Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

GC11 Pipe Thickness Calc

Caricato da

srinivasanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

GC11 Pipe Thickness Calc

Caricato da

srinivasanCopyright:

Formati disponibili

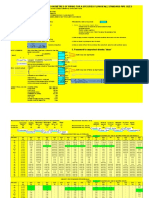

DOCUMENT TITLE PIPING CLASS. DOCUMENT NO.

PIPE THICKNESS CALCULATION REPORT GC11 - 2500#

PROJECT DESCRIPTION KAVIN PROJECT No. SHEET REV

OF

REVISION MARK

CONTRACTOR CONSULTANT PURCHASE ORDER No. REQUISITION No. SPECIFICATION No.

KAVIN ENGINEERING

AND SERVICES

PRIVATE LIMITED - - -

CLIENT NAME REV BY DATE CKD DATE APP. DATE DESCRIPTION

CLIENT'S REF.

-

ORIGINATOR ORIG. DATE

1 PIPE THICKNESS CALCULATION

2 BASIC THICKNESS CALCULATION

5 t=Pressure design thickness

6 C=corrosion allowance

7 P=Internal Design Pressure

8 Do=outside diameter of pipe

9 s=stress valve for material tableA-1

10 E= Quality factor from table A-1A or A-1B

11 W=Weld joint strength factor para 302.3.5(e) = 1

12 Y=Co-efficient from table 304.1.1

13 PIPING SPEC:GC11 BASE MATERIAL:CS RATING:2500#

Co-eff from 304.1.1

Selected Schedule

14

Thread Allowance

Actual Thickness

Thickness minus

Allowable Stress

Design Pressure

Value @ Design

Quality Factor

Mill Tolerance

Temperature

Adequate or

Dia. of Pipe

15

Inadequate

Calculated

Thickness

Allowance

Thickness

Corrosion

tolerance

Selected

16

Pipe

Material

17

18

19

20

OD

t (mm) tr (mm) c (mm) T(mm)

=t+c

21 P (kPa) D (mm) S (kPa) E Y (mm) (mm)

(mm)

22 NPS

23 0.5 21.34 27000 21.34 144790 1 0.4 1.8516 1.451 3 6.3026 SCH XXS 7.47 0.125 6.53625 OK

24 0.75 26.67 27000 26.67 144790 1 0.4 2.31406 1.451 3 6.76506 SCH XXS 7.82 0.125 6.8425 OK

SA 333 Gr.6

SEAMLESS

25 1 33.4 27000 33.4 144790 1 0.4 2.898 1.767 3 7.665 SCH XXS 9.09 0.125 7.95375 OK

26 1.5 48.3 27000 48.26 144790 1 0.4 4.18735 0 3 7.18735 SCH XXS 10.15 0.125 8.88125 OK

27 2 60.33 27000 60.33 144790 1 0.4 5.23462 0 3 8.23462 SCH XXS 11.07 0.125 9.68625 OK

28 3 88.9 27000 88.9 144790 1 0.4 7.71354 0 3 10.7135 SCH XXS 15.24 0.125 13.335 OK

29 4 114.3 27000 114.3 144790 1 0.4 9.91741 0 3 12.9174 SCH XXS 17.12 0.125 14.98 OK

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52 GENERAL NOTES:

53 1) THICKNESS CALCULATION AS PER CODE ASME B 31.3.

54 2) ALLOWABLE STRESS ARE BASED ON ASME B31.3

55 3) LINE DESIGN PRESSURE OF 270 Barg HAS BEEN CONSIDERED.

56 4) DESIGN TEMPERATURE CONSIDERED as 2000C

57

58

Potrebbero piacerti anche

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDocumento1 paginaPY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540Nessuna valutazione finora

- Thickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWDocumento117 pagineThickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWGohar ZamanNessuna valutazione finora

- Pipe Wall Thickness (Complete)Documento40 paginePipe Wall Thickness (Complete)Andri PutraNessuna valutazione finora

- Calculation of PipeReinforcement ASMEB31 1Documento4 pagineCalculation of PipeReinforcement ASMEB31 1threedlabsNessuna valutazione finora

- Steam tracing simulation determines Process Fluid TemperatureDocumento74 pagineSteam tracing simulation determines Process Fluid TemperaturecybermineNessuna valutazione finora

- Hydrotest Calculation FormulaDocumento1 paginaHydrotest Calculation FormulaSandipPatelNessuna valutazione finora

- ASME B31.3 CalculatorDocumento144 pagineASME B31.3 CalculatorLeoNessuna valutazione finora

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Documento1 paginaPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNessuna valutazione finora

- Trun CalcDocumento215 pagineTrun CalcmohamedeliasNessuna valutazione finora

- Pipe Wall Thickness CalculationDocumento8 paginePipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Material and anchor load data for steel pipeDocumento4 pagineMaterial and anchor load data for steel pipeMichael RobinsonNessuna valutazione finora

- PIPE THICKNESS CALCULATIONDocumento11 paginePIPE THICKNESS CALCULATIONvazzoleralex6884100% (1)

- Mechanical Design SpreadsheetDocumento1 paginaMechanical Design SpreadsheetHoney TiwariNessuna valutazione finora

- Pipes. Wall Thickness Calculation According ASME B31.3Documento98 paginePipes. Wall Thickness Calculation According ASME B31.3Saravanan SilambanNessuna valutazione finora

- Mitered BendsDocumento1 paginaMitered BendsTsouki TsoukiNessuna valutazione finora

- Code Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Documento4 pagineCode Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Edwardhutauruk100% (1)

- Calculate total pipe lengthDocumento6 pagineCalculate total pipe lengthImtinan MohsinNessuna valutazione finora

- Ancor Flanges Asme ViiiDocumento3 pagineAncor Flanges Asme ViiiAnjani PrabhakarNessuna valutazione finora

- Pipe SpecDocumento84 paginePipe SpecAbdullahNessuna valutazione finora

- Pdesign: 100 Barg Line Pipe Material: API Grade X60Documento64 paginePdesign: 100 Barg Line Pipe Material: API Grade X60Luong NgoNessuna valutazione finora

- Sizing Asme b31.3 2008Documento12 pagineSizing Asme b31.3 2008Enamul KhanNessuna valutazione finora

- Calculation BS 31.3Documento1 paginaCalculation BS 31.3prabhjot123Nessuna valutazione finora

- ASME Ver1 4 (Beta)Documento2 pagineASME Ver1 4 (Beta)arunradNessuna valutazione finora

- Pressure DropDocumento19 paginePressure DropGigis Kintan MyarthalunaNessuna valutazione finora

- Expansion LoopDocumento54 pagineExpansion Loopsteepa22Nessuna valutazione finora

- Pipe Branch Calculation SheetDocumento9 paginePipe Branch Calculation Sheetjleonos100% (3)

- Minimum Pipe Wall Thickness and MAWP SI Final ProtectedDocumento11 pagineMinimum Pipe Wall Thickness and MAWP SI Final Protectedjsfscibd100% (1)

- KHAZZAN/MAKAREM EWT PROJECT piping design parametersDocumento25 pagineKHAZZAN/MAKAREM EWT PROJECT piping design parametersRajeshvbNessuna valutazione finora

- SU Blind Plate ThicknessDocumento2 pagineSU Blind Plate Thicknessmanoj19801226100% (1)

- Calc Hoop StressDocumento11 pagineCalc Hoop StressApril TrevinoNessuna valutazione finora

- Gas Line Capacity CalculationDocumento2 pagineGas Line Capacity CalculationMario Mendoza100% (1)

- Weight and Size CalculatorDocumento4 pagineWeight and Size Calculatorbb84sharmaNessuna valutazione finora

- Pipe Thickness Calculation Data SheetDocumento1 paginaPipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9Nessuna valutazione finora

- Pump specifications and sizing for sewage treatment plantDocumento3 paginePump specifications and sizing for sewage treatment plantbharathNessuna valutazione finora

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocumento49 pagineDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Nessuna valutazione finora

- Pipe Wall Thickness Calculation @MechEngineersDocumento77 paginePipe Wall Thickness Calculation @MechEngineersHeri KurniawanNessuna valutazione finora

- Press "CTRL+M" To Calculate C: Calculation of Theoretical Orifice Flow and C For Sharp Edged OrificeDocumento14 paginePress "CTRL+M" To Calculate C: Calculation of Theoretical Orifice Flow and C For Sharp Edged Orificehardik033Nessuna valutazione finora

- PTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washingDocumento4 paginePTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washingalvinchuan100% (1)

- Line Sizing ProgramDocumento13 pagineLine Sizing ProgramYakubuNessuna valutazione finora

- Area Reinforcement CalculatorDocumento5 pagineArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Pipe Thickness Calculation AS Per ASME 31.3Documento11 paginePipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRNessuna valutazione finora

- Pressure Drop For Two Phase Flow in Horizontal Pipe: Chemical Engineer's GuideDocumento5 paginePressure Drop For Two Phase Flow in Horizontal Pipe: Chemical Engineer's GuideAbhijeet SachanNessuna valutazione finora

- INTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESDocumento89 pagineINTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESCastro Quinteros WinstonNessuna valutazione finora

- Hydraulic Sprinkler CalculationDocumento12 pagineHydraulic Sprinkler Calculation8benitez suiteNessuna valutazione finora

- Din 6618 1Documento10 pagineDin 6618 1Rad Imam VinoNessuna valutazione finora

- CCC1Documento5 pagineCCC1Uok RitchieNessuna valutazione finora

- Trunnion Calculation - MasterDocumento92 pagineTrunnion Calculation - MasterSrisaran Srinivas ArasavelliNessuna valutazione finora

- Cong Thuc Tinh Toan Piping ThicknessDocumento108 pagineCong Thuc Tinh Toan Piping ThicknessTruong Ngoc SonNessuna valutazione finora

- Piping Thickness by ScheduleDocumento4 paginePiping Thickness by SchedulekkabbaraNessuna valutazione finora

- Equipment ListDocumento7 pagineEquipment Listyadav yadavNessuna valutazione finora

- BRCDocumento1 paginaBRCRian ReffrainNessuna valutazione finora

- 102001-CRN-PIP-LIS-001 Line List - R0Documento3 pagine102001-CRN-PIP-LIS-001 Line List - R0Karl CaudalNessuna valutazione finora

- Petrofac: Side View B-BDocumento1 paginaPetrofac: Side View B-BNikhil chaundkarNessuna valutazione finora

- Partes PDFDocumento1 paginaPartes PDFdata493Nessuna valutazione finora

- Reference List ACHE PDFDocumento8 pagineReference List ACHE PDFMarakanaMaheshNessuna valutazione finora

- Design, Manufacturing, Supply, Installation, Construction & Commissioning of BQPS RLNG Spur Pipeline Project Line ListDocumento3 pagineDesign, Manufacturing, Supply, Installation, Construction & Commissioning of BQPS RLNG Spur Pipeline Project Line ListUmair A. KhanNessuna valutazione finora

- Issued For ConstructionDocumento1 paginaIssued For ConstructionTimothy OgbechieNessuna valutazione finora

- A_162_E01_EE_401_EQUIP-SS-1_REV-ModelDocumento1 paginaA_162_E01_EE_401_EQUIP-SS-1_REV-ModelManasNessuna valutazione finora

- 1778 0168 TH DWG 003BDocumento1 pagina1778 0168 TH DWG 003BAsyifa AldanaNessuna valutazione finora

- Data Entry: Larsen & Toubro Limited, Construction, Buildings & FactoriesDocumento17 pagineData Entry: Larsen & Toubro Limited, Construction, Buildings & FactoriesOuseppachan AmbookenNessuna valutazione finora

- Check List For Pipe Stress Analysis ReprotDocumento2 pagineCheck List For Pipe Stress Analysis ReprotsrinivasanNessuna valutazione finora

- Anchor Bolt DesignDocumento2 pagineAnchor Bolt DesignsamvendanNessuna valutazione finora

- A Case of Choice of Passive Fire ProtectionDocumento6 pagineA Case of Choice of Passive Fire Protectionعزت عبد المنعمNessuna valutazione finora

- 1Documento1 pagina1srinivasanNessuna valutazione finora

- GMCC air conditioner specifications comparisonDocumento1 paginaGMCC air conditioner specifications comparisonJose Enrique Sanchez Thompson100% (1)

- Trane XR202 Programmable Thermostat: TCONT202AS11MA Installation and User GuideDocumento12 pagineTrane XR202 Programmable Thermostat: TCONT202AS11MA Installation and User GuideOsvaldo Milla100% (2)

- Gas R134a Replament To AutomotiveDocumento6 pagineGas R134a Replament To AutomotiveSyamsul IrmaNessuna valutazione finora

- Cochran Boiler Working Construction DiagramDocumento5 pagineCochran Boiler Working Construction Diagrampankaj chaudharyNessuna valutazione finora

- Procedural Checklist: 1.1-1 Set Up and Prepare Machine and EquipmentDocumento2 pagineProcedural Checklist: 1.1-1 Set Up and Prepare Machine and Equipmentnelmar caneteNessuna valutazione finora

- 87ae5500 Cyr - Gen P 01 0001Documento1 pagina87ae5500 Cyr - Gen P 01 0001Raksha KMNessuna valutazione finora

- Lecture 7: Piping Drafting & Drawing: Prepared By: Nor Helya Iman Bt. Kamaludin Helya@unimap - Edu.myDocumento31 pagineLecture 7: Piping Drafting & Drawing: Prepared By: Nor Helya Iman Bt. Kamaludin Helya@unimap - Edu.myOsvaldo Junges BomfimNessuna valutazione finora

- Gra Series: Standard Top DischargeDocumento8 pagineGra Series: Standard Top DischargedavidNessuna valutazione finora

- Mark Qty Size Description Length: Petrobras P-52 Total Piping BOM 2/1/05Documento6 pagineMark Qty Size Description Length: Petrobras P-52 Total Piping BOM 2/1/05Marcos AndréNessuna valutazione finora

- Hot and cold water faucet fixture with adjustable valvesDocumento6 pagineHot and cold water faucet fixture with adjustable valvesmarlondijiNessuna valutazione finora

- Mitsubishi Electric Heat Pump Parts Outdoor MUZ-GE25-80VA-A1 - OBB532C PDFDocumento12 pagineMitsubishi Electric Heat Pump Parts Outdoor MUZ-GE25-80VA-A1 - OBB532C PDFTony SavageNessuna valutazione finora

- Fujitsu Service ManualDocumento19 pagineFujitsu Service ManualnovyNessuna valutazione finora

- Checklist For Airhandling Units Area: NO. Trait Status Remarks Pre-Commissioning ChecksDocumento39 pagineChecklist For Airhandling Units Area: NO. Trait Status Remarks Pre-Commissioning ChecksAzher ANessuna valutazione finora

- BILL OF MATERIALS FOR UNIT 5 HEADERDocumento1 paginaBILL OF MATERIALS FOR UNIT 5 HEADERLenin Casanova CNessuna valutazione finora

- Chiller Daikin CatalogueDocumento54 pagineChiller Daikin CatalogueSetiawan Indra Suradji100% (1)

- Split system heat pumps up to 7 kWDocumento2 pagineSplit system heat pumps up to 7 kWNedžadDžokoNessuna valutazione finora

- Brosur ITU - Rooftof Unit ..Documento5 pagineBrosur ITU - Rooftof Unit ..eep saepudinNessuna valutazione finora

- ملزمة منظومات التبريد والتكييف PagesExtractedDocumento6 pagineملزمة منظومات التبريد والتكييف PagesExtractedHayder AliNessuna valutazione finora

- MAYEKAWA Heat Pump System 09 09Documento12 pagineMAYEKAWA Heat Pump System 09 09alejandro obregonNessuna valutazione finora

- Comfort Star NS50-B2 BrochureDocumento2 pagineComfort Star NS50-B2 Brochuree-ComfortUSANessuna valutazione finora

- 2051-K09-010 Data Sheet - Control Damper Rev 1.0Documento14 pagine2051-K09-010 Data Sheet - Control Damper Rev 1.0Amro Metwally El HendawyNessuna valutazione finora

- CHI - BRE - YVAA Air Cooled ChillersDocumento8 pagineCHI - BRE - YVAA Air Cooled ChillersluxusNessuna valutazione finora

- STULZ CyberHandler Engineering Manual QENA003ADocumento24 pagineSTULZ CyberHandler Engineering Manual QENA003AAli WaseemNessuna valutazione finora

- DBR PDDDocumento13 pagineDBR PDDMEERANessuna valutazione finora

- AAA Installation & Service ManualDocumento36 pagineAAA Installation & Service ManualEurekia EvolutionNessuna valutazione finora

- Chapter One - Introduction to Air Conditioning SystemsDocumento273 pagineChapter One - Introduction to Air Conditioning SystemsliliNessuna valutazione finora

- BFS Power Plant ValvesDocumento24 pagineBFS Power Plant ValvesAnonymous lmCR3SkPrKNessuna valutazione finora

- Brazed Plate Heat ExchangerDocumento2 pagineBrazed Plate Heat ExchangerAndone GigiNessuna valutazione finora

- Introduction To HVAC&R Systems: Ir. Dr. Sam C. M. HuiDocumento48 pagineIntroduction To HVAC&R Systems: Ir. Dr. Sam C. M. HuiJerry ChanNessuna valutazione finora

- 63-9575 Residential CombustionDocumento56 pagine63-9575 Residential CombustionfaustoriverosNessuna valutazione finora