator Severity of Risk (S)- 3 • Operator to assess surroundings and be aware of any power lines Every hire

Likelihood of Risk (L)- 2 • Dial before you dig to ensure there are no underground cables, pipes etc

Overall Risk (S x L)= 6

MEDIUM

Noise and Operator Severity of Risk (S)-2 • Wear hearing protection Every hire

Fumes Spectator Likelihood of Risk (L)- 2 • Do not operate in enclosed spaces

Overall Risk (S x L)= 4

MEDIUM

Explosion or fire Severity of Risk (S)-2 • Machine to be switched off before refueling Every hire

when Likelihood of Risk (L)- 2 • Avoid spillage onto hot engine parts

refueling Overall Risk (S x L)= 4 • Tightly seal fuel cap after filling

MEDIUM

Climbing Into Cab Operator Severity of Risk (S)-1 • Always use handrail for assistance Every hire

Falling Likelihood of Risk (L)- 2 • Ensure feet are placed securely in the steps on machine

Overall Risk (S x L)= 2

LOW

Calculation of Risk Evaluation

Severity of Risk (S) is judged by evaluating the effects of the hazard if the risk occurs. This is evaluated as Minor = 1, Major = 2, Serious = 3

Risk Likelihood (L) - The likelihood of the harm occurring is evaluated on the basis of: Unlikely =1, Possible = 2, Likely = 3

Overall Risk is calculated by multiplying the figure for Severity (S) and Likelihood (L).

The overall risk figure calculated is related to the Risk Level of either Low: 1 to 3; Medium: 4 to 6 or High: 7 to 9

NB This is a generic risk assessment only. It is advisable to carry out a site-specific assessment prior to using this equipment.

RA-0040 Version 1.0

Page 1 of 1 Approval Date July 2018

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 2001 2002 DS Golf CarsDocumento228 pagine2001 2002 DS Golf CarsTajLegenDaryEdwds100% (2)

- Calculating PCN Using The FAA MethodDocumento43 pagineCalculating PCN Using The FAA MethodRobiansah Tri AchbarNessuna valutazione finora

- 1LAC000003 DistTrHandbook PDFDocumento92 pagine1LAC000003 DistTrHandbook PDFarmandoa71565100% (1)

- Suspension Rear Celica ST202Documento4 pagineSuspension Rear Celica ST202tomar@vp.plNessuna valutazione finora

- ULC UL142 Comparison SpreadsheetDocumento43 pagineULC UL142 Comparison Spreadsheetgrincheu70Nessuna valutazione finora

- Collings, David-Steel-Concrete Composite Bridges - Designing With Eurocodes (2nd Edition) - ICE Publishing (2013) PDFDocumento264 pagineCollings, David-Steel-Concrete Composite Bridges - Designing With Eurocodes (2nd Edition) - ICE Publishing (2013) PDFprakhar100% (1)

- G3608 Spec SheetDocumento4 pagineG3608 Spec SheetTu Pham100% (1)

- Fire DampersDocumento20 pagineFire DampersRommelNessuna valutazione finora

- NEC Product Brief InstructionDocumento15 pagineNEC Product Brief InstructionAHMEDKAMAL2011Nessuna valutazione finora

- Taylor & Francis: Drilling and Blasting of RocksDocumento1 paginaTaylor & Francis: Drilling and Blasting of RocksEdo SyawaludinNessuna valutazione finora

- Ground SupportDocumento8 pagineGround SupportEdo SyawaludinNessuna valutazione finora

- Graduate Student Handbook-2015-16 Final 0Documento23 pagineGraduate Student Handbook-2015-16 Final 0Edo SyawaludinNessuna valutazione finora

- Ppr2014 416maDocumento14 paginePpr2014 416maEdo SyawaludinNessuna valutazione finora

- Effect of Multicyclic Compaction On Cohesion in Lateritic SoilsDocumento7 pagineEffect of Multicyclic Compaction On Cohesion in Lateritic SoilsEdo SyawaludinNessuna valutazione finora

- Correlation Between Maximum Dry Density and Cohesion of Remoulded Nsukka ClaysDocumento6 pagineCorrelation Between Maximum Dry Density and Cohesion of Remoulded Nsukka ClaysEdo SyawaludinNessuna valutazione finora

- Moisture Content Impact On Mechanical Properties of Selected Cohesive Soils From The Wielkopolskie Voivodeship Southern PartDocumento10 pagineMoisture Content Impact On Mechanical Properties of Selected Cohesive Soils From The Wielkopolskie Voivodeship Southern PartEdo SyawaludinNessuna valutazione finora

- MPS DatasheetDocumento2 pagineMPS DatasheetrajendrasoloniNessuna valutazione finora

- Controlador Llama Siemens Lga PDFDocumento12 pagineControlador Llama Siemens Lga PDFPaolo CruzNessuna valutazione finora

- A) CCP420 CCP520Documento16 pagineA) CCP420 CCP520Eric Ruiz LopezNessuna valutazione finora

- Product Data Sheet LB 490Documento2 pagineProduct Data Sheet LB 490John SchmidtNessuna valutazione finora

- Rating Summary Cummins GeneratorDocumento2 pagineRating Summary Cummins GeneratorLaiqNessuna valutazione finora

- Iso 17020 Accreditation of Cnetsten NDT Laboratory: AbsractDocumento6 pagineIso 17020 Accreditation of Cnetsten NDT Laboratory: Absractsafeer ahmadNessuna valutazione finora

- Pandas For Machine Learning: AcadviewDocumento18 paginePandas For Machine Learning: AcadviewYash BansalNessuna valutazione finora

- Powercrete R95Documento2 paginePowercrete R95Jimmy CalderonNessuna valutazione finora

- 0091 Amercoat 91 PDS May 08Documento2 pagine0091 Amercoat 91 PDS May 08donaldoguerreroNessuna valutazione finora

- AssignmentDocumento7 pagineAssignmentKamran AhmedNessuna valutazione finora

- Global Flexible Power SolutionsDocumento8 pagineGlobal Flexible Power SolutionsTBS Máy Phát ĐiệnNessuna valutazione finora

- Trane TCIDocumento12 pagineTrane TCIReinerio Praxedes Castillo CespedesNessuna valutazione finora

- Standard Engine Exhause Silencer and Accessories Catalog PDFDocumento32 pagineStandard Engine Exhause Silencer and Accessories Catalog PDFslow_bbNessuna valutazione finora

- Iso14000 FamilyDocumento2 pagineIso14000 FamilyALPER ORHANNessuna valutazione finora

- LCD Monitor DC E2200hda 20080717 114144 Service Manual E2200hda 9h (1) .Y3vln - Ixx v01Documento42 pagineLCD Monitor DC E2200hda 20080717 114144 Service Manual E2200hda 9h (1) .Y3vln - Ixx v01stelianlazaroiu0% (1)

- MontessoriDocumento9 pagineMontessoriRaphael Sierra CalsinaNessuna valutazione finora

- CC ProjDocumento280 pagineCC ProjsidlaskarNessuna valutazione finora

- FLP Temperature IndicatorDocumento2 pagineFLP Temperature IndicatorNiranjan BeheraNessuna valutazione finora

- GLT Y StrainerDocumento1 paginaGLT Y StrainerBagusRekaNessuna valutazione finora

- 3bse046133 Vip ExtenDocumento69 pagine3bse046133 Vip ExtenSakhawat Hossain RonyNessuna valutazione finora

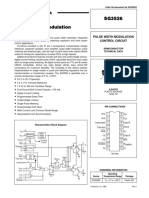

- SG3526Documento11 pagineSG3526RocioLLactaMartinezNessuna valutazione finora