Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DTR 1000 Kva

Caricato da

Abhinav TewariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DTR 1000 Kva

Caricato da

Abhinav TewariCopyright:

Formati disponibili

NOIDA POWER COMPANY LIMITED

Technical Specification

Noida Power Company Limited

Technical Specification for

1000kVA, 11/0.433kV

Distribution Transformer

APPLICABLE STANDARDS

IS No. Title

IS 1885 :Part 38 Electro technical vocabulary: Part 38:

Transformers (second revision)

IS 2026 : Power transformers

Part 1 General

Part 2 Temperature rise

Part 3 Insulation level and dielectric tests and external clearances in air

Part 5 Ability to withstand short circuit

Part 7 Guide for Loading of Oil immersed Transformers

Part 8 Application Guide

Part 10-1 Determination of sound levels

IS 2099 Specification for bushings for alternative voltages above 1 000 volts

(second revision)

IS 3024 : 2006 Grain oriented electrical steel sheets and strips

IS 3347 Dimensions for porcelain transformer bushings for use in normal and

polluted atmosphere

(Part 1/Sec 1&2) Part 1: Up to and including 1 kV bushings, Section 1 Porcelain parts,

and Section 2 Metal parts

(Part 2/Sec 1 &2) Part 2 : 3.6 kV bushings, Section I Porcelain parts, and Section 2 Metal

parts

(Part 3/Sec (1 &2) Part 3: 12 & 17.5 kV bushings, Section 1 Porcelain parts and Section 2

Metal parts

(Part 4/Sec 1 &2) Part 4 : 24 kV Bushings, Section1 Porcelain parts and Section 2 Metal

parts

(Part 5/Sec 1&2) Part 5 : 36 kV Bushings, Section 1 Porcelain parts and Section 2 Metal

parts

IS 7421 Specification for porcelain bushings for alternating voltages up to and

including 1 000V

IS 335 Specification for new insulating oils for transformers and switchgear

IS 8999 Gauging practice for pipe threads where pressure tight joints are

required on the threads

IS 554 Dimensions for pipe threads where pressure tight joints are required on

the threads (second revision)

IS 3639 Specification for fittings and accessories for Power Transformers

(under revision)

IS 2 Rules for rounding off numerical values

IS 1747 Specification for Nitrogen

IS 11149 Specification for Rubber Gaskets

IS 4253 (Part 2) Specification for Cork Composition Sheet-Part 2-Cork & Rubber

IS 7404:Part 1 Paper Covered Copper Conductors – Part 1 Round Conductors

IS 13730:Part 0:Sec 3 Specification for Particular Types of Winding Wires – Part 0:General

Requirements Sections 1: Enameled Round Copper Wire

IS 13730 : Part 17 Particular Types of Winding Wires : Part 17 Polyvinyl acetyl enameled

rectangular copper wire, Class 105

IS 13730:Part 27 Specification for Particular Type of Winding Wires – Part 27 : Paper

Covered Rectangular Copper Wire

IS 12444 Continuously cast and rolled electrolytic copper wire rods

IS 1897 Copper strip for electrical purpose

IS 191 Copper

IS 1608 Mechanical testing of metals – Tensile Testing

IS 3024 Grain Oriented Electrical Steel sheet strip

IS 649 Methods of testing steel sheets for magnetic circuits of power electrical

apparatus

IS 1576 Solid pressboard for electrical purpose

IS 3513: Part 1 Resin treated compressed wood laminates (compregs)

Part 1 For Electrical purposes

IS 9335 : Part 1 Cellulosic papers for electrical purposes: Part 1 Definitions and general

requirements

IS 9335 : Part 2 Cellulosic Papers for Electrical Purposes : Part 2 : Methods of test

IS 9335 : Part 3 : Sec 1 Cellulosic papers for electrical purposes: Part 3 Specifications for

individual materials, Section 1 General purposes electrical paper

IS 9335 : Part 3 : Sec 3 Cellulosic papers for electrical purposes: Part 3 Specifications for

individual materials, Section 3 Crepe paper

IS 9335 : Part 3 : Sec 5 Cellulosic papers for electrical purposes: Part 3 Specifications for

individual materials, Section 5 Special papers

Technical Specification for 11/0.433 KV, 1000 kVA

Distribution Transformer

3- Phase 1000 KVA Distribution Transformer

Reference standards Generally conformation to

IS:1180,IS:2026, IS:6600, IS:3347,

IS:2099, IS:335, BEE Speciation, CBIP

manual on transformers and all other

standards mentioned in previous page.

1 KVA Rating 1000 kVA

2 Rated Voltage

a) HV Winding 11.0kV

b) LV Winding 0.433 kV

3 Rated frequency 50 HZ

4 Number of phases THREE

5 Connection

a) HV Winding DELTA

b) LV Winding STAR

6 Connection Symbol Dyn-11

7 Tapping’s

a) Range +5% TO -10% @ 2.5%

b) No. of steps 7,(Including the Principal Tap)

c) For High Voltage or Low Voltage High Voltage Variation

variation

8 Maximum ambient temperature 50°c

9 Type of cooling ONAN

10 Maximum Temperature Rise:

a) Top Oil (by Thermometer) 40°c

b) Winding(by Resistance) 45°c

11 a) Total Losses at 50 % Loading 2.620 KW (max) (as per IS:1180)

b) Total Losses at 100 % Loading 7.000 KW (max) (as per IS:1180)

12 Percentage impedance at 75°C at rated

current & for principle tapping (HV-LV) 5.0 %

13 Reactance at rated current & rated frequency

(HV-LV) 4.351%

14 Percentage No load current

a) At rated voltage and frequency Vendor to Specify

b) At 12.5% of over fluxing Vendor to Specify

15 Max flux density Less than 1.5 Tesla

16 Insulation level:

16.A Separate source power frequency voltage

withstand

a) HV Winding 70 KV rms

b) LV Winding 3 KV rms

16.B Induced over voltage withstand:

a) HV Winding 66 KV Induced

b) LV Winding Twice the rated applied across LV

terminals

16.C Full wave lightening impulse withstand

voltage

a) HV winding 170 KV Peak

b) LV winding Not Applicable

17.A Efficiency at 75° and UPF Vendor to Specify

a) At 100 % full load

b) At 75% full load Vendor to Specify

c) At 50 % full load Vendor to Specify

17.B Efficiency at 75° and 0.8 pf Vendor to Specify

a) At 100 % full load

b) At 75% full load Vendor to Specify

c) At 50 % full load Vendor to Specify

18 a) The load at which max. efficiency occurs Vendor to Specify

b) The value of maximum efficiency

19 Regulation at full load at 75°C Vendor to Specify

a) At unity power factor

b) At 0.8 power factor Vendor to Specify

20 In case of off circuit voltage variation, state Off circuit tap switch on the HV

whether: windings, three phase, externally hand

a) Off circuit tap switch, or operated, having tap position markings

b) Off circuit links (Give brief on the dial and capable of being locked

description) in any particular tap position.

21 Termination Arrangement Outdoor, Plug in type, moulded epoxy

a) High voltage insulated part with a connector interface,

12kV voltage class and creepage

31mm/kV Bushing shall be suitable for

interfacing with plug-in type separable

connector of equivalent ratings

b) Low voltage Outdoor, Porcelain , 1.1kV rated voltage

and creepage 31mm/kV.

c) Neutral Outdoor Porcelain. Extra Neutral

Bushing shall be provided. Extra Neutral

Bushing shall be short internally with

LV Neutral Bushing.

d) LV Cable Box With Adequate Protection System

(ACB/Equivalent)

22 Approximate masses Vendor to Specify

a) Core and winding (assembly), Tank

with fittings & accessories

b) Oil weight (oil density taken as 0.82) Vendor to Specify

c) Total mass Vendor to Specify

Approximate quantity of oil required for first Vendor to Specify

filling

23 Approximate overall dimensions:

a) Length To be given in the outline & general

arrangement drawing to be furnished

separately, when required.

b) Breadth

Outdoor Type, Continuously rated

c) Height

d) Service

24 Warranty 5 years+

25 HV cable size for all sizes / Conductor size 11 kV (E) grade , 3C x 300 sqmm

26 Tinned Copper Busbar size on HV Not Required

side for cable termination, mm x mm

27 Provision for termination of LV cable size, Cable (3 runs per phase + 3 runs in

650 /1100 V grade , A2XY cable single core Neutral)

630 sqmm Copper cable with armoured

(approx cable dia 40 mm)

28 Tinned Copper Busbar size on LV side Required

for cable termination, for Phase & Neutral

29 Three phase dead short circuit at For 3 secs.

secondary terminal with rated voltage

maintained on the other side

30 Single phase short circuit at secondary For 3 secs.

terminal with rated voltage maintained

on other side

31 Overload Capability As per IS 6600/IEC 60905

32 Fittings and accessories on main tank i) Prismatic oil gauge with MINIMUM ,

conservator NORMAL and MAXIMUM marking

ii) End Cover

iii) Oil Filling Hole with cap

iv) Silica Gel Dehydrating Breather with

oil seal and dust filter with clear acrylic

single piece clearly transparent cover

resistant to UV rays(1kg). Silica gel

shall be of round ball type of 2.5mm

dia.

v) Drain Plug

vi) Air release plug as required

vii) Pressure/ Vacuum gauge

viii) Magnetic Oil Gauge with LOW

LEVEL ALARM

ix) Silica gel shall be of round ball type

of 2.5mm dia.

Potrebbero piacerti anche

- Mog TrafoDocumento27 pagineMog TrafoPandrayar MaruthuNessuna valutazione finora

- VLF High Voltage TestDocumento20 pagineVLF High Voltage TestAhmedRaafatNessuna valutazione finora

- Slip Ring Motor Liquid Resistor Soft Starting System (HV-LRS) PDFDocumento4 pagineSlip Ring Motor Liquid Resistor Soft Starting System (HV-LRS) PDFLouie FernandezNessuna valutazione finora

- MV Trafo SB - SMC - STP TI US - en 10 PDFDocumento6 pagineMV Trafo SB - SMC - STP TI US - en 10 PDFVictor ToledanoNessuna valutazione finora

- AEG Protect-8 INV ENDocumento4 pagineAEG Protect-8 INV ENibs434Nessuna valutazione finora

- I-P-1.01-W-2 (Packer Spouts)Documento1 paginaI-P-1.01-W-2 (Packer Spouts)Mechanical ShauryaNessuna valutazione finora

- SPAD330CDocumento17 pagineSPAD330CARA CESPEDES JORGENessuna valutazione finora

- LD-B10-10-catalog Temperature ControllerDocumento22 pagineLD-B10-10-catalog Temperature ControllerFareh KhanNessuna valutazione finora

- QJ71C24N PDFDocumento358 pagineQJ71C24N PDFalbertoNessuna valutazione finora

- Micomho P446: Technical ManualDocumento864 pagineMicomho P446: Technical ManualLuiz Augusto Reis e FreitasNessuna valutazione finora

- 1or 2 Pole Breaker For TractionDocumento8 pagine1or 2 Pole Breaker For Tractiongyanendra_vatsa4380Nessuna valutazione finora

- ATS LabDocumento8 pagineATS LabMostafa El SayedNessuna valutazione finora

- Self Dehydrating BreatherDocumento12 pagineSelf Dehydrating BreatherJOSE DANIEL PEREZNessuna valutazione finora

- Partial Discharge Diagnostic System PDFDocumento2 paginePartial Discharge Diagnostic System PDFSellappan MuthusamyNessuna valutazione finora

- 4.various Tests Part 1Documento53 pagine4.various Tests Part 1Rohit JoshiNessuna valutazione finora

- Anti Pumping RelayDocumento2 pagineAnti Pumping RelayAbdul RahmanNessuna valutazione finora

- Meggering Insulation Resistance Testing of Dry-Type Power TransformerDocumento3 pagineMeggering Insulation Resistance Testing of Dry-Type Power TransformerSugeng SumarnoNessuna valutazione finora

- Cn05, Cn10 Series: Non-Spring Return Direct-Coupled Damper Actuators For Modulating and Floating ControlDocumento8 pagineCn05, Cn10 Series: Non-Spring Return Direct-Coupled Damper Actuators For Modulating and Floating ControlLindEtjulietcapulet KplesetmontagueNessuna valutazione finora

- Test Procedure For VTDocumento2 pagineTest Procedure For VTSameer SyedNessuna valutazione finora

- Technical Data Fluokit m24 LengkapDocumento20 pagineTechnical Data Fluokit m24 LengkapAbdulhakk Agai100% (1)

- Unit-I Circuit BreakersDocumento13 pagineUnit-I Circuit Breakerspurushg62Nessuna valutazione finora

- 8204 User ManualDocumento41 pagine8204 User ManualDhaniraj SinghNessuna valutazione finora

- 01 Process Indicator Controller Single Display UT-101 102 PDFDocumento12 pagine01 Process Indicator Controller Single Display UT-101 102 PDFvishadkapadiaNessuna valutazione finora

- VCB ServiceDocumento1 paginaVCB ServiceimranNessuna valutazione finora

- 15mva 33-11KVDocumento1 pagina15mva 33-11KVMubarak AleemNessuna valutazione finora

- DMCR Protection Relay For Oil TransformerDocumento9 pagineDMCR Protection Relay For Oil TransformerDawn HernandezNessuna valutazione finora

- 1488285569Documento20 pagine1488285569NobodyNessuna valutazione finora

- Timers, Time, Switches, Hour Meters & Supply MonitorsDocumento24 pagineTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarNessuna valutazione finora

- Inspection AND Test Procedures 7.6.4 Circuit Breakers, SFDocumento7 pagineInspection AND Test Procedures 7.6.4 Circuit Breakers, SFCarlos AguiarNessuna valutazione finora

- Akm Manual TD34 Ec10001Documento12 pagineAkm Manual TD34 Ec10001JOSE DANIEL PEREZNessuna valutazione finora

- Manual Book Relay GE F35man-E2Documento310 pagineManual Book Relay GE F35man-E2Khoirin NidaNessuna valutazione finora

- Yc1h422342-612 - Sop of Apfc PanelDocumento5 pagineYc1h422342-612 - Sop of Apfc PanelRamkumar MuthuNessuna valutazione finora

- User Manual: HV Energization Equipment For Esp Ggaj02 (Jh3000D)Documento57 pagineUser Manual: HV Energization Equipment For Esp Ggaj02 (Jh3000D)Hoàng LongNessuna valutazione finora

- Sinha Power Plant QuestionDocumento14 pagineSinha Power Plant QuestionRaihanNessuna valutazione finora

- Installation Testing Troubleshooting Starters Overload RelaysDocumento34 pagineInstallation Testing Troubleshooting Starters Overload RelaysGogula Gunasekhar100% (1)

- MDM 3100 Power Meter ManualDocumento123 pagineMDM 3100 Power Meter ManualAnon EmousNessuna valutazione finora

- Minilec (India) PVT - LTD.: Price ListDocumento13 pagineMinilec (India) PVT - LTD.: Price Listarindam mallickNessuna valutazione finora

- PAT TestDocumento28 paginePAT Testmanzoor hassanNessuna valutazione finora

- L86-051 Test ReportDocumento6 pagineL86-051 Test ReportAMIT BISWASNessuna valutazione finora

- 8DJH - ST, 12 KV Montaje en CubiculoDocumento112 pagine8DJH - ST, 12 KV Montaje en CubiculoSebastian Soto NacharNessuna valutazione finora

- Avr 20 DatakomDocumento2 pagineAvr 20 DatakomMiguel Angel Pavon CarbonellNessuna valutazione finora

- LSR, Auto Sync, Lmu, Tavt Testing ProtocolDocumento19 pagineLSR, Auto Sync, Lmu, Tavt Testing Protocolpatel chandramani100% (1)

- Pressure Switch DMT02ATEX E019 - Op Manual - Decl of Conf - enDocumento6 paginePressure Switch DMT02ATEX E019 - Op Manual - Decl of Conf - ennemi90Nessuna valutazione finora

- Interface Software: EntecDocumento58 pagineInterface Software: EntecIsaac ShlamanNessuna valutazione finora

- Insulation Resistance Test of Circuit BreakerDocumento2 pagineInsulation Resistance Test of Circuit BreakerVedant .ChavanNessuna valutazione finora

- 3M CtalogueDocumento54 pagine3M CtalogueMasoud Baig100% (1)

- ED-2016 As On 12 Apr 16 PDFDocumento117 pagineED-2016 As On 12 Apr 16 PDFanimesh8672777100% (1)

- Basics of Motor Starting StudyDocumento18 pagineBasics of Motor Starting StudyJerome EugeneNessuna valutazione finora

- Maintenance of TransformerDocumento8 pagineMaintenance of TransformeranilsinghteslaNessuna valutazione finora

- Siemens Timer CatalogDocumento4 pagineSiemens Timer Catalogshamim93146Nessuna valutazione finora

- Zero Speed SwitchDocumento8 pagineZero Speed SwitchMRITUNJAY100% (1)

- Acb TroubleshootingDocumento3 pagineAcb TroubleshootingSomu JaganathanNessuna valutazione finora

- On Load Tap Changers Abb PDFDocumento12 pagineOn Load Tap Changers Abb PDFKushtrim MalaNessuna valutazione finora

- HVA 60 User ManualDocumento69 pagineHVA 60 User ManualKaruvelamNessuna valutazione finora

- Section-7.4 TransformerDocumento51 pagineSection-7.4 TransformerBRB CABLENessuna valutazione finora

- Supply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDocumento13 pagineSupply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDarwish MammiNessuna valutazione finora

- 125mvar Bus Reactor Spec - FinalDocumento38 pagine125mvar Bus Reactor Spec - FinalSE TPC-4Nessuna valutazione finora

- 01 Technical Specification For 160MVA 220 132 33KV Power TransformerDocumento88 pagine01 Technical Specification For 160MVA 220 132 33KV Power Transformerk. harikarasudhan33% (3)

- 33kV & 22kV GIS Specifications PDFDocumento15 pagine33kV & 22kV GIS Specifications PDFAlauddin khanNessuna valutazione finora

- Statement Showing The Requirement For H.V. InstallationDocumento6 pagineStatement Showing The Requirement For H.V. InstallationAbhinav TewariNessuna valutazione finora

- Schneider RTU Saitel DP Modules Manual-EN-Rev3.0 PDFDocumento136 pagineSchneider RTU Saitel DP Modules Manual-EN-Rev3.0 PDFAbhinav TewariNessuna valutazione finora

- Kaizen PPT For AAC BlockDocumento6 pagineKaizen PPT For AAC BlockAbhinav TewariNessuna valutazione finora

- Kaizen PPT For Double Compressor Based VRFDocumento6 pagineKaizen PPT For Double Compressor Based VRFAbhinav TewariNessuna valutazione finora

- Process Improvement Template - ONSDocumento13 pagineProcess Improvement Template - ONSAbhinav TewariNessuna valutazione finora

- Operation & Maintenance of TransformersDocumento46 pagineOperation & Maintenance of TransformersAbhinav TewariNessuna valutazione finora

- Scada System: Npcl-Automation Prepared By: Mohan SinghDocumento29 pagineScada System: Npcl-Automation Prepared By: Mohan SinghAbhinav TewariNessuna valutazione finora

- Concept of Losses and Loss Reduction MeasuresDocumento52 pagineConcept of Losses and Loss Reduction MeasuresAbhinav TewariNessuna valutazione finora

- 11 KV VCB With 1250A IC OG 12 Panel Board 13-05-19Documento17 pagine11 KV VCB With 1250A IC OG 12 Panel Board 13-05-19Abhinav TewariNessuna valutazione finora

- 33 KV GIS - 09 Panel Board 19-12-19Documento29 pagine33 KV GIS - 09 Panel Board 19-12-19Abhinav Tewari100% (1)

- Old LT Panel 400 AmpDocumento5 pagineOld LT Panel 400 AmpAbhinav TewariNessuna valutazione finora

- Specifications For Security Guard Cabin For TZ-4Documento1 paginaSpecifications For Security Guard Cabin For TZ-4Abhinav TewariNessuna valutazione finora

- Nest-In Portable CABIN - SPECSDocumento12 pagineNest-In Portable CABIN - SPECSAbhinav TewariNessuna valutazione finora

- Technical Specifications of 1Cx400 SQMMDocumento17 pagineTechnical Specifications of 1Cx400 SQMMAbhinav Tewari100% (1)

- Technical Specifications & BOQ For PEB at KasnaDocumento6 pagineTechnical Specifications & BOQ For PEB at KasnaAbhinav Tewari100% (2)

- 11 KV VCB With 1250A IC OG 6 Panel Board - FinalDocumento16 pagine11 KV VCB With 1250A IC OG 6 Panel Board - FinalAbhinav TewariNessuna valutazione finora

- Old LT Panel 400 AmpDocumento5 pagineOld LT Panel 400 AmpAbhinav TewariNessuna valutazione finora

- Troubleshooting Procedure For Vacuum Circuit BreakerDocumento26 pagineTroubleshooting Procedure For Vacuum Circuit BreakerAbhinav Tewari100% (2)

- Technical SPecifications 1Cx35 SQMM CableDocumento1 paginaTechnical SPecifications 1Cx35 SQMM CableAbhinav TewariNessuna valutazione finora

- Transformer 3Documento77 pagineTransformer 3Abhinav TewariNessuna valutazione finora

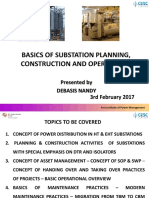

- Basics of Substation Planning, Construction and OperationsDocumento79 pagineBasics of Substation Planning, Construction and OperationsAbhinav TewariNessuna valutazione finora

- Troubleshooting Procedure For Vacuum Circuit BreakerDocumento26 pagineTroubleshooting Procedure For Vacuum Circuit BreakerAbhinav Tewari100% (2)

- Schneider RTU Saitel DP Modules Manual-EN-Rev3.0Documento136 pagineSchneider RTU Saitel DP Modules Manual-EN-Rev3.0Abhinav Tewari100% (3)

- Configuration & Startup of Saitel DR - EN - Rev1.0 - BorradorDocumento75 pagineConfiguration & Startup of Saitel DR - EN - Rev1.0 - BorradorAbhinav Tewari100% (2)

- 33 KV GIS Panel - SIEMENSDocumento41 pagine33 KV GIS Panel - SIEMENSAbhinav Tewari100% (1)

- Terminals and Connectors GuideDocumento220 pagineTerminals and Connectors Guidemiguel100% (2)

- Technical Data Sheet: Description Technical Particulars ValuesDocumento1 paginaTechnical Data Sheet: Description Technical Particulars ValuesAli ShahzadNessuna valutazione finora

- Ebook Electrical Wiring Residential Canadian 7Th Edition Mullin Solutions Manual Full Chapter PDFDocumento25 pagineEbook Electrical Wiring Residential Canadian 7Th Edition Mullin Solutions Manual Full Chapter PDFbonnieusefullygllin100% (7)

- 5 BTV ManualDocumento64 pagine5 BTV ManualRubenNessuna valutazione finora

- Stock-Material-and-Febricated-Material SOR-2016-17Documento35 pagineStock-Material-and-Febricated-Material SOR-2016-17souvikbesu89Nessuna valutazione finora

- International Standard: Steel Wire Ropes - Vocabulary, Designation and ClassificationDocumento11 pagineInternational Standard: Steel Wire Ropes - Vocabulary, Designation and ClassificationNorberto A. Ghiggi0% (1)

- As 3983-1991 Metal Drums For Insulated Electric Cables and Bare ConductorsDocumento6 pagineAs 3983-1991 Metal Drums For Insulated Electric Cables and Bare ConductorsSAI Global - APACNessuna valutazione finora

- F Sockets SurfaceDocumento19 pagineF Sockets SurfacebansalrNessuna valutazione finora

- A877A877M-10e1 Standard Specification For Steel Wire, Chromium-Silicon Alloy, Chrome - Silicon-Vanadium Alloy Valve Spring QualityDocumento5 pagineA877A877M-10e1 Standard Specification For Steel Wire, Chromium-Silicon Alloy, Chrome - Silicon-Vanadium Alloy Valve Spring Qualitytjt4779Nessuna valutazione finora

- MODULO 3 Carlo MonsalveDocumento14 pagineMODULO 3 Carlo Monsalvecarlomonsalve1Nessuna valutazione finora

- ACS 600 Installation ManualDocumento150 pagineACS 600 Installation Manuallalo_37Nessuna valutazione finora

- Wire RopeDocumento32 pagineWire RopeFariz SafarullaNessuna valutazione finora

- Considerations On Sand Control in Natural Gas1Documento8 pagineConsiderations On Sand Control in Natural Gas1Hari TharanNessuna valutazione finora

- 0463 645 001 GBDocumento38 pagine0463 645 001 GBimreNessuna valutazione finora

- Cables ConnectorsDocumento18 pagineCables ConnectorsRaviram BoppayNessuna valutazione finora

- Colour CodesDocumento3 pagineColour CodesjohnloopsNessuna valutazione finora

- Design Analysis: Proposed 1 Unit 2 CL Building For Capiniahan Primary SchoolDocumento1 paginaDesign Analysis: Proposed 1 Unit 2 CL Building For Capiniahan Primary SchoolPauline Joy AquinoNessuna valutazione finora

- Over All Drawings of PMCC-5 Panel-R0Documento24 pagineOver All Drawings of PMCC-5 Panel-R0GreenOlive ControlsNessuna valutazione finora

- ReviewDocumento10 pagineReviewJayson Deocareza Dela TorreNessuna valutazione finora

- Core Install Electrical Protective Devices For Distribution Power Lighting Auxiliary Lightning Protection and Grounding Systems - CompressDocumento43 pagineCore Install Electrical Protective Devices For Distribution Power Lighting Auxiliary Lightning Protection and Grounding Systems - CompressNiñaVizcondeNessuna valutazione finora

- 1.5 LEADER XLPE Cable - Catalogue PDFDocumento62 pagine1.5 LEADER XLPE Cable - Catalogue PDFGan SAIK NGAINessuna valutazione finora

- Winch, Manrider (FA150KGi) Product InstructionsDocumento16 pagineWinch, Manrider (FA150KGi) Product InstructionsTonyNessuna valutazione finora

- SRN-39-Tender Notice-11-2016-17 - Ambaji - Part - I - PDFDocumento12 pagineSRN-39-Tender Notice-11-2016-17 - Ambaji - Part - I - PDFalwaysharshNessuna valutazione finora

- Quad Sym 600 Manuel ServiceDocumento96 pagineQuad Sym 600 Manuel ServiceAndriamaro RajaonarifetraNessuna valutazione finora

- CM Tt9000-Eng-TerminationsDocumento18 pagineCM Tt9000-Eng-TerminationsTXEMANessuna valutazione finora

- 100095.12kV Electrical Drawings - Bid SetDocumento1 pagina100095.12kV Electrical Drawings - Bid SetAwlia Khan KakarNessuna valutazione finora

- Cable Tray Fill and Load CalculationDocumento2 pagineCable Tray Fill and Load Calculationklmsunny50% (2)

- Antibiotic Bead ProductionDocumento5 pagineAntibiotic Bead Productionratnav_ratanNessuna valutazione finora

- How To Run Electrical Wires in A Finished WallDocumento5 pagineHow To Run Electrical Wires in A Finished WallRi SovannaphumiNessuna valutazione finora

- Blast Monitoring Instrumentation and Analysis Techniques, With An Emphasis On Field ApplicationsDocumento44 pagineBlast Monitoring Instrumentation and Analysis Techniques, With An Emphasis On Field ApplicationsJEANCARLOCGNessuna valutazione finora