Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Work Simplification

Caricato da

ZabTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Work Simplification

Caricato da

ZabCopyright:

Formati disponibili

Work simplification

defined as the use of equipment, ergonomics, functional planning and behavior modification to reduce the physical and

psychological stresses on the body of activities at home or at work by reducing the physical demands on the body during tasks

acts to reduce the risk of injury or re-injury.

Doable for Work Simplification

Besides controlling the work environment to reduce or prevent risk of injury, the herein-listed finds very effective:

1. Establish in the workplace some simple guidelines for task set up, materials, tools, equipment storage, and work techniques

and routines for reduction of physical and mental strain.

2. Modify workplace layout to enable a task to be less strenuous by:

storing heavier and frequently used items at waist level;

setting up work tasks to avoid twisting of the spine, bending forwards or reaching away from the body;

using tools or mechanical equipment to reduce the physical force required to complete tasks, for instance, trolleys,

jacks & cranes;

storing infrequently used equipment below mid-thigh height or above shoulder height;

allowing tasks be done from a sitting or standing position or rotated to allow postural change where possible;

using a stepladder to access higher items and reduce the need for above the shoulder reaching.

3. Modify ways of load lifting to prevent further injury by considering the following:

Can large loads be broken down into smaller loads to reduce the impact on the body?

Can the load be lifted with two hands rather than one?

Can handles on loads be altered to make it easier to carry the load?

Can loads be carried safely against the body to allow the larger muscles of the legs to support the load rather than the

smaller muscles of the arms?

Can the load be lifted using a team lift?

Remember, it is more physically demanding to grip smaller items or large items with the hand at full stretch.

Philippine Occupational Health and Safety

The Occupational Safety and Health laws of the Philippines require employers, main contractors, self-employed people and

those in control of workplaces or access to workplaces, as far as practical, to:

identify each hazard to which a person at the workplace is likely to be exposed;

assess the risk of injury or harm to a person resulting from each hazard;

take action to control or reduce the risk.

DOLE – Department of Labor and Employment

Like in any other fields of human endeavor, masonry workers known as masons are protected by laws enabling their safety and

lives secured and promoted at all times. In doing so, Personal Protective Equipment (PPE) which includes protective clothing.

a safety helmet;

safety footwear;

safety goggles;

a face shield;

hearing protection;

sun and weather protection;

gloves to improve grip and reduce force and vibration; and

where hazardous dusts or fumes cannot be eliminated, respiratory protection.

Operators should avoid wearing loose fitting clothing or jewelry. Long hair worn loose and long beards can also be hazardous.

Cutting and drilling equipment especially saw blade discs and drill bits, should be removed from machines and stored where

they will not be damaged between use.

COMMON HAZARDS

1. Kick-back, push-back or pull-in – these are potentially violent forces that occur suddenly and can be difficult to control. They

are most likely to cause injury when hand-held or, quick-cut‟ concrete or masonry saws are used, especially when chasing.

They can also cause fixed concrete saws to be wrenched from their fittings, with the potential of the saw running free on the

ground. It is important that training for operators includes awareness of safe work practices and the risks of kick-back.

Employers and hire equipment suppliers must ensure operators have information and training on safe work practices.

2. Obstructions or resistance in the material being cut – these can cause sudden kick-back, push back or pull-in movements of

the saw. They occur when different quadrants of the blade come into contact with obstructions or resistance within the

concrete or masonry such as from reinforcing steel bars, steel mesh or brick ties.

3. Crooked or off-line cuts – these can cause the saw to bite or pinch resulting in kick- back, push-back or pull-in reactions.

These reactions are also most likely to occur with hand-held saws.

4. Pinched cuts – these are caused when the object being cut moves, resulting in the cutting groove tightening on the saw

blade, thus increasing the risk of kick-back etc.

5. Blunt cutting edges – these are caused by using a saw blade or drill bit with the wrong diamond cutting bond. If the bond or

matrix holding the cutting diamonds together is too hard for the material being cut, the bonding material does not wear

away quickly enough, resulting in the surface diamonds becoming blunt. This means extra force has to be applied by the

operator, especially with hand-held saws, increasing the risk of kick-back, push-back or pull-in.

6. Unsafe grip, stance or stop-start procedures for hand-held saws – these can cause the saw to swing out of control and

come into contact with the operator, or strike objects that may cause the saw to fall and run free on the ground.

7. Worn, misshapen, cracked or damaged saw blades, or the wrong type of blade – these can cause the blade to wobble,

vibrate, shatter, or fragment and fly off. Guarding on most concrete and masonry equipment is designed to protect the

operator from flying blade fragments, but not others in the workplace. Guarding should, therefore, not be regarded as a total

safeguard. Blades are most likely to disintegrate when force is used, for example when the diamond cutting edge becomes

dull, an obstruction is encountered, the cutting groove is not straight or the blade is pinched.

8. Worn blade shaft – incorrectly fitted blades or the wrong type of blade for the job can cause wear on the central shaft

causing even new blades to shudder, resulting in early wearing and risk of shatter.

9. Wrong-size blades – these are blades either too large, too small, or the wrong type for the cutting machine or size and

shape of the concrete or masonry item being cut. For example, a small diameter blade used to cut a thick slab may not

penetrate sufficiently; increasing the risk of kick-back or blade-shatter should the blade strike resistance.

10. Hazardous dusts – these are emitted by cutting and drilling operations or equipment that does not use water for cooling

cutting parts and capturing dust. Concrete dust may carry high levels of silica dust and repeated exposure can cause silicosis,

which is a scarring and stiffening of the lungs. The effects are irreversible, invariably resulting in death. Coarser rock particles

can cause short term throat irritation and bronchitis.

11. Insufficient flow of coolant water – this can cause overheating and expansion of both metal and masonry, resulting in poor

performance, jamming, severe blade damage and projectile hazards.

12. Incompatible flanges and blades – these can cause uneven blade movement, wear and tear and the risk of blade-shatter.

13. Incorrectly secured blades – these are caused by nuts and flanges which are not tightened sufficiently on the saw shaft,

which can cause uneven blade movement and the risk of blade-shatter.

14. Inadequate securing of anchor points – these can cause a fixed saw to break free from its track fittings.

15. A beard, loose hair or loose clothing – these can cause the operator to become entangled with moving saw blades, drill

bits and other moving parts.

16. Hand-held saw cutting above shoulder or below knee-height – this can reduce operator control and increase the risk of

kick-back, push-back or pull-in injury.

17. Cutting concrete pipes – this requires special safe procedures to prevent the pipe from rolling or moving during cutting,

particularly when a handheld saw is used. A specific hazard during pipe cutting is pressure from the raised flange on the pipe-

end causing the cut to close and pinch the saw blade, resulting in kick-back or blade shatter injury. Other hazards include the

presence of steel reinforcing mesh in concrete pipes, and a practice sometimes used for pipe-cutting involving a series of

plunge cuts around a pre-drawn line on the pipe’s outer surface.

18. Toxic fumes – without adequate ventilation, petrol motor emissions containing carbon monoxide and other toxic gases can

build up to hazardous levels.

19. Insufficient guarding – guarding on some concrete or masonry saws is more effective than on others. When purchasing,

consider the adequacy of guarding. Part of a safe work procedure should be to ensure that the manufacturer’s recommended

guarding is fitted to such saws. Removing guarding can greatly increase injury risk.

20. Electric wires, gas or water pipes – exposing services, especially in existing structures, can put the operator at risk of

slipping, electrocution, exposure to toxic gases, or explosion.

21. Power cords – when attached to electric-powered cutting equipment and other machinery, these may be cut or damaged.

Pools of water coolant and slurry could cause electrocution due to an immersed cord.

22. Uneven or unstable surfaces – these can increase the likelihood that the operator may trip or stumble, causing an

unexpected movement of the blade resulting in kick-back.

23. Wet, slippery floors – coolant water and slurry on floors can cause slips and falls.

24. Obstructions in access ways – blocks of masonry and bricks in areas where the operator and others must stand, work or

move can cause trips and falls.

25. Vibration – whole body or hand or arm vibration caused by prolonged use of cutting or drilling equipment can cause nerve,

circulatory and joint damage.

26. Working alone – this can be hazardous because of the potential need for assistance in the event of an emergency situation

or injury.

27. Noise – excessive noise from concrete cutting and drilling is a workplace hazard.

COMMON RISKS

The most likely risks of injury or harm come from:

flying saw fragments;

saw kick-back, push-back or pull-in;

out-of-control or free-running cutting machines;

falling concrete and masonry;

inadequate scaffolding;

noise;

electrocution;

hazardous dusts from dry cutting and drilling, such as silica dust, contributing to lung disease;

slips, trips and falls;

manual handling or strain injuries;

vibration damage to circulation, nerves and joints; and

suffocation or poisoning from hazardous fumes or gases emitted by petrol motors and other equipment or damaged

gas supply services.

RISK MANAGEMENT

How do we control risks?

1. Hazard Identification.

2. Risk Assessment.

3. Controlling Risks.

Safety Procedures

Hazard identification and risk assessment procedures should be carried out for each type of concrete or masonry cutting or

drilling job, in order to develop, implement and maintain control measures for each item of equipment and each job.

1. Control measures should be regularly reviewed.

Workplace communication and consultation

Safety and health committee meetings

Regular equipment and work safety checks

Incident, accident and near-miss records

Injury and lost time records

Repair and maintenance reports

2. Workers should be continuously trained specifically on information and instruction on

Workplace safety and health

hazards and risks associated with work activities

Safe work practices and procedures, safe handling (including lifting and moving), safe operation of equipment and the

control measures in place

Safe use of plant and associated equipment, electrical safety, safety in confined spaces and other training required

under hazard-specific regulations

Hazardous substances relevant to the work to be performed

Correct use, fit and care of PPE, tools and equipment and why the equipment is needed

Emergency and first aid procedures

Sun protection to prevent skin cancer

Fire protection

Information on dust, fumes and air quality

Recognition of poorly ventilated areas and confined spaces

Potrebbero piacerti anche

- ER Task 4Documento8 pagineER Task 4Chloe KnappNessuna valutazione finora

- Role of Counseling in Prisoner RehabilitationDocumento6 pagineRole of Counseling in Prisoner RehabilitationChuxGervase100% (1)

- Key Theories of Educational Psychology-Cristine AbudeDocumento10 pagineKey Theories of Educational Psychology-Cristine AbudeRoessi Mae Abude AratNessuna valutazione finora

- Measures of Central TendencyDocumento8 pagineMeasures of Central TendencyKikiez PathanasriwongNessuna valutazione finora

- Common Farm EquipmentDocumento5 pagineCommon Farm EquipmentZab100% (2)

- Columns: Advance of Computation Since These Codes FallDocumento2 pagineColumns: Advance of Computation Since These Codes FallAbhimanyu RavindranathNessuna valutazione finora

- Enemy Territory - Quake Wars - ManualDocumento22 pagineEnemy Territory - Quake Wars - ManualM_MolliNessuna valutazione finora

- Ihs Kingdom Hot Keys ReferenceDocumento1 paginaIhs Kingdom Hot Keys ReferenceMuhammad Jahangir100% (1)

- Assessment Literacy: Process of Gaining Information About The Gap and Learning IsDocumento7 pagineAssessment Literacy: Process of Gaining Information About The Gap and Learning IsGiselle Eclarino100% (1)

- Nature of Teaching Learning ProcessDocumento14 pagineNature of Teaching Learning ProcessDr. Nisanth.P.MNessuna valutazione finora

- Importance of Teacher Training in PakistanDocumento3 pagineImportance of Teacher Training in Pakistanather siddiqiNessuna valutazione finora

- Definition of Special EducationDocumento3 pagineDefinition of Special EducationMaridel Mugot-DuranNessuna valutazione finora

- Assessment in Special EdDocumento27 pagineAssessment in Special EdAlfred IntongNessuna valutazione finora

- Humanistic Approach (KCORPUZ) PPTDocumento20 pagineHumanistic Approach (KCORPUZ) PPTkarren corpuzNessuna valutazione finora

- 6 Strategies For Teaching Special Education ClassesDocumento2 pagine6 Strategies For Teaching Special Education Classesjoel dizonNessuna valutazione finora

- Meaning of Teacher Made TestDocumento8 pagineMeaning of Teacher Made TestUmesh PatilNessuna valutazione finora

- 5.children With Physical ImpairmentDocumento8 pagine5.children With Physical ImpairmentJunadrian GenitoNessuna valutazione finora

- Facilitating Learner-Centered Teaching (Report Guide)Documento10 pagineFacilitating Learner-Centered Teaching (Report Guide)Krisha Marie Fernando ValmoresNessuna valutazione finora

- Teaching of Science To The Visually ImpairedDocumento11 pagineTeaching of Science To The Visually ImpairedPallaviKulshrestha100% (1)

- Types of Values Reflection, AngkananDocumento2 pagineTypes of Values Reflection, AngkananMahathma Dalandas - AngkananNessuna valutazione finora

- Module 1 Activity 1Documento3 pagineModule 1 Activity 1Floyd LawtonNessuna valutazione finora

- Module-I Role and Application of Psychology in Education: Unit StructureDocumento20 pagineModule-I Role and Application of Psychology in Education: Unit StructureDebadatta AcharyaNessuna valutazione finora

- Code of Ethucs EssayDocumento10 pagineCode of Ethucs Essayapi-434739441Nessuna valutazione finora

- Activity Based Teaching StrategiesDocumento9 pagineActivity Based Teaching StrategiesMarielle Soriano100% (1)

- Act of Teaching Chapter 7Documento3 pagineAct of Teaching Chapter 7api-350726106Nessuna valutazione finora

- Psychological Foundation of Education EDUC 203Documento38 paginePsychological Foundation of Education EDUC 203Anthony OperarioNessuna valutazione finora

- Readi NGS. - .: Intellectual DisabilityDocumento29 pagineReadi NGS. - .: Intellectual DisabilityChambee ChambeeNessuna valutazione finora

- Learning Principles by Sandra de YoungDocumento2 pagineLearning Principles by Sandra de YoungMaricris BalinagNessuna valutazione finora

- FinalsDocumento241 pagineFinalsreadsriNessuna valutazione finora

- Fundamental Movement SkillsDocumento5 pagineFundamental Movement SkillsfigfarmerNessuna valutazione finora

- Asessment of For As LearningDocumento20 pagineAsessment of For As LearningGerald Ryan BartolomeNessuna valutazione finora

- Bloom's Taxonomy RevisedDocumento10 pagineBloom's Taxonomy RevisedJusteen BalcortaNessuna valutazione finora

- DAP Position Statement NAEYCDocumento32 pagineDAP Position Statement NAEYCAlexandria Denisse E. CruzNessuna valutazione finora

- Learning Strategies and Learner CharacteristicsDocumento3 pagineLearning Strategies and Learner CharacteristicsresearchparksNessuna valutazione finora

- Formative vs. Summative Assessments - What's The DifferenceDocumento11 pagineFormative vs. Summative Assessments - What's The DifferenceMerajuddin AhmedNessuna valutazione finora

- Critical ReflectionDocumento3 pagineCritical Reflectionapi-218682499Nessuna valutazione finora

- Teaching Strategies Essential For Teaching Students With Special NeedsDocumento2 pagineTeaching Strategies Essential For Teaching Students With Special NeedsfruittinglesNessuna valutazione finora

- Curriculum DevelopmentDocumento65 pagineCurriculum Developmentrindel0% (1)

- Slow LearnersDocumento4 pagineSlow LearnersSadiq Merchant100% (7)

- Levels of Teaching LearningDocumento20 pagineLevels of Teaching LearningDr. Nisanth.P.MNessuna valutazione finora

- Continuous and Comprehensive EvaluationDocumento16 pagineContinuous and Comprehensive EvaluationDr. Nisanth.P.M100% (2)

- C1a1 Mza FinalDocumento18 pagineC1a1 Mza Finalalfa bravocharlie100% (1)

- Visual Impairment: By: Michael Ron Francis D. DimaanoDocumento16 pagineVisual Impairment: By: Michael Ron Francis D. DimaanoMichael Ron DimaanoNessuna valutazione finora

- Educational Technology 13MBDocumento223 pagineEducational Technology 13MBArianne Rose Fangon100% (1)

- Unit 3: Vocational GuidanceDocumento5 pagineUnit 3: Vocational GuidanceMukul SaikiaNessuna valutazione finora

- Module 2. TTPDocumento12 pagineModule 2. TTPcesar pabilonaNessuna valutazione finora

- Formative Assessment vs. Summative AssessmentDocumento12 pagineFormative Assessment vs. Summative AssessmentZin Maung TunNessuna valutazione finora

- Improved Instructional PracticesDocumento25 pagineImproved Instructional Practicescj_tualaNessuna valutazione finora

- Student ProblemsDocumento4 pagineStudent ProblemsRDH 16Nessuna valutazione finora

- What Is Feedback?Documento7 pagineWhat Is Feedback?Mike BohnerNessuna valutazione finora

- Information and Communication Technology Ict and I PDFDocumento15 pagineInformation and Communication Technology Ict and I PDFjhuvy jalandoonNessuna valutazione finora

- 5 Principles of LearningDocumento2 pagine5 Principles of Learningjanine rivera100% (1)

- Week 1 ACTIVITYDocumento2 pagineWeek 1 ACTIVITYJohn Edward FajardoNessuna valutazione finora

- Multiple Disabilities: What's Inside?Documento5 pagineMultiple Disabilities: What's Inside?api-312955728Nessuna valutazione finora

- Prof Educ 2: Foundation of Special and Inclusive EducationDocumento12 pagineProf Educ 2: Foundation of Special and Inclusive EducationNerissa Custosa BastoNessuna valutazione finora

- Organization and Structure of GuidanceDocumento15 pagineOrganization and Structure of GuidanceAngelica FloraNessuna valutazione finora

- Essays On Teaching ProfessionDocumento11 pagineEssays On Teaching ProfessionSammy AngNessuna valutazione finora

- Guidelines For Classroom QuestioningDocumento2 pagineGuidelines For Classroom QuestioningTamuzNessuna valutazione finora

- Learners With Difficulty in HearingDocumento3 pagineLearners With Difficulty in HearingPortes, Hannah GraceNessuna valutazione finora

- Instuctional Management by Jacob KouninDocumento9 pagineInstuctional Management by Jacob KouninAhn NielNessuna valutazione finora

- Profed7 Cm1 Engaged: Classroom Visitor 7. Field Trip and Service Learning 8. Context Curriculum 9. Impact InvestigationDocumento9 pagineProfed7 Cm1 Engaged: Classroom Visitor 7. Field Trip and Service Learning 8. Context Curriculum 9. Impact InvestigationAndrea Mae DelimaNessuna valutazione finora

- Lesson No. 5: Learning TheoriesDocumento47 pagineLesson No. 5: Learning TheoriesJoshua SeñarosaNessuna valutazione finora

- Kratochwill DeRoosbBlair Classroom Management Teachers ModulesDocumento13 pagineKratochwill DeRoosbBlair Classroom Management Teachers ModulesМария РыжковаNessuna valutazione finora

- Healthcare Reflections, Insights, and Lessons: Proactive/ReactiveDa EverandHealthcare Reflections, Insights, and Lessons: Proactive/ReactiveNessuna valutazione finora

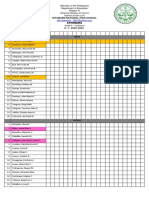

- AttendanceDocumento5 pagineAttendanceZabNessuna valutazione finora

- Document 13Documento2 pagineDocument 13ZabNessuna valutazione finora

- Oath of OfficeDocumento3 pagineOath of OfficeZabNessuna valutazione finora

- The History of Theatrical Forms and Their EvolutionDocumento3 pagineThe History of Theatrical Forms and Their EvolutionZab100% (1)

- Intervention-Plan For Midyear ExaminationDocumento1 paginaIntervention-Plan For Midyear ExaminationZabNessuna valutazione finora

- Locator SlipDocumento1 paginaLocator SlipZabNessuna valutazione finora

- SANGGUNIANDocumento2 pagineSANGGUNIANZabNessuna valutazione finora

- Mapeh 9 Culminating ActivityDocumento3 pagineMapeh 9 Culminating ActivityZabNessuna valutazione finora

- Demonstration ChecklistDocumento1 paginaDemonstration ChecklistZabNessuna valutazione finora

- Theories and Principles of Orthographic ProjectionDocumento19 pagineTheories and Principles of Orthographic ProjectionZab50% (2)

- 2019-2020 Villa Aurora Nhs Action PlanDocumento4 pagine2019-2020 Villa Aurora Nhs Action PlanZabNessuna valutazione finora

- Concrete and Masonry SafetyDocumento57 pagineConcrete and Masonry SafetyZabNessuna valutazione finora

- @santoselizabeth 96Documento2 pagine@santoselizabeth 96ZabNessuna valutazione finora

- Java Swing Demo (Class Name Test)Documento2 pagineJava Swing Demo (Class Name Test)bejarunNessuna valutazione finora

- Blast Furnace Presentation Ver1Documento39 pagineBlast Furnace Presentation Ver1abhijit kumarNessuna valutazione finora

- Motorized Hydraulic PressDocumento4 pagineMotorized Hydraulic PressDhiraj Shinde100% (2)

- HN1000 HN2000Documento44 pagineHN1000 HN2000Mose SodeNessuna valutazione finora

- 2 TensionDocumento28 pagine2 TensionRICKY IVANNessuna valutazione finora

- Excel To C I For Positive in PutDocumento23 pagineExcel To C I For Positive in PuthimanshuNessuna valutazione finora

- This Worksheet Is Due by The Deadline Posted On Blackboard. This Is An Individual SubmissionDocumento2 pagineThis Worksheet Is Due by The Deadline Posted On Blackboard. This Is An Individual SubmissionAhsan AliNessuna valutazione finora

- Planeur Tres Simple PDFDocumento3 paginePlaneur Tres Simple PDFAhmedNessuna valutazione finora

- Statistical Process Control & Cost of QualityDocumento114 pagineStatistical Process Control & Cost of QualityAshraf S. Youssef100% (2)

- Bicycle and Motorcycle DynamicsDocumento36 pagineBicycle and Motorcycle DynamicsChanakya ChNessuna valutazione finora

- Seb 1242-Soil Mechanics II SuppDocumento2 pagineSeb 1242-Soil Mechanics II Suppcharler kinyuajNessuna valutazione finora

- Inspection & Maintenance of Dams: Dam Safety GuidelinesDocumento79 pagineInspection & Maintenance of Dams: Dam Safety Guidelinesvishu1909100% (1)

- DTCNDocumento232 pagineDTCNCMM INFRAPROJECTS LTDNessuna valutazione finora

- Sqldatagrid Symbol User'S Guide: ArchestraDocumento36 pagineSqldatagrid Symbol User'S Guide: ArchestraAde SuryaNessuna valutazione finora

- Intelligent Control LED Integrated Light Source: Features and BenefitsDocumento6 pagineIntelligent Control LED Integrated Light Source: Features and BenefitsRazvy StoianNessuna valutazione finora

- SLAManualDocumento187 pagineSLAManualfarhadhassan100% (1)

- Case Adhesives BrochureDocumento6 pagineCase Adhesives BrochureChanakyaNessuna valutazione finora

- 07 Power Voltage FeedthroughsDocumento52 pagine07 Power Voltage FeedthroughsDeepak SomanNessuna valutazione finora

- Glass & Glazing WorkDocumento34 pagineGlass & Glazing WorkPratik ThakkarNessuna valutazione finora

- lfb10 Call PointDocumento1 paginalfb10 Call PointOmar AhmedNessuna valutazione finora

- IC Course Guide BookDocumento5 pagineIC Course Guide BookAddisu AyeleNessuna valutazione finora

- Tolerancia Pasador y BielaDocumento1 paginaTolerancia Pasador y BielaAlejandro ValenzuelaNessuna valutazione finora

- Epanet Vs Watergems (083011)Documento9 pagineEpanet Vs Watergems (083011)MABA02100% (1)

- Shear Key PDFDocumento3 pagineShear Key PDFBijaya RaulaNessuna valutazione finora

- Fortranv 7Documento173 pagineFortranv 7mu4viewNessuna valutazione finora

- SVT-RM10: Remote Control UnitDocumento2 pagineSVT-RM10: Remote Control UnitJOGITELENessuna valutazione finora

- A Review of Power Electronics Based Microgrids: Josep M. Guerrero, Xiongfei Wang, Zhe Chen, and Frede BlaabjergDocumento5 pagineA Review of Power Electronics Based Microgrids: Josep M. Guerrero, Xiongfei Wang, Zhe Chen, and Frede BlaabjergSaksham GuptaNessuna valutazione finora