Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pump start-up checklist

Caricato da

Gilver ApazaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pump start-up checklist

Caricato da

Gilver ApazaCopyright:

Formati disponibili

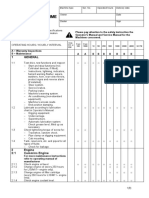

PROCEDURE CHECKLIST FOR START-UP

AMP Representative Representative Phone Number

Contractor Contractor Phone Number

Project Engineer ________________________________ Project Engineer Phone Number

Project Name___________________________________ Pump Location

Equipment Information

Pump Model Pump Serial Number

Motor: Mfg Model Serial Number

Engine: Mfg Model Serial Number

Gear Drive: Mfg Model Serial Number

Design Conditions

Flow TDH Drive RPM Drive HP Voltage Phase

Procedure Yes No N/A Comments

1. Prestart-Up

Has the procedure checklist for prestart-up been completed? □ □ □

Verify motor rotation □ CW □ CCW

2. Impeller Setting

Has impeller been properly adjusted? □ □ □

Lateral impeller setting for vertical turbine pump - Inches

Impeller setting for end suction pump - Inches

3. Lubrication

Have the bearing been properly lubricated? □ □ □

Oil lubricated vertical turbine pump - Drips per minute

Water flush vertical turbine pump - Minutes solenoid open

Type of pump ball bearing lubrication □ Oil □ Grease

Has the coupling been properly lubricated? □ □ □

Have the motors been properly lubricated? □ □ □

Type of pump ball bearing lubrication □ Oil □ Grease

4. System

Has flow been established? □ □ □

Have gauge readings been taken? □ □ □

Is excessive vibration present? □ □ □

Is bearing operating temperature excessive? □ □ □

5. Sealing Device

□ Mechanical Sealed □ Packed □ Other

Mechanical seal Mfg./Model

Is the API flush plan operable? □ □ □

Is seal lubricant pressure a constant 10 psi above discharge pressure? □ □ □

Has packing been adjusted to insure proper lubrication of packing? □ □ □

Installation of American-Marsh supplied equipment is acceptable.

Responsibility for operation and maintenance of the pump station by owner.

Customer’s Representative Witnessing Start-Up American-Marsh Pumps Representative Conducting Start-Up

Name Date Name Date

Potrebbero piacerti anche

- Intervalos de ServicioDocumento2 pagineIntervalos de ServicioAlejandro ValenzuelaNessuna valutazione finora

- Catalogo Patrol 672GDocumento4 pagineCatalogo Patrol 672GJulio cesarNessuna valutazione finora

- Check List Commissioning Report For Genset&AuxilaryDocumento12 pagineCheck List Commissioning Report For Genset&AuxilaryBoris SitorusNessuna valutazione finora

- Maintenance Tips for WD615 Diesel EnginesDocumento43 pagineMaintenance Tips for WD615 Diesel Enginesferanba100% (1)

- Owner's Manual & Service Records: Downloaded From Manuals Search EngineDocumento57 pagineOwner's Manual & Service Records: Downloaded From Manuals Search EngineVishnu RajNessuna valutazione finora

- FG Wilson India Operator (2 Cyl) PDFDocumento69 pagineFG Wilson India Operator (2 Cyl) PDFviraj arjun ghadageNessuna valutazione finora

- Copie de Start Up and Commissioning Checklist 1Documento7 pagineCopie de Start Up and Commissioning Checklist 1Amin ThabetNessuna valutazione finora

- Detroit DD15 Falla Freno de MtorDocumento4 pagineDetroit DD15 Falla Freno de Mtorcristian picadoNessuna valutazione finora

- Patriot 2008 2.4LDocumento260 paginePatriot 2008 2.4LCynthia MartinezNessuna valutazione finora

- Method Statement For Testing Precommissioning & Commissioning of Fuel Oil PumpsDocumento3 pagineMethod Statement For Testing Precommissioning & Commissioning of Fuel Oil Pumpsvin ssNessuna valutazione finora

- JGD4-L7044GSI Bangladesh Proposal PDFDocumento4 pagineJGD4-L7044GSI Bangladesh Proposal PDFmd. shahinNessuna valutazione finora

- Lycoming Reciprocating engine Break-In and Oil Consumption (1) (1)Documento7 pagineLycoming Reciprocating engine Break-In and Oil Consumption (1) (1)Christian Enrique Casique PajarNessuna valutazione finora

- Vehicle Checklist Form for Subic Bay FreeportDocumento2 pagineVehicle Checklist Form for Subic Bay FreeportMiguel Benedict GarciaNessuna valutazione finora

- AT2403 Vehicle Maintenance RecordsDocumento58 pagineAT2403 Vehicle Maintenance RecordsPethuraj100% (1)

- Engine Installation and Tuning Tips: Jetting Jetting Octane Temp. Altitude Front RearDocumento3 pagineEngine Installation and Tuning Tips: Jetting Jetting Octane Temp. Altitude Front ReargitmeNessuna valutazione finora

- Repair Options: Cat 777D Off-Highway TruckDocumento4 pagineRepair Options: Cat 777D Off-Highway TruckmkNessuna valutazione finora

- School of Mechanical Engineering Automobile Maintenance CourseDocumento93 pagineSchool of Mechanical Engineering Automobile Maintenance Coursejalda srikaranNessuna valutazione finora

- Maintenance Interval CaymanDocumento4 pagineMaintenance Interval CaymanJZM GulfNessuna valutazione finora

- Maintenance Table - 6161Documento2 pagineMaintenance Table - 6161Kushal KarNessuna valutazione finora

- PRM Owners HandbookDocumento22 paginePRM Owners HandbookOS-CARS LTDA100% (1)

- 460E - ADT - Uptime Maintenance PlannerDocumento3 pagine460E - ADT - Uptime Maintenance PlannerBassieNessuna valutazione finora

- Generaror Inspection ChecklistDocumento1 paginaGeneraror Inspection Checklistyibelta abebeNessuna valutazione finora

- Vehicle Inspection ChecklistDocumento1 paginaVehicle Inspection ChecklistAvishekh SharmaNessuna valutazione finora

- Commissioning Procedure - Man Genset (LCS)Documento13 pagineCommissioning Procedure - Man Genset (LCS)Umair A. KhanNessuna valutazione finora

- 2019 BEACON Product List PDFDocumento106 pagine2019 BEACON Product List PDFMiguel Angel Alvarado Alarcon100% (1)

- Schwing Concrete Pumps and MixersDocumento4 pagineSchwing Concrete Pumps and Mixersli geneNessuna valutazione finora

- Installation Check-Up and Commissioning Report: Large Diesel D25 D65Documento24 pagineInstallation Check-Up and Commissioning Report: Large Diesel D25 D65Naing Min HtunNessuna valutazione finora

- Pever MauldinDocumento22 paginePever Mauldinzae nurdin100% (1)

- Job Completion Report Presentation - Conventional RigDocumento16 pagineJob Completion Report Presentation - Conventional Rigmnscsc713321Nessuna valutazione finora

- GW491QE Petrol Engine Service Manual Lubrication+systemDocumento7 pagineGW491QE Petrol Engine Service Manual Lubrication+systemAlbert BriceñoNessuna valutazione finora

- 2.4l EngineDocumento237 pagine2.4l EngineRene SanchezNessuna valutazione finora

- Intech Pumps Maintenance Training for Diesel & Service Water PumpsDocumento15 pagineIntech Pumps Maintenance Training for Diesel & Service Water Pumpsfirdausshukri14Nessuna valutazione finora

- TMP XAPRtLDocumento17 pagineTMP XAPRtLengmohsen.ramadanhotmail.comNessuna valutazione finora

- Periodical Service KOMATSU D155-6: Maintenance SheetDocumento2 paginePeriodical Service KOMATSU D155-6: Maintenance SheetAndaru GunawanNessuna valutazione finora

- Vehicle Maintenance ManualDocumento51 pagineVehicle Maintenance ManualIbaadNessuna valutazione finora

- 3 10Documento9 pagine3 100lucasschmidtNessuna valutazione finora

- Sample Centrifugal Fire Pump Acceptance Test FormDocumento4 pagineSample Centrifugal Fire Pump Acceptance Test Formchylerg67% (3)

- Uptime Maintenance Planner: Service IntervalsDocumento3 pagineUptime Maintenance Planner: Service IntervalsBrian CareelNessuna valutazione finora

- 2.4 L ENGINEDocumento279 pagine2.4 L ENGINEJuan MederosNessuna valutazione finora

- Installation Guide & Operators ManualDocumento132 pagineInstallation Guide & Operators ManualMauricio OlayaNessuna valutazione finora

- Compass 2008 2.0LDocumento234 pagineCompass 2008 2.0LDavid Ulloa SalazarNessuna valutazione finora

- Service Program - CE Excapator KOREADocumento8 pagineService Program - CE Excapator KOREAtele123Nessuna valutazione finora

- TA1 Visual Hydraulic Excavator InspectionDocumento13 pagineTA1 Visual Hydraulic Excavator InspectionJoel RodríguezNessuna valutazione finora

- Qa10 PS GD535-5Documento3 pagineQa10 PS GD535-5Andaru GunawanNessuna valutazione finora

- Toyota Pickup Hilux PMDocumento10 pagineToyota Pickup Hilux PMalexberhane3Nessuna valutazione finora

- Porsche 911 Service Guide for 8 CountriesDocumento8 paginePorsche 911 Service Guide for 8 CountriesedNessuna valutazione finora

- Understanding Pump Performance: Advantage by KnowledgeDocumento29 pagineUnderstanding Pump Performance: Advantage by KnowledgeArman ManguerraNessuna valutazione finora

- Si 1427b Bolein Asentamieno de MoorDocumento7 pagineSi 1427b Bolein Asentamieno de MoorAnonymous rvAn04wk1YNessuna valutazione finora

- Engine Brake DD15Documento7 pagineEngine Brake DD15Hamilton miranda100% (1)

- Service Programme Checklist-Wide Body Dump TruckDocumento6 pagineService Programme Checklist-Wide Body Dump TruckRandi rNessuna valutazione finora

- RP2 Manual2 - 1Documento171 pagineRP2 Manual2 - 1Jonathan maximiliano0% (1)

- Scherzinger Flow Dividers and ValvesDocumento8 pagineScherzinger Flow Dividers and ValvesAbdNessuna valutazione finora

- Machine Inspection Manual (Work Flow)Documento6 pagineMachine Inspection Manual (Work Flow)Erfan.TNessuna valutazione finora

- DG Commissioning ProcedureDocumento2 pagineDG Commissioning ProcedureBabu100% (1)

- Periodical Service Scania P380: Maintenance SheetDocumento2 paginePeriodical Service Scania P380: Maintenance SheetWanda Panggih KurniawanNessuna valutazione finora

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsDa Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsValutazione: 1 su 5 stelle1/5 (1)

- Outboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairDa EverandOutboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairValutazione: 3 su 5 stelle3/5 (1)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDa EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreValutazione: 4.5 su 5 stelle4.5/5 (11)

- Ekhart BrassDocumento2 pagineEkhart BrassGilver ApazaNessuna valutazione finora

- Faltech Linea de AnclajeDocumento1 paginaFaltech Linea de AnclajeGilver ApazaNessuna valutazione finora

- Faltech Linea de AnclajeDocumento1 paginaFaltech Linea de AnclajeGilver ApazaNessuna valutazione finora

- Oilskimmer 6V PDFDocumento4 pagineOilskimmer 6V PDFGilver ApazaNessuna valutazione finora

- Ekhart BrassDocumento2 pagineEkhart BrassGilver ApazaNessuna valutazione finora

- Pump start-up checklistDocumento1 paginaPump start-up checklistGilver ApazaNessuna valutazione finora

- The Mpeg Dash StandardDocumento6 pagineThe Mpeg Dash Standard9716755397Nessuna valutazione finora

- Unit 3: The Catering Service Industry Topic: Catering Service Concept Digest (Discussion)Documento5 pagineUnit 3: The Catering Service Industry Topic: Catering Service Concept Digest (Discussion)Justin MagnanaoNessuna valutazione finora

- Electricity BillDocumento1 paginaElectricity BillSushila SinghNessuna valutazione finora

- Solar Winds OrionAPM DatasheetDocumento4 pagineSolar Winds OrionAPM DatasheetArun J D'SouzaNessuna valutazione finora

- ReportDocumento4 pagineReportapi-463513182Nessuna valutazione finora

- Regulations 2020: Mechanical Engineering CurriculumDocumento162 pagineRegulations 2020: Mechanical Engineering CurriculumdsathiyaNessuna valutazione finora

- Public Relations Proposal Template: Executive SummaryDocumento3 paginePublic Relations Proposal Template: Executive SummaryErmi SusilowatiNessuna valutazione finora

- Training and Development Project Report - MessDocumento37 pagineTraining and Development Project Report - MessIqra Bismi100% (1)

- Introduction To Management: Planning & Goal SettingDocumento31 pagineIntroduction To Management: Planning & Goal SettingMaisarah NorzihanNessuna valutazione finora

- Manage Hospital Records with HMSDocumento16 pagineManage Hospital Records with HMSDev SoniNessuna valutazione finora

- Modelo de NDA (English)Documento2 pagineModelo de NDA (English)Jorge Partidas100% (3)

- CLS1Documento3 pagineCLS1Shaina Kaye De GuzmanNessuna valutazione finora

- Module 1 (Social Innovation)Documento7 pagineModule 1 (Social Innovation)Marinette Medrano50% (2)

- Energy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefDocumento8 pagineEnergy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefSalomonlcNessuna valutazione finora

- DB51 BTP 160 8PDocumento1 paginaDB51 BTP 160 8Pnagaraj.ss@quest-global.comNessuna valutazione finora

- Customer Channel Migration in Omnichannel RetailingDocumento80 pagineCustomer Channel Migration in Omnichannel RetailingAlberto Martín JiménezNessuna valutazione finora

- Nikita Project 01-06-2016Documento38 pagineNikita Project 01-06-2016Shobhit GoswamiNessuna valutazione finora

- Armed Struggle in Africa (1969)Documento167 pagineArmed Struggle in Africa (1969)Dr.VolandNessuna valutazione finora

- Guidelines For Planning Conjunctive Use of SUR Face and Ground Waters in Irrigation ProjectsDocumento34 pagineGuidelines For Planning Conjunctive Use of SUR Face and Ground Waters in Irrigation Projectshram_phdNessuna valutazione finora

- What is a Server ClusterDocumento2 pagineWhat is a Server Clusterfikru tesefayeNessuna valutazione finora

- ROUTERDocumento26 pagineROUTERIsraelNessuna valutazione finora

- Everything You Need to Know About Distribution TransformersDocumento2 pagineEverything You Need to Know About Distribution TransformersDONNYMUCKTEENessuna valutazione finora

- Chapter-5-Entrepreneurial-Marketing Inoceno de Ocampo EvangelistaDocumento63 pagineChapter-5-Entrepreneurial-Marketing Inoceno de Ocampo EvangelistaMelgrey InocenoNessuna valutazione finora

- Interpretation 1Documento17 pagineInterpretation 1ysunnyNessuna valutazione finora

- TT1 2lecture SpinningDocumento29 pagineTT1 2lecture SpinninghaiNessuna valutazione finora

- Section 2 in The Forest (Conservation) Act, 1980Documento1 paginaSection 2 in The Forest (Conservation) Act, 1980amit singhNessuna valutazione finora

- Siemens ProjectDocumento17 pagineSiemens ProjectMayisha Alamgir100% (1)

- Direct FileActDocumento17 pagineDirect FileActTAPAN TALUKDARNessuna valutazione finora

- Econometrics ProjectDocumento17 pagineEconometrics ProjectAkash ChoudharyNessuna valutazione finora

- Cough: by Dr. Meghana Patil (Intern Batch 2016)Documento24 pagineCough: by Dr. Meghana Patil (Intern Batch 2016)Meghana PatilNessuna valutazione finora