Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

JFS Dual Flapper CV 3 (Catalogo Valvula Check)

Caricato da

fernando cordova zegarraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

JFS Dual Flapper CV 3 (Catalogo Valvula Check)

Caricato da

fernando cordova zegarraCopyright:

Formati disponibili

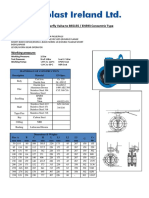

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

Dual Flapper Check Valve is designed as a non-return valve that is much stronger, lighter and

smaller in size compared to a conventional full-body check valve, due to its success including the

unique short face to face length, low purchase cost and non-slam principle of operation.

FEATURE

80-90% lighter than conventional full-body check valves.

Spring-loaded, double flapper (plate) design with low cracking pressure and low valve

pressure drop.

Resilient or metal seat available.

Inherently non-slamming, no external devices or attachments required.

Water-hammer almost non-existent.

Long life and trouble-free operation.

Horizontally or vertically installation.

Available in wafer, lug and double flange style.

PARTS LIST AND MATERIAL

No. Parts Name Material

1 Body Cast Iron/Ductile Iron/Carbon Steel/Stainless Steel

2 Disc Ductile Iron/Carbon Steel/Stainless Steel

3 Stop Pin Carbon Steel/Stainless Steel

4 Hinge Pin Carbon Steel/Stainless Steel

5 Holder Carbon Steel/Stainless Steel

8 Spring Spring Steel/Stainless Steel

*More material specifications are available on request.

STANDARD

Design and Manufacture API 594

Inspection and Testing API 598

End to End Dimension ASME B16.10

Flange Dimension ASME B16.5/ASME B16.47

*More standard specifications are available on request.

JFS reserves the right to change specifications without notice. 10

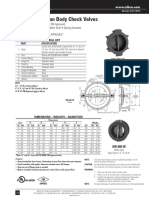

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

APPLICATION

Oil and Gas Production Water and Wastewater

Power Generation Steel/Primary Metals

Petroleum Refining Pulp and Paper

Petrochemicals Marine

Chemicals Hydrocarbons

OPERATION

The dual-flapper (plate) design employs two spring-loaded plates (disc halves) suspended on a central vertical hinge pin.

1. As flow begins, the plates open in response to a resultant force (F) which acts as the center of the sealed surface area.

The contact point of the reacting spring leg’s force (Fs) acts beyond the center of the plate area, causing the heel to open

first. This prevents rubbing of the seal surface prior to normal plate opening, eliminating wear.

2. As the velocity of flow decreases, torsion spring action reacts automatically. This moves the plates closer to the body

seats, reducing the distance and time of travel for closure. By having the plates closer to the body seats at the time of flow

reversal, the valve dynamic response is greatly accelerated. This dramatically reduces the water hammer effect for

non-slam performance.

SHORT BODY & LIGHT WEIGHT SEAT TYPE

Resilient Seat

12" (300mm) Cl 150 Swing Check Valve: L=28" (700mm), W=305kg

Metal Seat

12" (300mm) Cl 150 Dual Flapper Check Valve: L=7-1/8" (181mm), W=54kg

JFS reserves the right to change specifications without notice. 11

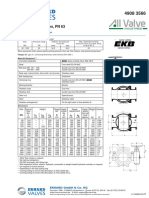

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

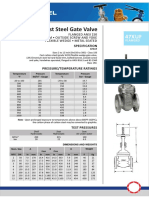

DIMENSION (Wafer type / 150 & 300 lb)

150lb 300lb

DN NPS

L D D2 D3 Est. Weight (kg) L D D2 D3 Est. Weight (kg)

50 2” 60 103 51 58 2.5 60 110 51 58 3

80 3” 73 135 80 88 4 73 147 80 88 6

100 4” 73 173 102 108 6 73 179 102 108 8

150 6” 98 220 152 160 13 98 249 152 160 18

200 8” 127 277 203 210 25 127 305 203 210 31

250 10” 146 337 254 266 39 146 359 254 266 51

300 12” 181 407 305 310 54 181 420 305 310 77

350 14” 184 448 350 355 80 222 483 350 355 117

400 16” 191 512 400 405 117 232 537 400 405 190

450 18” 203 547 450 455 138 264 594 450 455 200

500 20” 219 604 500 505 163 292 652 500 505 265

600 24” 222 715 600 605 331 318 772 600 605 410

650 26” 222 722 630 650 360 356 767 633 640 565

700 28” 305 773 700 700 380 368 821 685 685 585

750 30” 305 824 746 750 425 368 882 735 740 660

800 32” 305 878 796 800 560 368 936 784 784 970

900 36” 368 983 898 903 640 483 1044 873 880 1020

1000 40” 432 1090 976 985 870 546 1146 976 985 1420

1200 48” 524 1302 1200 1205 1400 629 1365 1166 1190 2260

1350 54” 591 1460 1312 1315 2245 718 1526 1312 1315 3102

1500 60” 660 1628 1458 1470 3200 838 1704 1458 1470 4315

*Face to face dimensions (L) herein are according to ASME B16.10.

*Flange dimensions (D) herein for sizes above DN600 (NPS24”) are according to ASME B16.47 Series B, Series A dimensions are available on request.

*More dimension specifications are available on request.

JFS reserves the right to change specifications without notice. 12

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

DIMENSION (Wafer type / 600 & 900 lb)

600lb 900lb

DN NPS

L D D2 D3 Est. Weight (kg) L D D2 D3 Est. Weight (kg)

50 2” 60 110 51 58 4 70 140 51 58 8

80 3” 73 147 80 88 8 86 165 80 90 14

100 4” 79 191 102 108 11 102 204 102 108 20

150 6” 136 264 152 162 26 159 286 150 162 42

200 8” 165 318 200 212 55 206 356 200 212 84

250 10” 213 398 250 266 95 241 432 250 266 145

300 12” 229 455 305 312 140 292 495 305 312 220

350 14” 273 490 337 355 223 356 518 337 355 350

400 16” 305 562 387 400 360 384 572 387 400 470

450 18” 362 610 438 450 395 451 635 438 450 605

500 20” 368 680 489 500 518 451 695 487 496 820

600 24” 438 786 591 600 836 495 835 591 600 1050

650 26” 457 761 633 640 950 533 835 617 630 1182

700 28” 483 815 684 690 1215 572 898 665 680 1441

750 30” 505 875 735 740 1378 635 955 712 75 1578

800 32” 533 928 779 784 1643 660 1012 760 784 2030

900 36” 635 1045 874 880 2120 718 1120 855 865 2607

*Face to face dimensions (L) herein are according to ASME B16.10.

*Flange dimensions (D) herein for sizes above DN600 (NPS24”) are according to ASME B16.47 Series B, Series A dimensions are available on request.

*More dimension specifications are available on request.

JFS reserves the right to change specifications without notice. 13

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

DIMENSION (Wafer type / 1500 & 2500 lb)

1500lb 2500lb

DN NPS

L D D2 D3 Est. Weight (kg) L D D2 D3 Est. Weight (kg)

50 2” 70 140 51 58 8 70 143 42 48 8

80 3” 83 172 80 90 19 86 194 62 68 8

100 4” 102 207 102 108 26 105 232 88 94 8

150 6” 159 280 150 162 68 159 315 150 162 8

200 8” 206 350 200 212 130 206 385 180 186 12

250 10” 248 433 254 266 210 254 474 225 232 12

300 12” 305 518 305 312 384 305 547 266 272 12

350 14” 356 576 337 355 550 - - - - -

400 16” 384 639 387 400 635 - - - - -

450 18” 468 701 430 438 790 - - - - -

500 20” 533 753 478 487 1275 - - - - -

600 24” 559 897 570 578 2710 - - - - -

*Face to face dimensions (L) herein are according to ASME B16.10.

*More dimension specifications are available on request.

JFS reserves the right to change specifications without notice. 14

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

DIMENSION (Wafer type / PN 10 & 16)

PN 10 PN 16

DN NPS

L D D2 D3 Est. Weight (kg) L D D2 D3 Est. Weight (kg)

50 2” 60 108 51 58 2 60 108 51 58 2

80 3” 73 142 80 88 4 73 142 80 88 4

100 4” 73 162 102 108 6 73 162 102 108 6

150 6” 98 218 152 160 13 98 218 152 160 13

200 8” 127 273 203 210 24 127 273 203 210 24

250 10” 146 328 254 266 37 146 328 254 266 37

300 12” 181 378 305 310 50 181 378 305 310 50

350 14” 184 438 350 355 76 184 438 350 355 76

400 16” 191 489 400 405 110 191 489 400 405 110

450 18” 203 539 450 455 135 203 539 450 455 135

500 20” 219 594 500 505 158 219 594 500 505 158

600 24” 222 696 600 605 320 222 696 600 605 320

700 28” 305 811 695 700 380 305 811 695 700 380

800 32” 305 918 796 800 560 305 918 796 800 560

900 36” 368 1018 898 903 640 368 1018 898 903 640

1000 40” 432 1124 976 985 900 432 1124 976 985 900

1200 48” 524 1340 1200 1205 1400 524 1340 1200 1205 1400

*More dimension specifications are available on request.

JFS reserves the right to change specifications without notice. 15

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

DIMENSION (Wafer type / PN 25 & 40)

PN 25 PN 40

DN NPS

L D D2 D3 Est. Weight (kg) L D D2 D3 Est. Weight (kg)

50 2” 60 108 51 58 2 60 108 51 58 3

80 3” 73 142 80 88 4 73 142 80 88 6

100 4” 73 168 102 108 6 73 168 102 108 8

150 6” 98 224 152 160 14 98 224 152 160 16

200 8” 127 284 203 210 27 127 291 203 210 28

250 10” 146 341 254 266 42 146 353 254 266 49

300 12” 181 401 305 310 54 181 418 305 310 76

350 14” 184 458 350 355 86 222 475 350 355 114

400 16” 191 515 400 405 120 232 547 400 405 190

450 18” 203 565 450 455 148 264 572 450 455 200

500 20” 219 622 500 505 165 292 626 500 505 260

600 24” 222 732 600 605 340 318 745 600 608 404

700 28” 305 831 695 700 400 - - - - -

800 32” 305 942 796 800 580 - - - - -

900 36” 368 1040 898 903 660 - - - - -

1000 40” 432 1155 976 985 960 - - - - -

1200 48” 524 1365 1200 1205 1440 - - - - -

*More dimension specifications are available on request.

JFS reserves the right to change specifications without notice. 16

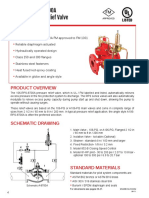

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

DIMENSION (Wafer type / PN 63 & 100)

PN 63 PN 100

DN NPS

L D D2 D3 Est. Weight (kg) L D D2 D3 Est. Weight (kg)

50 2” 60 114 51 58 4 60 120 51 58 5

80 3” 73 148 80 88 7 73 154 80 88 10

100 4” 79 174 102 108 10 79 181 102 108 12

150 6” 136 248 152 162 20 136 218 152 162 25

200 8” 165 310 200 212 38 165 258 200 212 56

250 10” 213 362 250 266 62 213 324 250 266 94

300 12” 229 422 305 310 100 229 392 305 312 142

350 14” 273 487 350 355 160 273 456 350 355 230

400 16” 305 541 400 405 260 305 510 400 405 366

*More dimension specifications are available on request.

JFS reserves the right to change specifications without notice. 17

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

DIMENSION (Lug type / 150 & 300 lb)

150lb 300lb

DN NPS

L D3 D4 Est. Weight L D2 D3 Est. Weight

50 2” 60 51 58 4 60 51 58 8

80 3” 73 80 88 4 73 80 88 8

100 4” 73 102 108 8 73 102 108 8

150 6” 98 152 160 8 98 152 160 12

200 8” 127 203 210 8 127 203 210 12

250 10” 146 254 266 12 146 254 266 16

300 12” 181 305 310 12 181 305 310 16

350 14” 184 350 355 12 222 350 355 20

400 16” 191 400 405 16 232 400 405 20

450 18” 203 450 455 16 264 450 455 24

500 20” 219 500 505 20 292 500 505 24

600 24” 222 600 605 20 318 600 605 24

750 30” 305 746 750 44 368 735 740 36

900 36” 368 898 903 44 483 873 880 32

1050 42” 432 1050 1055 48 568 1035 1045 36

1200 48” 524 1200 1205 44 629 1179 1190 40

*Face to face dimensions (L) herein are according to ASME B16.10.

*Flange dimensions (D1, D2) refer to Catalogue of Accessory: Series 8 – Flange.

*More dimension specifications are available on request.

JFS reserves the right to change specifications without notice. 18

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

DIMENSION (Lug type / 600 & 900 lb)

600lb 900lb

DN NPS

L D3 D4 Est. Weight L D2 D3 Est. Weight

50 2” 60 51 58 8 70 51 58 13

80 3” 73 80 88 8 86 80 90 21

100 4” 79 102 108 8 102 102 108 36

150 6” 136 152 162 12 159 150 162 92

200 8” 165 200 212 12 206 200 212 174

250 10” 213 250 266 16 241 250 266 264

300 12” 229 305 312 20 292 305 312 450

350 14” 273 337 355 20 356 337 355 612

400 16” 305 387 400 20 384 387 400 712

450 18” 362 438 450 20 451 438 450 1160

500 20” 368 489 500 24 451 487 496 1568

600 24” 438 591 600 24 495 591 600 1881

*Face to face dimensions (L) herein are according to ASME B16.10.

*Flange dimensions (D1, D2) refer to Catalogue of Accessory: Series 8 – Flange.

*More dimension specifications are available on request.

JFS reserves the right to change specifications without notice. 19

SERIES 3 CHECK VALVE JFS

DUAL FLAPPER CHECK VALVE

DIMENSION (Lug type / 1500 & 2500 lb)

1500lb 2500lb

DN NPS

L D3 D4 Est. Weight L D2 D3 Est. Weight

50 2” 60 51 58 8 70 42 48 8

80 3” 73 80 90 8 86 62 68 8

100 4” 79 102 108 8 105 88 94 8

150 6” 136 150 162 12 159 150 162 8

200 8” 165 200 212 12 206 180 186 12

250 10” 213 254 266 12 254 225 232 12

300 12” 229 305 312 16 305 266 272 12

350 14” 273 337 355 16 - - - -

400 16” 305 387 400 16 - - - -

*Face to face dimensions (L) herein are according to ASME B16.10.

*Flange dimensions (D1, D2) refer to Catalogue of Accessory: Series 8 – Flange.

*More dimension specifications are available on request.

JFS reserves the right to change specifications without notice. 20

Potrebbero piacerti anche

- Greenstar Oil System and Regular Boilers Technical and Specification InformationDocumento64 pagineGreenstar Oil System and Regular Boilers Technical and Specification InformationBabis PapadopoulosNessuna valutazione finora

- Knife Gate Valve: Product DescriptionDocumento2 pagineKnife Gate Valve: Product Descriptionviki851Nessuna valutazione finora

- Orbinox Ex PDFDocumento2 pagineOrbinox Ex PDFRio PurnamaNessuna valutazione finora

- Storagetech 100 Pressure Vacuum Relief Valve SMDocumento4 pagineStoragetech 100 Pressure Vacuum Relief Valve SMkhaled SAYEDNessuna valutazione finora

- DPCVDocumento4 pagineDPCVjamil voraNessuna valutazione finora

- Knife Gate Valve: Product DescriptionDocumento2 pagineKnife Gate Valve: Product DescriptionTamil SelvanNessuna valutazione finora

- Valves 1234Documento13 pagineValves 1234Goutham KSNessuna valutazione finora

- Econ Ball Valves Carbon Steel Stainless Steel 3 Way Port: Full Bore Blow-Out Proof StemDocumento1 paginaEcon Ball Valves Carbon Steel Stainless Steel 3 Way Port: Full Bore Blow-Out Proof StemChristianGuerreroNessuna valutazione finora

- Stainless Steel and Metal Hose (Section III) : Part No. Description Page NoDocumento10 pagineStainless Steel and Metal Hose (Section III) : Part No. Description Page NoVilius BukysNessuna valutazione finora

- Sakti Suria CatalogueDocumento112 pagineSakti Suria CatalogueChoon Wei WongNessuna valutazione finora

- Válvula de Cuchilla Cuerpo F.Dúctil + Disco Inox.316Documento2 pagineVálvula de Cuchilla Cuerpo F.Dúctil + Disco Inox.316jorgeproyectosperuNessuna valutazione finora

- Cast Steel WCB CF8M (316) Class 150: Butterfly Valve High PerformanceDocumento2 pagineCast Steel WCB CF8M (316) Class 150: Butterfly Valve High Performanceabdulaziz saif ali mansoorNessuna valutazione finora

- 300 - Model 1415 PDFDocumento2 pagine300 - Model 1415 PDFMEHDINessuna valutazione finora

- BAC SDB Ball Valves 3 or 4 Way Port Full Bore ANSI Class 150Documento1 paginaBAC SDB Ball Valves 3 or 4 Way Port Full Bore ANSI Class 150ChristianNessuna valutazione finora

- Butterfly Valves EgeplastDocumento4 pagineButterfly Valves EgeplastdsyashankaNessuna valutazione finora

- Bfs-Co-Ltd 29959 YezyivDocumento28 pagineBfs-Co-Ltd 29959 YezyivHisham ABD ALRASOULNessuna valutazione finora

- Datasheet 102 103 202 203 302 303 Flange SealDocumento5 pagineDatasheet 102 103 202 203 302 303 Flange SealD. Thanh NguyễnNessuna valutazione finora

- Knife Gate Valve: Product DescriptionDocumento2 pagineKnife Gate Valve: Product DescriptionVinay Kumar SahuNessuna valutazione finora

- BAC LD Butterfly Valves Lugged Type Carbon Steel/stainless Steel ANSI Class 150 and 300Documento1 paginaBAC LD Butterfly Valves Lugged Type Carbon Steel/stainless Steel ANSI Class 150 and 300ChristianNessuna valutazione finora

- Gate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsDocumento2 pagineGate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsJavier Hinojosa Garrido LeccaNessuna valutazione finora

- Ball Valve PN63 ErhardDocumento1 paginaBall Valve PN63 ErhardM MNessuna valutazione finora

- Model 3334SS-4003 Model 3334SS StandardDocumento4 pagineModel 3334SS-4003 Model 3334SS StandardErick MelendezNessuna valutazione finora

- 3.3 Valvula Os&y - SanfloDocumento2 pagine3.3 Valvula Os&y - SanfloYhonny ValenzuelaNessuna valutazione finora

- 9-10. Check ValveDocumento2 pagine9-10. Check ValveCost RootsNessuna valutazione finora

- PDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"Documento11 paginePDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"pablopasqualini18Nessuna valutazione finora

- Uni FlangeDocumento8 pagineUni FlangeBobbie RuckNessuna valutazione finora

- Wafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design DescriptionsDocumento2 pagineWafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design Descriptionsmigaspro energiaNessuna valutazione finora

- Cast Iron Foot Valves: Features MaterialsDocumento1 paginaCast Iron Foot Valves: Features MaterialsAnonymous ehqz93YNessuna valutazione finora

- Wafer Butterfly ValvesDocumento8 pagineWafer Butterfly ValvesTerry SmithNessuna valutazione finora

- 25 SP650 1 MS Series SeparatorsDocumento2 pagine25 SP650 1 MS Series SeparatorsLa Ode AdhanNessuna valutazione finora

- Liku-Tech - Accessories - V2 PDFDocumento5 pagineLiku-Tech - Accessories - V2 PDFAjay Krishna MNessuna valutazione finora

- V31 Flanged OSY Gate ValveDocumento1 paginaV31 Flanged OSY Gate ValveRolando CerezoNessuna valutazione finora

- Check Valves WaferDocumento1 paginaCheck Valves WaferwfjerrNessuna valutazione finora

- Catalogo StafsjoDocumento12 pagineCatalogo StafsjoBruno Bassotti SilveiraNessuna valutazione finora

- K-823-A, SCVDocumento1 paginaK-823-A, SCVamir shokrNessuna valutazione finora

- Maverick Valves CatalogueDocumento84 pagineMaverick Valves Cataloguer4mms3sNessuna valutazione finora

- Model 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesDocumento3 pagineModel 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesCandela BarbisanNessuna valutazione finora

- Silent Check Valve - Wafer and Globe Style - 2012Documento8 pagineSilent Check Valve - Wafer and Globe Style - 2012james_chan2178Nessuna valutazione finora

- Gate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature RatingsDocumento2 pagineGate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature Ratingsjaponesito01Nessuna valutazione finora

- Prextherm 107-470 (B)Documento4 paginePrextherm 107-470 (B)dragosm78Nessuna valutazione finora

- YFT - From 150 To 900Documento1 paginaYFT - From 150 To 900rodolfostiNessuna valutazione finora

- Technical Data: Globe Valve - AngleDocumento1 paginaTechnical Data: Globe Valve - Angledona gangulyNessuna valutazione finora

- Flexible Connectors Flanged - PCSSF Series: Features Standard MaterialsDocumento1 paginaFlexible Connectors Flanged - PCSSF Series: Features Standard MaterialsRamon De los ReyesNessuna valutazione finora

- De Va: Series D65/D69Documento2 pagineDe Va: Series D65/D69AZMATNessuna valutazione finora

- Valvula de Compuerta Crane 2.5Documento1 paginaValvula de Compuerta Crane 2.5Juan Arturo Hernandez RuizNessuna valutazione finora

- Series 3 & 4 U BonnetedDocumento9 pagineSeries 3 & 4 U BonnetedBaskaran RathinamNessuna valutazione finora

- KW900WFPDocumento1 paginaKW900WFPAlfredo BravoNessuna valutazione finora

- Removable Cover Check Valves For Potable Water Pump StationsDocumento4 pagineRemovable Cover Check Valves For Potable Water Pump StationsOleg ShkolnikNessuna valutazione finora

- Cast Iron Swing Check Valves With Counter Weight and Lever PN 10 and 16Documento2 pagineCast Iron Swing Check Valves With Counter Weight and Lever PN 10 and 16Baskaran RathinamNessuna valutazione finora

- Strainer InformationDocumento4 pagineStrainer InformationmusaveerNessuna valutazione finora

- Ivc Valves PDFDocumento4 pagineIvc Valves PDFNaveen ReddyNessuna valutazione finora

- Filvalco PRVDocumento1 paginaFilvalco PRVForhad AhmedNessuna valutazione finora

- Wafer Style Twin Disc Ductile Iron Check ValveDocumento1 paginaWafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNessuna valutazione finora

- Y-Pattern Strainer Cast Steel A216 WCB Class 300: Pressure Temperature RatingsDocumento2 pagineY-Pattern Strainer Cast Steel A216 WCB Class 300: Pressure Temperature RatingsjeanNessuna valutazione finora

- Insualting Joint Brochure Rev.1 FinalDocumento2 pagineInsualting Joint Brochure Rev.1 FinalKRUNAL SHAHNessuna valutazione finora

- Kingston Model 115: Kingston Safety & Relief ValvesDocumento2 pagineKingston Model 115: Kingston Safety & Relief ValvesAntonio SerranoNessuna valutazione finora

- Fire Valves PDFDocumento24 pagineFire Valves PDFSajjadNessuna valutazione finora

- ATEX Wall Chart Reduced PDFDocumento1 paginaATEX Wall Chart Reduced PDFVassoula Dar100% (1)

- C-00 & Er 91april - May-2012Documento39 pagineC-00 & Er 91april - May-2012John SandaNessuna valutazione finora

- TDS Gazpromneft Premium С3 5W-30 5W-40 engDocumento2 pagineTDS Gazpromneft Premium С3 5W-30 5W-40 engAdam R.R.Nessuna valutazione finora

- Activities On AC Motors in 2007Documento22 pagineActivities On AC Motors in 2007CarlosNessuna valutazione finora

- Boe (Boiler Operation Engineer) Short Type Question Answer For Examination - AskpowerplantDocumento15 pagineBoe (Boiler Operation Engineer) Short Type Question Answer For Examination - AskpowerplantRaju MaityNessuna valutazione finora

- Fans SoftDocumento291 pagineFans SoftAmitava PalNessuna valutazione finora

- Indian Automobile Sector Analysis January 2023 1693838553Documento1 paginaIndian Automobile Sector Analysis January 2023 1693838553Rohit PareekNessuna valutazione finora

- Short Wave DiathermyDocumento2 pagineShort Wave DiathermyAkshat Singh100% (1)

- Recovery PDFDocumento164 pagineRecovery PDFAzizi AbdullahNessuna valutazione finora

- BS en 1096-3-2012 - (2022-08-18 - 04-11-32 Am)Documento22 pagineBS en 1096-3-2012 - (2022-08-18 - 04-11-32 Am)Free MouseNessuna valutazione finora

- Automation Direct - An Industry Guide To Control System EngineeringDocumento93 pagineAutomation Direct - An Industry Guide To Control System EngineeringCesar CamachoNessuna valutazione finora

- Ib Physics Ch11Documento2 pagineIb Physics Ch11JoseManuelCuelloSantínNessuna valutazione finora

- Ci Ride Leader - Guide To Cycling On The Road PDFDocumento10 pagineCi Ride Leader - Guide To Cycling On The Road PDFΑυτός είμαι εγώNessuna valutazione finora

- FY B.Sc. Light Reactions IDocumento5 pagineFY B.Sc. Light Reactions IVijendraNessuna valutazione finora

- Booster Basics PresentationDocumento49 pagineBooster Basics PresentationbinhjukiNessuna valutazione finora

- Comparison of FACTS Devices For Power System Stability EnhancementDocumento6 pagineComparison of FACTS Devices For Power System Stability Enhancementrishabhshah2412Nessuna valutazione finora

- Diode (Semicond) - PART ADocumento30 pagineDiode (Semicond) - PART Anur ain natasyaNessuna valutazione finora

- Doordarshan ReportDocumento18 pagineDoordarshan ReportSajal DasNessuna valutazione finora

- Information & Operations Manual For Bavaria Cruiser 37Documento37 pagineInformation & Operations Manual For Bavaria Cruiser 37RDNessuna valutazione finora

- 1st Yr Lec3Documento16 pagine1st Yr Lec3abhijeetnarkhede69198Nessuna valutazione finora

- Your Guide To Hydraulic FracturingDocumento1 paginaYour Guide To Hydraulic FracturingMartin GriffinNessuna valutazione finora

- Lnk584-586 Linkzero-Ax: Zero Standby Consumption Integrated Off-Line SwitcherDocumento16 pagineLnk584-586 Linkzero-Ax: Zero Standby Consumption Integrated Off-Line Switchershiva1luNessuna valutazione finora

- 59529-Especificaciones para Preservacion EquiposDocumento65 pagine59529-Especificaciones para Preservacion EquiposrodolfostiNessuna valutazione finora

- Nükleer Tesi̇s DenetlemeDocumento276 pagineNükleer Tesi̇s DenetlemeSuphi YükselNessuna valutazione finora

- Wave Energy Conversion#Documento3 pagineWave Energy Conversion#DimSolNessuna valutazione finora

- D10.4 R1986PVDocumento7 pagineD10.4 R1986PVGabriela AxinteNessuna valutazione finora

- Sales Training Slides - NetSure 501 AC0 (Actura Flex 48420)Documento63 pagineSales Training Slides - NetSure 501 AC0 (Actura Flex 48420)chkimkimNessuna valutazione finora

- Dimmer SchneiderDocumento4 pagineDimmer SchneiderBog PenNessuna valutazione finora