Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Maintenance Chart

Caricato da

Alvin Badz0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

17 visualizzazioni1 paginalogistics

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentologistics

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

17 visualizzazioni1 paginaMaintenance Chart

Caricato da

Alvin Badzlogistics

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

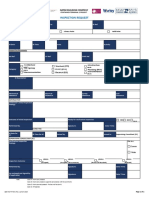

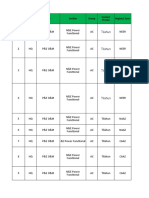

PROJECT NAME: Mozoon Towers

project no.: C-275

TYPE:

SAFETY INSPECTION INTERVALS SERIAL NO.

DATE:

Check list

EVERY HOURS OF OPERATION

ASSEMBLY ACTION

DAILY 50 100 250 500

CHECK AIR PRESSURE OF TYRE, IT IS NORMALLY AT 0.7~0.8MPa ●

TYRE

CHECK THE INSTALLATION BOLT OF TYRE LOOSENESS ●

WEAR CHECK OF CONCRETE PISTON AND GUIDE RING ●

CHECK WATER TANK FOR WATER LEVEL, MORTER LEAKAGE AND

SOLIDLY EYEWINKER . CHECK WATER FOR SUPERFLUOUS HYDRAULIC ●

OIL

CHECK AGITATOR MOTOR FOR OIL LEAKAGE AND AGITATOR SHAFT

FOR MORTAR LEAKAGE AND AGITATOR BLADE FOR WEAR ●

PUMPING MECHANISM CHECK SWING VALVE CYKINDER TO THE END ONCE ●

WEAR CHECK OF SPECTACLE WEAR PLATE AND CUTTING RING ●

CHECK CLEARANCE BETWEEN CUTTING RING AND END FACE OF S-

STUBE (= 4mm) ●

CHECK DELIVERY CYLINDER FOR ABNORMAL WEAR ●

WEAR CHECK OF TRANSITIONAL BUSHING (NOT LOWER THAN

DELIVERY CYLINDER) ●

CHECK GREASE LEVEL IN LUBRICATING GREASE PUMP ●

LUBRICATION SYSTEM CHECK OIL DISTRIBUTOR OF ABNORMITY ●

CHECK LUBRICATION OF DELIVERY CYLINDER ●

CHECK HYDRAULIC OIL LEVEL AND OIL QUALITY ●

CHECK INDICATOR ON HYDRAULIC OIL FILTER ●

CHECK HYDRAULIC ELEMENTS FOR OIL LEAKAGE ●

DRAIN OFF ACCUMULATED WATER IN HYDRAULIC OIL TANK ●

HYDRAULIC SYSTEM CHECK AND CLEAN RADIATOR BLADE ●

REPLACE HYDRAULIC OIL FILTER ●

CLEAN OIL SUCTION FILTER ELEMENT ●

REPLACE OIL RETURN FILTER ELEMENT ●

FULL HYDRAULIC OIL CHANGE ●

CHECK SUCH THREADED CONNECTORS AS TOGGLE SWITCH FOR

LOOSENESS ●

CHECK SUCH CONNECTORS AS FUSE AND RELAY FOR LOOSENESS ●

ELECTRICAL SYSTEM CHECK WATER TIGHTNESS FOR REMOTE CONTROL BOX ●

CHECK WIRING FOR DAMAGE ●

CHECK SOLENOID VALVE FOR ABNORMITY ●

PREPARED BY: Muhammad Moussa

POSITION:

SIGNATURE:

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Bensen B 8 Gyro Copter PlansDocumento42 pagineBensen B 8 Gyro Copter PlansDonald Foulk81% (26)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- SERVO-U/SERVO-n Ventilator System Service ManualDocumento140 pagineSERVO-U/SERVO-n Ventilator System Service Manualabu100% (3)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- CCTV System Installation ChecklistDocumento5 pagineCCTV System Installation ChecklistAlvin Badz100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Genset Startup and Commissioning Checklist C 175Documento13 pagineGenset Startup and Commissioning Checklist C 175Dwi Mulyanti DwimulyantishopNessuna valutazione finora

- Fans Checklist: Project Name: Project Ref. No.: Owner: Department: GroupDocumento1 paginaFans Checklist: Project Name: Project Ref. No.: Owner: Department: GroupAlvin BadzNessuna valutazione finora

- Quality Control Checklist Excavation: Consultant: Gulf Engineering&Industrial ConsultancyDocumento12 pagineQuality Control Checklist Excavation: Consultant: Gulf Engineering&Industrial ConsultancyAlvin Badz0% (1)

- D112 Wir 4211 ST 20967 - 0Documento1 paginaD112 Wir 4211 ST 20967 - 0Alvin BadzNessuna valutazione finora

- Readymix Plant Inspection Observation (Comments)Documento9 pagineReadymix Plant Inspection Observation (Comments)Alvin BadzNessuna valutazione finora

- Bimak 2020 Financial Year End ReportDocumento5 pagineBimak 2020 Financial Year End ReportAlvin BadzNessuna valutazione finora

- Technical Submittals - HBKDocumento29 pagineTechnical Submittals - HBKAlvin BadzNessuna valutazione finora

- R00000.00-DR-385 - Daily Report (08-May-2022) (12541)Documento23 pagineR00000.00-DR-385 - Daily Report (08-May-2022) (12541)Alvin BadzNessuna valutazione finora

- R00000.00-DR-383 - Daily Report (05-May-2022) (12724)Documento22 pagineR00000.00-DR-383 - Daily Report (05-May-2022) (12724)Alvin BadzNessuna valutazione finora

- R00000.00-DR-384 - Daily Report (07-May-2022) (12649)Documento23 pagineR00000.00-DR-384 - Daily Report (07-May-2022) (12649)Alvin BadzNessuna valutazione finora

- Aluminium Composite Panel CladdingDocumento23 pagineAluminium Composite Panel CladdingAlvin BadzNessuna valutazione finora

- R00000.00-DR-382 - Daily Report (01-May-2022) (12775)Documento23 pagineR00000.00-DR-382 - Daily Report (01-May-2022) (12775)Alvin BadzNessuna valutazione finora

- List of Activities For LSC Project - (16-May-2022)Documento16 pagineList of Activities For LSC Project - (16-May-2022)Alvin BadzNessuna valutazione finora

- Electrical Panels Installation ChecklistDocumento2 pagineElectrical Panels Installation ChecklistAlvin Badz100% (3)

- Standard Forms: Construction Supervision Department GeicDocumento1 paginaStandard Forms: Construction Supervision Department GeicAlvin BadzNessuna valutazione finora

- Inspection Request FormDocumento1 paginaInspection Request FormAlvin BadzNessuna valutazione finora

- Reinforcement Delivered Quantity: QA/QC Weekly Report - NEW NAVAL BASE PROJECT (Reinforcement Delivery)Documento4 pagineReinforcement Delivered Quantity: QA/QC Weekly Report - NEW NAVAL BASE PROJECT (Reinforcement Delivery)Alvin BadzNessuna valutazione finora

- D112 Wir 4211 ST 15349 - 0Documento1 paginaD112 Wir 4211 ST 15349 - 0Alvin BadzNessuna valutazione finora

- Design and Fabrication of Development of Sand Filter and Separator Pedal PoweredDocumento5 pagineDesign and Fabrication of Development of Sand Filter and Separator Pedal PoweredJithin V KNessuna valutazione finora

- Siemens Pricing Guide Horizontal ANEMA ANSP-60000-0211 R0Documento113 pagineSiemens Pricing Guide Horizontal ANEMA ANSP-60000-0211 R0Armando De La HozNessuna valutazione finora

- 45e PPB 246Documento16 pagine45e PPB 246HOMERO NOGUEDANessuna valutazione finora

- Rx70 SeriesDocumento406 pagineRx70 SeriesMiroslav TabakovskiNessuna valutazione finora

- Alt 55 Repair ManualDocumento296 pagineAlt 55 Repair ManualHiroKoNessuna valutazione finora

- Schindler 9700 Operation & Maintenance Manual 2012Documento8 pagineSchindler 9700 Operation & Maintenance Manual 2012KonstarothNessuna valutazione finora

- 8.2 - Interior Equipment (OCR)Documento38 pagine8.2 - Interior Equipment (OCR)mnbvqwertNessuna valutazione finora

- Mill Stage IIDocumento68 pagineMill Stage IIShift InchargeNessuna valutazione finora

- Load SchedDocumento10 pagineLoad SchedGary CudalNessuna valutazione finora

- .Operacion Del Governor G 3412.Documento15 pagine.Operacion Del Governor G 3412.Juan Carlos RivasNessuna valutazione finora

- QB400Documento2 pagineQB400Éverton KafskiNessuna valutazione finora

- Annunciator Sequences and Specifications: ISA-18.1-1979 (R2004)Documento54 pagineAnnunciator Sequences and Specifications: ISA-18.1-1979 (R2004)juliofelixNessuna valutazione finora

- Diagram CircuitDocumento1.242 pagineDiagram CircuitNEIKER 3001100% (1)

- proxxon کاتالوگDocumento70 pagineproxxon کاتالوگمرتضی فراهانیNessuna valutazione finora

- WEEK 44 Report (4 - 10)Documento10 pagineWEEK 44 Report (4 - 10)Melaku DesalegneNessuna valutazione finora

- LV100 3000Documento3 pagineLV100 3000Tibi IonNessuna valutazione finora

- Soft Bare Copper USA : DescriptionDocumento2 pagineSoft Bare Copper USA : Descriptiongerrzen64Nessuna valutazione finora

- Huawei ATR4518R11Documento2 pagineHuawei ATR4518R11cosconorNessuna valutazione finora

- Differential Pressure Transmitter Jumo Midas Dp10: Type 401050 Brief DescriptionDocumento3 pagineDifferential Pressure Transmitter Jumo Midas Dp10: Type 401050 Brief Descriptionguruh anindraNessuna valutazione finora

- Elevator Control Module: User'SDocumento19 pagineElevator Control Module: User'SJitheshbabu Babu100% (5)

- Mechatronic Systems Catalog: German - EnglishDocumento104 pagineMechatronic Systems Catalog: German - EnglishVent system СервисNessuna valutazione finora

- DFG/TFG 316-550: Operating InstructionsDocumento144 pagineDFG/TFG 316-550: Operating InstructionsbenjaminNessuna valutazione finora

- A1181 Macbook ProDocumento79 pagineA1181 Macbook ProAndrej PovhNessuna valutazione finora

- Asr Spec Cat Eu 2016 Catalogo ResortesDocumento212 pagineAsr Spec Cat Eu 2016 Catalogo ResortesIvan HuertaNessuna valutazione finora

- 2022 Nissan Pathfinder Brochure enDocumento9 pagine2022 Nissan Pathfinder Brochure enYudyChenNessuna valutazione finora

- Section 4 - Basic Hydraulics PDFDocumento25 pagineSection 4 - Basic Hydraulics PDFKhalid ZaeemNessuna valutazione finora

- Laboratory Report Cover SheetDocumento6 pagineLaboratory Report Cover SheetPre DatorNessuna valutazione finora