Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

28 - RG-Rod Gland Cartridge Kit

Caricato da

Enrique Murgia0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni1 paginaGland cartridge kit

Titolo originale

28_RG-Rod Gland Cartridge Kit

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoGland cartridge kit

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni1 pagina28 - RG-Rod Gland Cartridge Kit

Caricato da

Enrique MurgiaGland cartridge kit

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

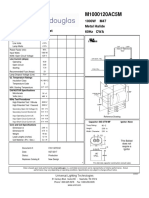

Series MP

Cylinders Gland Seal Kits

Gland Seal Kits Service kits of expendable parts for fluid power cylinders are stocked in

principal industrial locations across the U.S.A. and other countries. For prompt

delivery and complete information, contact your nearest Parker distributor or

(Gland Cartridges & Rod Seals) office.

For Series “MP” Air Cylinders See Fig. B 45

for Viton 40

Pneumatic Service Temperatures:

Nitrile Seals: –10° F. (–23° C.) to +165° F. (+74° C.)

seal design

Viton Seals: –10° F. (–23° C.) to +250° F. (+121° C.)

Nitrile Seal design – (Shown)

(See Fig. B for Viton seal design)

45 Figure C

14 Ref.

134 40 ROD SEAL KIT

40 (RK) Kit contains 1 each of the following:

symbol #40, Rod Lipseal / Wiper.

14 symbol #45, O-Ring, gland to head.

symbol #134, Retaining Ring. (Viton seal kit - ONLY)

Installation

Figure A Figure B 1) Reinspect the surface of the piston rod for scratches, dents and

other surface damage and make the necessary repairs.

GLAND CARTRIDGE KIT (RG) Kit contains 1 each of the following:

2) Clean and lubricate the surface of the piston rod with Lube-A-Cyl.

symbol #14, Gland, threaded cartridge type.

symbol #40, Rod Lipseal / Wiper. 3) If replacing complete gland cartridge proceed to step #6. If gland

(symbol #14) is not worn, replace seals only using appropriate rod

symbol #45, O-Ring, gland to head.

seal kit (RK) and proceed as follows.

symbol #134, Retaining Ring. (Viton seal kit - ONLY)

4) Lubricate gland seal groove and new Lipseal / Wiper (symbol #40)

Servicing the Rod Gland and install in gland groove. The seal should be installed orientated

(Cylinder disassembly is not required) as shown in Figure A or Figure B above. If the seal kit contains a

Retaining Ring (symbol #134) install it as shown in Figure B.

Fluid leakage around the piston rod at the gland area will normally indicate

a need to replace the gland seals. 5) Install new gland to head o-ring (symbol #45) in position on gland

The series MP Gland is a unique cartridge design. It is threaded into the as pictured above. Be careful not to cut the O-Ring.

cylinder head and all sizes are removable without disturbing the end cap 6) Lubricate all seals (including symbol #45) and inside bearing

fasteners. surfaces of gland with Lube-A-Cyl or clean light oil.

7) Slide the gland cartridge onto the piston rod, squaring it with the

To Remove the Gland Cartridge threads in the head, and tightening (clockwise) until seated firmly

A) Inspect the piston rod to be sure it is free of burrs or other foreign against the head.

material that would prevent sliding the cartridge off the rod. 8) Torque the gland cartridge to the specifications shown below.

B) Disconnect any attachments to the piston rod end thread.

C) Lubricate the rod with Lube-A-Cyl. ! CAUTION: Make sure the gland is sufficiently tight.

D) Unscrew the gland cartridge from the head using appropriate Failure to do so may result in loosening during operation.

gland and spanner wrench listed below.

E) Slide the cartridge off over the piston rod.

F) Make sure the gland to head O-Ring (symbol #45) is also

removed from the assembly.

G) Remove all seals from the gland, inspect the gland (symbol #14)

for wear & replace if necessary.

F

RG-Rod Gland Cartridge Kit RK-Rod Seal Kit

NITRILE Seals VITON Seals NITRILE Seals VITON Seals Gland Spanner Gland To Head

Bore Rod Rod Consisting of: 1 ea. Consisting of: 1 ea. Consisting of: 1 ea. Consisting of: 1 ea. Wrench Wrench Torque Units

Size Dia. No. sym. # 14, 40 & 45 sym. # 14, 40, 45 & 134 sym. # 40 & 45 sym. # 40, 45 & 134 U.S.A. Metric E

mm mm Part No. Part No. Part No. Part No. Part No. Part No. Ft. Lbs. N.m

32 12 1 RG0MP00121 RG0MP00125 RK0MP00121 RK0MP00125 0695900000 0116760000 35 - 40 47 - 54

40 16 1 RG0MP00161 RG0MP00165 RK0MP00161 RK0MP00165 0695910000 0116760000 40 - 45 54 - 61

50 & 63 20 1 RG0MP00201 RG0MP00205 RK0MP00201 RK0MP00205 0695910000 0116760000 45 - 50 61 - 68

80 & 100 25 1 RG0MP00251 RG0MP00255 RK0MP00251 RK0MP00255 0695910000 0116760000 45 - 50 61 - 68

125 32 1 RG0MP00321 RG0MP00325 RK0MP00321 RK0MP00325 0695920000 0117030000 70 - 75 95 - 102

160 & 200 40 1 RG0MP00401 RG0MP00405 RK0MP00401 RK0MP00405 0695940000 0116770000 85 - 90 115 -122

For Cylinder Division Plant Locations – See Section H.

13

Potrebbero piacerti anche

- BA DL Brustbeinsaege EFA 57 en 02.2020Documento34 pagineBA DL Brustbeinsaege EFA 57 en 02.2020Enrique MurgiaNessuna valutazione finora

- BA DL Brustbeinsaege EFA 57 en 02.2020Documento34 pagineBA DL Brustbeinsaege EFA 57 en 02.2020Enrique MurgiaNessuna valutazione finora

- Mayr Torque LimitersDocumento28 pagineMayr Torque LimitersEnrique MurgiaNessuna valutazione finora

- SS Cnpulse 12132018Documento2 pagineSS Cnpulse 12132018Enrique MurgiaNessuna valutazione finora

- Sauer Danfoss Hydraulic Gear Pump Group 4Documento23 pagineSauer Danfoss Hydraulic Gear Pump Group 4Enrique MurgiaNessuna valutazione finora

- Sauer Danfoss Hydraulic Gear Pump Group 3Documento33 pagineSauer Danfoss Hydraulic Gear Pump Group 3Enrique Murgia100% (1)

- M1000120AC5MDocumento1 paginaM1000120AC5MEnrique MurgiaNessuna valutazione finora

- Gear Pump Shhark Low NoiseDocumento2 pagineGear Pump Shhark Low NoiseEnrique MurgiaNessuna valutazione finora

- LTBT BCM PDFDocumento2 pagineLTBT BCM PDFEnrique MurgiaNessuna valutazione finora

- Mini Squirt Hot Melt Adhesive ApplicatorDocumento2 pagineMini Squirt Hot Melt Adhesive ApplicatorEnrique MurgiaNessuna valutazione finora

- Itsupply: Hardware ManualDocumento131 pagineItsupply: Hardware ManualEnrique MurgiaNessuna valutazione finora

- Universal Bugomatic Bro 3 19Documento4 pagineUniversal Bugomatic Bro 3 19Enrique MurgiaNessuna valutazione finora

- Mud Pump Parts ExpendablesDocumento82 pagineMud Pump Parts ExpendablesAnonymous Yo43Kif0Nessuna valutazione finora

- Thyristor Product CatalogDocumento224 pagineThyristor Product CatalogMohamed ReyadNessuna valutazione finora

- CATALOGODocumento1 paginaCATALOGOEnrique MurgiaNessuna valutazione finora

- Sandvik RH550r DTH hammer replacement partsDocumento1 paginaSandvik RH550r DTH hammer replacement partsEnrique MurgiaNessuna valutazione finora

- AC Motors Asynchronous Servomotors: Operating InstructionsDocumento56 pagineAC Motors Asynchronous Servomotors: Operating InstructionsEnrique MurgiaNessuna valutazione finora

- 108Documento21 pagine108Juan Pablo Chumba LaraNessuna valutazione finora

- Yanmar America publication listing for engine parts, service, and operation manualsDocumento602 pagineYanmar America publication listing for engine parts, service, and operation manualsEnrique Murgia50% (2)

- Robotic Shotcrete Applications For Mining and Tunneling: A History of Robotic ApplicatorsDocumento6 pagineRobotic Shotcrete Applications For Mining and Tunneling: A History of Robotic ApplicatorsEnrique MurgiaNessuna valutazione finora

- High Head Drainage PumpsDocumento9 pagineHigh Head Drainage PumpsEnrique MurgiaNessuna valutazione finora

- X55-600 BrochureDocumento9 pagineX55-600 BrochureEnrique MurgiaNessuna valutazione finora

- Wikus Precision Band SawDocumento52 pagineWikus Precision Band SawEnrique Murgia100% (1)

- Port Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestDocumento3 paginePort Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestEnrique MurgiaNessuna valutazione finora

- Danroll Drum MotorDocumento112 pagineDanroll Drum MotorEnrique MurgiaNessuna valutazione finora

- 2693i GC PDFDocumento2 pagine2693i GC PDFEnrique MurgiaNessuna valutazione finora

- Price DetroitDocumento31 paginePrice DetroitEnrique MurgiaNessuna valutazione finora

- 962 Stager Manual Rev BDocumento18 pagine962 Stager Manual Rev BEnrique MurgiaNessuna valutazione finora

- TFP1511 09 2015Documento8 pagineTFP1511 09 2015Enrique MurgiaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Catalogo GIW KSB LSADocumento50 pagineCatalogo GIW KSB LSASebastián Retamal ArriazaNessuna valutazione finora

- Eik Am 200-3 Amphibious Undercarriage Parts BookDocumento41 pagineEik Am 200-3 Amphibious Undercarriage Parts BookPrudz100% (1)

- Grundfos NK SKC LDocumento50 pagineGrundfos NK SKC Lhufuents-1Nessuna valutazione finora

- Overview of Centrifugal PumpsDocumento5 pagineOverview of Centrifugal Pumpsrahul_choubey_9Nessuna valutazione finora

- Ball Wce5seriesDocumento11 pagineBall Wce5seriesAnonymous j5XYgIuNessuna valutazione finora

- Blick Ins Buch en 01knečkjf FQFMQLKFJ DjkeDocumento26 pagineBlick Ins Buch en 01knečkjf FQFMQLKFJ DjkeivanmatijevicNessuna valutazione finora

- Training Material For CCWP - ACWPDocumento25 pagineTraining Material For CCWP - ACWPToan NguyenNessuna valutazione finora

- Dean Pump® Series PHDocumento12 pagineDean Pump® Series PHEnrique FuentesNessuna valutazione finora

- Dragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198Documento16 pagineDragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198jesus alfonso fragozo calderonNessuna valutazione finora

- G.V. Manual (FC Type)Documento20 pagineG.V. Manual (FC Type)sambhajiNessuna valutazione finora

- 200912517184673552Documento23 pagine200912517184673552GBHJRNessuna valutazione finora

- Schedule of Rates Electrical&Mechanical 2021-2022Documento504 pagineSchedule of Rates Electrical&Mechanical 2021-2022Feng Yu0% (1)

- Bombas Galigher Serie VRADocumento7 pagineBombas Galigher Serie VRARAUL PEREZ NEGREIROSNessuna valutazione finora

- Stern TubeDocumento24 pagineStern Tubevigambetkar100% (3)

- Hy Andritz Pumps Portfolio en - PDDocumento45 pagineHy Andritz Pumps Portfolio en - PDMark CentenoNessuna valutazione finora

- End Seal ComponentsDocumento7 pagineEnd Seal ComponentsJose Miguel Paredes LajoNessuna valutazione finora

- Shan-Rod Fabricated Butterfly Valves 4300 Series: Bulletin 4300Documento4 pagineShan-Rod Fabricated Butterfly Valves 4300 Series: Bulletin 4300drNessuna valutazione finora

- Fisher Snoppy N511 ESVDocumento2 pagineFisher Snoppy N511 ESVWynn ChoNessuna valutazione finora

- Manual de Servicio KSB WKDocumento46 pagineManual de Servicio KSB WKHeriberto MendozaNessuna valutazione finora

- Turbine Pumps VEP SeriesDocumento8 pagineTurbine Pumps VEP SeriesamanhappyNessuna valutazione finora

- CEP Design Features And Parameters ComparisonDocumento35 pagineCEP Design Features And Parameters ComparisonGaurav100% (1)

- Hso422567 Issue2Documento13 pagineHso422567 Issue2Александр ЩербаковNessuna valutazione finora

- d10021 PDFDocumento16 pagined10021 PDFfarra0216Nessuna valutazione finora

- Econosto 1Documento81 pagineEconosto 1mengineering0% (1)

- KSB GIW Bombas PDFDocumento53 pagineKSB GIW Bombas PDFAlejandro Smilovic100% (1)

- Manual de Reparación Sello FlowserveDocumento8 pagineManual de Reparación Sello FlowservejorgeNessuna valutazione finora

- Dynamic Filter Press ManualDocumento23 pagineDynamic Filter Press ManualMobeen MurtazaNessuna valutazione finora

- CAT 4110 NV NeedleValves Dec2010Documento56 pagineCAT 4110 NV NeedleValves Dec2010amin110110Nessuna valutazione finora

- Pump Course Material Chapter 2Documento16 paginePump Course Material Chapter 2engr victorNessuna valutazione finora

- Centrifugal Pump Report PDFDocumento1 paginaCentrifugal Pump Report PDFandrew rachmanNessuna valutazione finora