Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pulley DI

Caricato da

Den Yogi HardiyantoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pulley DI

Caricato da

Den Yogi HardiyantoCopyright:

Formati disponibili

Pulley Ductile Iron, Green Sand Casting

Insight: The ductile iron pulley casting of

overall size 231 mm x 231 mm x 182 mm

weighing 30 kg is produced in a ferrous

foundry. After fettling and machining the

circumferential face, it exhibited a small

shrinkage cavity just beside the riser.

Thickness contour

analysis of the part

shows a thick region

all around the part,

equivalent to an

inscribed sphere

diameter of 60 mm.

The current methoding of the

casting included a cylindrical side

feeder of 70 mm diameter and 160

mm height with a insulating sleeve

of 10 mm. The dimensions of square

neck used are 30 X 30 mm.

Solidification analysis of the casting

indicates isolated hotspot due to

undersized neck, which freezes early

and prevents feeding. The hot spot

exactly matches the defect

observed in the actual casting.

Hot Spots

© 3D Foundry Tech. Pvt. Ltd.

Pulley Ductile Iron, Green Sand Casting

Liquid fraction shows metal solidifying

last in the thick ring section of the

casting which leads to porosity . Due

to undersized neck design, this section

get disconnected from the feeder.

Shrinkage defect

Solidification temperature analysis

shows isolated temperature regions

in front of the neck of feeder which

leads to shrinkage at the same

location of shop floor defect.

Thermal Isolation

Solidification time analysis shows last

solidifying region is at in front of neck

that is circular section which matches

with hotspot and solidification

temperature analysis along with

shop floor defect

Thermal Isolation

Shrinkage porosity analysis gives

the same locations for the

shrinkage in circular section

where defects observed in shop

floor .

Shrinkage defect

© 3D Foundry Tech. Pvt. Ltd.

Pulley Ductile Iron, Green Sand Casting

Thermocouple in part

Thermocouple analysis

reveals that thermocouple

in part region crosses

solidus temperature at last

and thermocouple at Thermocouple in feeder

feeder crosses solidus

before the part thus

feeder solidifies earlier

than casting.

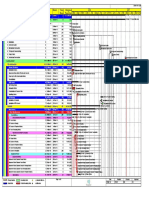

The revised methods design includes a

larger feeder of height 200 and

diameter 90 mm, also neck size is

increased up to 50 X 50 mm

dimensions.

Liquid fraction shows liquid region

which solidifies last. Figure shows

improved results of Liquid fraction

and feeder will be solidify at last.

Solidification temperature analysis

shows isolated temperature region

inside the feeder. So casting is free

from shrinkage defect.

© 3D Foundry Tech. Pvt. Ltd.

Pulley Ductile Iron, Green Sand Casting

Solidification time analysis shows

better solidification results and the

last solidifying region is inside the

feeder and casting will solidify

before the feeder. So it is resulted

in shrinkage free casting.

Shrinkage porosity results also shows

that it is observed in the feeders only.

Shrinkage porosity from casting is

completely eliminated.

Thermocouple in feeder

Thermocouple analysis Thermocouple in part

reveals that thermocouple

in part region crosses

solidus temperature

earlier and thermocouple

at feeder crosses solidus

afterwards thus feeder

solidifies last.

Summary: Simulation reveals that the modulus

of neck is comparatively smaller than the feeder

and casting section, thereby altering the

dimensions of feeder and feeder neck, resulted

in defect free casting.

© 3D Foundry Tech. Pvt. Ltd.

Potrebbero piacerti anche

- Housing FrameDocumento4 pagineHousing FrameDen Yogi HardiyantoNessuna valutazione finora

- Insight:: Ductile Iron, Green Sand CastingDocumento4 pagineInsight:: Ductile Iron, Green Sand CastingM PankajNessuna valutazione finora

- Bimetallic and Alloy Welds in HP Hydrogen and Nitrogen ServiceDocumento18 pagineBimetallic and Alloy Welds in HP Hydrogen and Nitrogen Servicevaratharajan g rNessuna valutazione finora

- Lecture 2 Continuous CastingDocumento41 pagineLecture 2 Continuous Castingnoahshredx13Nessuna valutazione finora

- U3p2riserdesign 150422035837 Conversion Gate02 PDFDocumento27 pagineU3p2riserdesign 150422035837 Conversion Gate02 PDFசெல்வ குமார்Nessuna valutazione finora

- Design and Analysis of Riser For Sand Casting: MGES JournalsDocumento17 pagineDesign and Analysis of Riser For Sand Casting: MGES JournalsManjunath ReddyNessuna valutazione finora

- Comminution of Ceramics in Stirred Media Mills and Wear ofDocumento8 pagineComminution of Ceramics in Stirred Media Mills and Wear of王柏昆Nessuna valutazione finora

- Mec 323Documento68 pagineMec 323VINAY B.SNessuna valutazione finora

- Journal of Materials Processing Technology: S.K. Choudhary, S. Ganguly, A. Sengupta, V. SharmaDocumento10 pagineJournal of Materials Processing Technology: S.K. Choudhary, S. Ganguly, A. Sengupta, V. SharmaShivam SrivastavaNessuna valutazione finora

- Polvo Colada AnalisisDocumento8 paginePolvo Colada AnalisisJose Marval RodriguezNessuna valutazione finora

- Fine Surface Cracks in CastingDocumento8 pagineFine Surface Cracks in Castingilham zuhdi anantaNessuna valutazione finora

- Malleability of GoldDocumento7 pagineMalleability of GoldTanzimNessuna valutazione finora

- CH 3 PDFDocumento20 pagineCH 3 PDFHassaan SajidNessuna valutazione finora

- WRM Proceses - Copy (Autosaved)Documento41 pagineWRM Proceses - Copy (Autosaved)Vikrant HanwatNessuna valutazione finora

- Auto Tube ReportDocumento6 pagineAuto Tube ReportRao UsamaNessuna valutazione finora

- 3a-BMCG 2323 Net Shape Process FILE 1aDocumento51 pagine3a-BMCG 2323 Net Shape Process FILE 1ahemarubini96Nessuna valutazione finora

- Carbide Roll MaterialDocumento10 pagineCarbide Roll MaterialziadNessuna valutazione finora

- 98 373 1 PBDocumento6 pagine98 373 1 PBFazry NurokhmanNessuna valutazione finora

- Shot Sleeve and Plunger TipDocumento3 pagineShot Sleeve and Plunger TipSebastian Gomez MorenoNessuna valutazione finora

- Program Branch B.E Mechanical Engineering: S.No Choose The Best AnswersDocumento3 pagineProgram Branch B.E Mechanical Engineering: S.No Choose The Best AnswersdsathiyaNessuna valutazione finora

- Procemin 2015 Understanding The Slag Cooling Phenomenon and Its Impact On The Slag Flotation Process.Documento28 pagineProcemin 2015 Understanding The Slag Cooling Phenomenon and Its Impact On The Slag Flotation Process.Nereo SpenglerNessuna valutazione finora

- Sand CastingDocumento16 pagineSand CastingEthio Dangote TubeNessuna valutazione finora

- Effect of Ceria Particle-Size Distribution and Pressure Interactions in Chemo-Mechanical Polishing (CMP) of Dielectric MaterialsDocumento8 pagineEffect of Ceria Particle-Size Distribution and Pressure Interactions in Chemo-Mechanical Polishing (CMP) of Dielectric MaterialsAverage JoeNessuna valutazione finora

- TMT ProcesesDocumento39 pagineTMT ProcesesVikrant HanwatNessuna valutazione finora

- Contoh JurnalDocumento4 pagineContoh JurnalLely DauphinNessuna valutazione finora

- BCE - H2SO4 Tower InternalsDocumento3 pagineBCE - H2SO4 Tower InternalsDũng LêNessuna valutazione finora

- Lecture 5-6-Grossman and Jominy HardenabilityDocumento58 pagineLecture 5-6-Grossman and Jominy Hardenabilitychristofer kevinNessuna valutazione finora

- Phoenix - Visit - 25 08 2017Documento22 paginePhoenix - Visit - 25 08 2017Adeeb RizviNessuna valutazione finora

- L R G TreloarDocumento5 pagineL R G Treloarapi-3733260Nessuna valutazione finora

- Stainless Steel Casting Impeller Engineering Simulation 1691129440Documento15 pagineStainless Steel Casting Impeller Engineering Simulation 1691129440soner ozdenNessuna valutazione finora

- Cold Roll Lab ReportDocumento14 pagineCold Roll Lab ReportSean BiseNessuna valutazione finora

- KCL PDFDocumento8 pagineKCL PDFSmile TheattractiveevilNessuna valutazione finora

- Micro Analysis On LaminationDocumento6 pagineMicro Analysis On LaminationPrasenjit PuriNessuna valutazione finora

- Burn Std. ReportDocumento18 pagineBurn Std. Reporttuhin royNessuna valutazione finora

- Development of Soft Reduction at Lnexa Profil For The Possibility of Increased Productivity With Maintained or Improved Product QualityDocumento8 pagineDevelopment of Soft Reduction at Lnexa Profil For The Possibility of Increased Productivity With Maintained or Improved Product QualityAkash YadavNessuna valutazione finora

- Experimental Analysis of Hard Coating On Spur Gear: ISSN (PRINT) :2394-6202, (ONLINE) :2394-6210, VOLUME-3, ISSUE-5,2017 1Documento6 pagineExperimental Analysis of Hard Coating On Spur Gear: ISSN (PRINT) :2394-6202, (ONLINE) :2394-6210, VOLUME-3, ISSUE-5,2017 1Jamsheer IbrahimNessuna valutazione finora

- Lecture Notes IIDocumento71 pagineLecture Notes IITuğbaNessuna valutazione finora

- The Jominy EndDocumento11 pagineThe Jominy Endanne2003900% (1)

- Tyre Flap (EPDM) Specification306 - 83 - SEP - 2016Documento5 pagineTyre Flap (EPDM) Specification306 - 83 - SEP - 2016Purchase and Stores Officer Contract Cell-IINessuna valutazione finora

- Riser DesignDocumento14 pagineRiser DesignRahul KumarNessuna valutazione finora

- Dead Endclamp Failure AnalysisDocumento26 pagineDead Endclamp Failure AnalysisRK KumarNessuna valutazione finora

- Metal CastingDocumento61 pagineMetal CastingPhilip Anthony MasilangNessuna valutazione finora

- Testing of NEOPRENE Bearings SKGDocumento60 pagineTesting of NEOPRENE Bearings SKGshujaNessuna valutazione finora

- A Study Into The Effects of Residual Stresses and Hot Dip GalvanizingDocumento4 pagineA Study Into The Effects of Residual Stresses and Hot Dip GalvanizingSteve HornseyNessuna valutazione finora

- Risers Design Unit-IDocumento24 pagineRisers Design Unit-IQUAZI ADYAN AHMAD 160419736049Nessuna valutazione finora

- Spe Distinguished Lecturer SeriesDocumento34 pagineSpe Distinguished Lecturer SeriesEkoSoejiantoNessuna valutazione finora

- Civil QualityDocumento89 pagineCivil QualitymithileshNessuna valutazione finora

- Tech Uddeholm Die Casting ENDocumento24 pagineTech Uddeholm Die Casting ENSajal GoelNessuna valutazione finora

- Presented By:: Introduction To Accumulative Roll Bonding Process (Arb)Documento106 paginePresented By:: Introduction To Accumulative Roll Bonding Process (Arb)amelNessuna valutazione finora

- Drilling Parameter Analysis in Solving Pipe Sticking in A Total Loss Circulation Zone Case Study: Well "X" and Well "Y" Geothermal Well Ulubelu FieldDocumento21 pagineDrilling Parameter Analysis in Solving Pipe Sticking in A Total Loss Circulation Zone Case Study: Well "X" and Well "Y" Geothermal Well Ulubelu FieldJeva VienaNessuna valutazione finora

- Dry Granulation of Slags - Turning Waste Into Valuable ProductsDocumento5 pagineDry Granulation of Slags - Turning Waste Into Valuable ProductsIwan AbdurahmanNessuna valutazione finora

- Chapter 2 - Metal CastingDocumento75 pagineChapter 2 - Metal CastingAbhik RoyNessuna valutazione finora

- Ball Wear and Ball Size Distributions in Tumbling Ball Mills - AustinDocumento8 pagineBall Wear and Ball Size Distributions in Tumbling Ball Mills - AustinnemersaibNessuna valutazione finora

- Thermal Expansion of Investment Casting ShellsDocumento8 pagineThermal Expansion of Investment Casting ShellsehsanNessuna valutazione finora

- Kimmco-Isover Rigid Pipe Covering (K450)Documento8 pagineKimmco-Isover Rigid Pipe Covering (K450)amirNessuna valutazione finora

- U02P01 B.A.A Intro MetalCastingDocumento35 pagineU02P01 B.A.A Intro MetalCastingmaria100% (1)

- International Journal of Educational Development: Su Jung Choi, Jin Chul Jeong, Seoung Nam KimDocumento10 pagineInternational Journal of Educational Development: Su Jung Choi, Jin Chul Jeong, Seoung Nam KimDen Yogi HardiyantoNessuna valutazione finora

- CHAPTER 2 Press WorkingDocumento29 pagineCHAPTER 2 Press WorkingDen Yogi HardiyantoNessuna valutazione finora

- MIG Flux-Cored Welding CalculatorDocumento1 paginaMIG Flux-Cored Welding CalculatorDen Yogi Hardiyanto100% (1)

- WPS-PQR Pengelasan (AA)Documento12 pagineWPS-PQR Pengelasan (AA)Abrianto AkuanNessuna valutazione finora

- Rockwool Intumescent PillowsDocumento3 pagineRockwool Intumescent PillowsBobana AdamovicNessuna valutazione finora

- Dog Legged StaircaseDocumento6 pagineDog Legged StaircaseIshwor PrajapatiNessuna valutazione finora

- Stocrete Aeg Tds Se 08.06.2022Documento3 pagineStocrete Aeg Tds Se 08.06.2022Wai Phyo HeinNessuna valutazione finora

- STRC06 PrestressedConcrete 0717 r1 PDFDocumento96 pagineSTRC06 PrestressedConcrete 0717 r1 PDFnickNessuna valutazione finora

- Brochure Bekaert 3 25 Jun 09 PDFDocumento16 pagineBrochure Bekaert 3 25 Jun 09 PDFEmalaith BlackburnNessuna valutazione finora

- Structure Work OnlyDocumento1 paginaStructure Work OnlyShreekant SharmaNessuna valutazione finora

- 4 Ceilings & Floors: Gypsum IndustriesDocumento27 pagine4 Ceilings & Floors: Gypsum IndustriesrealdarossNessuna valutazione finora

- 2019-2021 BerlinerLuft. Flexible-ConnectorsDocumento9 pagine2019-2021 BerlinerLuft. Flexible-ConnectorsWillian SoaresNessuna valutazione finora

- Pipe LineDocumento75 paginePipe Linekiran raghukiranNessuna valutazione finora

- Two-Way Slab Design Based On ACI 318-19 Using Finite Element Method Input Data & Design SummaryDocumento4 pagineTwo-Way Slab Design Based On ACI 318-19 Using Finite Element Method Input Data & Design SummaryChrispin BarnigoNessuna valutazione finora

- Am220kxvjnh Id PDFDocumento1 paginaAm220kxvjnh Id PDFMarwene HlaouiNessuna valutazione finora

- A. Steps For A Drawing ReviewDocumento24 pagineA. Steps For A Drawing ReviewAkdas ArmanNessuna valutazione finora

- Fuller Factory#PricingDocumento39 pagineFuller Factory#PricingkkkhattabbbNessuna valutazione finora

- Preparing Coupons For Flexural and Washout Tests On Glass Fiber Reinforced ConcreteDocumento2 paginePreparing Coupons For Flexural and Washout Tests On Glass Fiber Reinforced ConcreteJerome PalicteNessuna valutazione finora

- BTQS 3044 - Measurement of External Works - L4 - SurfaceWaterDrainage - NewDocumento49 pagineBTQS 3044 - Measurement of External Works - L4 - SurfaceWaterDrainage - NewLE PEI CHIANessuna valutazione finora

- SHW Series NG 1700 Structural Concrete (Dec 2014)Documento52 pagineSHW Series NG 1700 Structural Concrete (Dec 2014)sandycastleNessuna valutazione finora

- Air Conditioning PPT of EMEDocumento24 pagineAir Conditioning PPT of EMEAbhishek Agrahari100% (1)

- Life Cycle Costing of A Building Adapting To ASHRAE StandardsDocumento85 pagineLife Cycle Costing of A Building Adapting To ASHRAE StandardsDivisha Jindal100% (2)

- ICEA-S 96-659 5kVDocumento2 pagineICEA-S 96-659 5kVAnamulKabirNessuna valutazione finora

- Final Report Group Front PDFDocumento14 pagineFinal Report Group Front PDFAbhi ChavanNessuna valutazione finora

- 2 Laticrete SystemsDocumento32 pagine2 Laticrete Systemseromax1Nessuna valutazione finora

- Pan Humidifier Load Calculation: Air Conditioning SystemDocumento1 paginaPan Humidifier Load Calculation: Air Conditioning SystemRamachandran Venkatesh100% (1)

- HVAC Interview QuestionsDocumento4 pagineHVAC Interview QuestionsMohammed Ahmed Khan100% (1)

- Rate Analysis For Vitrified FLOORINGDocumento2 pagineRate Analysis For Vitrified FLOORINGAnusha ChikmathNessuna valutazione finora

- 15 1 3 Mechanical InsulationDocumento7 pagine15 1 3 Mechanical Insulationfarshan296015Nessuna valutazione finora

- The Green Way To BuildDocumento4 pagineThe Green Way To BuildnfahmiNessuna valutazione finora

- Bq5-External Works (R)Documento16 pagineBq5-External Works (R)TimNessuna valutazione finora

- Innovative Building Materials: Presented byDocumento19 pagineInnovative Building Materials: Presented byMuhamet AhmetiNessuna valutazione finora

- Girls Hostel Project Girls Hostel Project: Project Milestone Project MilestoneDocumento8 pagineGirls Hostel Project Girls Hostel Project: Project Milestone Project Milestonezubair-scribdNessuna valutazione finora

- ISO 4427 Polyethylene (PE) Pipes For Water Supply Specifications PDFDocumento19 pagineISO 4427 Polyethylene (PE) Pipes For Water Supply Specifications PDFHarryIstepanian100% (2)