Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CH 2

Caricato da

Abdul RashidTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CH 2

Caricato da

Abdul RashidCopyright:

Formati disponibili

Metallurgyعلم المعادن

Chapter Two

Crystal Structure of Metals

Introduction

Solid materials may be classified according to the regularity with which

atoms or ions are arranged with respect to one another.

A crystalline material: is one in which the atoms are situated in a

repeating or periodic array over large atomic distances; that is, long-range

order exists, such that upon solidification, the atoms will position

themselves in a repetitive three-dimensional pattern, in which each atom is

bonded to its nearest-neighbor atoms. All metals, many ceramic materials,

and certain polymers form crystalline structures under normal

solidification conditions.

For those that do not crystallize, this long-range atomic order is absent;

these non-crystalline or amorphous materials. For example (glass) and

some of complex metallic materials.

Some of the properties of crystalline solids depend on the crystal structure of the

material

Lattice Space and Unit Cell:

When describing crystalline structures, atoms (or ions) are thought of as

being solid spheres having well-defined diameters. This is termed the

1

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

atomic hard sphere model in which spheres representing nearest-neighbor

atoms touch one another.

An example of the hard sphere model for the atomic arrangement found in

some of the common elemental metals is displayed in Figure (2.1). In this

particular case all the atoms are identical. Sometimes the term lattice is

used in the context of crystal structures; in this sense “lattice” means a

three-dimensional array of points coinciding with atom positions (or

sphere centers).

Figure (2.1): Lattice space and unit cell

The unit cell:

The atomic order in crystalline solids indicates that small groups of atoms

form a repetitive pattern. Thus, in describing crystal structures, it is often

convenient to subdivide the structure into small repeat entities called unit

cells. Is the basic structural unit or building block of the crystal structure

and defines the crystal structure by virtue of its geometry and the atom

positions within.

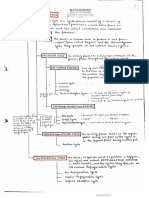

There are 14 types of crystal structure in various engineering materials as shown in

figure (2.2). The important crystal structures among all of them are:

- The body- centered cubic structure (BCC).

- The face- centered cubic structure (FCC).

- Hexagonal close- packed structure (HCP).

2

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Figure (2.2): Types of Crystal structure of materials

The Face-Centered Cubic Crystal Structure

The crystal structure found for many metals has a unit cell of cubic

geometry, with atoms located at each of the corners and the centers of all

the cube faces. It is called the face-centered cubic (FCC) crystal

structure. Some of the familiar metals having this crystal structure are

copper, aluminum, silver, and gold.

The mechanical properties of FCC are:

- Low young modulus

- Low yield strength

- Low hardness

3

- Good ductility and high ability for forming.

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Figure 2.3a shows a hard sphere model for the FCC unit cell, whereas in

Figure 2.3b the atom centers are represented by small circles to provide a

better perspective of atom positions. The aggregate of atoms in Figure 2.3c

represents a section of crystal consisting of many FCC unit cells. These

spheres or ion cores touch one another across a face diagonal; the cube

edge length a and the atomic radius R are related through

For the FCC crystal structure, each corner atom is shared among eight unit cells,

whereas a face-centered atom belongs to only two. Therefore, one-eighth of each

of the eight corner atoms and one-half of each of the six face atoms, or a total of

four whole atoms, may be assigned to a given unit cell.

Figure(2.3): a. Hard sphere model of FCC , b. reduced sphere unit cell, and c. crystal

consist many FCC unit cells.

4

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Two other important characteristics of a crystal structure are the

coordination number and the atomic packing factor (APF). For metals,

each atom has the same number of nearest-neighbor or touching atoms,

which is the coordination number.

For face-centered cubics, the coordination number is 12. This may be

confirmed by examination of Figure, below the front face atom has four

corner nearest-neighbor atoms surrounding it, four face atoms that are in

contact from behind, and four other equivalent face atoms residing in the

next unit cell to the front, which is not shown.

The APF is the sum of the sphere volumes of all atoms within a unit cell (assuming

the atomic hard sphere model) divided by the unit cell volume—that is

For the FCC structure, the atomic packing factor is 0.74, which is the

maximum packing possible for spheres all having the same diameter.

The Body-Centered Cubic Crystal Structure

Another common metallic crystal structure also has a cubic unit cell with

atoms located at all eight corners and a single atom at the cube center. This

is called a body-centered cubic (BCC) crystal structure. A collection of

spheres depicting this crystal structure is shown in Figure 2.4c, whereas

Figures 2.4a and 2.4b are diagrams of BCC unit cells with the atoms

represented by hard sphere and reduced-sphere models, respectively.

Chromium, iron, and tungsten are listed through BCC structure, and their

mechanical properties are:

- High yield strength

5

- High young modulus

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

- High hardness

- High tensile strength

- Limited ability to forming.

Figure(2.4): a. Hard sphere model of BCC , b. reduced sphere unit cell, and c. crystal

consist many BCC unit cells.

Center and corner atoms touch one another along cube diagonals, and unit

cell length a and atomic radius R are related through

Two atoms are associated with each BCC unit cell: the equivalent of one

atom from the eight corners, each of which is shared among eight unit

cells, and the single center atom, which is wholly contained within its cell.

The coordination number for the BCC crystal structure is 8; each

center atom has as nearest neighbors its eight corner atoms as shown in

figure below.

6

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Since the coordination number is less for BCC than FCC, so also is the

atomic packing factor for BCC lower—0.68 versus 0.74.

The Hexagonal Close-Packed Crystal Structure

Not all metals have unit cells with cubic symmetry; the final common

metallic crystal structure to be discussed has a unit cell that is hexagonal.

Figure 2.5a shows a reduced-sphere unit cell for this structure, which is

termed hexagonal close packed (HCP); an assemblage of several HCP

unit cells is presented in Figure 2.5b.

Figure(2.5): a. a reduced-sphere unit cell and (b) an aggregate of many atoms.

The top and bottom faces of the unit cell consist of six atoms that form

regular hexagons and surround a single atom in the center. Another plane

that provides three additional atoms to the unit cell is situated between the

top and bottom planes. The atoms in this midplane have as nearest

neighbors atoms in both of the adjacent two planes.

The equivalent of six atoms is contained in each unit cell; one-sixth of

each of the 12 top and bottom face corner atoms, one-half of each of the 2

center face atoms, and all 3 midplane interior atoms.

7

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

The coordination number and the atomic packing factor for the HCP

crystal structure are the same as for FCC: 12 and 0.74, respectively. see

figure below.

unit cell length a and atomic radius R are related through

a = 2R

The HCP metals include cadmium, magnesium, titanium, and zinc; their

properties are:

- Is brittle

- Low yield strength

- Inability to forming

These are some metals listed in Table 2.1.

8

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Example Problem1:

9

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Example Problem 2

DENSITY COMPUTATIONS

A knowledge of the crystal structure of a metallic solid permits computation of its

theoretical density through the relationship

Where:

NA: Avogadro’s number (6.023 × 1023 atoms/mol(

VC : volume of the unit cell

A : atomic weight

10

n : number of atoms associated with each unit cell

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Example Problem 3:

Problems:

1. If the atomic radius for Pb= 0.175nm, find the volume of the unit cell where

Pb is fcc.

2. Determine the atomic (metallic) radius of Mo where it has BCC crystal

structure , atomic weight = 95.94 g/mole and 𝜌 = 10.2 g/cm3 .

11

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Crystallographic Directions:

A crystallographic direction is defined as a line between two points, or a vector.

The following steps are utilized in the determination of the three

directional indices:

1. A vector of convenient length is positioned such that it passes through

the origin of the coordinate system. Any vector may be translated

throughout the crystal lattice without alteration, if parallelism is

maintained.

2. The length of the vector projection on each of the three axes is

determined; these are measured in terms of the unit cell dimensions a, b,

and c.

3. These three numbers are multiplied or divided by a common factor to

reduce them to the smallest integer values.

4. The three indices, not separated by commas, are enclosed in square

brackets, thus: [uvw]. The u, v, and w integers correspond to the reduced

projections along the x, y, and z axes, respectively.

For each of the three axes, there will exist both positive and negative

coordinates. Thus negative indices are also possible, which are represented

by a bar over the appropriate index. For example, the [111] direction

would have a component in the (- y) direction. Also, changing the signs of

all indices produces an antiparallel direction; that is, [111] is directly

opposite to [111]. The [100], [110], and [111] directions are common

ones; they are drawn in the unit cell shown in Figure 2.6

Figure(2.6): The [100], [110], and [111] directions

within a unit cell.

12

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Examples:

13

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Crystallographic Planes

The orientations of planes for a crystal structure are represented in a

similar manner.

Miller indices are specified by three Miller indices as (hkl). Any two

planes parallel to each other are equivalent and have identical indices. The

procedure employed in determination of the h, k, and l index numbers is as

follows:

1. The crystallographic plane either intersects or parallels each of the three

axes; the length of the planar intercept for each axis is determined in terms

of the lattice parameters a, b, and c.

2. The reciprocals of these numbers are taken. A plane that parallels an

axis may be considered to have an infinite intercept, and, therefore, a zero

index.

3. If necessary, these three numbers are changed to the set of smallest

integers by multiplication or division by a common factor.

4. Finally, the integer indices, not separated by commas, are enclosed

14

within parentheses, thus: (hkl).

An intercept on the negative side of the origin is indicated by a bar or

Page

minus sign positioned over the appropriate index.

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Examples:

15

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

16

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Liner and Planer Density

Linear density (LD): is defined as the number of atoms per unit length

whose centers lie on the direction vector for a specific crystallographic

direction; that is,

Of course, the units of linear density are reciprocal length (e.g., nm-1 , m-1 ).

Planar density (PD): is taken as the number of atoms per unit area that

are centered on a particular crystallographic plane

The units for planar density are reciprocal area (e.g., nm-2 , m-2 ).

Example: Determine the liner and planer density of the [110] direction for the

FCC crystal structure.

Solution:

There are 2 atoms

through the vector [110]

can be seen from figure

(b) and the length of this

vector is 4R so linear

density is:

17

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

From figure below:

consider the section of

a (110) plane within an

FCC unit cell as

represented in Figures

a and b. Although six

atoms have centers

that lie on this plane

(Figure b), only one-

quarter of each of

atoms A, C,D, and F,

and one half of atoms B and E, for a total equivalence of just 2 atoms are

on that plane. Furthermore, the area of this rectangular section is equal to

the product of its length and width. From Figure b, the length (horizontal

dimension) is equal to 4R, whereas the width (vertical dimension) is equal

to 2R√2.

Thus, the area of this planar region is and

Examples.1:

18

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Metallurgyعلم المعادن

Example.2:

Example.3:

19

Page

University of Baghdad / Aeronautics Engineering Department Dr. Suhair G. Hussein

Potrebbero piacerti anche

- Imperfections in Crystalline Solids - Wei CaiDocumento2.037 pagineImperfections in Crystalline Solids - Wei CaiJack Ryder44% (9)

- Atomic and Ionic ArrangementsDocumento50 pagineAtomic and Ionic ArrangementsUğurörengülNessuna valutazione finora

- Aste T., Weaire D. Pursuit of Perfect Packing (IOP 2000) (147s) PDFDocumento147 pagineAste T., Weaire D. Pursuit of Perfect Packing (IOP 2000) (147s) PDFJoão Victor SoaresNessuna valutazione finora

- Materials Science and Engineering Notes 091110Documento12 pagineMaterials Science and Engineering Notes 091110Mete MetelanNessuna valutazione finora

- Crystal Structure of Metals: Chapter TwoDocumento19 pagineCrystal Structure of Metals: Chapter TwoRitika JainNessuna valutazione finora

- Structure of MetalsDocumento13 pagineStructure of Metalshammad00Nessuna valutazione finora

- Chapter 3 SummaryDocumento7 pagineChapter 3 Summarykarl zurcNessuna valutazione finora

- The Structure of Crystalline SolidsDocumento36 pagineThe Structure of Crystalline SolidsPROSPERNessuna valutazione finora

- Crystal StructureDocumento30 pagineCrystal StructureSujit Singh100% (1)

- Crystal StructureDocumento8 pagineCrystal StructurekdNessuna valutazione finora

- Structure of Engineering MaterialsDocumento12 pagineStructure of Engineering Materialsjust_killing_pplNessuna valutazione finora

- Chem 113E Module 7Documento9 pagineChem 113E Module 7Kenneth John FerrarizNessuna valutazione finora

- Lecture Note EEE 3515 Stenza 1Documento17 pagineLecture Note EEE 3515 Stenza 1md kayesNessuna valutazione finora

- Metallic Crystal StructuresDocumento6 pagineMetallic Crystal StructuresJayaraman KamarajNessuna valutazione finora

- 3Documento67 pagine3Louise UmaliNessuna valutazione finora

- Module 2. Structure of Crystalline SolidsDocumento20 pagineModule 2. Structure of Crystalline SolidsPearl Alexandra FabitoNessuna valutazione finora

- The Chemistry of Engineering Materials 20192020Documento19 pagineThe Chemistry of Engineering Materials 20192020potassiumNessuna valutazione finora

- 03-MS-ME - The Structure of Crystalline SolidsDocumento83 pagine03-MS-ME - The Structure of Crystalline Solidsfarah Al-zgoulNessuna valutazione finora

- Crystal StructuresDocumento87 pagineCrystal Structuresrogerio-camposNessuna valutazione finora

- EMG 1204 Lecture 3Documento15 pagineEMG 1204 Lecture 3James musambakiNessuna valutazione finora

- Crystalline Materials3Documento32 pagineCrystalline Materials3Abdel-Menam AlhaddadNessuna valutazione finora

- Chapter 2Documento59 pagineChapter 2Temesgen Zeleke100% (1)

- The Structure of Crystalline SolidsDocumento40 pagineThe Structure of Crystalline SolidsGeleta Bekele100% (1)

- Unit 3. Basic Concepts of Crystal StructuresDocumento72 pagineUnit 3. Basic Concepts of Crystal StructuresClaresse NavarroNessuna valutazione finora

- 2 - Structure of Crystalline SolidsDocumento18 pagine2 - Structure of Crystalline Solidslhudielyn abeNessuna valutazione finora

- Crystal: Name: Avinda Arista Putri Class: 1C NIM: 201710140311143Documento57 pagineCrystal: Name: Avinda Arista Putri Class: 1C NIM: 201710140311143Rizal MawardiNessuna valutazione finora

- Ch-3 - Structure of Crystalline Solids Lecture 1Documento23 pagineCh-3 - Structure of Crystalline Solids Lecture 1mintuwondeNessuna valutazione finora

- 1.physical and Mechanical Properties of Wrought AlloysDocumento83 pagine1.physical and Mechanical Properties of Wrought AlloysDhanush kumarNessuna valutazione finora

- 2.4 Basic Concepts of Crystal StructureDocumento7 pagine2.4 Basic Concepts of Crystal Structurecory kurdapyaNessuna valutazione finora

- Lecture 2 Forming NptelDocumento12 pagineLecture 2 Forming Nptelaghosh704Nessuna valutazione finora

- Rangkuman Materi Crystalline Structure (IBE) Ahmad Naufal Waliyyuddin - 1513623068Documento12 pagineRangkuman Materi Crystalline Structure (IBE) Ahmad Naufal Waliyyuddin - 1513623068Ahmad NaufalNessuna valutazione finora

- The Structure of Crystalline SolidsDocumento40 pagineThe Structure of Crystalline SolidsAsif AliNessuna valutazione finora

- MaterialDocumento2 pagineMaterialAtif AhmadNessuna valutazione finora

- Structure of Crystalline 1-DikonversiDocumento24 pagineStructure of Crystalline 1-DikonversiAndhika Setyo AdjieNessuna valutazione finora

- C2ADocumento22 pagineC2AYong Meng HowNessuna valutazione finora

- Metallic and Ceramic StructureDocumento32 pagineMetallic and Ceramic StructurebasitNessuna valutazione finora

- Chem 1Documento23 pagineChem 1Adi SoNessuna valutazione finora

- Files Chapters ME215 Ch3 RDocumento93 pagineFiles Chapters ME215 Ch3 RMohammad Tabrez AlamNessuna valutazione finora

- Chapter 3Documento59 pagineChapter 3XNessuna valutazione finora

- Lecture 5 - CHEMISTRY OF ENGINEERING MATERIALSDocumento114 pagineLecture 5 - CHEMISTRY OF ENGINEERING MATERIALS23-07736Nessuna valutazione finora

- Lesson 4.0 Basic Concepts of Crystalline StructureDocumento11 pagineLesson 4.0 Basic Concepts of Crystalline StructureyoureqtNessuna valutazione finora

- CHAPTER 3: Materials StructureDocumento35 pagineCHAPTER 3: Materials StructureRabihNessuna valutazione finora

- The Structure of Crystalline SolidDocumento32 pagineThe Structure of Crystalline SolidRakesh Lingayat100% (2)

- Unit Iv. Structures of Crystalline Solids Learning ObjectivesDocumento14 pagineUnit Iv. Structures of Crystalline Solids Learning ObjectivesIvyy Joyce BuanNessuna valutazione finora

- CHE414 PRT 2Documento6 pagineCHE414 PRT 2Looking forwardNessuna valutazione finora

- Material Science Lec.3Documento49 pagineMaterial Science Lec.3Abdallah SalahNessuna valutazione finora

- FPEM1013 Chapter 1Documento24 pagineFPEM1013 Chapter 1ahmedhaid1312Nessuna valutazione finora

- Chapter 3. Structure of CrystalsDocumento4 pagineChapter 3. Structure of CrystalsRaunak RajpurohitNessuna valutazione finora

- M 1.2.1 Structure and Properties of Metals SteelDocumento18 pagineM 1.2.1 Structure and Properties of Metals Steeldokumen qcNessuna valutazione finora

- Chap 1 - Crystalline & Noncrystalline StructureDocumento55 pagineChap 1 - Crystalline & Noncrystalline StructureJordan ThongNessuna valutazione finora

- Crystal Lattice, Space LatticeDocumento6 pagineCrystal Lattice, Space LatticeSelemon AssefaNessuna valutazione finora

- Module Test 7Documento3 pagineModule Test 7Dobal PunioNessuna valutazione finora

- Materials Science and Materials Engineering (Or Engineering Materials)Documento25 pagineMaterials Science and Materials Engineering (Or Engineering Materials)Siseneg TasmaNessuna valutazione finora

- Fundametals of Material Science Week 1Documento6 pagineFundametals of Material Science Week 1Hanin AqilahNessuna valutazione finora

- Engineering Materials: Crystallographic PlanesDocumento45 pagineEngineering Materials: Crystallographic Planessamurai7_77Nessuna valutazione finora

- 3.0 Structures of Metals and Ceramics: How Do Atoms Arrange Themselves in Ordered Structures (Crystals) ?Documento70 pagine3.0 Structures of Metals and Ceramics: How Do Atoms Arrange Themselves in Ordered Structures (Crystals) ?Williams AkandiNessuna valutazione finora

- Chapter 3Documento26 pagineChapter 3Bala SubramanianNessuna valutazione finora

- MMS Module 1 NotesDocumento25 pagineMMS Module 1 NotesAthul K SNessuna valutazione finora

- Material Science and Engineering: "Metals"Documento31 pagineMaterial Science and Engineering: "Metals"Baltazar MharkNessuna valutazione finora

- How Do Atoms Arrange Themselves To Form Solids?: Chapter Outline Types of SolidsDocumento7 pagineHow Do Atoms Arrange Themselves To Form Solids?: Chapter Outline Types of SolidsAbhijith MadabhushiNessuna valutazione finora

- 1) Atonomic Number: Each Chemical Element Is Characterized by The Number of Protons in TheDocumento2 pagine1) Atonomic Number: Each Chemical Element Is Characterized by The Number of Protons in TheRiyanitaNessuna valutazione finora

- Lecture-1: Gas Power CycleDocumento20 pagineLecture-1: Gas Power CycleAbdul RashidNessuna valutazione finora

- Advance Manufacturing Processes (IM-307)Documento31 pagineAdvance Manufacturing Processes (IM-307)Abdul RashidNessuna valutazione finora

- Thermodynamic CyclesDocumento1 paginaThermodynamic CyclesAbdul RashidNessuna valutazione finora

- Logistics & Inventory ManagementDocumento19 pagineLogistics & Inventory ManagementAbdul RashidNessuna valutazione finora

- Cam CepDocumento21 pagineCam CepAbdul RashidNessuna valutazione finora

- BCE Week 13, EthicsDocumento17 pagineBCE Week 13, EthicsAbdul Rashid100% (1)

- Im-408 Industrial Robotics 01Documento22 pagineIm-408 Industrial Robotics 01Abdul RashidNessuna valutazione finora

- Critical Examination: by Dr. Asim ZaheerDocumento7 pagineCritical Examination: by Dr. Asim ZaheerAbdul RashidNessuna valutazione finora

- Measurement System Analysis (MSA) : IM-213 MQCDocumento9 pagineMeasurement System Analysis (MSA) : IM-213 MQCAbdul RashidNessuna valutazione finora

- Measurement System Analysis (MSA) : IM-213 MQCDocumento9 pagineMeasurement System Analysis (MSA) : IM-213 MQCAbdul RashidNessuna valutazione finora

- Overall Equipment EffectivenessDocumento12 pagineOverall Equipment EffectivenessAbdul RashidNessuna valutazione finora

- Maintenance ManagementDocumento28 pagineMaintenance ManagementAbdul RashidNessuna valutazione finora

- Calibration: IM-213 MQCDocumento27 pagineCalibration: IM-213 MQCAbdul RashidNessuna valutazione finora

- Calibration: IM-213 MQCDocumento27 pagineCalibration: IM-213 MQCAbdul RashidNessuna valutazione finora

- Chapter 12:electrostatics HSSC IiDocumento12 pagineChapter 12:electrostatics HSSC IiAbdul RashidNessuna valutazione finora

- ch#16 Nine ChemistryDocumento17 paginech#16 Nine ChemistryAbdul RashidNessuna valutazione finora

- Theory 20Documento5 pagineTheory 20Abdul RashidNessuna valutazione finora

- Project Profile - IM-212-CAEDDocumento2 pagineProject Profile - IM-212-CAEDAbdul RashidNessuna valutazione finora

- 11 PhysicsDocumento65 pagine11 PhysicsMaisamNessuna valutazione finora

- Past Questions 02 PDFDocumento1 paginaPast Questions 02 PDFAbdul RashidNessuna valutazione finora

- Class XII Chemistry Book NotesDocumento76 pagineClass XII Chemistry Book NotesSyed Usman100% (1)

- ch#15 Nine ChemistryDocumento15 paginech#15 Nine ChemistryAbdul RashidNessuna valutazione finora

- ch#14 Nine ChemistryDocumento13 paginech#14 Nine ChemistryAbdul RashidNessuna valutazione finora

- Chap#08 Phy 10Documento16 pagineChap#08 Phy 10Abdul RashidNessuna valutazione finora

- Chap#05 Phy 11Documento13 pagineChap#05 Phy 11Abdul RashidNessuna valutazione finora

- Chap#01 Phy 10Documento8 pagineChap#01 Phy 10Abdul RashidNessuna valutazione finora

- 10th MATHDocumento22 pagine10th MATHAbdul RashidNessuna valutazione finora

- Practical Centre: Periodic Classification - Theory & Question Answers - Chemistry 12thDocumento12 paginePractical Centre: Periodic Classification - Theory & Question Answers - Chemistry 12thAbdul RashidNessuna valutazione finora

- Chap#01 Phy 11Documento5 pagineChap#01 Phy 11Abdul RashidNessuna valutazione finora

- ch#18 Nine ChemistryDocumento16 paginech#18 Nine ChemistryAbdul RashidNessuna valutazione finora

- Crystalline Solids Crystalline Structure: Major Types ofDocumento40 pagineCrystalline Solids Crystalline Structure: Major Types ofJersey PerlasNessuna valutazione finora

- Solid State ChemistryDocumento105 pagineSolid State ChemistryNishit Kumar100% (1)

- Interstitial Void SpacesDocumento4 pagineInterstitial Void SpacessaleemNessuna valutazione finora

- Materia Engineering Cha 1Documento236 pagineMateria Engineering Cha 1amanuelfitsum589Nessuna valutazione finora

- Close PackingDocumento20 pagineClose Packingchepad1Nessuna valutazione finora

- Solid State Unit IIDocumento20 pagineSolid State Unit IISivakumar PonnusamyNessuna valutazione finora

- Plastic Deformation of Single crystal-AA PDFDocumento42 paginePlastic Deformation of Single crystal-AA PDFdecent mrdNessuna valutazione finora

- Xii Neet Chemistry McqsDocumento30 pagineXii Neet Chemistry McqsNAZMA NAZNessuna valutazione finora

- Unit 2. Structure of Solids and Characterization of Materials PDFDocumento83 pagineUnit 2. Structure of Solids and Characterization of Materials PDFShail RajNessuna valutazione finora

- Hsslive Xii Chemistry Quick Notes Based On Scert Focus AreaDocumento63 pagineHsslive Xii Chemistry Quick Notes Based On Scert Focus AreavaishnavNessuna valutazione finora

- 6 CoordDocumento58 pagine6 Coordrosenthal elvis chimpay ariasNessuna valutazione finora

- Namma Kalvi 12th Chemistry Unit 6 PPT Material EM 219395Documento93 pagineNamma Kalvi 12th Chemistry Unit 6 PPT Material EM 219395Anant Mathew SibyNessuna valutazione finora

- Inorganic Chemistry SummaryDocumento8 pagineInorganic Chemistry SummaryClara1212Nessuna valutazione finora

- 12 Chemistry Test PapersDocumento236 pagine12 Chemistry Test Paperstabizh50% (2)

- 02 PrsolDocumento20 pagine02 PrsolNgô Tuấn KiệtNessuna valutazione finora

- Nearly Free ElectronDocumento15 pagineNearly Free ElectronJohnNessuna valutazione finora

- 1.solid StateDocumento33 pagine1.solid StateBHAVITH SD VNS 06Nessuna valutazione finora

- Chap 1 - Crystalline & Noncrystalline StructureDocumento55 pagineChap 1 - Crystalline & Noncrystalline StructureJordan ThongNessuna valutazione finora

- Solids JEE NEET PDFDocumento12 pagineSolids JEE NEET PDFArpit RawatNessuna valutazione finora

- Crystal StructureDocumento7 pagineCrystal StructureSREERAGHAV KNessuna valutazione finora

- Inorganic Chemistry II (100 Items)Documento11 pagineInorganic Chemistry II (100 Items)maria jeusa matiasNessuna valutazione finora

- Class NoteDocumento18 pagineClass NoteNafis AhmedNessuna valutazione finora

- Crystal Structure: Chapter - IDocumento33 pagineCrystal Structure: Chapter - IAkmal KhanNessuna valutazione finora

- Chapter 3. The Structure of Crystalline SolidsDocumento45 pagineChapter 3. The Structure of Crystalline SolidsDiego AbadNessuna valutazione finora

- Solid StateDocumento72 pagineSolid StateSTUDY GRINDNessuna valutazione finora

- The Solid State Class 12 MCQs Questions With AnswersDocumento19 pagineThe Solid State Class 12 MCQs Questions With AnswersRohit Chavariya100% (1)