Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

EXP-3 To Perform Polarity Test On Single Phase Transformer and Polarity

Caricato da

sameerpatel15770Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

EXP-3 To Perform Polarity Test On Single Phase Transformer and Polarity

Caricato da

sameerpatel15770Copyright:

Formati disponibili

G.H.PATEL COLLEGE OF ENGINEERING AND TECHNOLOGY V.V.

NAGAR

2180901-TESTING AND COMMISSIONING OF ELECTRICAL EQUIPMENT

Department of Electrical Engineering

Date: __/__/20__

Experiment: 3

AIM: To perform Polarity test on single phase transformer and polarity

and ratio test on current transformer.

APPARATUS REQUIRED: 825VA transformer, variac, multimeter, jumper wire,

Current transformer, DC supply, Galvanometer.

PART A: Polarity test on single phase transformer

RATIONLE: With power or distribution transformers, polarity is important only if the need arises

to parallel transformers to gain additional capacity or to hook up three single-phase transformers to

make a three-phase bank. In situations where the secondary bushing identification is not available or

when a transformer has been rewound, it may be necessary to determine the transformer polarity by

test. The way the connections are made affects angular displacement, phase rotation, and direction of

rotation of connected motors.

Polarity is also important when hooking up current transformers for relay protection and

metering. Transformer polarity depends on which direction coils are wound around the core

(clockwise or counterclockwise) and how the leads are brought out. Transformers are sometimes

marked at their terminals with polarity marks. Often, polarity marks are shown as white paint dots

(for plus) or plus-minus marks on the transformer and Symbols on the nameplate. These marks show

the connections where the input and output voltages (and currents) have the same instantaneous

polarity.

In case of transformer each terminal of primary and secondary winding is alternatively

positive and negative w.r.t each other. It is important to know the relative polarity of primary and

secondary terminal at any instant of time for making the correct connections under the situation

mentioned above.

FORMULAE: V3=V1+V2

+ve for additive polarity

-ve for subtractive polarity

Department of Electrical Engineering--GCET

G.H.PATEL COLLEGE OF ENGINEERING AND TECHNOLOGY V.V.NAGAR

2180901-TESTING AND COMMISSIONING OF ELECTRICAL EQUIPMENT

Department of Electrical Engineering

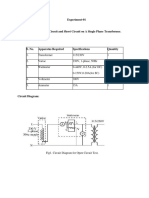

CIRCUIT CONNECTION

PROCEDURE:

1. The P1 (left-hand) primary bushing and the left-hand secondary bushing are temporarily

jumpered together and a test voltage is applied to the transformer primary.

2. The resultant voltage is measured between the right-hand bushings.

3. If the measured voltage is greater than the applied voltage, the transformer is Additive

Polarity because the polarity is such that the secondary voltage is being added to the applied

primary voltage.

4. If, the measured voltage across the right-hand bushings is less than the applied primary

voltage, the transformer is Subtractive Polarity.

TABULAR COLUMN:

Sr. Primary Secondary V3=V1+V2 Remarks

No Voltage voltage Additive/Subtractive

V1 V2

1

Department of Electrical Engineering--GCET

G.H.PATEL COLLEGE OF ENGINEERING AND TECHNOLOGY V.V.NAGAR

2180901-TESTING AND COMMISSIONING OF ELECTRICAL EQUIPMENT

Department of Electrical Engineering

PART B: polarity and ratio test on current transformer.

RATIONALE: Polarity markings of transformer windings are a means of describing the relative

directions in which the two windings are wound on the transformer core. The terminals identified by

solid

marks indicate the starting ends of the two windings, meaning that if these are considered to be the

starting points, and we trace the two windings along the transformer core, both windings will go

around the core in the same sense (i.e. counterclockwise or clockwise). In a transformer, if one of the

winding currents is considered to be flowing into the marked terminal, the current in the other

winding should be considered to be leaving its marked terminal. The two currents will then be

(approximately) in phase with each other. Similarly, the voltages of the two windings, when

measured from the unmarked terminal to the marked terminal, will be (approximately) in phase with

each other. This convention for polarity marking is also used for current transformers. An alternative

way is to label the primary winding terminals H1 and H2, and the secondary winding terminals Xl

and X2. H1 and X1 may then be assumed to have the polarity mark on them. Both of these

conventions are shown in Figure. Since current transformer secondary windings are connected in

quite complex networks in the overall protection systems for three-phase apparatus, it is extremely

important that the meaning of the polarity marking be clearly understood. A current I1 in the primary

winding of the CT will produce a current I2 in its secondary winding, where the magnitudes of I1 and

I2 are in inverse proportion to the turns ratio (neglecting the magnetizing current for the moment),

and their phase angles will be as indicated by the polarity markings. An easy way to remember this is

to think of H1 being the same terminal as X1. The continuity of the current is then reflected by the

polarity markings. It is well to think of the current transformer secondary winding as a constant

current source of I2 as determined by I1.

Polarity in a CT is similar to the identification of +ve and –ve terminals of a battery. Polarity is very

important when connecting relays, as this will determine correct operation or not depending on the

types of relays. The terminals of CT are marked by P1 and P2 on the primary, and S1 and S2 on the

secondary as per Fig. BS 3938 states that at the instant when current is flowing from P1 to P2 in

primary, then current, in secondary must flow from S1 to S2 through the external circuit.

Department of Electrical Engineering--GCET

G.H.PATEL COLLEGE OF ENGINEERING AND TECHNOLOGY V.V.NAGAR

2180901-TESTING AND COMMISSIONING OF ELECTRICAL EQUIPMENT

Department of Electrical Engineering

Polarity Test

Perform a polarity test of each current transformer. There are two generally accepted methods of

testing a CT’s polarity using simple meters and connections:

1. DC Kick/Flick Test For this test, a dc battery, a dc voltmeter or ammeter (preferably analog), and

test leads are required. This method is a quick and easy test for polarity, but there is a possibility that

it may leave remnant flux in the CT. Remnant flux may cause saturation when the CT is next

energized. Always perform an excitation/saturation test after performing this test. The steps of the dc

kick/flick test are as follows

PROCEDURE:

1. Connect the positive of the voltmeter to the H1 (marked) terminal of the high-voltage side of

the CT and the negative lead to the H2 as shown in Figure 3.

2. Calculate the expected voltage using the battery voltage and the CT ratio. (Battery voltage/CT

ratio.)

3. Connect the negative terminal of the battery to the non polarity of the CT winding under test.

Momentarily touch or connect the battery’s positive terminal to the polarity terminal of the CT

winding under test.

4. Closely watch the needle or analog scale of the voltmeter. It should jump in the positive

direction.

This happens in a fraction of a second, so the meter must be monitored very closely. If the

voltmeter kicks in the positive direction, the polarity marks are correct. If it kicks in the

negative direction, the polarity marks are incorrect.

2. AC Voltage Method: This method digs deep into transformer theory and can be used with any

kind of transformer. Most transformer polarities are marked with additive polarity that allows

creation of an autotransformer by connecting X1 and H2 or H1 and X2 together. This method is

limited by the accuracy of the meters and may not be reliable with unstable source voltages (such as

construction power or generator) and high ratio CTs due to the low H side voltages induced

Department of Electrical Engineering--GCET

G.H.PATEL COLLEGE OF ENGINEERING AND TECHNOLOGY V.V.NAGAR

2180901-TESTING AND COMMISSIONING OF ELECTRICAL EQUIPMENT

Department of Electrical Engineering

Ratio test

Ratio testing involves simultaneously measuring the primary current and the secondary current in

order to calculate the operating ratio of the circuit. This ratio value is compared to the rated ratio to

determine the percent error for that CT. Ratio values greater than the rated ratio result in under-billing

and ratio values less than the rated ratio result in over-billing. As presented in the Table, ratio errors

can be caused by manufacturer error, shorting bar left connected at the CT, shorted primary turns,

shorted secondary turns, magnetization, etc. Most utilities use an error threshold of plus or minus 2

percent to determine adequate ratio performance of installed CT’s. Others choose to have an error

threshold of 1 percent for their large CT customers and 2 percent for their smaller CT customers.

Department of Electrical Engineering--GCET

G.H.PATEL COLLEGE OF ENGINEERING AND TECHNOLOGY V.V.NAGAR

2180901-TESTING AND COMMISSIONING OF ELECTRICAL EQUIPMENT

Department of Electrical Engineering

Sr.No Primary Current/P1 Secondary Current Ratio

S2

Questions:

1. List out Various test conducted on transformer.

2. Explain importance of polarity in transformer.

3. Explain polarity test of power transformer.

4. Explain polarity test of 1 phase transformer.

5. Why Polarity test important for CT?

6. How polarity test on CT is performed explain in brief.

7. Explain accuracy class of CT.

8. What is the ratio error?

Conclusion

Department of Electrical Engineering--GCET

Potrebbero piacerti anche

- Transformer Theory Questions and AnswersDocumento9 pagineTransformer Theory Questions and AnswersVishal Sawh100% (3)

- Core and Copper Losses of A Single Phase TransformerDocumento7 pagineCore and Copper Losses of A Single Phase TransformerAsim NoonNessuna valutazione finora

- 3 Phase Transformer-1.SolutionDocumento30 pagine3 Phase Transformer-1.Solutionajeet kumarNessuna valutazione finora

- Polarity Test of TransformerDocumento3 paginePolarity Test of Transformerdebarshi100% (1)

- Transformer Solved Examples of Basic Electrical Eng by Nagrath and KothariDocumento4 pagineTransformer Solved Examples of Basic Electrical Eng by Nagrath and KothariAnurag ZwNessuna valutazione finora

- To Determine The Voltage Regulation With Resistive, Inductive and Capacitive Loading of A TransformerDocumento3 pagineTo Determine The Voltage Regulation With Resistive, Inductive and Capacitive Loading of A TransformerMd RionNessuna valutazione finora

- Auto TransformerDocumento20 pagineAuto TransformerDawa PenjorNessuna valutazione finora

- 2-Charge Formation in Clouds-1Documento26 pagine2-Charge Formation in Clouds-1Gokulraja GokulNessuna valutazione finora

- Generation of High D.C. Voltages & AC VoltagesDocumento14 pagineGeneration of High D.C. Voltages & AC VoltagesSumaira SaifNessuna valutazione finora

- Power Electronics & Drives: Unit: 1 Power Semiconductor DevicesDocumento24 paginePower Electronics & Drives: Unit: 1 Power Semiconductor DevicesTapobroto ChatterjeeNessuna valutazione finora

- Transformer Per Unit CalculationsDocumento19 pagineTransformer Per Unit CalculationsOwais Afzal Jan100% (1)

- EE4003 Power Systems II: Course SyllabusDocumento24 pagineEE4003 Power Systems II: Course SyllabusKalum ChandraNessuna valutazione finora

- EXP-4 To Perform Vector Group Testing On 3 Phase Transformer.Documento7 pagineEXP-4 To Perform Vector Group Testing On 3 Phase Transformer.sameerpatel15770Nessuna valutazione finora

- Merz Price Differential Protection For TransformerDocumento2 pagineMerz Price Differential Protection For TransformerapjbalamuruganNessuna valutazione finora

- Transformers 17.7.14Documento7 pagineTransformers 17.7.14TharinduNessuna valutazione finora

- Tutorial EDDocumento10 pagineTutorial EDPavan KhetrapalNessuna valutazione finora

- Test On TransformerDocumento13 pagineTest On TransformerGurvinder Singh Virdi100% (2)

- Raw 05 - MATLAB Simulation of Reactive Power Compensation (26-31)Documento6 pagineRaw 05 - MATLAB Simulation of Reactive Power Compensation (26-31)qw erNessuna valutazione finora

- Current Transformer - Electrical Notes & ArticlesDocumento47 pagineCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- 1.6 MVA Dry Transformer DesignDocumento21 pagine1.6 MVA Dry Transformer DesignJemal MusaNessuna valutazione finora

- Determination of Positive, Negative and Zero Sequence Impedances of Three Phase TransformerDocumento3 pagineDetermination of Positive, Negative and Zero Sequence Impedances of Three Phase Transformerarjuna4306100% (1)

- 1.per Unit System PDFDocumento10 pagine1.per Unit System PDFlaxman100% (1)

- RMSDocumento11 pagineRMSRsuneelNessuna valutazione finora

- IEEMA-Basics of Dual Ratio TransformersDocumento3 pagineIEEMA-Basics of Dual Ratio TransformersHari Krishna.MNessuna valutazione finora

- Chapter 7Documento15 pagineChapter 7Khaled RabeaNessuna valutazione finora

- 10eel58 Transformers and Induction Machines LaboratoryDocumento32 pagine10eel58 Transformers and Induction Machines Laboratorysvinod s100% (2)

- Scott-T Connection of Transformer Power Point - EditedDocumento27 pagineScott-T Connection of Transformer Power Point - EditedLloydPanganiban75% (4)

- Testing of Transformers-OC&SC-Sumpners TestDocumento15 pagineTesting of Transformers-OC&SC-Sumpners Testshree100% (1)

- A Review About Vector Group Connections in TransformersDocumento7 pagineA Review About Vector Group Connections in TransformersMohamed Wahid100% (1)

- 10 4 Ffab: Calculate Here If The Primary Input Current Is Unknown. Select Primary Wire Gauge For 200A/Sq - CM PG 336Documento8 pagine10 4 Ffab: Calculate Here If The Primary Input Current Is Unknown. Select Primary Wire Gauge For 200A/Sq - CM PG 336Geovany Mena VillagraNessuna valutazione finora

- unit-II TransformersDocumento19 pagineunit-II Transformersc.naresh9727100% (1)

- Pe Chapter 6 DC Ac 1Documento32 paginePe Chapter 6 DC Ac 1Muhammad UsamaNessuna valutazione finora

- Three Phase Transformers PDFDocumento53 pagineThree Phase Transformers PDFSanya0% (1)

- Transformer PolarityDocumento4 pagineTransformer Polarityboy2959Nessuna valutazione finora

- Short Transmission LineDocumento18 pagineShort Transmission LineNaga AnanthNessuna valutazione finora

- Multilevelinverter PPT FINALDocumento27 pagineMultilevelinverter PPT FINALROSHAN KUMAR GUPTANessuna valutazione finora

- Questions & Answers On Efficiency and Voltage RegulationDocumento18 pagineQuestions & Answers On Efficiency and Voltage Regulationkibrom atsbhaNessuna valutazione finora

- Series & Shunt CapacitorsDocumento5 pagineSeries & Shunt Capacitorsneo100% (3)

- EM-I Lab Viva Questions Updated OnDocumento6 pagineEM-I Lab Viva Questions Updated OnNagamohan BilluNessuna valutazione finora

- TransformersDocumento77 pagineTransformersAvik PoudelNessuna valutazione finora

- EE 8602 - Protection and Switchgear Unit I - MCQ BankDocumento11 pagineEE 8602 - Protection and Switchgear Unit I - MCQ Bankpoonam yadavNessuna valutazione finora

- Lecture TransformersDocumento32 pagineLecture TransformersDr-Gurpreet KumarNessuna valutazione finora

- Vector GroupDocumento8 pagineVector GroupSuraj Kumar GuptaNessuna valutazione finora

- 4 Controlled Rectifier DC DrivesDocumento25 pagine4 Controlled Rectifier DC DrivesshonmlrNessuna valutazione finora

- Lab 13-Under Voltage and Over Voltage Monitoring Numerical RelayDocumento5 pagineLab 13-Under Voltage and Over Voltage Monitoring Numerical RelayAliza Sharif100% (1)

- Dual Ratio Transformer MonographDocumento7 pagineDual Ratio Transformer MonographGhanshyam Lalwani0% (1)

- AutotransformerDocumento16 pagineAutotransformerKuzma John PadriqueNessuna valutazione finora

- HW 3 SolDocumento3 pagineHW 3 SolJonathan Bathistoel100% (1)

- Solution Manual of Electric Machines (2n Edition) - Charles I. HubertDocumento22 pagineSolution Manual of Electric Machines (2n Edition) - Charles I. HubertMohammadAshraful100% (1)

- Machine LabDocumento7 pagineMachine LabNurjahan-Ara StudentNessuna valutazione finora

- Per Unit System Lecture NotesDocumento22 paginePer Unit System Lecture NotesMukasa Mercy PeterNessuna valutazione finora

- 6 Electrical Tests For CTDocumento13 pagine6 Electrical Tests For CTbhukya lachiramNessuna valutazione finora

- Cycloaliphatic Epoxy ResinDocumento13 pagineCycloaliphatic Epoxy Resinbishnu pada palNessuna valutazione finora

- Power System Lab-IIDocumento14 paginePower System Lab-IIharshadeepmukherjee529Nessuna valutazione finora

- Potentiometers: Nstrument Ransformers ANDDocumento26 paginePotentiometers: Nstrument Ransformers ANDDIVYA PRASOONA CNessuna valutazione finora

- Power Systems 2 CT PT AllDocumento6 paginePower Systems 2 CT PT Allharshadeepmukherjee529Nessuna valutazione finora

- 1.testing of CT, PT and Insulator StringsDocumento8 pagine1.testing of CT, PT and Insulator StringsBhanu100% (2)

- What Is The Polarity Test - Simple Guide - LinquipDocumento9 pagineWhat Is The Polarity Test - Simple Guide - Linquipbiju mrNessuna valutazione finora

- Electrical Machine-1 Manual PDFDocumento40 pagineElectrical Machine-1 Manual PDFsoumencha80% (5)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Load Test On DC Shunt Motor: Expt. No: DateDocumento7 pagineLoad Test On DC Shunt Motor: Expt. No: Datesameerpatel15770Nessuna valutazione finora

- Design of AC MachinesDocumento24 pagineDesign of AC Machinessameerpatel1577050% (2)

- Load Test of Single Phase Transformer Phase: Expt. No: DateDocumento11 pagineLoad Test of Single Phase Transformer Phase: Expt. No: Datesameerpatel15770Nessuna valutazione finora

- Experiment-1 Speed Control of DC Motor Using Matlab SimulinkDocumento4 pagineExperiment-1 Speed Control of DC Motor Using Matlab Simulinksameerpatel15770Nessuna valutazione finora

- Open Circuit & Short Open Circuit & Short Circuit Test Single Phase Transformer Tests of RmerDocumento14 pagineOpen Circuit & Short Open Circuit & Short Circuit Test Single Phase Transformer Tests of Rmersameerpatel15770Nessuna valutazione finora

- General Design AspectsDocumento14 pagineGeneral Design Aspectssameerpatel15770Nessuna valutazione finora

- Magnetic HysteresisDocumento6 pagineMagnetic Hysteresissameerpatel15770Nessuna valutazione finora

- Transformer 4Documento87 pagineTransformer 4sameerpatel15770Nessuna valutazione finora

- Design of Cooling SystemDocumento5 pagineDesign of Cooling Systemsameerpatel15770100% (1)

- Exp-1 To Get The Hysteresis Loop of Ferromagnetic Material.Documento6 pagineExp-1 To Get The Hysteresis Loop of Ferromagnetic Material.sameerpatel15770Nessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological Universitysameerpatel15770Nessuna valutazione finora

- Group Discussion ETC 3130004Documento15 pagineGroup Discussion ETC 3130004sameerpatel15770Nessuna valutazione finora

- Electrical Machine Design - See1304: Unit - IDocumento61 pagineElectrical Machine Design - See1304: Unit - Isameerpatel15770Nessuna valutazione finora

- Chapter-1: Introduction: 1.2 Aim and Objective of ProjectDocumento12 pagineChapter-1: Introduction: 1.2 Aim and Objective of Projectsameerpatel15770Nessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological Universitysameerpatel15770Nessuna valutazione finora

- Formal Presentations - ETC - 3130004Documento19 pagineFormal Presentations - ETC - 3130004sameerpatel15770Nessuna valutazione finora

- Synchronous Machines Synchronous Machines: OutlineDocumento31 pagineSynchronous Machines Synchronous Machines: Outlinesameerpatel15770Nessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological Universitysameerpatel15770Nessuna valutazione finora

- Electrical Machines & Measurement B.E. 4 SemesterDocumento4 pagineElectrical Machines & Measurement B.E. 4 Semestersameerpatel15770Nessuna valutazione finora

- Gujarat Technological University: Subject Code:150901 Date: Subject Name: Electrical Machine - II Time: Total Marks: 70Documento1 paginaGujarat Technological University: Subject Code:150901 Date: Subject Name: Electrical Machine - II Time: Total Marks: 70sameerpatel15770Nessuna valutazione finora

- Gujarat Technological UniversityDocumento1 paginaGujarat Technological Universitysameerpatel15770Nessuna valutazione finora

- Gujarat Technological UniversityDocumento1 paginaGujarat Technological Universitysameerpatel15770Nessuna valutazione finora

- EXP-4 To Perform Vector Group Testing On 3 Phase Transformer.Documento7 pagineEXP-4 To Perform Vector Group Testing On 3 Phase Transformer.sameerpatel15770Nessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological Universitysameerpatel15770Nessuna valutazione finora

- Lecture 08 - Smart GridDocumento45 pagineLecture 08 - Smart GridSaskia ClaraNessuna valutazione finora

- Drive Selection For LNG FPSODocumento5 pagineDrive Selection For LNG FPSOthlim19078656Nessuna valutazione finora

- L&T MN RelaysDocumento6 pagineL&T MN RelaysArun KumarNessuna valutazione finora

- Battery Load Cycle-23.04.10Documento12 pagineBattery Load Cycle-23.04.10Navneet SinghNessuna valutazione finora

- Facts Devices in EHV LINESDocumento19 pagineFacts Devices in EHV LINESAbhishekNessuna valutazione finora

- PLC RSC 24DC 21 UwlDocumento3 paginePLC RSC 24DC 21 Uwlsteam100deg8229Nessuna valutazione finora

- Discussion of The Importance of IGBT in Variable-Frequency DriveDocumento6 pagineDiscussion of The Importance of IGBT in Variable-Frequency DriveakramNessuna valutazione finora

- Cable Sizing Calculator IEC 60364 and HD 60364Documento4 pagineCable Sizing Calculator IEC 60364 and HD 60364KhalilKolachiNessuna valutazione finora

- DS20180615 Conext SmartGen Power SystemDocumento2 pagineDS20180615 Conext SmartGen Power SystemIsmo TalkaNessuna valutazione finora

- Aruna Biomass Company ProfileDocumento9 pagineAruna Biomass Company ProfileAdhavan ThamizhanNessuna valutazione finora

- Power ElecsDocumento7 paginePower Elecsjj012586Nessuna valutazione finora

- Dsa 8059Documento8 pagineDsa 8059joseNessuna valutazione finora

- Siemens SGen-1000A+Series Nov14Documento4 pagineSiemens SGen-1000A+Series Nov14Jaylord CrisostomoNessuna valutazione finora

- P345 20Hz Stator Earth Fault Application GuideDocumento25 pagineP345 20Hz Stator Earth Fault Application GuiderajeshNessuna valutazione finora

- Design and Control of Microgrid Fed by RenewableDocumento10 pagineDesign and Control of Microgrid Fed by RenewablestarboyNessuna valutazione finora

- The Chernobyl Nuclear DisasterDocumento2 pagineThe Chernobyl Nuclear DisasterZorisbel MedinaNessuna valutazione finora

- Techno-Economic Evaluation of 1500MW Generation Connection To The Main Interconnected Transmission System in OmanDocumento11 pagineTechno-Economic Evaluation of 1500MW Generation Connection To The Main Interconnected Transmission System in OmanKoti ReddyNessuna valutazione finora

- Thermal Power PlantDocumento29 pagineThermal Power PlantSiri VenniNessuna valutazione finora

- Plts Chemco Karawang 3.2 MWP: LegendDocumento3 paginePlts Chemco Karawang 3.2 MWP: LegendmuliamakmurNessuna valutazione finora

- Presentation of Protection & Control IEDs - Selection GuideDocumento12 paginePresentation of Protection & Control IEDs - Selection GuidecostelchelariuNessuna valutazione finora

- ZEESHAN AHMED Industrial Training ReportDocumento19 pagineZEESHAN AHMED Industrial Training ReportAsifNessuna valutazione finora

- Substation Filter BankSpecsDocumento7 pagineSubstation Filter BankSpecsTudor BostanNessuna valutazione finora

- K2ZK 001 PDFDocumento32 pagineK2ZK 001 PDFJoan HillNessuna valutazione finora

- How To Calculate Load Capacity of A HomeDocumento16 pagineHow To Calculate Load Capacity of A HomeMarine OpsNessuna valutazione finora

- LS 01 - Cke - LS.01.01. (04) .2017Documento114 pagineLS 01 - Cke - LS.01.01. (04) .2017Arisa Afiq0% (1)

- P410545 en 192S1P 8 Lto Smart Battery HDDocumento2 pagineP410545 en 192S1P 8 Lto Smart Battery HDQiang LiuNessuna valutazione finora

- Rectifier PS4890 DescriptionDocumento57 pagineRectifier PS4890 DescriptionMuhammad Rauf AkramNessuna valutazione finora

- Half-Wave Rectifier Feeding A DC MotorDocumento4 pagineHalf-Wave Rectifier Feeding A DC Motorhamza abdo mohamoudNessuna valutazione finora

- 1040 Day 1 SolarVision Ir Abdul Rahim Bin Ibrahim Energy Commission (Suruhanjaya Tenaga) CompressedDocumento28 pagine1040 Day 1 SolarVision Ir Abdul Rahim Bin Ibrahim Energy Commission (Suruhanjaya Tenaga) Compressedaramis_crosnierNessuna valutazione finora

- 2LBS+2VCB Ext Out Door With FrtuDocumento36 pagine2LBS+2VCB Ext Out Door With FrtuAnmol Srivastava100% (1)