Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CEO Report

Caricato da

Bridget Anne BenitezCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CEO Report

Caricato da

Bridget Anne BenitezCopyright:

Formati disponibili

5 – 4 Location of Cleanout

The waste pipe installation must be provided with an ample number of cleanouts, strategically located, to

be opened in ease of pipeline trouble. Cleanout is a receptacle of the plumbing system accessible on floor,

walls or ceiling. It is equipped with a plug or flush plate so designed as not to impair the aesthetical view

of the room. The location of cleanout must be indicated in the plan. It should be sized equal to the

diameter of the waste pipe, where it is to be connected. This is to avoid interference in the rodding or

cleaning process. Cleanout must be readily accessible to the plumber in case of waste line stoppage.

5 – 5 Right Slope or Grade of Waste Pipe

The ideal position of horizontal waste pipe, were those installed at 2% slope. Meaning, the pipe was

installed with an inclined ratio of 2 centimeters tier meter length. For instance, a 3.00 meters pipe installed

as a waste line will have an inclination of 3 x 2 - 6 centimeters.

Waste pipe must be of sufficient diameter to afford adequate velocity of flow in order to make them as

nearly self-scouring as is practical. The latest scientific tests and experiments conducted by the National

Bureau of Standards sponsored by the Housing and Home Finance Agency, showed that, wet venting and

stack venting are safe in certain type of installations. The experiments revealed that the Trap Seal Loss

occurs when the grade or slope of the pipe is increased from 2% to 4%.

Trap Seal Loss means the loss or escape of standing water inside the P-Trap. This is usually caused by

siphonage induced by rapid flow of waste inside the pipe. It is also referred to as Wafer Seal Escape.

Plumbing installations usually suffer grave abuse of function brought about by human dements. Record

shows that; waste lines identically designed with the same size and grade, installed in different residences,

but used by different persons, functions differently. The materials and methods used in food preparation,

plus the habits of the housewife, accounts for this. Some people use plumbing fixtures as a means of get-

ting rid of almost any kind of unwanted waste. Waste such as garbage, grease, hair lint matches. Cigar,

paper and the like are found in most clogged waste lines. Take note that, Plumbing installations are not

intended to convey materials of this kind of unwanted waste.

5 – 6 Manner of Joining Pipes

Injudicious connection of fittings should not be per-mitted in any plumbing installation. Each kind of pipe

has its own manner of joining recommended and specified by the manufacturers. For instance, cast iron

pipes are joined by the use of oakum and lead at the hub and spigot connections. Likewise, plastic pipes

clearly specify the use of solvent plastic cement, or by special fitting connector. Remember that any

alteration or deviation from the manufacturer's specifications will only endanger the effective-ness of the

pipe joints.

5 – 7 Determining the Size of Waste Pipe

The National Plumbing Code on the size of waste pipe provides that:

"The waste pipe diameter shall be adequate enough to serve the installation of fixtures in a general way,

but the best way is to fit the diameters of commercial pipe into the fixture pattern in the most efficient

manner."

The size of waste pipe intended to receive waste from the future must be of sufficient diameter. This is to

accommodate the velocity of flow, making them as nearly scouring as necessary to prevent the silting of

the pipe.

Scouring means to flush or wash out, to remove dirt or grease by flowing through. There are those who

believed that by making the drainage pipe larger than what is necessary, will increase its service efficiency.

This without scientific basis, has triggered disagreement among people in the plumbing industry.

Disagreement on this matter however, was resolved when the Uniform Plumbing Code Committee

formulated data as guide and references in determining the size of the waste and other drain-pipes. The

data formulated by the Committee for incorporation in the Plumbing Code were product of countless

tests and experiments conducted for years. In addition, installation experiences that were proven

satisfactory in service compiled over a long period of time were also incorporated

The Uniform Plumbing Code Committee's Findings are Enumerated Briefly as Follows:

1. By increasing the size of the drainage pipe, does not guarantee effective scouring action, or self-cleaning

ability of the pipe. Self-cleaning ability is present, when the liquid and waste inside the pipe flow smoothly

and simultaneously together.

2. Water flow inside a larger pipe is relatively shallow. The solid waste does not flow on shallow water but

tend to remain at the bottom of the pipe. This is practically the most common cause of the many clogging

problems of drainage installation.

3. Drainage pipe must be of the right size to have a liquid flow -of about 50% of the pipe diameter.

Meaning, that the flowing water inside the pipe must have a depth equal to l4 the pipe diameter.

4. For instance, if the pipe is 100 mm diameter, the water flow inside the pipe must have a depth of about

50 mm to attain the scouring action. This is where the 3% slope becomes effective.

5. On the other hand, too small pipeline is subject to overloading of flow. The tendency is to create back-

pressure, siphonage, and floor flooding.

Potrebbero piacerti anche

- Transcription and Translation NarrativeDocumento3 pagineTranscription and Translation NarrativeBridget Anne BenitezNessuna valutazione finora

- Theory of Life and Theories of EvolutionDocumento12 pagineTheory of Life and Theories of EvolutionBridget Anne BenitezNessuna valutazione finora

- Empowerment Technologies - Lesson 1Documento4 pagineEmpowerment Technologies - Lesson 1Bridget Anne BenitezNessuna valutazione finora

- Physical Education - Jive DanceDocumento6 paginePhysical Education - Jive DanceBridget Anne BenitezNessuna valutazione finora

- EntrepreneurshipDocumento2 pagineEntrepreneurshipBridget Anne BenitezNessuna valutazione finora

- Project IN ScienceDocumento25 pagineProject IN ScienceBridget Anne BenitezNessuna valutazione finora

- Simple InterestDocumento13 pagineSimple InterestBridget Anne BenitezNessuna valutazione finora

- Practical Research - TitlesDocumento18 paginePractical Research - TitlesBridget Anne BenitezNessuna valutazione finora

- Tephra and Ballistic ProjectilesDocumento4 pagineTephra and Ballistic ProjectilesBridget Anne Benitez100% (1)

- Pe Written ReportDocumento4 paginePe Written ReportBridget Anne BenitezNessuna valutazione finora

- Regular NounsDocumento17 pagineRegular NounsBridget Anne BenitezNessuna valutazione finora

- Calculus - Hyperbola ProblemDocumento2 pagineCalculus - Hyperbola ProblemBridget Anne BenitezNessuna valutazione finora

- Measures of Central TendencyDocumento6 pagineMeasures of Central TendencyBridget Anne BenitezNessuna valutazione finora

- Freedom of Choice ResearchDocumento15 pagineFreedom of Choice ResearchBridget Anne BenitezNessuna valutazione finora

- Eudoxus of CnidusDocumento3 pagineEudoxus of CnidusBridget Anne BenitezNessuna valutazione finora

- Psychology - Attachment and AttractionDocumento2 paginePsychology - Attachment and AttractionBridget Anne BenitezNessuna valutazione finora

- Psychology - Several Theories and Research Results Related To Attraction and LikingDocumento2 paginePsychology - Several Theories and Research Results Related To Attraction and LikingBridget Anne BenitezNessuna valutazione finora

- Transmitted Infections (Stis) - A Few Barrier Methods (Spermicide, Condom, and Sponge) Can BeDocumento7 pagineTransmitted Infections (Stis) - A Few Barrier Methods (Spermicide, Condom, and Sponge) Can BeBridget Anne BenitezNessuna valutazione finora

- As If It's Your Last: BlackpinkDocumento17 pagineAs If It's Your Last: BlackpinkBridget Anne BenitezNessuna valutazione finora

- Parts of Sewing Machine Under The BedDocumento1 paginaParts of Sewing Machine Under The BedBridget Anne BenitezNessuna valutazione finora

- Biaxial BendingDocumento13 pagineBiaxial BendingBridget Anne BenitezNessuna valutazione finora

- CIVDES3L10Documento6 pagineCIVDES3L10Bridget Anne BenitezNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Construction Operation and Maintenance of Plumbing SystemDocumento12 pagineConstruction Operation and Maintenance of Plumbing Systemssgjmlim100% (1)

- National Plumbing Code of The Philippines: Basic PrinciplesDocumento10 pagineNational Plumbing Code of The Philippines: Basic PrinciplescorbitecoNessuna valutazione finora

- Module 25 SAHITA Plumbing Pipes DrainsDocumento15 pagineModule 25 SAHITA Plumbing Pipes Drainszolalkk0% (1)

- 86-51-IM Cooling Trap CT 60e - UKDocumento10 pagine86-51-IM Cooling Trap CT 60e - UKJdNessuna valutazione finora

- Plumbing in ArchitectureDocumento8 paginePlumbing in ArchitectureNethajiNessuna valutazione finora

- Sanitary Plumbing in High Rise Building PDFDocumento2 pagineSanitary Plumbing in High Rise Building PDFDrew B Mrtnz100% (1)

- SPDIDocumento501 pagineSPDIEugene Odullada MangaringNessuna valutazione finora

- Fundamentals of Plumbing DesignDocumento60 pagineFundamentals of Plumbing DesignBianca MendozaNessuna valutazione finora

- ATTEMPT 2 Definition of Terms 1 - Mastery TestDocumento10 pagineATTEMPT 2 Definition of Terms 1 - Mastery TestGigi AguasNessuna valutazione finora

- Refresher Exam 3Documento15 pagineRefresher Exam 3Christopher Joshua MartinezNessuna valutazione finora

- GCP 9-5 PlumbingDocumento0 pagineGCP 9-5 PlumbingHanniel MadramootooNessuna valutazione finora

- Electrical TerminologiesDocumento11 pagineElectrical TerminologiesVincent Ganasi LipawenNessuna valutazione finora

- Module 01 Definition of Terms ArTY 1Documento14 pagineModule 01 Definition of Terms ArTY 1JOSE RAFAEL COLUMNANessuna valutazione finora

- Mebs6000 1011 05 DrainageDocumento72 pagineMebs6000 1011 05 Drainagesmartysky100% (1)

- PTC and PTF Pivotrol Pump ManualDocumento10 paginePTC and PTF Pivotrol Pump Manualsakura_jNessuna valutazione finora

- 11 - FEM101 SU1-Plumbing Sys 2020 07 (R1)Documento93 pagine11 - FEM101 SU1-Plumbing Sys 2020 07 (R1)Ong LayLiNessuna valutazione finora

- Basic Plumbing SkillsDocumento44 pagineBasic Plumbing Skillsroncekey100% (2)

- 22 42 01 Plumbing Specialties and AccessoriesDocumento5 pagine22 42 01 Plumbing Specialties and AccessoriesLangzkie NalipaNessuna valutazione finora

- Drainage EquipmentDocumento4 pagineDrainage EquipmentEricson Puig EuropaNessuna valutazione finora

- MODULE 1. Basic Principles of Sanitary DesignDocumento5 pagineMODULE 1. Basic Principles of Sanitary DesignKervin SangalangNessuna valutazione finora

- Fixture TrapsDocumento2 pagineFixture TrapsBrenzell BarugNessuna valutazione finora

- BUILDING PLUMBING SYSTEM - Part 2Documento11 pagineBUILDING PLUMBING SYSTEM - Part 2nibirNessuna valutazione finora

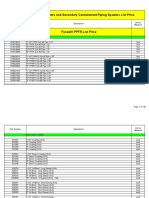

- Waste Piping Systems and Secondary Containment Piping Systems List PriceDocumento146 pagineWaste Piping Systems and Secondary Containment Piping Systems List PriceAaron Marius JuliusNessuna valutazione finora

- Sanitary Ans DrainageDocumento40 pagineSanitary Ans DrainageBJ Topenio LibasteNessuna valutazione finora

- 1609052035lec 04 Plumbing of Multistoried Building CE 3223Documento45 pagine1609052035lec 04 Plumbing of Multistoried Building CE 3223shifatNessuna valutazione finora

- 31 Wyvern RD Second UnitDocumento7 pagine31 Wyvern RD Second UnitTom MinNessuna valutazione finora

- Utilities Sample QuestionDocumento26 pagineUtilities Sample QuestionNel Colene Borja CaminianNessuna valutazione finora

- Steam Heating ApplicationDocumento108 pagineSteam Heating ApplicationbryandownNessuna valutazione finora