Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Alfa Laval Cpo Washing Editorial Article

Caricato da

favian guevaraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Alfa Laval Cpo Washing Editorial Article

Caricato da

favian guevaraCopyright:

Formati disponibili

60 TECHNOLOGY & PRODUCT NEWS 61

3-MPCDE in Feed Oil vs. Product Oil

9

8

7 3-MCPDE in Feed

3- MCPDE, ppm

6

Average: 4.005 ppm

5

4

3

2

1 3-MCPDE in Product

0 Average: 0.328 ppm

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Number of samples

Feed Oil Product Oil Average Feed Average Product

» The Alfa Laval CPO Washing method has significantly brought down 3-MCPDE level in feed oil to achieve an average of 0.328ppm in product oil, as shown in graph above

presented by Sime Darby R&D team.

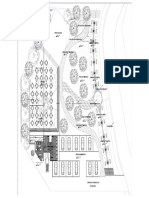

Wash water

(Chloride-free water)

In the last two years, Alfa Laval

has been actively working with various

palm oil producers on the mitigation of

3-MCPDE and GE, always emphasizing

CPO Washing on cost-efficiency and sustainability. If

Pure Oil Tank Plant (Vendor Bulk Storage you’d like to know how Alfa Laval can

equipment to Vacuum Dryer help you optimize your plant’s processes,

(POT) Tank (BST)

achieve Point A please contact Alfa Laval at sharmayne.

guaranteed value)

cheng@alfalaval.com.

Alfa Laval will be exhibiting at

Washed water to ETP PALMEX Indonesia, Medan from 9 – 11

Point B Oct 2018, and IPOC Bali from 1 – 2 Nov.

No Parameters Sampling Point Target Achievement Catch Alfa Laval palm oil experts and

1 % Oil Loss to OER B 0.08 0.03 talk about anything palm oil-related.

2 % Dirt in CPO A 0.02 0.006 Alfa Laval’s palm oil supply chain

The Alfa Laval CPO Washing Plant for Tennamaram Palm Oil Mill is built on a skid. It is highly space-saving and can be easily mobilized to other Sime Darby locations. takes care of your processing needs

3 % VM in CPO A 0.50 0.48

– from milling and refining to fats

Sime Darby R&D Team

4 % Total Chlorine Removal A 40 66.92 modification, from by-products and

related processes to end-products. The

5 % 3-MCPDE Reduction A - 90.02

company also has strong service presence

across the region to continuously help

Presents Validated CPO » Above chart shows favourable results achieved according to initial parameters set by the Sime Darby R&D team. you optimize your performance and keep

your operations online.

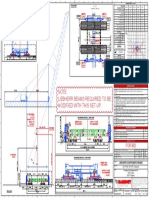

Washing Results from Alfa LAval separator range caters to both mill and refinery

Tennamaram Palm Oil Mill Alfa Laval

Separators

VO Range PX Range

A

s a fully-integrated palm oil producer that is also the CPO Washing is to reduce the level of 3-MCPDE by removing

world’s largest producer of certified sustainable palm the precursor, chloride. According to validated field results

oil (CSPO), Sime Darby has seen the industry through from the Sime Darby R&D team, data from the Tennamaram

many changes since the early 19th century. Plant has shown successful chloride removal at 67%, which is

higher than the expected performance. This finding is also in

Since February 2017, Sime Darby has started working closely congruent with the initial literature which showed that CPO

with Alfa Laval, a leading global supplier to the vegetable oil Washing can significantly reduce 3-MCPDE to below 1 ppm Suitable for Mills & Small Refineries L a rg e R e f i n e r i e s

industry on the mitigation of 3-MCPDE and GE. Subsequently, an under recommended variables.

Alfa Laval CPO Washing Plant was commissioned in November Application D e g u m m i n g , N e u t r a l i z a t i o n , Wa s h i n g

2017 in the Sime Darby Tennamaram Palm Oil Mill in Batang The CPO Washing plant comprises of Alfa Laval’s F e e d Ty p e To p f e e d i n l e t , a s e l f - c l e a n i n g B o t t o m f e e d i n l e t e n s u re s

Berjuntai, Selangor. Frequent sampling and close supervision of separator, heat exchanger, several pumps and mixers. However, separator gentle, non-destructive

the 3-MCPDE level by the Sime Darby R&D team ensued over the separator, where the main separation and ‘washing’ action acceleration of the feedstock

the next few months. takes place is the heart of the entire plant. In this case, Alfa Laval

C e n t r i z o o m TM T h i s p a t e n t e d i n n o v a t i o n i s c a l l e d C e n t r i z o o m TM a n d m a k e s i t

has dispatched a VO model to handle the CPO Washing duties. possible to adjust the position of the separation interface

Adjustable Paring

Two quarters later, Sime Darby presented their experience For heavier oil flow capacity such as those in refinery however, during operation, facilitating optimal separation

Disc

on ‘CPO Washing as a 3-MCPDE Mitigation Measure’ during the would require the PX range of separators.

Transfer of Technology (TOT) seminar organized by Malaysian Models Va r i o u s m o d e l s a v a i l a b l e t o c a t e r t o d i ff e re n t c a p a c i t i e s

Palm Oil Board (MPOB) on the 3rd July 2018. The main aim of

ASIA PALM OIL MAGAZINE | Oct - Dec 2018 Oct - Dec 2018 | ASIA PALM OIL MAGAZINE

Potrebbero piacerti anche

- Single Stroke FrasesDocumento2 pagineSingle Stroke FrasesRuan Pablo BateraNessuna valutazione finora

- LBS CableDocumento1 paginaLBS CableArry ArekKulonanNessuna valutazione finora

- Esp32 Cam V1.6 PDFDocumento1 paginaEsp32 Cam V1.6 PDFBuzatu Giani100% (1)

- Arduino UNO Tc4-ControllerDocumento1 paginaArduino UNO Tc4-ControllerJuan CastroNessuna valutazione finora

- PH I2cDocumento1 paginaPH I2cbethania Maria Paz Apaza GodoyNessuna valutazione finora

- Proyeccion de Cubierta: Oficio BARDocumento1 paginaProyeccion de Cubierta: Oficio BARBruce JimenezNessuna valutazione finora

- Sven Ha-385 SCHDocumento2 pagineSven Ha-385 SCHАндрюха КорнNessuna valutazione finora

- Physics Booklet2 2017Documento31 paginePhysics Booklet2 2017Anas OsamaNessuna valutazione finora

- Prof Ghafoor Ahmed - by Khurram BadrDocumento192 pagineProf Ghafoor Ahmed - by Khurram BadrDr FaiyazNessuna valutazione finora

- Attachment - 4,5,7,8,9 (P3963 - Weekly Revised PMS - Rev-D - 25-10-18)Documento63 pagineAttachment - 4,5,7,8,9 (P3963 - Weekly Revised PMS - Rev-D - 25-10-18)Daniyal KhursheedNessuna valutazione finora

- Bikeways MapDocumento1 paginaBikeways MapfdgsNessuna valutazione finora

- Progress Chart: Bermudez Center For Arts and Technology, IncDocumento1 paginaProgress Chart: Bermudez Center For Arts and Technology, IncJoshua CianoNessuna valutazione finora

- VM360 - Esquema Elétrico V2.1Documento3 pagineVM360 - Esquema Elétrico V2.1Luciano João MildeNessuna valutazione finora

- 15112739-D-T01-02 (STS Crane - GH) - SGNDocumento1 pagina15112739-D-T01-02 (STS Crane - GH) - SGNdheeraj SureshNessuna valutazione finora

- Programa de Mejora Continua: Metodología Incrementa Lean Six SigmaDocumento70 paginePrograma de Mejora Continua: Metodología Incrementa Lean Six SigmaROCIO RoSALYN EGOAVIL CONDORNessuna valutazione finora

- HT 2Documento2 pagineHT 2Rauncy rcNessuna valutazione finora

- MPC Aug 18Documento8 pagineMPC Aug 18Kunal SinhaNessuna valutazione finora

- Snímka Obrazovky 2023-09-02 o 23.19.09Documento1 paginaSnímka Obrazovky 2023-09-02 o 23.19.09Kokt KorNessuna valutazione finora

- Pilcd01 Pilcd02 Pilcd03 Pilcd04 Pilcd05 Pilcd06 Pilcd07 Pilcd08 Pilcd09 Pilcd010 Pilcd011 Pilcd012 Pilcd013 Pilcd014 Pilcd015 Pilcd016Documento4 paginePilcd01 Pilcd02 Pilcd03 Pilcd04 Pilcd05 Pilcd06 Pilcd07 Pilcd08 Pilcd09 Pilcd010 Pilcd011 Pilcd012 Pilcd013 Pilcd014 Pilcd015 Pilcd016William moreNessuna valutazione finora

- Botoneras ScneiderDocumento43 pagineBotoneras ScneiderSalvador MurilloNessuna valutazione finora

- Crowdstrike Incident Response InfographicDocumento1 paginaCrowdstrike Incident Response Infographicshekhar'Nessuna valutazione finora

- Solo Chris PotterDocumento3 pagineSolo Chris PotterAlexandria NatashaNessuna valutazione finora

- CIRCUITSDocumento17 pagineCIRCUITSSteven WassaakaNessuna valutazione finora

- 123-Smart Locker FingerprintDocumento1 pagina123-Smart Locker FingerprintzulNessuna valutazione finora

- Softball-Score-Sheet1 Versi IdhamDocumento2 pagineSoftball-Score-Sheet1 Versi IdhamAdang100% (1)

- Radio TroubleshootingDocumento14 pagineRadio TroubleshootingrolandNessuna valutazione finora

- The Intel Microprocessors 8086 - 8088, 80... Itecture, Programming, and InterfacingDocumento944 pagineThe Intel Microprocessors 8086 - 8088, 80... Itecture, Programming, and InterfacingRenato RamirezNessuna valutazione finora

- Coupe D-D: SEA BDocumento1 paginaCoupe D-D: SEA BMahmoud ElboraeNessuna valutazione finora

- схема Supra STV-LC1522W MAIN SP208ESA HK-7050ADocumento10 pagineсхема Supra STV-LC1522W MAIN SP208ESA HK-7050AВалерий МашинскийNessuna valutazione finora

- Week-5-Group Assignment (2) - Product Concept Generation and SelectionDocumento4 pagineWeek-5-Group Assignment (2) - Product Concept Generation and Selectionpavan kalyanNessuna valutazione finora

- PluckDocumento9 paginePluckMarcello Di LorenzoNessuna valutazione finora

- 08 Sixteenth Notes, Eighth NotesDocumento1 pagina08 Sixteenth Notes, Eighth NotesjyidouNessuna valutazione finora

- Authorization Pa RequestorDocumento1 paginaAuthorization Pa Requestorclara nicole antonioNessuna valutazione finora

- Catalogue-Agriparts-New-HollandDocumento36 pagineCatalogue-Agriparts-New-HollandArmorNessuna valutazione finora

- Plan Parter-Layout1Documento1 paginaPlan Parter-Layout1AndreiNessuna valutazione finora

- Reading Power: - Lestoury EducationDocumento24 pagineReading Power: - Lestoury EducationRui YeNessuna valutazione finora

- Ejercicios 2.c y 2.d: Michelle WakenDocumento1 paginaEjercicios 2.c y 2.d: Michelle WakenMichelle WakenNessuna valutazione finora

- Harmony XK, XD Controllers For Hoisting Applications: CatalogDocumento50 pagineHarmony XK, XD Controllers For Hoisting Applications: CatalogMauro MiguelNessuna valutazione finora

- Book of Ruth - Telugu (PDFDrive)Documento122 pagineBook of Ruth - Telugu (PDFDrive)snraj269Nessuna valutazione finora

- Level 01 Dimensioned LayoutDocumento1 paginaLevel 01 Dimensioned LayoutRebecca WangNessuna valutazione finora

- It Is WellDocumento4 pagineIt Is WellMiguelina Ruiz ContrerasNessuna valutazione finora

- 3.catalogo 2014 ATS 01Documento22 pagine3.catalogo 2014 ATS 01Jose Manuel Moa PerezNessuna valutazione finora

- Praeludium Und Fuge BWV 861 - ATC 10.ºDocumento1 paginaPraeludium Und Fuge BWV 861 - ATC 10.ºrodrigocastroalves08Nessuna valutazione finora

- Denah Tampak - Detail Pintu JendelaDocumento8 pagineDenah Tampak - Detail Pintu Jendelahansen 97Nessuna valutazione finora

- N Up PDF - 720988310 1 5042314579284066427 50 93Documento3 pagineN Up PDF - 720988310 1 5042314579284066427 50 93thiagomateowaos12Nessuna valutazione finora

- Ach Gott, Erhör' Mein Seufzen! (Bach-Ausgabe Bd. 39. N°2)Documento2 pagineAch Gott, Erhör' Mein Seufzen! (Bach-Ausgabe Bd. 39. N°2)bachsNessuna valutazione finora

- Tupelo Honey - MibDocumento2 pagineTupelo Honey - MibjordillacersaxoNessuna valutazione finora

- Plano ViviendaDocumento1 paginaPlano ViviendaChristian Erick La Rosa RojasNessuna valutazione finora

- 8 Funk Rock Drum Beats With 16th Note Hi Hats - Grade 5 PDFDocumento1 pagina8 Funk Rock Drum Beats With 16th Note Hi Hats - Grade 5 PDFd52gpyk+f1lxuoNessuna valutazione finora

- Melody of Aqua MandolinDocumento2 pagineMelody of Aqua MandolinTorsten JörresNessuna valutazione finora

- Foundation Plan: LegendDocumento1 paginaFoundation Plan: LegendVince GarciaNessuna valutazione finora

- Shab e QadarDocumento1 paginaShab e QadarMuhammad KHalidNessuna valutazione finora

- SW Ws v6 Teil 02 Sps enDocumento79 pagineSW Ws v6 Teil 02 Sps enAlberto AguiarNessuna valutazione finora

- Ground Floor Plan Balcony Plan: Auditorium 1Documento6 pagineGround Floor Plan Balcony Plan: Auditorium 1Ashutosh PatilNessuna valutazione finora

- Q3510-00-SCIFCMI-45000013161317-Z-Z01-0024 - 01 Rev.1 - Code B Work Method Statement For Rubber Lining - Tail Gas Scrubber & StackDocumento124 pagineQ3510-00-SCIFCMI-45000013161317-Z-Z01-0024 - 01 Rev.1 - Code B Work Method Statement For Rubber Lining - Tail Gas Scrubber & StackIlyas AmriNessuna valutazione finora

- 1-Ritmos BasicosDocumento5 pagine1-Ritmos BasicosItiel SanchezNessuna valutazione finora

- Cobarramento012V Cobarramento0Gnd: Cognd4Documento3 pagineCobarramento012V Cobarramento0Gnd: Cognd4Gustavo MoraesNessuna valutazione finora

- Drumas 12Documento1 paginaDrumas 12Rijarda AristótelesNessuna valutazione finora

- PSM-ME-RS232/RS485-P: Interface Converter For RS-232 To RS-485 2-/4-Wire or RS-422Documento12 paginePSM-ME-RS232/RS485-P: Interface Converter For RS-232 To RS-485 2-/4-Wire or RS-422Creshi Lopez100% (1)

- PaySlip 05 201911 5552Documento1 paginaPaySlip 05 201911 5552KumarNessuna valutazione finora

- Pandit Automotive Pvt. Ltd.Documento6 paginePandit Automotive Pvt. Ltd.JudicialNessuna valutazione finora

- TIPS As An Asset Class: Final ApprovalDocumento9 pagineTIPS As An Asset Class: Final ApprovalMJTerrienNessuna valutazione finora

- 4 P'sDocumento49 pagine4 P'sankitpnani50% (2)

- Irda CircularDocumento1 paginaIrda CircularKushal AgarwalNessuna valutazione finora

- SKS Microfinance CompanyDocumento7 pagineSKS Microfinance CompanyMonisha KMNessuna valutazione finora

- QQy 5 N OKBej DP 2 U 8 MDocumento4 pagineQQy 5 N OKBej DP 2 U 8 MAaditi yadavNessuna valutazione finora

- Daily ChecklistDocumento1 paginaDaily ChecklistPatel AspNessuna valutazione finora

- Delivering The Goods: Victorian Freight PlanDocumento56 pagineDelivering The Goods: Victorian Freight PlanVictor BowmanNessuna valutazione finora

- Nike Pestle AnalysisDocumento10 pagineNike Pestle AnalysisAchal GoyalNessuna valutazione finora

- HPAS Prelims 2019 Test Series Free Mock Test PDFDocumento39 pagineHPAS Prelims 2019 Test Series Free Mock Test PDFAditya ThakurNessuna valutazione finora

- PT Berau Coal: Head O CeDocumento4 paginePT Berau Coal: Head O CekresnakresnotNessuna valutazione finora

- MHO ProposalDocumento4 pagineMHO ProposalLGU PadadaNessuna valutazione finora

- Vtiger Software For CRMDocumento14 pagineVtiger Software For CRMmentolNessuna valutazione finora

- Is Enron OverpricedDocumento3 pagineIs Enron Overpricedgarimag2kNessuna valutazione finora

- Session 2Documento73 pagineSession 2Sankit Mohanty100% (1)

- Calander of Events 18 3 2020-21Documento67 pagineCalander of Events 18 3 2020-21Ekta Tractor Agency KhetasaraiNessuna valutazione finora

- Accra Resilience Strategy DocumentDocumento63 pagineAccra Resilience Strategy DocumentKweku Zurek100% (1)

- EU Regulation On The Approval of L-Category VehiclesDocumento15 pagineEU Regulation On The Approval of L-Category Vehicles3r0sNessuna valutazione finora

- Lecture 6Documento19 pagineLecture 6salmanshahidkhan100% (2)

- Presentation NGODocumento6 paginePresentation NGODulani PinkyNessuna valutazione finora

- Coconut Oil Refiners Association, Inc. vs. TorresDocumento38 pagineCoconut Oil Refiners Association, Inc. vs. TorresPia SottoNessuna valutazione finora

- Financial Literacy PDFDocumento44 pagineFinancial Literacy PDFGilbert MendozaNessuna valutazione finora

- Zubair Agriculture TaxDocumento3 pagineZubair Agriculture Taxmunag786Nessuna valutazione finora

- Nissan Leaf - The Bulletin, March 2011Documento2 pagineNissan Leaf - The Bulletin, March 2011belgianwafflingNessuna valutazione finora

- Literature ReviewDocumento14 pagineLiterature ReviewNamdev Upadhyay100% (1)

- DX210WDocumento13 pagineDX210WScanner Camiones CáceresNessuna valutazione finora

- Ship Breaking Report Dec 2010Documento105 pagineShip Breaking Report Dec 2010rezababakhaniNessuna valutazione finora

- Correlations in Forex Pairs SHEET by - YouthFXRisingDocumento2 pagineCorrelations in Forex Pairs SHEET by - YouthFXRisingprathamgamer147Nessuna valutazione finora

- Economy Is DeadDocumento17 pagineEconomy Is DeadAna SoricNessuna valutazione finora