Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

JBSS304 Usermanual

Caricato da

Iskandar GhinaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

JBSS304 Usermanual

Caricato da

Iskandar GhinaCopyright:

Formati disponibili

JB-SS304 Junction box user manual

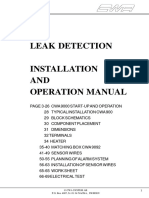

Content

- Specifications

- Installation guidelines

- Dimensions

- Mounting

- Electrical connections

- Calibration

- I Corner adjustment

- II Span adjustment

- III Trouble-shooting

- Printed Circuit Board Picture

Specifications

Stainless steel 304 (1.4301)

Plastic cable glands PG9

Available for 4, 6 or 8 load cells connections

Excitation trim (+/- 10 turns, +/- 10 Ohm)

4-wire load cell connection

4-wire output connection

Cable glands for cable diameter 5 to 6.2 mm

Fit for 0.6mV/V up to 3 mV/V load cells

Environmental protection IP65

Screw-clamp terminals

Installation guidelines

The junction box model JB-SS304 provides an economic answer for a variety of weighing applications.

Excitation trim makes it fast and easy to adjust the load cell outputs.

Model JB-SS304-4 offers connection and individual adjustment for up to 4 load cells. Models JB-SS304-6

and JB-SS304-8 offer connection and adjustment up to 6 and 8 load cells respectively. Cable glands that

are not used need to be closed with suitable plugs.

Model JB-SS304 has a 5-way terminal strip for each load cell, enabling connection of 4 and 6-wire load

cells with screen. Connection to the instrument is achieved via a 5-way terminal strip. Terminal strips are

screw-operated cage clamp design.

To overcome disturbance, make sure not to create ground-loops whilst connecting the cable screens.

Confirm ( via the load cell data sheet) whether or not the load cell has its screen connected to its body.

Trimming of signal output is accomplished using 20-turn trim potentiometers. The operating temperature

range of the Junction Box is -40°C to 85°C.

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2015.12 JB-SS304 Junction box user manual Rev0 F: +31 76 50 39481

4871 EN Etten-Leur info@zemic.nl

The Netherlands 1/4 www.zemic.nl

JB-SS304 Junction box user manual

Dimensions

Width 178mm

Height 45mm

Length 193mm

(dimensions without cable glands)

Fig 1: Outline Dimensions

Mounting

The Junction Box can be mounted through the 4 mounting holes (dia. 8mm). The load cells used should

be of the same model, capacity and have the same rated output (mV/V). When installing the junction box,

be sure that the enclosure is connected to the scale framework with a lowest risk to get wet.

Electrical Connections

Remove the cover and connect the load cell cables to the circuit board and the circuit board output

(marked with OUT) to the associated indicator. See fig. 2 for the connection termination on the Printed

circuit board and how the parallel connection is made when load cells are connected. Each load cell

terminal strip has the same sequence for connecting the respective wires as the output terminal strip. Be

sure that all terminal strip connections are tight and that the cables are not damaged. Tinning the leads is

not recommended for vibrant applications.

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2015.12 JB-SS304 Junction box user manual Rev0 F: +31 76 50 39481

4871 EN Etten-Leur info@zemic.nl

The Netherlands 2/4 www.zemic.nl

JB-SS304 Junction box user manual

It is possible to use the JB-SS304 with fewer load cells than for which it is designed. There is no need to

change anything. Make sure the un used cable glands are sealed properly.

+ EXC excitation +

- EXC excitation -

+ SIG signal +

- SIG signal -

SHIE shield

Fig 2: Load Cell and Output Connection

Calibration

After all wiring is completed and the scale instrument is powered up, check the scale for repeatability and

correct any problems. Model JB-SS304 has two (2) cornering potentiometers per load cell. The

potentiometers nearest to the terminal strip E+ and E- adjusts the respective load cell connected to it.

Two ways are described to adjust the corners. 1a can be used for relative large differences in load cell

specifications. 1b can be used to achieve the largest possible output for best performance.

Ia Corner adjustment:

The cornering potentiometers have all been set to their mid points during manufacturing. There is no

need to adjust them before calibration.

A. Apply the cornering load to each corner in turn and record the weight value.

B. Calculate the average (mean) value of all the weight readings as a reference value.

C. Apply the cornering load to each corner in turn and adjust the appropriate potentiometers

up/down so that the weight reading is the same as the calculated reference value.

D. Repeat steps 2-4 until the corner readings are all within the error allowed.

Ib Corner adjustment:

A. Turn each of the potentiometers fully anti-clockwise (maximum 28 turns, click will be heard

and/or felt), to obtain the highest possible output from each load cell.

B. Place a test weight over each of the load cells in turn and record their readings and location. The

lowest reading will be used as your target weight.

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2015.12 JB-SS304 Junction box user manual Rev0 F: +31 76 50 39481

4871 EN Etten-Leur info@zemic.nl

The Netherlands 3/4 www.zemic.nl

JB-SS304 Junction box user manual

C. Replace the test weight over each of the load cells in turn and if necessary, adjust the

corresponding potentiometers so that the weight indicated matches the target weight.

D. Place the test weight over the load cell located in the step A. Record this weight as the new target

weight and repeat steps B & C until all cells are matched and all the scale corners read the same.

II Span adjustment:

For span adjustment please see the manual of the indicator.

III Troubleshooting:

The scale seems to be reading incorrectly:

1. Unload the scale and check for a zero reading with no load on the scale.

2. Ensure that the object being weighed is fully on the scale and not supported

otherwise.

The scale corner readings are not equal:

1. Repeat the setup and adjustment procedure.

2. Check the load cells for damage.

The scale readings drift rapidly:

1. Check for water in the junction box

2. Check the load cells and their cables for damage.

3. Disconnect one load cell at a time from the junction box. If the scale becomes stable,

then the disconnected load cell is probably defective.

Use a load cell simulator to verify that the indicator is stable and operating correctly.

Printed Circuit Board Picture

Zemic Europe B.V. T: +31 76 50 39480

Leerlooierstraat 8 Nr. 2015.12 JB-SS304 Junction box user manual Rev0 F: +31 76 50 39481

4871 EN Etten-Leur info@zemic.nl

The Netherlands 4/4 www.zemic.nl

Potrebbero piacerti anche

- JB02 Junction Box User Manual: ContentDocumento3 pagineJB02 Junction Box User Manual: Contentfery setyawanNessuna valutazione finora

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDa EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsValutazione: 3 su 5 stelle3/5 (2)

- EKM Omnimeter Pulse v.4 Spec SheetDocumento4 pagineEKM Omnimeter Pulse v.4 Spec SheetAdam BrouwerNessuna valutazione finora

- 110 Integrated Circuit Projects for the Home ConstructorDa Everand110 Integrated Circuit Projects for the Home ConstructorValutazione: 4.5 su 5 stelle4.5/5 (2)

- Philips Mod 21pt9470-55 - 44 - 21sl9 - Chasis Sk8.0l CADocumento36 paginePhilips Mod 21pt9470-55 - 44 - 21sl9 - Chasis Sk8.0l CACarlos MedinaNessuna valutazione finora

- Atex Load Cell Instruction ManualDocumento9 pagineAtex Load Cell Instruction ManualTaha ZiaNessuna valutazione finora

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- OmniMeter Universal Smart Meter User Manual EKM MeteringDocumento2 pagineOmniMeter Universal Smart Meter User Manual EKM MeteringChris CalderónNessuna valutazione finora

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaDa EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNessuna valutazione finora

- EKM Omnimeter Pulse UL v.4 Spec SheetDocumento4 pagineEKM Omnimeter Pulse UL v.4 Spec SheetAdam BrouwerNessuna valutazione finora

- A Guide to Electronic Maintenance and RepairsDa EverandA Guide to Electronic Maintenance and RepairsValutazione: 4.5 su 5 stelle4.5/5 (7)

- EKM OmniMeter UL User Manual Spec Sheet SubmeterDocumento3 pagineEKM OmniMeter UL User Manual Spec Sheet SubmeterAdam BrouwerNessuna valutazione finora

- How Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityDa EverandHow Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityNessuna valutazione finora

- Te1.1e AaDocumento57 pagineTe1.1e AaSicoe VasileNessuna valutazione finora

- BT200 V2 eDocumento31 pagineBT200 V2 eFernando DallaquaNessuna valutazione finora

- Hfe Classe Audio Cap-80 101 ServiceDocumento19 pagineHfe Classe Audio Cap-80 101 Servicehesso1Nessuna valutazione finora

- Reflow Soldering: Apparatus and Heat Transfer ProcessesDa EverandReflow Soldering: Apparatus and Heat Transfer ProcessesNessuna valutazione finora

- Paralleling Generators With Different Pitches ACI 002 01 - 3/20/20Documento3 pagineParalleling Generators With Different Pitches ACI 002 01 - 3/20/20ArielJrFernandezNessuna valutazione finora

- OmniMeter Universal Smart Meter User Manual EKM MeteringDocumento3 pagineOmniMeter Universal Smart Meter User Manual EKM MeteringAdam BrouwerNessuna valutazione finora

- Atex Loadcell InstructionDocumento12 pagineAtex Loadcell Instructionfery jarimNessuna valutazione finora

- EKM Omnimeter Pulse UL v4 Spec SheetDocumento4 pagineEKM Omnimeter Pulse UL v4 Spec SheetAdam BrouwerNessuna valutazione finora

- Service Manual: History Information For The Following ManualDocumento56 pagineService Manual: History Information For The Following ManualMalanie Sriya De SilvaNessuna valutazione finora

- L7.1a - AaDocumento46 pagineL7.1a - AaMarcelo PianaNessuna valutazione finora

- Test Procedure For Cable BoxDocumento7 pagineTest Procedure For Cable BoxmridgreatNessuna valutazione finora

- Philips L7.3a Aa Chassis TV SMDocumento49 paginePhilips L7.3a Aa Chassis TV SMRoger_74Nessuna valutazione finora

- Exp 1 Multimeter, Breadboard and Power Supply (2012)Documento14 pagineExp 1 Multimeter, Breadboard and Power Supply (2012)usmpowerlab50% (2)

- Panasonic PT-53WX42F Service Repair Manual - Ep824Documento130 paginePanasonic PT-53WX42F Service Repair Manual - Ep824Larry LeavittNessuna valutazione finora

- NE Datasheet ManDocumento20 pagineNE Datasheet ManszenandreiNessuna valutazione finora

- Handheld Digital Multimeter: GDM-350BDocumento34 pagineHandheld Digital Multimeter: GDM-350B0307aliNessuna valutazione finora

- sk4 (1) 1LDocumento49 paginesk4 (1) 1LWall BrysonNessuna valutazione finora

- Sony - DCR - hc44 DCR hc46 l3 v1.3Documento56 pagineSony - DCR - hc44 DCR hc46 l3 v1.3h_trifonovNessuna valutazione finora

- Loadcell CablingDocumento8 pagineLoadcell CablingDemian Matias BadinNessuna valutazione finora

- Flexible Coil Current Transformer Installation GuideDocumento19 pagineFlexible Coil Current Transformer Installation GuideTrần Quang TuyênNessuna valutazione finora

- Panasonic+Pt 53tw53g,+Pt 56tw53g+Difference+Pt 53wx53g+Parts+List,+Service+ManualDocumento101 paginePanasonic+Pt 53tw53g,+Pt 56tw53g+Difference+Pt 53wx53g+Parts+List,+Service+ManualAnjoli OrtowskiNessuna valutazione finora

- Cat Data Link Circuit - Test (RENR5096)Documento2 pagineCat Data Link Circuit - Test (RENR5096)Josip MiškovićNessuna valutazione finora

- Adi TV Philips 21pt5221 60 Chassis L01.2A ABDocumento70 pagineAdi TV Philips 21pt5221 60 Chassis L01.2A ABbioteky33% (3)

- Lab 1 EEC 010Documento12 pagineLab 1 EEC 010Abhash SapkotaNessuna valutazione finora

- LED Philips 32PFL3008D 39PFL3008D 42PFL3008D 46PFL3008D Chassis TPS10.1L-LA Televisor LCD Manual de Servicio Editado Con Notas Ojo LeerDocumento71 pagineLED Philips 32PFL3008D 39PFL3008D 42PFL3008D 46PFL3008D Chassis TPS10.1L-LA Televisor LCD Manual de Servicio Editado Con Notas Ojo Leerelectronicampos100% (1)

- Philips Chasis l9Documento58 paginePhilips Chasis l9videosonNessuna valutazione finora

- How To Use Solenoid ValvesDocumento47 pagineHow To Use Solenoid ValvesvickersNessuna valutazione finora

- 29PT8321 Em1.1aDocumento148 pagine29PT8321 Em1.1aRam KumarNessuna valutazione finora

- ECE110S E F - S: Laboratory InstructionsDocumento34 pagineECE110S E F - S: Laboratory InstructionsJonathan LeungNessuna valutazione finora

- L01 2aabDocumento72 pagineL01 2aab111sNessuna valutazione finora

- TV Philips l03.1l Aa 21pt6446Documento53 pagineTV Philips l03.1l Aa 21pt6446José Mamani Oyardo100% (1)

- Colour Television Chassis: Electrical Diagram's en PWB's Diagram PWBDocumento30 pagineColour Television Chassis: Electrical Diagram's en PWB's Diagram PWBSotiris IoannouNessuna valutazione finora

- 25pt4622Philips+L7 3A+AADocumento48 pagine25pt4622Philips+L7 3A+AAWall BrysonNessuna valutazione finora

- Mini FM Phone Transmitter: DescriptionDocumento6 pagineMini FM Phone Transmitter: DescriptionadamNessuna valutazione finora

- Leak Detection - DC PipeDocumento75 pagineLeak Detection - DC Pipeراموندولدولاو50% (2)

- Patch Panel NPP TBDocumento11 paginePatch Panel NPP TBIlaiyaa RajaNessuna valutazione finora

- Interfacing Case-Isolated Two Wire Devices To Bently Nevada's 3500 Monitoring SystemDocumento8 pagineInterfacing Case-Isolated Two Wire Devices To Bently Nevada's 3500 Monitoring SystemRabah AmidiNessuna valutazione finora

- Projection TV: Service ManualDocumento67 pagineProjection TV: Service ManualJurie WesselsNessuna valutazione finora

- Manual Servico TV LCD Sony KDL 55ex525 Chassis Az2wDocumento86 pagineManual Servico TV LCD Sony KDL 55ex525 Chassis Az2waugustinhodjNessuna valutazione finora

- HUAWEI BSC6810 Quick Installation Guide-02Documento18 pagineHUAWEI BSC6810 Quick Installation Guide-02tinhlt82Nessuna valutazione finora

- 3-Phase and Electr Inst Lab - 200130 - HRDocumento28 pagine3-Phase and Electr Inst Lab - 200130 - HRwaleed.murad@gmail.comNessuna valutazione finora

- Rotax 912 Electrical SystemDocumento12 pagineRotax 912 Electrical SystemMarian GrigoreNessuna valutazione finora

- KDL42BX 320 420 AZ2 Uk ChassisDocumento34 pagineKDL42BX 320 420 AZ2 Uk ChassisDamon Brunger100% (1)

- March 2009 Caro-Kann B12 by Sasa Velickovic Informant83Documento6 pagineMarch 2009 Caro-Kann B12 by Sasa Velickovic Informant83kiprijanovNessuna valutazione finora

- DocumentDocumento4 pagineDocumentJuliana ZamorasNessuna valutazione finora

- The Example of Text That Contains Present Perfect TenseDocumento2 pagineThe Example of Text That Contains Present Perfect TenseRahmiSyariif100% (1)

- Types of CounsellingDocumento5 pagineTypes of CounsellingAnkita ShettyNessuna valutazione finora

- How To Write A ThesisDocumento14 pagineHow To Write A ThesisPiyushNessuna valutazione finora

- Making Effective Pres. Academic Lit I. Weeks 4 5Documento27 pagineMaking Effective Pres. Academic Lit I. Weeks 4 5irfanaNessuna valutazione finora

- Kosem SultanDocumento2 pagineKosem SultanAmaliaNessuna valutazione finora

- Pdf-To-Word EditedDocumento48 paginePdf-To-Word EditedJames Genesis Ignacio LolaNessuna valutazione finora

- Grade 3 MathematicsDocumento3 pagineGrade 3 Mathematicsailaine grace alapNessuna valutazione finora

- Chapter 15 NegotiationsDocumento16 pagineChapter 15 NegotiationsAdil HayatNessuna valutazione finora

- ABS Parametric RollDocumento2 pagineABS Parametric RollAdvan Zuidplas100% (1)

- Marketing Plan For Optimo InternationalDocumento47 pagineMarketing Plan For Optimo InternationalNiña Alfonso100% (1)

- Amnesty - Protest SongsDocumento14 pagineAmnesty - Protest Songsimusician2Nessuna valutazione finora

- Compilation 2Documento28 pagineCompilation 2Smit KhambholjaNessuna valutazione finora

- Gayatri Mantram SPDocumento17 pagineGayatri Mantram SPvaidyanathan100% (1)

- Advanced Finite Element Model of Tsing Ma Bridge For Structural Health MonitoringDocumento32 pagineAdvanced Finite Element Model of Tsing Ma Bridge For Structural Health MonitoringZhang ChaodongNessuna valutazione finora

- MarshallingDocumento7 pagineMarshallinggeetika singhNessuna valutazione finora

- Description: S&P 500 Dividend AristocratsDocumento7 pagineDescription: S&P 500 Dividend AristocratsCalvin YeohNessuna valutazione finora

- Tapan Pathak Case StudiesDocumento33 pagineTapan Pathak Case StudiesNeelee SoniNessuna valutazione finora

- Prejudicial QuestionDocumento1 paginaPrejudicial QuestionlmafNessuna valutazione finora

- Code of Conduct of Dabur Company - 1Documento5 pagineCode of Conduct of Dabur Company - 1Disha KothariNessuna valutazione finora

- Chapter 4 - Transfer FunctionsDocumento36 pagineChapter 4 - Transfer FunctionsFakhrulShahrilEzanie100% (1)

- Att.3 Training Evaluation For Course Trainer & FacilitiesDocumento2 pagineAtt.3 Training Evaluation For Course Trainer & FacilitiesYusufNessuna valutazione finora

- Group 4 CariCRIS Case SubmissionDocumento6 pagineGroup 4 CariCRIS Case SubmissionKingsuk MaityNessuna valutazione finora

- 17373.selected Works in Bioinformatics by Xuhua Xia PDFDocumento190 pagine17373.selected Works in Bioinformatics by Xuhua Xia PDFJesus M. RuizNessuna valutazione finora

- Concept Paper For Business ResearchDocumento4 pagineConcept Paper For Business ResearchRobertchristian RagaNessuna valutazione finora

- RUBEEEEDocumento44 pagineRUBEEEEAhlyssa de JorgeNessuna valutazione finora

- Icivics MontesquieuDocumento3 pagineIcivics Montesquieuapi-32806152578% (9)

- The First Converts in Chin Hills - Ni Kong HongDocumento7 pagineThe First Converts in Chin Hills - Ni Kong HongLTTuangNessuna valutazione finora

- Demonstration MethodDocumento16 pagineDemonstration Methodfrankie aguirreNessuna valutazione finora