Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Liftingplan Accommodation

Caricato da

arunDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Liftingplan Accommodation

Caricato da

arunCopyright:

Formati disponibili

THE RED SEA DEVELOPMENT COMPANY (TRSDC)

DESIGN & BUILD

5,000 WORKERS ACCOMMODATION VILLA

CONSTRUCTION

METHOD STATEMENT FOR LIFTING OF

ACCOMMODATION UNITS SINGLE & DOBLE STORY

CODE DESCRIPTION

1 WORK MAY PROCEED

REVISE AND RESUBMIT WORK MAY PROCEED SUBJECT

2

TO INCORPORATION OF CHANGES INDICATED

3 REVISE AND RESUBMIT. WORK MAY NOT PROCEED

4 REVIEW NOT REQUIRED FOR INFO ONLY

5 CANCELLED / DELETED

Name:

Date:

Signature:

A 28 Oct 2019 DE AR PR Issued for Approval

REV. DATE ORIGINATOR REVIEWED APPROVED DESCRIPTION

THIS DOCUMENT IS INTENDED FOR USE BY ARCCO/SPEEDHOUSE JV AND ITS NOMINATED CONSULTANTS, CONTRACTORS, MANUFACTURERS AND

SUPPLIERS.

ORIGINATOR:

ARCCO / SPEEDHOUSE JV REV 1 Discipline

DOC No:R11-T02B02-ASH-MTS-CI-0020 00 Civil

Revision Description

Rev. No. Section Revision Description

A All Issued for Approval

HOLDS

Rev. No. Section Description

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 2OF 13

Table of Contents

1.0 PURPOSE ....................................................................................................................................................4

2.0 SCOPE .........................................................................................................................................................4

3.0 DEFINITIONS .............................................................................................................................................4

4.0 EQUIPMENTS.............................................................................................................................................4

5.0 RESPONSIBILITY ......................................................................................................................................4

6.0 COMPETENT RIGGER ..............................................................................................................................5

7.0 PRE LIFT CHECK .......................................................................................................................................5

8.0 PROCEDURE AND METHOD...................................................................................................................6

9.0 ATTACHMENTS ........................................................................................................................................7

9.1 SITE EXECUTION PLAN. .....................................................................................................................7

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 3OF 13

1.0 PURPOSE

This procedure details the control measure to be applied when using mobile

cranes to lift, load and install modular accommodation units.

2.0 SCOPE

This procedure applies to the use of mobile cranes which normally lift loads

independently. This procedure applies to lift.

3.0 DEFINITIONS

3.1 COMPANY The Red Sea Development Company

3.2 CONTRACTOR ARCCO / SPEEDHOUSE JV

4.0 EQUIPMENT

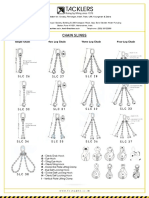

4.1 CRANE & LIFTING ACCESSORIES

For the purpose of this procedure, a crane is defined as the equipment

or machinery used to lift materials and units into place, and such

equipment and its operator must have third party certifications.

All lifting accessories like slings, D-shackles must be proof load tested

and have third party inspected certificates prior to enter the site.

All lifting gear shall be inspected daily by Riggers and log sheet shall be

maintained. Color code for the month shall be wrapped around the lifting gear.

Any damaged lifting gear shall be marked "Not fit for use" and then removed

from site.

5.0 RESPONSIBILITY

5.1 Contractor Site Engineer in conjunction with the HSE Officer, Supervisor /

Foreman shall be responsible for overall execution of the works carried out

during the lifting operations.

5.2 The Certified competent lifting operations supervisor is directly responsible for

the lifting activities carried out on site.

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 4OF 13

5.3 Contractor Civil Engineer is responsible for verifying the soil condition and the

underground services.

5.4 Contractor HSE officer shall be responsible for verifying the crane, operator and

rigger valid certificates before lifting commence.

5.5 Crane operators with valid certification authorized to operate the class of

equipment as noted on the certification.

5.6 Only Crane operators with valid certification will be authorized to operate cranes

on site.

5.7 The crane operator is responsible for Complying with all applicable regulations

and codes of practice including customer restrictions and TRSDC job site-

specific requirements.

5.8 Operating cranes and heavy lift equipment within the specifications provided by

the manufacturer, operator manuals, load charts, and operator notes.

5.9 This includes pre-start and post-start inspection, maneuvering skills, shutdown

and Securing procedure.

6.0 COMPETENT RIGGER

The competent rigger is responsible for completing the pre-lift safety checklist

and performing rigging in accordance with TRSDC Procedure and applicable

regulations, including customer restrictions and job-site specific requirements, as

necessary. He shall identify and predict hazards in the surroundings or working

conditions and take prompt corrective measures to eliminate or correct them.

7.0 PRE LIFT CHECK

7.1 For all lifting made with the crane the competent lifting operations supervisor,

Rigger and Crane Operators shall follow the pre lift safety checklist prior to job

execution.

7.2 Site HSE officer shall complete the pre lift safety check list prior to starting of

the lifting activities.

7.3 The Site HSE officer shall examine the records to establish that the crane is

certified thorough a TRSDC approved agency and examination issued within the

last 12 months with current boom certification.

7.4 The crane operators shall perform a daily Crane inspection in accordance with

crane manufacturers recommendations to ensure the lifting equipment and

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 5OF 13

systems are in good condition and do not require repair, adjustment, or

lubrication prior to use.

7.5 The crane operator shall also ensure that the outriggers of the crane are fully

extended and that displacement pads are in place.

7.6 A pre-lift discussion shall take place between Erection Supervisor, the rigging

crew and equipment operators prior to making the lifting. Clear communication

between the crane operators and the rigging crew shall be emphasized.

7.7 Lifting operations supervisor shall ensure that tag lines are attached to the load,

ensure that temporary barricades are placed around the work area and that

adjacent work crews are notified of the rigging work operations.

8.0 PROCEDURE AND METHOD

8.1 PLANNING

Lifting operations should always be planned and a written work plan

should be produced in advance by a competent lifting operations

supervisor who is conversant with this procedure.

Operators of cranes being used to carry out the Lifting must be trained,

assessed and certified from a third party agencies acknowledged by

TRSDC and conversant with the contents of this procedure.

During the operation of crane lifting, Safe Working Load and radius

should not be exceeded at any time.

The individual lifting plans must show the weight capacity of the

slings and shackles, how far the boom will be extended and the radius

it will be operated at in order to confirm a safe lift according to the

load chart prior to the lifting operation.

Initially the load should only be lifted 1 meter off the ground to ensure

proper slinging and balance prior to allowing lifting to continue. The

1 meter lift will be a hold point for verification.

8.2 SITE WORK

The competent lifting operations supervisor and rigger must be

trained, assessed and certified as competent in Lifting by TRSDC

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 6OF 13

approved certificate issuing agency.

One more Rigger shall be engaged in case of any obstruction of direct

vision between Crane operator and Rigger.

Before any Lifting commences the operation controller must ensure

that the operators have a clear understanding about the work to be

undertaken and the communications to be used, as well as the

procedures being adopted. Banks man /signal man / competent riggers

shall be identified for lifting operation and tool box talks to be

conducted prior to lift, discussing the lift plan and risk associated with

the lifts.

If any Ladders are used to rich the lifting points in order to secure the

straps, 3- point contact must be maintained at all times.

Any tools that might be used when working at heights must be secured

by lanyard.

9.0 ATTACHMENTS

9.1 LIFTING EQUPMENT TEST CERTIVICATES

9.2 DRAWINGS OF LIFTING DETIAL.

9.3 CRANE OPERATOR DAILY CHECK LIST.

9.1 SITE EXECUTION PLAN FOR PLACEMENT & INSTALATION OF

ACCOMMODATION UNITS.

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 7OF 13

Following the step by step site execution plan for the Accommodation units.

Check dimensions and level of prefabricated foundation pears set out on site.

Position crane next to foundation setup within rich of offloading area.

Move truck with the building into position.

With the use of a certified spreader bar, lifting hook extensions and lifting equipment,

lift the unit from the truck with guide lines on opposing corners.

Swing the unit into position over the foundations controlling it with the guide lines.

Slowly lower the unit onto the foundations insuring it is in the right position.

If it is a building consisting of multiple units, proceed in the same manner with the

second, third and fourth ground floor units.

Position each unit next to the previously placed one and lower into position.

With all the ground floor units in place and leveled.

Proceed in the same manner lifting the first floor units into place one by one and placing

them on top of the ground floor units as per the building layout.

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 8OF 13

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 9OF 13

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 10OF 13

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 11OF 13

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 12OF 13

LIFTING & VERTICAL TRANSPORTATION EQUIPMENT - CHECKLIST

LOCATION / AREA:

Sl.

Activities / Items to be Inspected Remarks by Safety staff

No.

1 Condition of carnage and hoisting

equipment

2 Valid certification of carnage and

hoisting equipment

3 Competency of crane and hoist

operators

4

Effective use of trained banks men

5

Use of outriggers and floats

6 Equipment storage, issuing and

receiving.

7

Colour Code

General / specific observations:

CONTRACTOR– SAFETY ENGR. APPROVAL

SIGNATURE

NAME

DESIGNATION

DATE

METHOD STATEMENT DOC. NO. R11-T02B02-ASH-MTS-CI-0020

FOR LIFTING OF

ACCOMMODATION REV. 00 DATE: 28 Oct 2019

UNITS PAGE 13OF 13

Potrebbero piacerti anche

- Chapter 1 To 23 Ques-AnswersDocumento13 pagineChapter 1 To 23 Ques-AnswersRasha83% (12)

- Risk Assessment 2 PDFDocumento15 pagineRisk Assessment 2 PDFarunNessuna valutazione finora

- Lifting Procedure PDFDocumento25 pagineLifting Procedure PDFAhmad Husnul MutaqinNessuna valutazione finora

- Risk Assessment Form - RadiographyDocumento3 pagineRisk Assessment Form - RadiographyIndermohan Mehta0% (1)

- Crane LiftsDocumento1 paginaCrane LiftsJasonNessuna valutazione finora

- Rigging Equipment Inspection FormDocumento4 pagineRigging Equipment Inspection FormWaqar AhmedNessuna valutazione finora

- Code of EthicsDocumento13 pagineCode of EthicsnelzerNessuna valutazione finora

- Construction Risk Assessment PackDocumento41 pagineConstruction Risk Assessment Packmasoodae100% (4)

- Crane Hoist Sling Safety ProgramDocumento14 pagineCrane Hoist Sling Safety Programomar sadiqNessuna valutazione finora

- LP 1T Pipes Critical Crane Lift Plan 25T Crane CPFDocumento1 paginaLP 1T Pipes Critical Crane Lift Plan 25T Crane CPFMPS PSKNessuna valutazione finora

- Louis Vuitton: by Kallika, Dipti, Anjali, Pranjal, Sachin, ShabnamDocumento39 pagineLouis Vuitton: by Kallika, Dipti, Anjali, Pranjal, Sachin, ShabnamkallikaNessuna valutazione finora

- Diesel Generator Inspection Procedure PDFDocumento6 pagineDiesel Generator Inspection Procedure PDFSelva GanapathiNessuna valutazione finora

- Pre Use and Monthly Inspection Checklist For Overhead Cranes and HoistsDocumento1 paginaPre Use and Monthly Inspection Checklist For Overhead Cranes and HoistsAnsarNessuna valutazione finora

- Anthony James CV Feb 24 - 2023 PDFDocumento3 pagineAnthony James CV Feb 24 - 2023 PDFanthony jamesNessuna valutazione finora

- Man Basket Checklist FinalDocumento1 paginaMan Basket Checklist FinalMohammed Amer PashaNessuna valutazione finora

- Nursing Law and JurisprudenceDocumento9 pagineNursing Law and JurisprudenceKaren Mae Santiago AlcantaraNessuna valutazione finora

- Crane Checklist PDFDocumento2 pagineCrane Checklist PDFWaqar IftikharNessuna valutazione finora

- Fire Safetytool Box Talk 02Documento4 pagineFire Safetytool Box Talk 02arun100% (2)

- Mobile Crane Load TestDocumento4 pagineMobile Crane Load TestMeritorious KhanNessuna valutazione finora

- 002 Bolt Tightening Structural PDFDocumento22 pagine002 Bolt Tightening Structural PDFarunNessuna valutazione finora

- 01 - Method Statement For Excavation WorkhhhjkDocumento10 pagine01 - Method Statement For Excavation WorkhhhjkAhmed Samir SalimNessuna valutazione finora

- 1 - EXPERTISE ALL DOCUMENT-ilovepdf-compressedDocumento29 pagine1 - EXPERTISE ALL DOCUMENT-ilovepdf-compressedNZ NZNessuna valutazione finora

- Safe Use of Site Dumpers On Construction SitesDocumento4 pagineSafe Use of Site Dumpers On Construction SitesMusharaf ShahNessuna valutazione finora

- Daily Observation SheetDocumento2 pagineDaily Observation Sheetarun100% (2)

- Dewa Phase Iii 800 MW PV Solar Power ProjectDocumento14 pagineDewa Phase Iii 800 MW PV Solar Power ProjectPEMCO InspectionNessuna valutazione finora

- B18 Rigging Plan For Heavy Lifting: Radius 6 MDocumento2 pagineB18 Rigging Plan For Heavy Lifting: Radius 6 MAli Ahmed PathanNessuna valutazione finora

- Liftingplan AccommodationDocumento13 pagineLiftingplan Accommodationarun100% (1)

- Risk Assessment and Allocation For Highway Construction ManagementDocumento73 pagineRisk Assessment and Allocation For Highway Construction Managementmikekyr100% (1)

- Rigging View Modular Overland ConveyorDocumento84 pagineRigging View Modular Overland Conveyorrtyuibnm100% (2)

- Marketing Case - Cowgirl ChocolatesDocumento14 pagineMarketing Case - Cowgirl Chocolatessarah_alexandra2100% (4)

- BP 42 Guidance On The Safe Use of Container Lifting LugsDocumento7 pagineBP 42 Guidance On The Safe Use of Container Lifting LugsGaniyuNessuna valutazione finora

- Counselling Adults With Learning Disabilities Basic Texts in Counselling and PsychotherapyDocumento207 pagineCounselling Adults With Learning Disabilities Basic Texts in Counselling and PsychotherapyCristinaMarinNessuna valutazione finora

- Document No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomDocumento3 pagineDocument No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomShaikh Mohd QaisarNessuna valutazione finora

- Crane and Lifting SafetyDocumento77 pagineCrane and Lifting Safetyandi setiadiNessuna valutazione finora

- Crane Lifting Plan Lifting Operation Method Statement/Lift Plan & Risk AssessmentDocumento20 pagineCrane Lifting Plan Lifting Operation Method Statement/Lift Plan & Risk AssessmentIskandar AzriNessuna valutazione finora

- Lifting MaterialsDocumento6 pagineLifting MaterialsRoselyn SharronNessuna valutazione finora

- OB Case Study Jack StackDocumento12 pagineOB Case Study Jack StackPratik Sharma100% (1)

- Lift Plan - Method Statement - Risk Assessment - SafetyCultureDocumento21 pagineLift Plan - Method Statement - Risk Assessment - SafetyCulturebalachander100% (1)

- Lifting Plan Counter WeightDocumento1 paginaLifting Plan Counter WeightAzhar RimaNessuna valutazione finora

- Critical Lift ChecklistDocumento4 pagineCritical Lift ChecklistUdha Pengen SuksesNessuna valutazione finora

- Crane 3612 LoadChartDocumento6 pagineCrane 3612 LoadChartZura RamliNessuna valutazione finora

- HSE in ConstructionDocumento106 pagineHSE in ConstructionAlex CharlesNessuna valutazione finora

- Method Statement - Fabrication and Installation of Prefabricated Coodo 64Documento15 pagineMethod Statement - Fabrication and Installation of Prefabricated Coodo 64arunNessuna valutazione finora

- Ppe Tool Box Talk 01Documento4 paginePpe Tool Box Talk 01arunNessuna valutazione finora

- Chain Chain SlingsDocumento8 pagineChain Chain SlingsDharmendra MeenaNessuna valutazione finora

- Lifting Plan Procedure 25 TonDocumento1 paginaLifting Plan Procedure 25 TonEm NiaxNessuna valutazione finora

- JMS For MroDocumento9 pagineJMS For Mroalexius lucasNessuna valutazione finora

- Hip Self Assessment Tool & Calculator For AnalysisDocumento14 pagineHip Self Assessment Tool & Calculator For AnalysisNur Azreena Basir100% (9)

- Procedure For Scaffolding Work - Dukhan Fields PDFDocumento14 pagineProcedure For Scaffolding Work - Dukhan Fields PDFIrshad Alam100% (1)

- Nebosh Obe Learner Guide PDFDocumento12 pagineNebosh Obe Learner Guide PDFAsmaael adnanNessuna valutazione finora

- Nebosh Obe Learner Guide PDFDocumento12 pagineNebosh Obe Learner Guide PDFAsmaael adnanNessuna valutazione finora

- DefaultDocumento2 pagineDefaultBADER AlnassriNessuna valutazione finora

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDocumento36 pagineDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823Nessuna valutazione finora

- Environmental and Social MGT PlanDocumento15 pagineEnvironmental and Social MGT PlanarunNessuna valutazione finora

- Ig1 Sample Eng Obe QP PDFDocumento5 pagineIg1 Sample Eng Obe QP PDFAsmaael adnanNessuna valutazione finora

- Safe Use of Cranes: Site Lifting PlanDocumento26 pagineSafe Use of Cranes: Site Lifting PlanMuhammad BabarNessuna valutazione finora

- 2 0 2 0 Rigging Study & Lifting Study: SeptemberDocumento57 pagine2 0 2 0 Rigging Study & Lifting Study: SeptemberTaufan Arif ZulkarnainNessuna valutazione finora

- Lifting Plan For Off-Loading of Tanks at Mazari YardDocumento9 pagineLifting Plan For Off-Loading of Tanks at Mazari Yardmeshahan100% (1)

- SPUBSDocumento6 pagineSPUBSkuxmkini100% (1)

- Scaffold LadderDocumento123 pagineScaffold LadderTarun KakkarNessuna valutazione finora

- Lift Plan-Wilco Extenral StairsDocumento25 pagineLift Plan-Wilco Extenral StairsEdgar ChecaNessuna valutazione finora

- Cranes, Derricks, Hoists, Elevators, and ConveyorsDocumento19 pagineCranes, Derricks, Hoists, Elevators, and ConveyorsAmeerUlHaqNessuna valutazione finora

- Qualification Approval Request Form: Application TypeDocumento1 paginaQualification Approval Request Form: Application TypeMohamed Reda Hussein SengarNessuna valutazione finora

- Lift Study ChecklistDocumento3 pagineLift Study ChecklistIkhsan Awan0% (1)

- SICIM Form # JAPL RED-Hot Work Permit Rev. 01Documento1 paginaSICIM Form # JAPL RED-Hot Work Permit Rev. 01Farrukh EjazNessuna valutazione finora

- TBT - Working On Live Electrical EquipmentDocumento1 paginaTBT - Working On Live Electrical EquipmentJohn Vem BansagNessuna valutazione finora

- Job Safety Analysis - Cone ErectionDocumento6 pagineJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNessuna valutazione finora

- (After Installation) : Tikaria Expansion Project, ACC Checklist For Tower CraneDocumento2 pagine(After Installation) : Tikaria Expansion Project, ACC Checklist For Tower CraneRajuNessuna valutazione finora

- Safe Systems of Work 2Documento23 pagineSafe Systems of Work 2Hossam AbdelmoneimNessuna valutazione finora

- Almansoori Inspection Services: Travelling Block AssemblyDocumento2 pagineAlmansoori Inspection Services: Travelling Block AssemblyRanjithNessuna valutazione finora

- Cert - Mobile Crane 30T - LOLER - Model Rok300Documento2 pagineCert - Mobile Crane 30T - LOLER - Model Rok300Rafael Lecu100% (1)

- Pre Crane Lift ChecklistDocumento1 paginaPre Crane Lift Checklistg665013Nessuna valutazione finora

- Tower Crane-Inspections-ListDocumento3 pagineTower Crane-Inspections-ListLuffy11Nessuna valutazione finora

- 10 IMS - DocumentationDocumento4 pagine10 IMS - DocumentationantivariNessuna valutazione finora

- Curriculum For The Trade Of: RiggerDocumento34 pagineCurriculum For The Trade Of: Riggermd nasimNessuna valutazione finora

- The Identified Crane Below, It Was Inspected and Certified According To The Standard ASME / ANSI B.30Documento1 paginaThe Identified Crane Below, It Was Inspected and Certified According To The Standard ASME / ANSI B.30Reynaldo CaballeroNessuna valutazione finora

- Suspended Personnel Platform Check List PDFDocumento1 paginaSuspended Personnel Platform Check List PDFmark lester caluzaNessuna valutazione finora

- Lifting PlanDocumento1 paginaLifting PlanZubair KhawarNessuna valutazione finora

- 8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureDocumento5 pagine8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureGbenga MoboladeNessuna valutazione finora

- Grating RemovalDocumento1 paginaGrating RemovalKishor KoshyNessuna valutazione finora

- LCC Docs 12144732 v1 Gantry Crane PfsDocumento2 pagineLCC Docs 12144732 v1 Gantry Crane PfsShaiju NarayananNessuna valutazione finora

- LiftingDocumento5 pagineLiftingBoma IpaliboNessuna valutazione finora

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocumento7 pagineLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- Sc-75 Waste Handling and Disposal IIDocumento4 pagineSc-75 Waste Handling and Disposal IIarunNessuna valutazione finora

- Risk Assessment of Coronavirus COVID-19 OutbDocumento12 pagineRisk Assessment of Coronavirus COVID-19 OutbSmiley AndraNessuna valutazione finora

- Daily House Keeping RegisterDocumento1 paginaDaily House Keeping RegisterarunNessuna valutazione finora

- Dac Accredited Certification Bodies in UaeDocumento2 pagineDac Accredited Certification Bodies in UaearunNessuna valutazione finora

- Healthscope 8 1 58267Documento7 pagineHealthscope 8 1 58267arunNessuna valutazione finora

- Sc-75 Waste Handling and Disposal IIDocumento4 pagineSc-75 Waste Handling and Disposal IIarunNessuna valutazione finora

- Waste Handling DisposalDocumento5 pagineWaste Handling DisposalarunNessuna valutazione finora

- Sc-75 Waste Handling and Disposal IIDocumento4 pagineSc-75 Waste Handling and Disposal IIarunNessuna valutazione finora

- Sc-75 Waste Handling and Disposal IIDocumento4 pagineSc-75 Waste Handling and Disposal IIarunNessuna valutazione finora

- Webbing Sling Certificate UpdatedDocumento1 paginaWebbing Sling Certificate UpdatedarunNessuna valutazione finora

- Hazard Communication Tool Box Talk 04Documento4 pagineHazard Communication Tool Box Talk 04arunNessuna valutazione finora

- Lifting Beam Inspection ReportDocumento1 paginaLifting Beam Inspection ReportarunNessuna valutazione finora

- Daily House Keeping Register PDFDocumento1 paginaDaily House Keeping Register PDFarunNessuna valutazione finora

- Daily House Keeping RegisterDocumento1 paginaDaily House Keeping RegisterarunNessuna valutazione finora

- Hand and Powertools Btool Box Talk 05Documento4 pagineHand and Powertools Btool Box Talk 05arunNessuna valutazione finora

- Hand Protection Tool Box Talk 03Documento4 pagineHand Protection Tool Box Talk 03arunNessuna valutazione finora

- Daily House Keeping Register PDFDocumento1 paginaDaily House Keeping Register PDFarunNessuna valutazione finora

- Sunrisers HyderabadDocumento22 pagineSunrisers Hyderabadsagar pajankarNessuna valutazione finora

- Testimonies and PioneersDocumento4 pagineTestimonies and Pioneerswally ziembickiNessuna valutazione finora

- Acme Corporation: Strategic Plan 2014-2016: What Is Our Purpose? Financial How Will We Measure Success?Documento1 paginaAcme Corporation: Strategic Plan 2014-2016: What Is Our Purpose? Financial How Will We Measure Success?Peter Garga PanalanginNessuna valutazione finora

- The Rise of Big Data Policing - Surveillance, Race, and The Future of Law Enforcement On JSTORDocumento11 pagineThe Rise of Big Data Policing - Surveillance, Race, and The Future of Law Enforcement On JSTORFeroze KareemNessuna valutazione finora

- Construction Safety ChetanDocumento13 pagineConstruction Safety ChetantuNessuna valutazione finora

- SES 4 at 22. °W: Advertisements AdvertisementsDocumento6 pagineSES 4 at 22. °W: Advertisements Advertisementsemmanuel danra10Nessuna valutazione finora

- Blockchain in ConstructionDocumento4 pagineBlockchain in ConstructionHasibullah AhmadzaiNessuna valutazione finora

- Critical Analysis of The Concept of Plea Bargaining in IndiaDocumento8 pagineCritical Analysis of The Concept of Plea Bargaining in IndiaSRUTHI KANNAN 2257024Nessuna valutazione finora

- George Moses Federal ComplaintDocumento11 pagineGeorge Moses Federal ComplaintWXXI NewsNessuna valutazione finora

- Employee Engagement and Patient Centered Care PDFDocumento8 pagineEmployee Engagement and Patient Centered Care PDFSrinivas GoudNessuna valutazione finora

- School Form 5 (SF 5) Report On Promotion and Level of Proficiency & AchievementDocumento2 pagineSchool Form 5 (SF 5) Report On Promotion and Level of Proficiency & AchievementNeølie Abello LatúrnasNessuna valutazione finora

- MSC Biotech 02sem ProfBhuminathTripathiDocumento6 pagineMSC Biotech 02sem ProfBhuminathTripathiAtashi MandalNessuna valutazione finora

- Geissele v. Joe Bob Complaint PDFDocumento24 pagineGeissele v. Joe Bob Complaint PDFMark JaffeNessuna valutazione finora

- Front Desk Staff-Giezel Bell Staff - Marc Client - Augustus Friend - AthenaDocumento4 pagineFront Desk Staff-Giezel Bell Staff - Marc Client - Augustus Friend - Athenagener magbalitaNessuna valutazione finora

- Westernization of East Asia: Asian Civilizations II Jervy C. Briones Lecturer, Saint Anthony Mary Claret CollegeDocumento29 pagineWesternization of East Asia: Asian Civilizations II Jervy C. Briones Lecturer, Saint Anthony Mary Claret CollegeNidas ConvanterNessuna valutazione finora

- Consejos y Recomendaciones para Viajar A Perú INGLESDocumento3 pagineConsejos y Recomendaciones para Viajar A Perú INGLESvannia23Nessuna valutazione finora

- When The Artists of This Specific Movement Gave Up The Spontaneity of ImpressionismDocumento5 pagineWhen The Artists of This Specific Movement Gave Up The Spontaneity of ImpressionismRegina EsquenaziNessuna valutazione finora

- Advantages and Disadvantages of Free HealthcareDocumento1 paginaAdvantages and Disadvantages of Free HealthcareJames DayritNessuna valutazione finora

- Public Service Vacancy Circular 05 of 2019Documento186 paginePublic Service Vacancy Circular 05 of 2019jonnydeep1970virgilio.itNessuna valutazione finora

- Kincade 2010Documento12 pagineKincade 2010varghees johnNessuna valutazione finora