Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ESET 212 LECTURE - Week 7

Caricato da

eglits4170Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ESET 212 LECTURE - Week 7

Caricato da

eglits4170Copyright:

Formati disponibili

ESET-212

Boiler and Auxiliaries

School of Engineering Technology & Applied Science

(SETAS)

Week: 7

Steam and Water

Fittings and Accessories

Centennial College - SDRE: ESET 212 Week 7 1

STEAM FlTTINGS AND ACCESSORIES

Steam fittings (trim) are attached to the boiler and are necessary

for its safe and efficient operation.

Steam accessories are pieces of equipment not only directly

attached to the boiler and are also required for the operation of

the boiler.

Steam fittings must be constructed in accordance with the ASME

code. The ASME code also specifies how these fittings are to be

attached to the boiler as determined by the temperatures and

pressures present in the boiler.

Centennial College - SDRE: ESET 212 Week 7

2

STEAM FlTTINGS AND ACCESSORIES

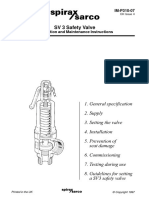

Safety Valves

A safety valve is a valve used to release pressure and protect the

boiler from exceeding its MAWP and is the most important valve

on the boiler.

If the MAWP is exceeded, a failure on the pressure side of the

boiler could occur.

Safety valves must be located at the highest part of the steam

side of the boiler.

They must be connected to the boiler shell according to ASME

code, with no intervening valves between the safety valve and the

boiler.

Centennial College - SDRE: ESET 212 Week 7

3

STEAM FlTTINGS AND ACCESSORIES

Safety Valves

The only type of safety valve allowed is the spring-loaded pop-

type safety valve.

Lever-type and deadweight safety valves can be easily tampered

with and are not permitted.

The ASME code requires that every boiler have at least one

safety valve.

Boilers with more than 500 sq ft of heating surface shall have two

or more safety valves.

Safety valves over 3" in diameter for pressures over 15 psi shall

have a flanged or a weld-end inlet.

Safety valve discharge piping must be installed and connected to

the safety valve, which allows proper discharge of steam, but

does not place strain on the safety valve.

Centennial College - SDRE: ESET 212 Week 7

4

STEAM FlTTINGS AND ACCESSORIES

Safety Valves

Safety valve capacity must be enough to discharge all steam the

boiler can generate without allowing the pressure to rise more

than 6% above the MAWP.

Safety valves must be designed to open fully at a predetermined

pressure.

Centennial College - SDRE: ESET 212 Week 7

5

STEAM FlTTINGS AND ACCESSORIES

Safety Valves

Safety valves must remain

open until there is a definite

drop in pressure.

Blowdown, or blowback, is

the drop in pressure that

allows the safety valve to

close.

Blowdown is normally 2 to 8

psi below popping pressure,

but not more than 4% of set

pressure.

Centennial College - SDRE: ESET 212 Week 7

6

STEAM FlTTINGS AND ACCESSORIES

Safety Valves

Safety valves must close tight without chattering.

Once the safety valve has reseated, it must remain tightly closed.

Setting or adjusting safety valves must be done by qualified

personnel who are familiar with safety valve construction,

operation, and maintenance.

Repairs must only be done by the manufacturer or an authorized

representative.

Safety valve springs are calibrated for the correct popping

pressure. For pressures up to 250 psi, the safety valve can be set

10% above or 10% below this pressure.

For pressures over 250 psi, safety valves can only be set 5%

above or 5% below the set pressure without changing the safety

valve spring.

Centennial College - SDRE: ESET 212 Week 7

7

STEAM FlTTINGS AND ACCESSORIES

Safety Valves

One or more boiler safety valves shall be set at or below MAWP. If

additional safety valves are used, the highest pressure setting

shall not exceed the MAWP by more than 3%.

The complete range of pressure settings of all safety valves on a

boiler shall not exceed 10% of the highest pressure to which any

safety valve is set.

For example, if the safety valve with the highest setting is at 100

psi, the safety valve with the lowest setting cannot be lower than

90 psi.

Centennial College - SDRE: ESET 212 Week 7

8

STEAM FlTTINGS AND ACCESSORIES

Safety Valves

Any change in the settings of a safety valve blowdown or pressure

requires a new safety valve data plate. The safety valve data plate

should include the following:

• manufacturer's name or trademark

• manufacturer's design or type number

• size of safety valve (in inches), seat diameter

• popping pressure setting (in psig)

• blowdown (in psi)

• capacity (in lb/hr)

• lift of the valve (in inches)

• year built or code mark

• ASME symbol

• serial number

Centennial College - SDRE: ESET 212 Week 7

9

STEAM FlTTINGS AND ACCESSORIES

Safety Valves

Popping-pressure tolerance is the difference between the set

pressure and the popping pressure of a safety valve.

Popping-pressure tolerance, plus or minus, is

• 2 psi for pressures up to 70 psi

• 3% for pressures from over 70 psi to 300 psi

• 10 psi for pressures over 300 psi to 1000 psi

• 1% for pressures over 1000 psi

For example, at 70 psi, safety valves pop open between 68 psi and

72 psi.

At 200 psi, safety valves pop open between 194 psi and 206 psi.

Centennial College - SDRE: ESET 212 Week 7

10

STEAM FlTTINGS AND ACCESSORIES

Safety Valves

At 500 psi, safety valves pop open between 490 psi and 510 psi.

Over 1200 psi, safety valves pop open between 1188 psi and 1212

psi and are still within popping-pressure tolerances.

Normally, valves under pressure are opened slowly. However,

safety valves are designed to pop open.

A spring on the safety valve exerts a downward force, which keeps

the valve disc in contact wilh the valve seat.

Steam pressure acts on the safety valve disc and exerts an

upward force that tries to force the valve open.

The total force of steam trying to overcome the spring force is

equal to the area of the safety valve disc times the steam pressure.

Centennial College - SDRE: ESET 212 Week 7

11

STEAM FlTTINGS AND ACCESSORIES

Safety Valves

When steam pressure starts to

overcome the force of the

safety valve spring, the safety

valve will start to open.

The steam then enters the

huddling chamber to expose

steam to a larger area of the

valve disc.

This increases the force, which

causes the safety valve to open

quickly, or pop open.

Centennial College - SDRE: ESET 212 Week 7

12

STEAM FlTTINGS AND ACCESSORIES

Centennial College - SDRE: ESET 212 Week 7

13

STEAM FlTTINGS AND ACCESSORIES

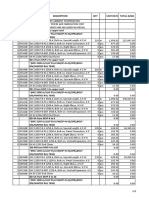

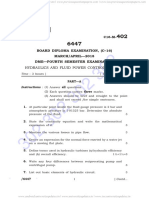

Safety Valve Size.

• To determine the safety valve size required for a boiler, the boiler

capacity must be known.

• Boiler capacity is rated in pounds of steam generated per hour.

• According to ASME code, boiler capacity in pounds of steam per

hour is determined by the maximum amount of fuel consumed by

the burners of the boiler.

• Pounds of steam per hour is found by using the following

equation:

Centennial College - SDRE: ESET 212 Week 7

14

STEAM FlTTINGS AND ACCESSORIES

Centennial College - SDRE: ESET 212 Week 7

15

STEAM FlTTINGS AND ACCESSORIES

Centennial College - SDRE: ESET 212 Week 7

16

STEAM FlTTINGS AND ACCESSORIES

Centennial College - SDRE: ESET 212 Week 7

17

STEAM FlTTINGS AND ACCESSORIES

Centennial College - SDRE: ESET 212 Week 7

18

STEAM FlTTINGS AND ACCESSORIES

Prob:

A watertube boiler generates a maximum of 35,795 lbs of steam/hr

at 300 psi. What is the safety valve diameter required to relieve that

quantity of steam?

Centennial College - SDRE: ESET 212 Week 7

19

STEAM FlTTINGS AND ACCESSORIES

Main Steam Stop Valves

A main steam stop valve is a valve on the main steam line leaving

the boiler that is used to cut the boiler in on-line or take the boiler

off-line.

The main steam line requires two main steam stop valves when

boilers are in battery. The main steam line leaves the boiler and

connects to the main steam header.

The main steam header is the distribution line. From the main

steam header, branch lines supply steam to working stations.

The main steam line is constructed using steam bends to allow for

expansion and contraction.

The main steam header must also have steam traps to remove

condensate built up in the lines. Any condensate in the steam lines

could lead to water hammer and a possible pipe rupture.

Centennial College - SDRE: ESET 212 Week 7

20

STEAM FlTTINGS AND ACCESSORIES

Centennial College - SDRE: ESET 212 Week 7

21

STEAM FlTTINGS AND ACCESSORIES

Centennial College - SDRE: ESET 212 Week 7

22

STEAM FlTTINGS AND ACCESSORIES

Main Steam Stop Valves

boilers in batteries must have two main steam stop valves with an

ample free-blowing drain between them.

Main steam stop valves must be of the os&y (Outside Screw and

Yoke) type that show if the valves are open or closed by the

position of their stem.

The main steam stop valves should be gate valves

An automatic nonreturn valve may be used in place of one stop

valve, but must be located as close to the boiler shell as practical.

The main steam stop valve is used to place a boiler in service or

isolate it from the system.

Centennial College - SDRE: ESET 212 Week 7

23

STEAM FlTTINGS AND ACCESSORIES

Main Steam Stop Valves

Automatic nonretum valves improve the safety and efficiency of the

plant by cutting a boiler in on the line automatically or taking it off

the line automatically.

Automatic nonretum valves also protect the system in case of a

failure on the pressure side of any boiler on the line.

Centennial College - SDRE: ESET 212 Week 7

24

STEAM FlTTINGS AND ACCESSORIES

os&y (Outside Screw and Yoke) valve

Centennial College - SDRE: ESET 212 Week 7

25

STEAM FlTTINGS AND ACCESSORIES

Blowdown Valves and Lines

All boilers must have a blowdown valve with a blowdown pipe

located at the lowest part of the water side of the firetube boiler, or

on the mud drum on a watertube boiler.

The blowdown pipe must run full size, with no reducers or

bushings.

All blowdown piping outside the boiler should be exposed for

inspection.

Boilers with an MAWP exceeding 125 psi require extra-heavy

blowdown pipe(s) from the boiler to the valve or valves per ASME

code.

Centennial College - SDRE: ESET 212 Week 7

26

STEAM FlTTINGS AND ACCESSORIES

Blowdown Valves and Lines

All fittings between the boiler and valve shall be steel or extra-

heavy bronze or brass, malleable iron, or cast iron suitable for the

temperatures and pressures involved.

Boilers exceeding an MAWP of 125 psi must have each bottom

blowdown pipe fitted with at least a 250 lb standard valve or cock.

Two extra-heavy valves, or an extra-heavy valve and cock are

preferred

Centennial College - SDRE: ESET 212 Week 7

27

STEAM FlTTINGS AND ACCESSORIES

Blowdown Valves and Lines

Must be protected and easy to be inspected.

the blowdown pipe should be arranged to allow for free expansion

and contraction.

Blowdown piping must be protected from freezing, heat, or

corrosive conditions.

The minimum size for pipes and fittings is 1" and the maximum is

2.5".

Waterwall blowdown valves shall be locked or sealed closed to

prevent being opened by mistake when the boiler is firing.

Centennial College - SDRE: ESET 212 Week 7

28

STEAM FlTTINGS AND ACCESSORIES

Blowdown Valves and Lines

If the waterwall blowdown valves are opened, the loss of water or

circulation will cause the waterwall tubes to overheat.

Waterwall blowdown valves should only be blown down when the

furnace has cooled properly.

Waterwalls are usually blown down when the boiler is being taken

off the line.

The frequency of blowing down the boiler is determined through

boiler water analysis.

the boiler should be blown down at least once every 24 hours.

Centennial College - SDRE: ESET 212 Week 7

29

STEAM FlTTINGS AND ACCESSORIES

Blowdown- why?

Makeup water contains a certain amount of scale-forming salts.

Scale-forming salts start to settle on the boiler heating surfaces

when the boiler water temperature reaches about 150°F.

The settling of these salts on the boiler heating surfaces

reduces the required heat transfer by insulating the surface. As

a result, the boiler heating surfaces overheat and burn out.

Chemicals added to the boiler water turn scale-forming salts

into a nonadhering sludge. The sludge stays in suspension and

settles to the lowest part of the water side of the boiler when

the boiler is at a light load.

Bottom blowdown valves and lines are located at the lowest

part of the water side of the boiler.

Centennial College - SDRE: ESET 212 Week 7

30

STEAM FlTTINGS AND ACCESSORIES

Blowdown- requirement

Boilers operating at 100 psi or higher must have two approved

blowdown valves.

The two valves may be two slow-opening valves (screw-type),

or one quick-opening valve and one slow opening valve.

The fast opening valve must be located closest to the boiler

shell.

Centennial College - SDRE: ESET 212 Week 7

31

STEAM FlTTINGS AND ACCESSORIES

Blowdown- requirement

In blowing down, the quick-opening valve should be opened

first and closed last.

The quick-opening valve functions as a sealing valve.

Centennial College - SDRE: ESET 212 Week 7

32

STEAM FlTTINGS AND ACCESSORIES

Blowdown- requirement

The slow-opening valve is located farthest from the boiler shell.

The slow-opening valve is the blowing valve and takes all the

wear and tear of blowing down.

Bottom blowdown is used to:

remove sludge and sediment,

control high water,

control chemical concentration, and

dump the boiler for cleaning and inspection.

Centennial College - SDRE: ESET 212 Week 7

33

STEAM FlTTINGS AND ACCESSORIES

Blowdown- requirement

There must be pressure on the boiler when blowing down

unless it is dumped (out of service).

The best time to blow down a boiler is at its lightest load

because sludge and sediment have had a chance to settle to

the bottom of the water side of the boiler.

While blowing down, blowdown lines are subject to a sudden

pressure and temperature.

The blowdown valves and piping must be designed for

maximum capacity and allow for expansion and contraction.

Centennial College - SDRE: ESET 212 Week 7

34

STEAM FlTTINGS AND ACCESSORIES

Blowdown- requirement

Straight-run globe valves or other valves that may impede

boiler water flow or collect sediment must not be used.

Globe Valve Gate Valve

Blowdown or flash tank

To prevent hot water and steam from entering the sewer

system, a blowdown or flash tank is used between the

blowdown line and the sewer.

Centennial College - SDRE: ESET 212 Week 7

35

STEAM FlTTINGS AND ACCESSORIES

Blowdown or flash tank

Hot water and steam enter the top of the tank. Flash steam

leaves through the vent and the hot water stays in the tank.

Centennial College - SDRE: ESET 212 Week 7

36

STEAM FlTTINGS AND ACCESSORIES

Blowdown or flash tank

As the level in the tank rises, cooler water from the bottom of

the tank flows into the sewer.

After blowing down a boiler, water remains in the blowdown

tank to cool until another boiler is blown down.

A siphon breaker is installed to prevent possible siphoning of

the water from the tank.

A blowdown centrifugal separator can be used between the

blowdown line and blowdown tank.

A blowdown centrifugal separator is a separator that reduces

the pressure and temperature before the boiler water enters the

blowdown tank.

Centennial College - SDRE: ESET 212 Week 7

37

STEAM FlTTINGS AND ACCESSORIES

Blowdown Surface

Some boilers are equipped with

surface blowdown valves.

Surface blowdown valves are

located at the normal operating

water level (NOWL) of the boiler

and are used to remove impurities

from the surface of boiler water.

This reduces surface tension and

prevents carryover of water and

impurities.

The surface blowdown line

discharges to the blowdown tank.

Centennial College - SDRE: ESET 212 Week 7

38

STEAM FlTTINGS AND ACCESSORIES

Continuous Blowdown:

Large boilers carrying heavy steam loads require closer control

of the total dissolved solids in the boiler water.

This is accomplished by using continuous proportioning of

feedwater treatment in conjunction with a continuous blowdown

line.

The continuous blowdown line is located below the NOWL and

discharges to a flash tank or continuous blowdown tank.

The flash tank can be used to reclaim heat from boiler water

from the continuous blowdown line.

Centennial College - SDRE: ESET 212 Week 7

39

STEAM FlTTINGS AND ACCESSORIES

Centennial College - SDRE: ESET 212 Week 7

40

STEAM FlTTINGS AND ACCESSORIES

Continuous Blowdown:

Water from the continuous blowdown line is piped to the flash

tank.

As the water pressure drops, some of the water flashes into

steam. This steam flows to the open feed water heater.

Makeup water passes through coils below the water level in the

flash tank and is heated.

For every 10°F rise in feedwater temperature, there is

approximately a 1% savings in fuel.

http:/www.atperesources.com/qr/SE_5/735728.htm

Centennial College - SDRE: ESET 212 Week 7

41

Potrebbero piacerti anche

- Pressure Safety Valve Theory and PSV Valve MechanismDocumento5 paginePressure Safety Valve Theory and PSV Valve MechanismmusNessuna valutazione finora

- Pressure Safety Valve TheoryDocumento5 paginePressure Safety Valve TheorySurya Kiran KNessuna valutazione finora

- S.V Reg. in Asme TDP 1, Asme Sec 1, b31.1Documento9 pagineS.V Reg. in Asme TDP 1, Asme Sec 1, b31.1K.S.MAYILVAGHANANNessuna valutazione finora

- AquaFuse PolyBaSS CatalogueDocumento11 pagineAquaFuse PolyBaSS Catalogueani_datNessuna valutazione finora

- ES - Installation of Safety Valves - BP - 17Documento3 pagineES - Installation of Safety Valves - BP - 17rajeevme84Nessuna valutazione finora

- 15-Mercer Valve - SafetyDocumento33 pagine15-Mercer Valve - SafetycarlosNessuna valutazione finora

- 3-5400 SERIES Safety Relief Valves: Instruction ManualDocumento16 pagine3-5400 SERIES Safety Relief Valves: Instruction ManualPrashant ChauhanNessuna valutazione finora

- Breather ValveDocumento14 pagineBreather Valvezamijaka100% (1)

- Power Plant and Calculations - Safety Valves and Its Basic ConceptsDocumento4 paginePower Plant and Calculations - Safety Valves and Its Basic ConceptsV U P RaoNessuna valutazione finora

- Valves: Continuing Education From The American Society of Plumbing EngineersDocumento19 pagineValves: Continuing Education From The American Society of Plumbing Engineers185412Nessuna valutazione finora

- ESD ValvesDocumento19 pagineESD Valvesrkubal100% (1)

- "Gəmi Energetik Qurğuları" Kafedrası: Gəmi Buxar Qazanları, Buxar VƏ Qaz TurbinləriDocumento3 pagine"Gəmi Energetik Qurğuları" Kafedrası: Gəmi Buxar Qazanları, Buxar VƏ Qaz TurbinləriNihad KazimovNessuna valutazione finora

- Discharge Bypass Valves: Installation & Service InstructionsDocumento4 pagineDischarge Bypass Valves: Installation & Service InstructionsAbdulSattarNessuna valutazione finora

- 15-Pressure Safety ValvesDocumento33 pagine15-Pressure Safety ValvesUmair A. KhanNessuna valutazione finora

- Safety Valve LaserDocumento15 pagineSafety Valve Lasersajjad_naghdi241Nessuna valutazione finora

- Esd Valve Actuator SizingDocumento19 pagineEsd Valve Actuator Sizingshinojbaby4148Nessuna valutazione finora

- A Coverage On Safety ValveDocumento55 pagineA Coverage On Safety Valveagaurav2001100% (4)

- gps1 - gps220 gps230 EomDocumento28 paginegps1 - gps220 gps230 EomThanh Nghị BùiNessuna valutazione finora

- HansenDocumento4 pagineHansenBruna MacedoNessuna valutazione finora

- Boiler Safety Valve Regulations: Based On ABS Rules (2005)Documento18 pagineBoiler Safety Valve Regulations: Based On ABS Rules (2005)Muhammad Nasim AbbasNessuna valutazione finora

- 03 Valve ENGDocumento34 pagine03 Valve ENGEzrizalSaidinNessuna valutazione finora

- Guide: Expansion VesselDocumento2 pagineGuide: Expansion VesselVivek KhannaNessuna valutazione finora

- Installation of Steam Safety ValvesDocumento3 pagineInstallation of Steam Safety ValvestylerstearnsNessuna valutazione finora

- Win General CatalogDocumento14 pagineWin General CatalogSandi AslanNessuna valutazione finora

- ValvesDocumento44 pagineValvesأحمد محمد قدريNessuna valutazione finora

- BirkettDocumento104 pagineBirkettscribdkhatnNessuna valutazione finora

- 08-Conv Valves Product InfoDocumento18 pagine08-Conv Valves Product Infoakrk777Nessuna valutazione finora

- Best Practices For Steam Control Valve InstallationDocumento4 pagineBest Practices For Steam Control Valve InstallationYasmin.Shunmugam4188Nessuna valutazione finora

- Best Practices For Steam Control Valve InstallationDocumento4 pagineBest Practices For Steam Control Valve InstallationBen MusimaneNessuna valutazione finora

- Kenmore Power Miser 9 #153.327466 ManualDocumento32 pagineKenmore Power Miser 9 #153.327466 ManualjkwandmanNessuna valutazione finora

- What Is Valve Backseat TestDocumento2 pagineWhat Is Valve Backseat TestMADHAN RAMAMOORTHYNessuna valutazione finora

- Boiler Safety ValveDocumento11 pagineBoiler Safety ValveAayush Agrawal100% (1)

- Breather Valves - Pressure - Vacuum Relief ValvesDocumento6 pagineBreather Valves - Pressure - Vacuum Relief Valvesmohamed abd eldayemNessuna valutazione finora

- LuoDocumento20 pagineLuohacenescribdNessuna valutazione finora

- PRV Oil Safety Valve Henry 5600Documento3 paginePRV Oil Safety Valve Henry 5600pm2013Nessuna valutazione finora

- Basics of Pressure Relief Valves, Article, Beswick EngineeringDocumento4 pagineBasics of Pressure Relief Valves, Article, Beswick EngineeringAnonymous 818o0FhNpNessuna valutazione finora

- Training Program On: Pressure Relief ValveDocumento71 pagineTraining Program On: Pressure Relief ValveShoaib JadoonNessuna valutazione finora

- 10 ValvesDocumento23 pagine10 ValvesPower PlantNessuna valutazione finora

- Writeup On Safety Valve Erv PDFDocumento28 pagineWriteup On Safety Valve Erv PDFSravan DasariNessuna valutazione finora

- Boiler Mounting and AccessoriesDocumento20 pagineBoiler Mounting and AccessoriesAshok Joshi92% (12)

- Inspection Inspection and Test Plan For Pressure Safety Valve and Test Plan For Pressure Safety ValveDocumento4 pagineInspection Inspection and Test Plan For Pressure Safety Valve and Test Plan For Pressure Safety ValveTri Budiman Jabarti100% (1)

- SAES-L-140 PDF Download - Thermal Expansion Relief in Piping - PDFYARDocumento6 pagineSAES-L-140 PDF Download - Thermal Expansion Relief in Piping - PDFYARZahidRafiqueNessuna valutazione finora

- 7 Steam - SafetyDocumento5 pagine7 Steam - SafetyYeshitilaAyalewNessuna valutazione finora

- Best Practices For Installing Safety ValvesDocumento6 pagineBest Practices For Installing Safety ValvesAndhika HerdiawanNessuna valutazione finora

- Manual Valvula PCVDocumento16 pagineManual Valvula PCVzamirgothNessuna valutazione finora

- Batu Pig Valve Brochure v4Documento16 pagineBatu Pig Valve Brochure v4Tariq NbsNessuna valutazione finora

- Breather ValvesDocumento3 pagineBreather Valves@@ng100% (1)

- Standard Gate Valves ManualDocumento8 pagineStandard Gate Valves ManualmechanikyNessuna valutazione finora

- Becker EmergShtdwnValve BrochureDocumento8 pagineBecker EmergShtdwnValve BrochureAnonymous b9ylgFXNessuna valutazione finora

- Incorporated ValvesDocumento7 pagineIncorporated ValvesAlp HaNessuna valutazione finora

- Katalog p310 - 07Documento7 pagineKatalog p310 - 07agustinusidNessuna valutazione finora

- Valve Safety With M2 SeriesDocumento4 pagineValve Safety With M2 SeriesYang Gul LeeNessuna valutazione finora

- MSS SP 134 2006Documento18 pagineMSS SP 134 2006Rio WitcandraNessuna valutazione finora

- Tech Boiler Operation and Maintenance 20111025Documento3 pagineTech Boiler Operation and Maintenance 20111025Fana AkalNessuna valutazione finora

- 45Kg Cylinder & Valve Assembly PN.81-100067-002Documento4 pagine45Kg Cylinder & Valve Assembly PN.81-100067-002max_powerNessuna valutazione finora

- Sur - Flo Turbine MeterDocumento40 pagineSur - Flo Turbine MeterCheng HuangNessuna valutazione finora

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Prevention of Actuator Emissions in the Oil and Gas IndustryDa EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNessuna valutazione finora

- GNED500 Originial Textbook PDFDocumento200 pagineGNED500 Originial Textbook PDFeglits4170100% (1)

- Child Labour in IndiaDocumento9 pagineChild Labour in Indiaeglits4170Nessuna valutazione finora

- ESET211-Week 1 - Introduction and Numbering SystemsDocumento27 pagineESET211-Week 1 - Introduction and Numbering SystemsMonique HepburnNessuna valutazione finora

- GNED500 Originial Textbook PDFDocumento200 pagineGNED500 Originial Textbook PDFeglits4170100% (1)

- ESET 212 LECTURE - Week 6 PDFDocumento34 pagineESET 212 LECTURE - Week 6 PDFeglits4170Nessuna valutazione finora

- Russian Church Cuts Ties With Indian Orthodox Catholicos Over UkraineDocumento2 pagineRussian Church Cuts Ties With Indian Orthodox Catholicos Over Ukraineeglits4170Nessuna valutazione finora

- Assignment On Renewable EnergyDocumento3 pagineAssignment On Renewable Energyeglits4170Nessuna valutazione finora

- 014.offer MechelDocumento1 pagina014.offer Mecheleglits4170Nessuna valutazione finora

- About GeologyDocumento8 pagineAbout Geologyeglits4170Nessuna valutazione finora

- Fundamentals - 21 Apr 18Documento826 pagineFundamentals - 21 Apr 18eglits4170Nessuna valutazione finora

- Busbar Quotation Bank 1Documento5 pagineBusbar Quotation Bank 1eglits4170Nessuna valutazione finora

- CV Template Finance Bank TellerDocumento2 pagineCV Template Finance Bank TellerWemmy TakaNessuna valutazione finora

- FaxDocumento3 pagineFaxeglits4170Nessuna valutazione finora

- 013.hotel and Residental Tower 2B+G+38F EscDocumento2 pagine013.hotel and Residental Tower 2B+G+38F Esceglits4170Nessuna valutazione finora

- SFD and BMDDocumento278 pagineSFD and BMDRama KumarNessuna valutazione finora

- East & West Express (An ATCO Group of Company)Documento12 pagineEast & West Express (An ATCO Group of Company)eglits4170Nessuna valutazione finora

- Quotation of PVC-U Drainage Pipe Sell3 Final2Documento5 pagineQuotation of PVC-U Drainage Pipe Sell3 Final2Im ChinithNessuna valutazione finora

- Penawaran Harga PT. Sinar Laut InternusaDocumento26 paginePenawaran Harga PT. Sinar Laut InternusaSalwa AnggreaniNessuna valutazione finora

- Solving Pump Inlet ProblemsDocumento4 pagineSolving Pump Inlet ProblemsterracesNessuna valutazione finora

- Komatsu HydraulicsDocumento50 pagineKomatsu Hydraulicserick_oke100% (8)

- 3.fluid Power EngineeringDocumento13 pagine3.fluid Power Engineeringsnemo30Nessuna valutazione finora

- IS4997.1968 Hyd Jump N Stilling BasinDocumento25 pagineIS4997.1968 Hyd Jump N Stilling BasinmitnathNessuna valutazione finora

- Hydraulics & Pneumatics Chapter 1: Hydraulics (Hydraulic Pump)Documento21 pagineHydraulics & Pneumatics Chapter 1: Hydraulics (Hydraulic Pump)gkhnNessuna valutazione finora

- P&ID Check ListDocumento3 pagineP&ID Check Listankur2061Nessuna valutazione finora

- Pumps and CompressorsDocumento16 paginePumps and CompressorsAbc AbcNessuna valutazione finora

- Chapter 7 Rev 2 Rotation CircuitsDocumento19 pagineChapter 7 Rev 2 Rotation CircuitsAnonymous 340A7vnwV1Nessuna valutazione finora

- Plumbing - Max Fajardo PDFDocumento175 paginePlumbing - Max Fajardo PDFKim Agbon SabayNessuna valutazione finora

- Geoline Spare Parts Catalogue 2018 A00 LQDocumento428 pagineGeoline Spare Parts Catalogue 2018 A00 LQGuilherme PaesNessuna valutazione finora

- Case SR130, SR160, SR175, SV185, SR220, SR250, SV250, SV30, TR320, TV380 Sist HidráulicoDocumento62 pagineCase SR130, SR160, SR175, SV185, SR220, SR250, SV250, SV30, TR320, TV380 Sist Hidráulicojhon castroNessuna valutazione finora

- Final Examination For Tech 1d and Btled Ia 20Documento5 pagineFinal Examination For Tech 1d and Btled Ia 20cyrelle rose jumentoNessuna valutazione finora

- Yanbu: Export Refinery ProjectDocumento7 pagineYanbu: Export Refinery ProjectJanakiraman MalligaNessuna valutazione finora

- M8456 2 TrusealDocumento3 pagineM8456 2 Trusealk_tevenNessuna valutazione finora

- Design Construction EjectorDocumento136 pagineDesign Construction EjectorChirag SabalparaNessuna valutazione finora

- Technical Data Sheet: Model MD2 - 2" Dry Valve Riser AssemblyDocumento13 pagineTechnical Data Sheet: Model MD2 - 2" Dry Valve Riser AssemblyDjapaNessuna valutazione finora

- (Centrifugal Pump Calculation For DM PW Water To R-401Documento20 pagine(Centrifugal Pump Calculation For DM PW Water To R-401Ashish PawarNessuna valutazione finora

- Reciprocating Pump - Useful EquationsDocumento3 pagineReciprocating Pump - Useful EquationsvishwanathNessuna valutazione finora

- Calzoni3 5 1100aDocumento2 pagineCalzoni3 5 1100aSilvio RomanNessuna valutazione finora

- Application of Pump: CentrifugalDocumento8 pagineApplication of Pump: CentrifugalLipika GayenNessuna valutazione finora

- Fluid Mechanics and Hydraulics (Revised Edition) - GillesaniaDocumento249 pagineFluid Mechanics and Hydraulics (Revised Edition) - GillesaniaBLANK BLANK95% (79)

- Piping Design AidsDocumento248 paginePiping Design AidsSunday PaulNessuna valutazione finora

- 2347 Hydraulics and Fluid Power Control SystemsDocumento3 pagine2347 Hydraulics and Fluid Power Control SystemsKollikonda RameshNessuna valutazione finora

- Component Locations: 777F and 777F OEM Off-Highway Truck Hydraulic SystemDocumento4 pagineComponent Locations: 777F and 777F OEM Off-Highway Truck Hydraulic SystemMScLxNessuna valutazione finora

- (KENR9561-00) Schematic - 793F OHT Air SystemDocumento2 pagine(KENR9561-00) Schematic - 793F OHT Air SystemFredy Manrique Asto100% (1)

- Oilgear Specificl Controls TrainingDocumento26 pagineOilgear Specificl Controls TrainingYuriPasenkoNessuna valutazione finora

- KSB VALVE With HS CodeDocumento2 pagineKSB VALVE With HS Codezakaria masud sonyNessuna valutazione finora

- Appendix - EDocumento21 pagineAppendix - EIqbalNessuna valutazione finora