Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Steel Interchange AISC PDF

Caricato da

Jorge SalinasTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Steel Interchange AISC PDF

Caricato da

Jorge SalinasCopyright:

Formati disponibili

If you've ever asked yourself "why" about something related to structural steel design or construction,

Modern Steel Construction's monthly Steel Interchange column is for you!

This month's Steel Interchange is compiled from a few of the 4. The repair should be inspected to assure soundness.

many frequently asked questions (FAQs) posted at

The discontinuity should be suitably prepared for good

www.aisc.org/faq. Numerical references such as "2.2.6" are

welding.

references to FAQs in this feature of the AISC web site.

Roughness Limitations Tolerances

3.5.1. How are tolerances determined if they are not

2.2.6. What are the appropriate roughness limitations for

addressed in the applicable standards?

thermally cut edges?

The fabrication and erection tolerances in the AISC LRFD

Inadvertent notches or gouges of varying magnitude might

Specification, the AISC Code of Standard Practice, AWS Dl.1, and

occur in thermally cut edges, depending upon the cleanliness

other existing specifications and codes have evolved over

of the material surface, the adjustment and manipulation of

nearly three-quarters of a century. Although these standards

the cutting head, and other factors. When thermally cut edges

generally present a workable format for the fabricator and

are prepared for the deposition of weld metal, the 1999 AISC

erector, they tend to address individual members, rather than

LRFD Specification Section M2.2 and AWS Dl.1-2002 Section

the role of individual members in the completed structure.

5.15.1.1 provide acceptance criteria that consider the effect of

Tolerances for assemblies, such as those on shop-assembled

discontinuities that are generally parallel to the applied stress

bents, frames, platforms, pairs of girders, etc., are not covered

on the soundness of welded joints. Additionally, correction

by any code or standard. AWS Dl.l-2002 Section 5.23.11.4

methods for defects of various magnitudes are stipulated.

states that " ... other dimensional tolerances of members not

When thermally cut edges are to remain unwelded, the fol-

covered by [Sectionj5.23 shall be individually determined and

lowing surface-condition guidelines are recommended:

mutually agreed upon by the Contractor and the owner with

1. If subjected to a calculated tensile stress parallel to the proper regard for erection requirements. " This practice is rec-

edge, edges should, in general, have a surface-roughness ommended in all cases. The agreed-upon tolerances should

value not greater than 1,000 as defined in ASME B46.1. account for the erection tolerances specified in the AISC Code

of Standard Practice.

2. Mechanically guided thermally cut edges not subjected to a

calculated tensile stress should have a surface roughness

value not greater than 2,000 as defined in ASME B46.1. Odd-Sized Holes

5.1.1. Maximum hole sizes for bolts are specified in the 1999

3. Hand-guided thermally cut edges not subjected to a calcu-

LRFD Specification Table J3.3. What if an actual hole dimen-

lated tensile stress should have a roughness not greater

sion is between two of the values?

than 1/ 16".

AISC Specification Table J3.3 is based upon the 2000 RCSC

4. All thermally cut edges should be free of notches' and rea- Specification Table 3.1 and contains the maximum dimensions

sonably free of gouges'. Occasional gouges not more than of standard, oversized, short-slotted, and long-slotted holes. If

3/16" deep are permitted. an actual dimension exceeds the tabulated maximum, it must

be treated as the next larger hole size. For example, a

Gouges greater than 3/16" deep and all notches should be

13/16" -by- liN ' slotted hole for a 314" -diameter bolt must be

repaired as indicated in 2.2.7.

treated as a long-slotted hole because it exceeds the maximum

'defined as a V-shaped indentation or hollow

short-slotted hole size (13/16" by 1"). Note that the 2000 RCSC

'defined as a groove or cavity having a curved shape

Specification Section 3(c) allows a lj32" tolerance on these maxi-

mum hole sizes as discussed in 2.4.2 and 2.5.5.

Repairing Rough Edges

2.2.7. When surface roughness for thermally cut edged does

not meet the limitations in 2.2.6, how is the surface repaired?

Paint on Faying Surfaces

6.7.1. When is paint permitted on the faying surfaces of

Roughness exceeding the criteria in 2.2.6 and notches not

bolted connections?

more than 3/16" deep should be removed by machining, or

In snug-tight and pretensioned bearing connections, paint

grinding and fairing-in at a slope not to exceed 1:2Y2. The

is permitted unconditionally on the faying surfaces. In slip-

repair of notches or gouges greater than 3/16" deep by welding

critical connections, however, if paint is present, it must be a

should be permitted. The following criteria are recommended:

qualified paint. A qualified paint is one that has been tested in

1. Low-hydrogen electrodes not exceeding 5/32" diameter accordance with the 2000 RCSC Specification Appendix A and

should be used. offers a defined slip-coefficient. Other paints that do not offer

a defined slip-coefficient are not permitted on the faying sur-

2. Other applicable welding requirements of AWS D1.1

faces of slip-critical connections, even when due to inadver-

should be observed.

tent over-spray.

3. The repair should be made flush with the adjacent surface

with good workmanship.

June 2004 • Modern Steel Construction • 11

Paint Under Nuts and Bolt Heads In exterior exposed applications, steel must be protected

6.7.2. Both the AISC and RCSC specifications require that from corrosion by painting or other means. Likewise, steel

paint on the faying surfaces of slip-critical connections be must be protected from corrosion in special applications such

qualified (providing a minimum slip coefficient) or that as the corrosive environment of a paper-processing plant or a

such surfaces remain unpainted. Does this requirement structure with oceanfront exposure.

apply to the surfaces under the bolt head and nut? IBigos, J., C.w. Smith, E.F. Ball, and P.J. Foehl, 1954, "Shop

No. In a slip-critical connection, the faying surfaces are Paint and Painting Practice," Proceedings of the 1954 AISC

those that resist relative movement (or slip) of the plies. This National Engineering Conference, AISC, Chicago, IL.

occurs on the contact surfaces between the plies, not those

surfaces under the bolt head or nut. Selecting Paint Systems

10.1.2. When a paint system is required, how should it be

Fillet Weld Size Limitations selected?

8.3.6. Why is a fillet-weld size generally limited to 1!t6" less When paint is required, SSPC emphasizes the importance

than the material thickness when placed along the edge of a of the development of a total paint system. Among the pri-

connected part? mary considerations for this design decision by the owner,

As explained in the 1999 AISC LRFD Specification Commen- architect, or engineer are:

tary Section J2.2b, "For plates of 1,4" (6 mm) or more in thick- 1. The end use of the member.

ness, it is necessary that the inspector be able to identify the

edge of the plate to position the weld gage." Note that this 2. A realistic estimate of time and severity of exposure of each

requirement is qualified in AISC LRFD Specification Section coat of paint.

J2.2b: the weld toe is permitted to be less than !j16" away from 3. An economic evaluation of the initial cost as compared to

the edge of the base metal, provided the weld size is clearly future maintenance cost.

verifiable. Additionally, the weld size can match the thickness

of the plate edge for plates that are less than 1,4" thick. 4. A practical determination of the division between shop and

field work and responsibilities.

Weld Symbols

8.3.7. Is the weld-aU-around symbol acceptable when a fillet

weld must be continued out-of-plane?

No. Use of the weld-all-around symbol at conditions that

would require the weld to be continued out-of-plane calls for

a condition that is specifically prohibited in the 1999 AISC Steel Interchange is a forum for Modern Steel Construction

LRFD Specification Section J2.2b and AWS D1.1:2002 Section readers to exchange useful and practical professional

2.8.3.5. Instead, when an out-of-plane transition occurs, the

ideas and information on all phases of steel building and

welds must be interrupted at the corner common to both

bridge construction. Opinions and suggestions are wel-

welds.

come on any subject covered in this magazine.

The opinions expressed in Steel Interchange do not

When to Paint necessarily represent an official position of the American

10.1.1. When must structural steel be painted?

Institute of Steel Construction, Inc . and have not been

As stated in the 1999 AISC LRFD Specification Section M3.1,

reviewed. It is recognized that the design of structures is

"Shop paint is not required unless specified by the contract

documents. " Therefore, fabricated structural steel is left within the scope and expertise of a competent licensed

unpainted unless painting requirements are outlined in the structural engineer, architect or other licensed professional

contract documents. for the application of principles to a particular structure.

In building structures, steel need not be primed or painted If you have a question or problem that your fellow read-

if it will be enclosed by building finish, coated with a contact- ers might help you to solve, please forward it to us . At the

type fireproofing, or in contact with concrete. When enclosed, same time , feel free to respond to any of the questions

the steel is trapped in a controlled environment and the prod- that you have read here . Contact Steel Interchange via

ucts required for corrosion are quickly exhausted. As indi- AISC's Steel Solutions Center:

cated in the 1999 AISC LRFD Specification Commentary

Section M3, "The surface condition of steel framing disclosed

by the demolition of long-standing buildings has been found

to be unchanged from the time of its erection, except at iso-

Sol~etfonscenfer

lated spots where leakage may have occurred. Even in the Your connection to

ideas + answers

presence of leakage, the shop [primer] coat is of minor influ-

ence (Bigos, Smith, Ball, and Foehl, 1954)1." A similar situation One East Wacker Dr., Suite 3100

exists when steel is fireproofed or in contact with concrete; in Chicago, IL 60601

fact, paint is best omitted when steel is to be fireproofed tel: 866.ASK.AISC

because primer decreases its adhesion. fax: 312.670.9032

solutions@aisc.org

12 • Modern Steel Construction • June 2004

Potrebbero piacerti anche

- Section 19 Welded JointsDocumento14 pagineSection 19 Welded JointsJ T Mendonça SantosNessuna valutazione finora

- AISE No. 7 Specifications For Ladle HooksDocumento7 pagineAISE No. 7 Specifications For Ladle HookscadyfemNessuna valutazione finora

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Documento2 pagineSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNessuna valutazione finora

- Deck Construction, Residential, CEDDocumento45 pagineDeck Construction, Residential, CEDAK AKNessuna valutazione finora

- Is 6735Documento11 pagineIs 6735Sunil AgarwalNessuna valutazione finora

- Steelwise PDFDocumento4 pagineSteelwise PDFBilal RasheedNessuna valutazione finora

- Monthly Steel Quiz Tests Your KnowledgeDocumento2 pagineMonthly Steel Quiz Tests Your KnowledgeRajed MaglinteNessuna valutazione finora

- Guidance Note Shear Connectors No. 2.11: ScopeDocumento4 pagineGuidance Note Shear Connectors No. 2.11: ScopeDesigns3 ShreeprefabNessuna valutazione finora

- CRAHF Weld OverlayDocumento2 pagineCRAHF Weld OverlayGogulu KumarNessuna valutazione finora

- AISE No7 Ladle Hooks 1991Documento9 pagineAISE No7 Ladle Hooks 1991Zhifan FuNessuna valutazione finora

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You! SendDocumento2 pagineSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You! SendAndres CasadoNessuna valutazione finora

- Steel Interchange: Steel's Monthly Steel Interchange Is For You! Send YourDocumento2 pagineSteel Interchange: Steel's Monthly Steel Interchange Is For You! Send Yourgv Sathishkumar KumarNessuna valutazione finora

- 5.0 Fabrication-7 PDFDocumento1 pagina5.0 Fabrication-7 PDFRohit KambleNessuna valutazione finora

- DN Iso 5817Documento13 pagineDN Iso 5817Phani Sridhar ChNessuna valutazione finora

- Use Caution When Specifying "Seal Welds": Design FileDocumento4 pagineUse Caution When Specifying "Seal Welds": Design FilePrabhat K KarnaNessuna valutazione finora

- BKI Rules For Hull-Inland Waterway 2015: Section 8-Construction and Testing Point A. Welding and Weld ConnectionDocumento17 pagineBKI Rules For Hull-Inland Waterway 2015: Section 8-Construction and Testing Point A. Welding and Weld Connectionvendry mofuNessuna valutazione finora

- Steel Interchange: Concrete Cover For Steel Headed Stud Anchors Connection Design LoadsDocumento2 pagineSteel Interchange: Concrete Cover For Steel Headed Stud Anchors Connection Design Loadshector diazNessuna valutazione finora

- Cast Iron Detachable Joints For Use With Asbestos Cement Pressure Pipes (Light Duty) - SpecificationDocumento9 pagineCast Iron Detachable Joints For Use With Asbestos Cement Pressure Pipes (Light Duty) - SpecificationAbinashBeheraNessuna valutazione finora

- Precast Concrete Manhole Covers and Frames-Specification: Indian StandardDocumento10 paginePrecast Concrete Manhole Covers and Frames-Specification: Indian StandardUppala Krishna ChaitanyaNessuna valutazione finora

- Good Weld Bead Finish (W-10)Documento21 pagineGood Weld Bead Finish (W-10)hardish_trivedi7005Nessuna valutazione finora

- Guidance Note Steel Deck Plate For Footbridges No. 2.10: ScopeDocumento1 paginaGuidance Note Steel Deck Plate For Footbridges No. 2.10: ScopedertyuNessuna valutazione finora

- Paint Application Guide No. 11: SSPC: The Society For Protective CoatingsDocumento6 paginePaint Application Guide No. 11: SSPC: The Society For Protective CoatingsaRiTo!Nessuna valutazione finora

- (W5Aty???Fq: Precast Concrete Manhole Cover and Frame - SpecificationDocumento12 pagine(W5Aty???Fq: Precast Concrete Manhole Cover and Frame - SpecificationAbinashBeheraNessuna valutazione finora

- AAMA TIR-A11-04: Maximum Allowable Deflection of Framing Systems For Building Cladding Components at Design Wind LoadsDocumento6 pagineAAMA TIR-A11-04: Maximum Allowable Deflection of Framing Systems For Building Cladding Components at Design Wind LoadsMarian Joyce Macadine100% (2)

- 5.0 Fabrication-6 PDFDocumento1 pagina5.0 Fabrication-6 PDFRohit KambleNessuna valutazione finora

- ASME 331.4 piping standardsDocumento1 paginaASME 331.4 piping standardsJoelHernandezGonzalezNessuna valutazione finora

- Consider Penetration When Determining Fillet Weld SizeDocumento3 pagineConsider Penetration When Determining Fillet Weld SizecanakyuzNessuna valutazione finora

- Plain and Laminated Elastomeric Bridge Bearings: Standard Specification ForDocumento4 paginePlain and Laminated Elastomeric Bridge Bearings: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Is 2372Documento6 pagineIs 2372awasarevinayakNessuna valutazione finora

- Quenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded FastenersDocumento8 pagineQuenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded Fastenersist93993Nessuna valutazione finora

- Fusion Bonded Epoxy Coated Reinforcing Bars - Specification: Indian StandardDocumento12 pagineFusion Bonded Epoxy Coated Reinforcing Bars - Specification: Indian StandardsssmouNessuna valutazione finora

- Galvanized Slip-Critical ConnectionsDocumento2 pagineGalvanized Slip-Critical Connectionsaams_sNessuna valutazione finora

- Section 19 Welded Joints: PrefaceDocumento16 pagineSection 19 Welded Joints: PrefacealiNessuna valutazione finora

- Ship in Operation Renewal CriteriaDocumento8 pagineShip in Operation Renewal CriteriaThe MatrixNessuna valutazione finora

- Repair Procedures: Connection Field Repair (Refacing)Documento5 pagineRepair Procedures: Connection Field Repair (Refacing)islam atif100% (1)

- Seccion 16 Abs SoldaduraDocumento9 pagineSeccion 16 Abs SoldaduraRoberto DavilaNessuna valutazione finora

- Long Term CurvatureDocumento21 pagineLong Term CurvatureArlandooNessuna valutazione finora

- Is 1977Documento11 pagineIs 1977rahulmechdceNessuna valutazione finora

- 30 Rules For Good Connections.5Documento4 pagine30 Rules For Good Connections.5chipchipperson100% (1)

- ACI Tolerances On D and SpecifiedDocumento1 paginaACI Tolerances On D and Specifiedhz135874Nessuna valutazione finora

- Astm F871M 1998Documento7 pagineAstm F871M 1998Jesse ChenNessuna valutazione finora

- Guidance Note Surface Defects On Steel Materials No. 3.05: ScopeDocumento2 pagineGuidance Note Surface Defects On Steel Materials No. 3.05: ScopeTa InNessuna valutazione finora

- Detailing and Placing Reinforcing BarsDocumento6 pagineDetailing and Placing Reinforcing Barsتوان امتياس سامسدينNessuna valutazione finora

- Aisc Standard HoleDocumento2 pagineAisc Standard HoleMoe Oo HtunNessuna valutazione finora

- Precast Ferrocement Water Tanks Upto Ioooolitres Capacity-SpecificationDocumento12 paginePrecast Ferrocement Water Tanks Upto Ioooolitres Capacity-SpecificationRomani Noel S. Chavez Jr.Nessuna valutazione finora

- Steel Quiz: Manual (Documento2 pagineSteel Quiz: Manual (Seismotec EngineersNessuna valutazione finora

- Construction Steel GirderDocumento11 pagineConstruction Steel GirderAek JayNessuna valutazione finora

- SCBF X-Brace Bolt Hole Sizes: If You'Ve Ever Asked Yourself "Why?"Documento2 pagineSCBF X-Brace Bolt Hole Sizes: If You'Ve Ever Asked Yourself "Why?"Juan Esteban Torres DuqueNessuna valutazione finora

- Steel Interchange: Fillet Weld Terminations Built-Up Column DesignDocumento2 pagineSteel Interchange: Fillet Weld Terminations Built-Up Column Designhector diazNessuna valutazione finora

- 30 Good RulesDocumento4 pagine30 Good RulesSamet Karataş100% (1)

- Welding DesignDocumento28 pagineWelding DesignSitaram JhaNessuna valutazione finora

- Control of Crack WidthsDocumento55 pagineControl of Crack WidthsMahmood Mufti100% (1)

- Connection Design GuidelinesDocumento4 pagineConnection Design GuidelinesABDUL REHMANNessuna valutazione finora

- Compliance SheetDocumento4 pagineCompliance Sheetمحمد عبدالرحيمNessuna valutazione finora

- Astm A827-14Documento3 pagineAstm A827-14Артем Титов100% (1)

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsDa EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsValutazione: 5 su 5 stelle5/5 (1)

- Copper Flashings And Weatherings - A Practical HandbookDa EverandCopper Flashings And Weatherings - A Practical HandbookNessuna valutazione finora

- 01-02d Orifice Plates Type ISB 3 For RTJ FlangesDocumento2 pagine01-02d Orifice Plates Type ISB 3 For RTJ Flangesxaaabbb_550464353Nessuna valutazione finora

- Farkas, Jármai (2003) - Cost Comparison of Bolted and Welded Frame JointsDocumento7 pagineFarkas, Jármai (2003) - Cost Comparison of Bolted and Welded Frame JointsGogyNessuna valutazione finora

- RTJ Gasket Catalogue Rev3Documento9 pagineRTJ Gasket Catalogue Rev3klich77Nessuna valutazione finora

- Rate ListDocumento24 pagineRate ListMuhammad JunaidNessuna valutazione finora

- Soil Mechanics ReviewDocumento25 pagineSoil Mechanics ReviewKiprono VincentNessuna valutazione finora

- Final Pts 12cc348Documento233 pagineFinal Pts 12cc348shantivan50% (2)

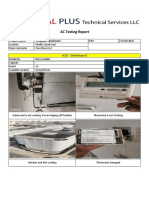

- AC Testing Report - Caspaiou at Sheikh Zayed RoadDocumento5 pagineAC Testing Report - Caspaiou at Sheikh Zayed RoadLalitha TammanaNessuna valutazione finora

- (Multi V Task) Technical Seminar - Multi V AHU Solution - FinalDocumento36 pagine(Multi V Task) Technical Seminar - Multi V AHU Solution - FinalPaulo Augusto GarayNessuna valutazione finora

- Hydraulic Competitive Product Crossover ListDocumento24 pagineHydraulic Competitive Product Crossover ListAbderrahim RiadNessuna valutazione finora

- A Detailed Investigation of Reinforced Concrete Column Jacketing: Experiment, Theory and Numerical AnalysisDocumento6 pagineA Detailed Investigation of Reinforced Concrete Column Jacketing: Experiment, Theory and Numerical AnalysishburitiNessuna valutazione finora

- Reddot R9757 (Rh40e) - 1Documento8 pagineReddot R9757 (Rh40e) - 1Rodny Romero0% (1)

- Boq Pekerjaan BendunganDocumento67 pagineBoq Pekerjaan Bendungansuhadi wahanaNessuna valutazione finora

- Gua Conduit Outlet BoxesDocumento4 pagineGua Conduit Outlet BoxesPipitlyNessuna valutazione finora

- Roof Electric PlanDocumento1 paginaRoof Electric PlanVinita KumariNessuna valutazione finora

- Post-Tensioning Tendon Installation and Grouting ManualDocumento90 paginePost-Tensioning Tendon Installation and Grouting ManualThập NguyễnNessuna valutazione finora

- Building Phase 2 Floor Apply To All Room Corridor Equip. No. FCU-L4-C-01 ZoneDocumento8 pagineBuilding Phase 2 Floor Apply To All Room Corridor Equip. No. FCU-L4-C-01 ZonebaparisNessuna valutazione finora

- Damage Mechanism and NDTDocumento1 paginaDamage Mechanism and NDTNurul AinNessuna valutazione finora

- (Doi 10.1002/9781119013228.Ch1) Kassapoglou, Christos - Modeling the Effect of Damage in Composite Structures (Simplified Approaches) Damage in Composite Structures- Notch SensitiDocumento7 pagine(Doi 10.1002/9781119013228.Ch1) Kassapoglou, Christos - Modeling the Effect of Damage in Composite Structures (Simplified Approaches) Damage in Composite Structures- Notch SensitiAdimasu AyeleNessuna valutazione finora

- Grade Slab Design For Heavy LoadsDocumento2 pagineGrade Slab Design For Heavy LoadsIrshad Farrukh100% (1)

- Discussion CH 2Documento21 pagineDiscussion CH 2Ahmed FatoohNessuna valutazione finora

- Ethiopian Building Code PDFDocumento2 pagineEthiopian Building Code PDFDerek79% (14)

- 525 Huntington Avenue (Project Notification Form)Documento81 pagine525 Huntington Avenue (Project Notification Form)bcc2007Nessuna valutazione finora

- Izod Impact Test - ManualDocumento3 pagineIzod Impact Test - Manualamber19995100% (1)

- Plumbing Code CoachingDocumento21 paginePlumbing Code CoachingNomer AzanaNessuna valutazione finora

- Type of Construction: 1. Overhead Construction 2. Underground Construction Overhead ConstructionDocumento9 pagineType of Construction: 1. Overhead Construction 2. Underground Construction Overhead ConstructionLaxmi YadavNessuna valutazione finora

- LNG 4 - Operational Integrity 7-3-09-Aacomments-Aug09Documento8 pagineLNG 4 - Operational Integrity 7-3-09-Aacomments-Aug09nangkarak8201Nessuna valutazione finora

- BE FeeguideDocumento18 pagineBE FeeguideIrzam Hardiansyah100% (1)

- Bt5 Topic1 FoundationDocumento25 pagineBt5 Topic1 FoundationDM AndradeNessuna valutazione finora

- EHB en File 10.7.3 Welding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9Documento2 pagineEHB en File 10.7.3 Welding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9goodspeed_ph0% (1)

- How To Make A Fire Devil StickDocumento9 pagineHow To Make A Fire Devil StickPrimaria AvrigNessuna valutazione finora