Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Transformation of Project Management in Industry 4

Caricato da

Andius D. PutraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Transformation of Project Management in Industry 4

Caricato da

Andius D. PutraCopyright:

Formati disponibili

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/329415337

Transformation of Project Management in Industry 4.0

Conference Paper · November 2018

CITATION READS

1 2,726

Some of the authors of this publication are also working on these related projects:

Two-staged Filter Based Feature Selection to Reduce High Dimension of Big Data View project

All content following this page was uploaded by Thee Zin Win on 05 December 2018.

The user has requested enhancement of the downloaded file.

A06

Transformation of Project Management in Industry 4.0

Thee Zin Win Nang Saing Moon Kham

University of Computer Studies Yangon

While Industry 4.0 concept is implementing, most of the working environment are automatized and interoperated as a smart factory

with Cyber Physical Systems, Internet of Things and Big Data being processed real time using cloud computing. Industry 4.0 has

brought many careers to transform and businesses to change as well. One of those careers is industry 4.0 project manager that gets

another dimension with coming of Industry 4.0. Traditional project management strategies need to be transformed in fourth

industrialization because it is a challenging job with a lot of variations. After analyzing necessary skills and responsibilities of

traditional software development project managers and industry 4.0 project managers, there are many changes and challenges in

industry 4.0 project manager. Transformations include digitization and automation of manufacturing operations, connecting various

machines with multiple software platforms and interconnecting departments within production environment, collecting and analyzing

big data stream, providing data to partners such as suppliers and machine builders, monitoring IoT predictive maintenance and cloud

platforms, and virtual and augmented reality. This paper is one of the initial attempts to highlight the importance of industry 4.0 project

management in implementing the fourth industrial revolution successfully although most of the recent studies are talking about

technological aspect.

Keywords and Phrases: Project Management, Industry 4.0, Transformation of Project Management, Elements of Industry 4.0

1. Introduction be integrated increasingly scientifically and they will

be more automated, networking, intellectuality.

In Cheng,et al. (2016), it is stated that the first Moreover personalized, customized manufacturing

industrial revolution began within the half of 18th will become to fulfill market demands and customer

century to transform the steam engine to requirements personally. Industry 4.0 offers cyber

manufacturing facility mechanization. The second physical systems to cooperate profitably, aiming to

industrial revolution began in the half of the build smart factories by redefining the role of humans.

nineteenth century, to use the electricity into large- Dilberoglu (2017) predicted that the role of designers,

scale mass manufacturing. The third industrial factories, and customers will be redefined remarkably

revolution brought both the electrical and information since the manufacturing business will be distributed to

technology to achieve automated manufacturing in the many separate locations like small workplaces or

half of the 20th century also in Cheng,et al. (2016). homes. Especially, project management in

Now, the Fourth Industrial Revolution is the Digital implementing Industry 4.0 is becoming more and

Revolution which is well known as Industry 4.0. This more challenging because of different elements of that

digital technology is emerging breakthroughs in a and emerging new technologies. Project Management

number of fields such as robotics, artificial has been one of the most important disciplines in

intelligence, Nano-technology, quantum computing, determining the success of any project.

biotechnology, the Internet of Things (IoT), 3D

printing, Augmented Reality and autonomous vehicles, 2. The traditional project management

systems, manufacturing. Many industrial leaders

predict that the Industry 4.0 will deliver extraordinary The project management responsibilities are usually

levels of growth and productivity over the coming planning, managing the projects, organizing, preparing

decades as described in De Pace F,et al. (2018). estimates and schedules, monitoring, and report on

Business leaders, governments, academics, and activities and progress through the projects. The basic

technology vendors are enthusiastically working essential skills for a project manager are shown in

together in order to apply this huge potential. Industry table (1). The viewpoints of project management can

4.0 described that the future of manufacturing will be be adopted and implemented by a single group of

established on the Internet and information technology people for a single project. A department or division

based interactive platform, factors of production will can also and the entire company as well. In fact, as the

Proceedings of the 12th International Conference on Project Management (ProMAC2018) 37

Ⓒ 2018 The Society of Project Management

scope grows and communications improves, the tasks will be progressively automated. This process

methodology should be more consistently applied. The leads the corporate structures which were based on

scope of project management affects many people and hierarchical functions to be gradually changed by

aspects. more streamlined structures.

The typical project managers may have to plan Massive amount of data will be produced in

and direct the use of resources on projects, and prepare every millisecond in the automated manufacturing

risk management since planning step. Department industry. This streaming huge data will be analyzed to

managers will administer resources and control enable adapts the business process to fulfill demand

projects within an area. Executive management should for products and services. The time needed to market

establish project priorities and monitor project of mass production will definitely short. To get along

progress. Obviously, project management should not with that, more fast adaptable and flexible production

be restricted to a handful of people or projects. Dozens processes will be compulsory to get adaptable quickly

of projects may be active at any one time, involving to the demands of the market. The consolidation of

hundreds of workers across departmental boundaries. Industry 4.0 will be characterized by the implementation of

Synchronization of the work effort is required to pervasive change project management processes that

maximize effect and minimize confusion. According will deal with inevitable resistance from people who

to Tim Bryce (2013), only when a standard and will have to revolutionize their ways of working. It is

consistent approach to Project Management is adopted sure that project managers and teams will require

by a company will it become an integral part of the higher variant soft skills and hard skills than those

corporate culture. needed in the past and a greater degree of autonomy in

order to handle industry 4.0 projects. The project

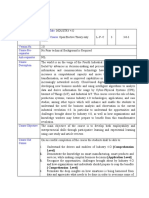

Table 1 Basic skills of project management teams will be increasingly delocalized, with people

1. Communication 4. Team Building that will interact from different places of the world

Listening Empathy and they all have their own cultural and professional

Persuading Motivation identity that needs to be integrated.

2. Organizational 5. Surviving Skills

Planning Flexibility 3.1 New emerging high-technology has changed

Goal-setting Creativity project management

3. Leadership Skills Patience The future of project management will be

Responsibility Persistence heavily influenced by technological breakthroughs,

and there is no doubt that AI will change the course of

Energetic Risk management

how project management tasks are delivered and

Vision 6. Technological Skills

controlled in the future. Practitioners are convinced

Delegates Experience

that AI will evolve from simple task automation to

Positive Project Knowledge

predictive project analytics, advice and actions as

described in M Lahmann, et al. (2018). New high-

3. Industry 4.0 project management

technology has made a lot of things in life easier, but it

has affected management of organizations. To put it

Industry 4.0’s core is the dynamic configuration mode

simply, it has changed project management in every

of productions. It is significantly different from

possible way. While new technology’s capabilities

traditional production methods. Dynamic

often lead to heightened expectations of customers and

configurations in production and in the manufacturing

senior management, the net result is that project teams

process are able to change the original design at any

should be able to achieve more during less time than

time. In order to ensure the best competitiveness, the

ever before. Consequently, the project managers get

integrated management of the projects will become

uncountable benefits starting from easier collaboration

increasingly important and, as a result, the project

to more accurate reporting via emerging technologies.

teams will become more and more focused on specific

Some of them are as follow.

objectives related with diverse elements of Industry

4.0. Most of business tasks and processes that do not

3.1.1 Team based structure

require analytical and design skills such as back-office

A team based structure can be useful for

Proceedings of the 12th International Conference on Project Management (ProMAC2018) 38

Ⓒ 2018 The Society of Project Management

Industry 4.0 settings, because it put multiple functions 3.1.4 Improved communication

and processes in a single group heading towards Communication is one of the most important

common objectives in Griffin, A.; Hauser, J.R.(1996). uses in project management to ensure proper

It enables organizational learning which leads to communication between managers, team members and

enhanced general skills, and a speedy decision making stakeholders. A few decades ago, project managers

process by breaking the interdepartmental barriers. replaced email instead of interoffice memos, faxes,

Project based teams can especially be a really good voice messages and other less-reliable forms of

facilitator of learning and innovation capabilities of communication. Now, as social collaboration tools and

organizations and individual employees in Aubry and other innovations have begun to replace email,

Lièvre(2010), which are required in the uncertain and successful project managers continue to use the latest

unstable environment of Industry 4.0. Team members technology to share updates, documents and other

come up with ideas, evaluation options and provide critical information with their project teams stated in

specialized knowledge. This balance ensures that the Angela(2016). Advances in communication

project manager can consider all angles to complex technology can build project teams with stakeholders

problems and solves them efficiently. located in various places over the world.

3.1.2 The integrated project teams 3.1.5 Various tools for varied stakeholders

Despite Agile development offers the more Some of the tech trends increasingly responding

collaborative approach in projects, IT still goes off to to a dynamic and changing world are collaboration,

code and test most new applications on its own and IT mobility and social networking, not just within teams

technicians have to provide services by themselves but also among stakeholders. Collaboration tools

even after the application is delivered at customer’s support groups working together to accomplish a

production site. This typical work procedure will not specific task. But project managers nowadays should

work with IoT projects, because IoT is so integrally be careful when identifying the proper channel to

linked into company operations that the software and reach stakeholders. The project manager should use a

hardware cannot be separated from its actual operating variety of tools such as instant messages, phone calls,

environment according to Shacklett. M (2017). For the webinars, and document collaboration tools. The

entire duration of the project, IT projects and project manager should always try to get approved

industries’ operations have to work hand in hand on formally by stakeholders’ organizations before

IoT all of the time. choosing one to support a project. The project

manager’s ability to choose the appropriate

3.1.3 Longer project timelines communication tools to communicate stakeholders

Unlike traditional IT projects, an Industry 4.0 and teams has a great impact on the project outcome.

project is not terminated once it is implemented. There

should have a plan for how the IoT will be supported, 3.2 Soft skills for Industry 4.0 project manager

and for what the failover mechanics are going to be In Industry 4.0, the soft skills of project

fixed if a failure occurs in production for some reason managers will undertake a significant transformation

as stated in Mary Shacklett (2017). As a team's project mainly related to the new ways of interacting with

manager, he or she might also prepare failover and project stakeholders:

recovery actions for ongoing project. Until Internet

industries mature in autonomous manufacturing 3.2.1 Communication skills

industry, IIoT projects will have a longer tail that In order to react in real time and consequently

extends into support and failover of IoT even after it is speed up the processes of problem solving and

cutover to production. As described in Mary decision making, the management and sharing of

Shacklett(2017), the project timeline will be longer for knowledge will play in a main role. While time is

that the project team will need ongoing support from passing, information is going to decrease value.

automated systems, network, database, storage and IT Information should be shared with all stakeholders in

operations functions because IIoT will impact all of order to enhance the management of critical issues and

them. encourage the creation of integrated collaboration.

Customers and suppliers from the network cannot be

Proceedings of the 12th International Conference on Project Management (ProMAC2018) 39

Ⓒ 2018 The Society of Project Management

longer excluded from knowledge management; they and on the other hand manage the relations among

can all make an important contribution to problem other stakeholders with a sense of responsibility.

solving. To achieve this goal, the project managers

should promptly prepare a well-prepared 3.3 Hard skills for Industry 4.0 project manager

communication plan. Although a project manager is the general

manager of a project, Industry 4.0 projects require a

3.2.2 Authority full comprehension of Cyber-physical Spaces from the

In Industry 4.0, project managers are among the project managers along with deep domain knowledge

main actors of this industrialization change process. while the implementation is mainly delegated to

Their leadership will be expressed as more project team experts or virtual assistants. The most

authoritative and less as a simple position in the important hard skill for PMs is experience with

organizational chart. An authoritative PM should have innovative technologies and projects, predictive

rights to create project agreements, resource algorithms and big data analysis that will help them

management, his or her team position in the processes, manage projects correctly and stay focused on the

be available to get involved and demonstrate skills in objectives to be achieved. The authoritativeness of

valuing resources. project managers will be based on their ability to see

the flow of the processes that will regulate the projects

3.2.3 Team management of the future not only in its entirety, but in all its

The PM’s fundamental task should be to components. Humans are always at the center of

encourage the team's spirit of initiative without losing Industry 4.0, dominating through their know-how and

sight of the strategic objectives of the project. From skills to use the tools that will guide success. In this

both technical or cognitive view and relational point of sense, project managers could adopt the principles of

view, the project manager should be able to choose the lean management. When integrated with the tools of

right people for the composition of the team with the Industry 4.0, this will allow them to overcome the

delocalization of the different project teams. Moreover, operational criticalities of the management of projects

the Industry 4.0 PM should have the efficient that usually cross all company areas. For example,

interaction among projects such as IoT, Big Data with pull techniques, lean management will allow us

Analytic, System integration, Simulation, cloud to enhance the potential of digital tools to perform

computing and cyber security projects. rapid analysis that will provide operators with

instructions to intervene effectively in critical areas.

3.2.4 Management of unforeseen event At the same time, this will enable to adapt production

Speed will be a key word in Industry 4.0. An processes to requirements changes and stay aligned

integrated flow of data and communications which with customer requests.

allows stakeholders to have a picture of the situation

in real time will be essential the high speed of decision 3.4 Challenges of Industry 4.0 elements for project

making and the diligence in reacting to unexpected management

events in a system governed. Project managers should At the company level, the impact of the fourth

have consistent problem-solving capacity and act industry revolution on production processes will not

quickly, maintaining the right balance at the same time. only be limited to technological but also

infrastructural aspects. This revolution will endorse

3.2.5 Negotiation skills the development of new professions, new structures of

Traditional hierarchical relationships will organizations and the growth of a new management

gradually change into flat structure in Industry 4.0. style. Project managers will be the main leaders of

Project team members will become independent those developments, facing a new situation with

professional figures, able to develop their creativity different elements of Industry 4.0. Some significant

with greater freedom than in the past. The PM should elements are Internet of Things, Addictive

build her authority on the 360-degree knowledge of Manufacturing, System Integration, Autonomous

the project and of its related domain. In order to Systems, Augmented Reality, Simulation, Big Data,

manage effectively, the project manager should Cyber Security and Cloud Computing.

communicate the team members with transparency

Proceedings of the 12th International Conference on Project Management (ProMAC2018) 40

Ⓒ 2018 The Society of Project Management

3.4.1 Internet of things hardware of software which need to be utilized in

The Internet of Things is the ever-growing harmony so that maximum value can be derived.

infrastructure of internet-connected devices which can Keeping existing systems up to date and working

transfer data and commands between points. The basic properly is one of the main challenges of the fourth

idea of this concept is the pervasive presence around industrialization. Projects to integrate new and old

us of a variety of things or objects such as Radio- systems will be essential the skillful project manager

Frequency IDentification (RFID) tags, sensors, who have enough awareness to accomplish the system

actuators, mobile phones, through unique addressing integration projects. Connecting a system, equipment

schemes such as IP address, which are able to interact and component to a network is not such an easy job.

with each other and cooperate with their neighbors to Moreover, it also brings vulnerabilities that weren’t

reach common goals described in Giusto, D. et al. there before. Nick (2015) indicated that Ensuring that

(2010). While the system becomes a crucial tool for the system is secure from cyber threats and attacks

understanding complexity and elaborate quick while interconnecting systems is a new challenge fit

responses, the objects can sense and interconnect for Industry 4.0. Flexibility with new modern

within themselves and the environment in this system. automated systems and smart factories is essential for

Increasing the complexity of the projects’ processes good systems integrators and industry 4.0 project

and management style is bringing shifting elements managers. While also keeping up to date with the

inside the environment. The number of stakeholders in latest technologies, the best way to maximize industry

the project is also increasing significantly. The knowledge and expertise is being familiar with a wide

project’s success mostly depends on sharing range of systems and working with different

information and communication and high uncertainty manufactures.

of the situation is making challenges and they are

usually more tricky and complicated to manage. It is 3.4.4 Autonomous systems

the sure that project management within diverse In this 4th iteration, not only objects and

groups which are often located in remote locations, machines can communicate with each other, they can

will face many deviations in the original project plan also act autonomously. Robotics and artificial

according to Luigi Atzori, et al. (2010). intelligence have evolved mostly in the autonomous

systems where high standards on various tasks can be

3.4.2 Additive manufacturing operated without constant human intervention. In the

Additive Manufacturing is advances in 3D future of Industry 4.0, autonomous systems will

printing and can make product components lighter and perform complex tasks without requirements of

less cost. The 3D printing is a central part of a more specific programming or human input. Their ability to

broad computerized transformation procedure in the learn will enable them to decide between alternative

smart factories of manufacturing industry. The smart actions, make the best use of their skills, interact with

factory will make manufacturing leaner and faster, and the real world, perceive their surroundings, and adapt

provide data on components and products in real time. to changes as stated in Siemens Corp. (2017). While

Because businesses involved in additive settling those autonomous systems, there is a demand

manufacturing will add complexity and bring new to manage these complex technical projects efficiently

legal challenges, an increased awareness and coherent to support the technical development. To enable that,

strategy will be required for industry 4.0 project project manager is needed to manage the projects

manager, especially additive manufacturing project towards set goals, project organization and framework

manager to adequately address issues like the for ways of working within the project. The project

protection of intellectual property rights, trade secrets manager of autonomous system should make to ensure

and data, as well as increasing liability risks. that all project activities are undertaken in a systematic

manner with a Systems Engineering approach at the

3.4.3 Systems integration core of the technical solution to project objectives.

System integration in this connected industry

4.0 comes with its challenges, so industries need to 3.4.5 Augmented reality

keep up to speed and get creative with technology Augmented reality (AR) refers to the

because a business can have many different pieces of integration of additional computer generated

Proceedings of the 12th International Conference on Project Management (ProMAC2018) 41

Ⓒ 2018 The Society of Project Management

information into a real-world environment. In an fourth industrialization according to Jie Xu, et al.

Industry 4.0 context, AR can add into internet industry (2016).

network to enable generate the highest value, enable

avoid risks, issues and downtime the most, optimize 3.4.7 Big data

the end-to-end manufacturing process and workflows Businesses can create huge volumes of data

with the best possible way, and finally to make without realizing it and this data can be a source of

productivity, satisfaction and experiences of field untapped value for business improvement and growth.

engineers, factory workers, customers and On the other hand, a lot of data sources of different

stakeholders the most satisfactory. Virtually aspects of industries will generate big data in disparate

Augmenting (VR) what people can see with their own formats. Big data analytics is an important challenge

eyes with data and hidden systems can be immensely for Industry 4.0 project managers because its data

powerful when it comes to process and product variety may be hinder of Industry 4.0 big data

improvement. The AR application is relevant to analytics. Although there are a large number of tools

industries for its prominently improvement of the for processing big data, people who have expertise and

product design and production, distribution processes deep knowledge in a specific domain only may not be

because it can reduce the number of physical able to use these tools according to Gökalp, et al.

prototypes, it saves time and cost. AR systems use (2016). Therefore, Industry 4.0 project manager needs

digital visualization to show users exactly where to put to deep understanding of big data analytics too in

parts, what parts may be broken and also give order to able manage project team effectively.

information on the part while process manufacturing

training, assembly and safety are the main use of VR 3.4.8 Cyber security

and AR. According to De Pace F,et al. (2018), AR is Connected systems especially diverse systems

considered as a valuable tool for improving and within industry 4.0 require being optimized and secure

accelerating product and process development in many so that personal to organization assets and information

industrial applications. It sounds greatly that AR are safe from intrusion. It does not need to say that the

project is filled with high technology. Therefore, AR array of tasks that fall to the project manager is

project manger’s one of the most important skill to seemingly endless. Time management, resource

achieve the project goal is familiarity with AR management, risk management, budgeting,

technology additionally to project management skills. motivational and diplomacy skills and leadership skills

are some of what a project manager needs to tackle in

3.4.6 Simulation order to successfully manage a project. But,

In the engineering world, we have been using increasingly cyber security is another area within

simulations that are computer programs that mimic or project management. It is an area that a project

model the behavior of physical systems for years to manager cannot afford to overlook even while

predict and explore system capabilities and limitations ensuring systems are secure. Serious security breaches

according to Arora, A. (2007). It can often be more make cost very much to fix. It can also cause long-

cost-effective to trial something in the virtual world term damage and numerous negative consequences to

than to make a physical prototype for each variable an organization’s brand and reputation. Therefore,

being tested. The simulations save expenses for Project managers should be alert of their project data

physical prototypes and even lives in many cases. value, especially if data is cutting edge technology or

Applying them in industry 4.0 projects can have confidential information. They should ensure that

similar impact to project owners and stakeholders. access to data is under-controlled. Moreover, they

Because of projects are both varied and numerous, should also consider the unauthorized access to the

however, many projects experience schedules late and data as part of their risk management. The cost of

cost overruns. Computer simulation provides a protecting data needs to be discussed upfront and

modeling and evaluation tool for complex systems that included in project budget.

are analytically intractable. The simultaneous

emergence of of ubiquitous sensing and unprecedented 3.4.9 Cloud computing

interconnection between sensing and control devices IT services are increasingly being provided by

constitutes a new paradigm of industrial systems of the the ‘cloud’ to generate cost and space savings as well

Proceedings of the 12th International Conference on Project Management (ProMAC2018) 42

Ⓒ 2018 The Society of Project Management

as to offer innovative use models. When applications dramatically changed over the last 30 years according

are deployed in the cloud, the project manager's role to Treb Gatte(2016). Different management

does not change much. The project manager typically methodologies may be used, but collecting and

keeps the project on track and provides status reports, disseminating manually information between the

and is not required to be an expert in the particular various roles on a project is spent a great deal of time.

technologies. However, the project manager needs to The information gaps caused by diverse systems that

make sure cloud providers take steps to address cannot capture what is truly happening within the

performance, security and disaster recovery organization cause this expenditure. The combination

management problems. The project manager needs to of artificial intelligence in the form of bots, cloud

understand each area of risk and identify who is computing could radically change this situation into

responsible for tasks associated with problems. autonomous system. Project management efficiency

would be enhanced in some projects and diminished in

4. Analysis of typical and Industry 4.0 project some projects in the fourth industrialization. Analysis

manager responsibilities of typical software development and industry 4.0

project manager can be seen in the following table (2).

Much of the daily work of a project manager has not

Table 2 Analysis of typical and Industry 4.0 project manager’s responsibilities

Industry 4.0

Roles and Responsibilities Typical PM

PM

Provide to ensure adherence to budget, schedule, and scope v v

Work with the Project Sponsor to develop the agreed Project Management Plan

through interactions with stakeholders. v v

Execute and maintain project document management for the project cycle in

compliance with the Authorities Quality Assurance requirements. v v

Provide a timely and accurate report to the management team and team members. v v

Assist business development team with negotiating and definitive agreements

with external suppliers, vendors, and customers. v v

Develop best practices and tools for project execution in an agile development

environment. v v

Ensure all project activities are undertaken in a systematic manner with a

Systems Engineering approach at the core of the technical solution to project x v

objectives.

Identify and execute strategic initiatives to enable growth strategy. x v

Motivate cross-functional, multi-location team members and manage deliverables

to meet project milestones.

x v

Provide deep dive analysis, proposal, and help implement improvements to a

wide variety of cross organizational challenges.

x v

Manage project execution, risks; identify, resolve issues in a real time. x v

Ability to manage highly complex, technical projects x v

Support the tracking and managing of a complex autonomous fleet. x v

Ensure prototype development and vehicle conversion and replication is executed

flawlessly.

x v

Drive the testing and technical assessment of next generation hardware and

software technology with partners

x v

Familiar with technical process improvement and development in start-up and

complex settings.

x v

Complex systems execution strategy formation and delivery x v

Proceedings of the 12th International Conference on Project Management (ProMAC2018) 43

Ⓒ 2018 The Society of Project Management

5. Conclusion De Pace F. et al. (2018) Augmented Reality in

Industry 4.0. Am J Compt Sci Inform

Complexity and uncertainty, two main theoretical

Technol Vol.6 No.1:17.doi: 10.21767/2349-

traditions in project management play a big part in

3917.100017.

Industry 4.0 projects, shaping and defining necessary

features to handle the workload and they are related Giusto, D. et al. (2010), The Internet of Things, 263-

with the increasing complexity of the projects. 272, Springer. ISBN: 978-1-4419-1673-0.

Traditional project management styles have to be Dilberoglu, U. et al. (2017). The Role of Additive

changed in order to adaptable with the fourth Manufacturing in the Era of Industry 4.0.

industrialization with a lot of variations. After Procedia Manufacturing. 11. 545-554.

analyzing necessary skills and responsibilities of

Siemens Corp. 2017, Factory of the Future: Future

traditional software development project managers

Automation and Autonomous Systems

and industry 4.0 project managers, we found that

there are many challenges in industry 4.0 project Revolution Innovation Day USA 2017,

manager, especially ways of management and (Accessed 2018.10.3).

technical skills. Although there are specialized Gökalp, O. et al. (2016). Big Data for Industry 4.0: A

project manager related with each element of Industry Conceptual Framework. 431-434. 10.1109/

4.0, it is sure that project manager must have CSCI.2016.0088.

enhanced soft skills and hard skills to accomplish the Griffin, A.; Hauser, J.R. Integrating R&D and

complex and autonomous Industry 4.0 projects. marketing: A review and analysis of the

literature. J. Prod. Innov. Manag. 1996, 13,

Acknowledgement

191–215.

Xu, J. et al. (2016), Simulation optimization in the era

This study was supported by University of Computer

Studies, Yangon (UCSY), Myanmar. of Industrial 4.0 and the Industrial Internet,

Journal of Simulation, 10:4, 310-320.

References Bryce, T. (2013), MBJB Investment Company, Why

project Project Management fails, 2013,

Arora, A. (2007). Dynamic project management using https://www.stakeholdermap.com/project-

simulations. Paper presented at PMI® Global management/why-project-management-

Congress 2007—Latin America, Cancún, fails.html (Accessed Oct 1, 2018).

Mexico. Newtown Square, PA: Project Atzori, L., Iera, A. and Morabito. G. (2010). The

Management Institute. Internet of Things: A survey. Comput. Netw.

Aubry, M., Lièvre, P. Ambidexterity as a competence 54, 15 (October 2010), 2787-2805.

of project leaders: A case study from two Boughton, N. (2015), System integration for Industry

polar expeditions. Proj. Manag. J. 2010, 41, 4.0.https://www.automation.com/automation-

32–44. news/article/systems-integration-for-industry

Bunner, A. (2016), 5 ways technology has changed -40 (Accessed Oct 4, 2018).

project management. https://www.clarizen. Lahmann, M. et al. (2018), AI will transform project

com/5-ways-technology-has-changed-project management. Are you ready? PwC.

-management/, (Accessed 2018.9.10). Shacklett, M. (2017), 6 ways IoT will change project

Cheng, G. et al. (2016). Industry 4.0 Development management, (Accessed 2018. 10. 5).

and Application of Intelligent Manufacturing. Gatte, T. (2016), The augmented project manager,

407-410. 10.1109/ISAI.2016.0092. CIO, (Accessed 2018.10.6).

Proceedings of the 12th International Conference on Project Management (ProMAC2018) 44

Ⓒ 2018 The Society of Project Management

View publication stats

Potrebbero piacerti anche

- 1 Introduction To Project ManagementDocumento34 pagine1 Introduction To Project ManagementLearning everythingNessuna valutazione finora

- Job Hunting ExtraActivities PDFDocumento13 pagineJob Hunting ExtraActivities PDFAulyd DaynaNessuna valutazione finora

- Artificial Intelligence in Project ManagDocumento22 pagineArtificial Intelligence in Project Manag5F2 SHAIK PALUR SAMEENANessuna valutazione finora

- Contract Administration Ver-6Documento172 pagineContract Administration Ver-6Moi Bon SayyNessuna valutazione finora

- An Experts Guide To ERP Success Chapter FourDocumento18 pagineAn Experts Guide To ERP Success Chapter Fourcoyote41Nessuna valutazione finora

- Implementation of Industry 4.0 Smart Manufacturing: MD Rafiqul Islam KhanDocumento9 pagineImplementation of Industry 4.0 Smart Manufacturing: MD Rafiqul Islam KhanJatin SinghNessuna valutazione finora

- How To Write A Research Paper On ArchitectureDocumento13 pagineHow To Write A Research Paper On ArchitectureCamille Daigo100% (1)

- (International Series in Operations Research & Management Science) Erik Leuven Demeulemeester, Willy S. Herroelen - Project Scheduling - A Research Handbook (2002, Springer)Documento710 pagine(International Series in Operations Research & Management Science) Erik Leuven Demeulemeester, Willy S. Herroelen - Project Scheduling - A Research Handbook (2002, Springer)Khalil Kafrouni0% (1)

- Developer VelocityDocumento41 pagineDeveloper VelocityWilliams TrumanNessuna valutazione finora

- Whitepaper - State of Construction TechnologyDocumento16 pagineWhitepaper - State of Construction TechnologyRicardo FigueiraNessuna valutazione finora

- IT Outsourcing Transformation Whitepaper PDFDocumento20 pagineIT Outsourcing Transformation Whitepaper PDFDhruvi Netzone100% (1)

- Industry 4.0Documento54 pagineIndustry 4.0santhosha ks100% (2)

- Certified Scrum Master Random NotesDocumento4 pagineCertified Scrum Master Random NotesamagazineNessuna valutazione finora

- PlagiarismDocumento33 paginePlagiarismMahrukh BaigNessuna valutazione finora

- How to Be a Successful Software Project ManagerDa EverandHow to Be a Successful Software Project ManagerNessuna valutazione finora

- Use of Data Analytics in Project ManagementDocumento12 pagineUse of Data Analytics in Project ManagementPraful PawarNessuna valutazione finora

- How To Write A Project ProposalDocumento3 pagineHow To Write A Project ProposalHARLEY L. TANNessuna valutazione finora

- Industry4 161112133940Documento19 pagineIndustry4 161112133940Tran Anh100% (1)

- Engineer To Order Project Management with SAP and NovecoDocumento97 pagineEngineer To Order Project Management with SAP and NovecoSubramanian S (IN)Nessuna valutazione finora

- The BIM Manager A Practical Guide For BIM Project ManagementDocumento306 pagineThe BIM Manager A Practical Guide For BIM Project ManagementBelen RG100% (4)

- Industy 4.0 AppliedDocumento17 pagineIndusty 4.0 Appliedcagan.ulNessuna valutazione finora

- 2020-12 - Project Management in Industry 4.0 - Choudhary ShreyasDocumento9 pagine2020-12 - Project Management in Industry 4.0 - Choudhary ShreyasShreyas ChoudharyNessuna valutazione finora

- 1 s2.0 S266672152100020X MainDocumento12 pagine1 s2.0 S266672152100020X Mainalbertus tuhuNessuna valutazione finora

- COMP1611 WEEK1 Introduction To PMDocumento21 pagineCOMP1611 WEEK1 Introduction To PMswharaNessuna valutazione finora

- DescargaDocumento15 pagineDescargahectorfa1Nessuna valutazione finora

- iot project management research paperDocumento3 pagineiot project management research paper0901CD211005 ADITYA SINGH CHAUHANNessuna valutazione finora

- Mitpe Brochure Cpi 4.0 EngDocumento21 pagineMitpe Brochure Cpi 4.0 Engopeda normanNessuna valutazione finora

- Lectura 1 Artificial - Intelligence - Enabled - Project - ManagementDocumento23 pagineLectura 1 Artificial - Intelligence - Enabled - Project - ManagementliberatahilarioNessuna valutazione finora

- Proposed Managerial Competencies For Industry 4.0 - Implications ForDocumento13 pagineProposed Managerial Competencies For Industry 4.0 - Implications ForJAIRO ALEXANDER ALDANA OCHOANessuna valutazione finora

- MITPE-DTR-ENGDocumento22 pagineMITPE-DTR-ENGYasir ShigileeniNessuna valutazione finora

- Cezar-Petre SIMION, Ștefan-Cătălin POPA, Cătălina ALBU: Project Management 4.0 - Project Management in The Digital EraDocumento8 pagineCezar-Petre SIMION, Ștefan-Cătălin POPA, Cătălina ALBU: Project Management 4.0 - Project Management in The Digital EraBiancaNessuna valutazione finora

- Oztemel-Gursev2020 Article LiteratureReviewOfIndustry40AnDocumento56 pagineOztemel-Gursev2020 Article LiteratureReviewOfIndustry40AnMarko BrkicNessuna valutazione finora

- WP - Digital Transformation Engineering and Construction IndustryDocumento31 pagineWP - Digital Transformation Engineering and Construction IndustryWilly AragonNessuna valutazione finora

- Educating The Industry 4.0 WorkforceDocumento3 pagineEducating The Industry 4.0 WorkforceDhillukshanNessuna valutazione finora

- Smart Design Engineering Leveraging Product Design and DevelopmentDocumento21 pagineSmart Design Engineering Leveraging Product Design and DevelopmentMUHAMAD RIZKI DWI SYAHPUTRANessuna valutazione finora

- Technologies Enabling Sustainable Enterprise 4.0Documento15 pagineTechnologies Enabling Sustainable Enterprise 4.0Umar AliNessuna valutazione finora

- 2023 1 P11 Lectura P11Documento11 pagine2023 1 P11 Lectura P11Amalia Rosa Vega DavilaNessuna valutazione finora

- 3D Systems in Industrial Renaissance 4Documento4 pagine3D Systems in Industrial Renaissance 4sunithaNessuna valutazione finora

- Industry 4.0 Carabajo - MizqueroDocumento3 pagineIndustry 4.0 Carabajo - MizqueroDaniel Mizquero Zarate0% (1)

- 06 Predavanja - Upravljanje Finansijskim RizikomDocumento7 pagine06 Predavanja - Upravljanje Finansijskim Rizikomlavanda 2Nessuna valutazione finora

- E-Commerce Class Project Management SoftwareDocumento67 pagineE-Commerce Class Project Management SoftwaredereckNessuna valutazione finora

- Project Management IssueDocumento1 paginaProject Management Issueapi-233596763Nessuna valutazione finora

- Industry 4.0: Tools and Implementation: September 2019Documento12 pagineIndustry 4.0: Tools and Implementation: September 2019Ibrahim KukićNessuna valutazione finora

- Assignment 1 Research MethodologyDocumento4 pagineAssignment 1 Research MethodologyDon PabloNessuna valutazione finora

- Evolving Manufacturing Mobility in Industry 4.0Documento20 pagineEvolving Manufacturing Mobility in Industry 4.0Lidia ValladolidNessuna valutazione finora

- 021 Production Plant and Warehouse Automation With IoT and Industry 50applied Sciences SwitzerlandDocumento34 pagine021 Production Plant and Warehouse Automation With IoT and Industry 50applied Sciences SwitzerlandÁgost VitaNessuna valutazione finora

- Sustainability 13 09965Documento23 pagineSustainability 13 09965ANGIE GARCIANessuna valutazione finora

- McKinsey Explainer-What - Are - Industry - 4 - 0 - The - Fourth - Industrial - Revolution - and - 4irDocumento7 pagineMcKinsey Explainer-What - Are - Industry - 4 - 0 - The - Fourth - Industrial - Revolution - and - 4irYudhi PermadiNessuna valutazione finora

- Ref11 - The Contribution of Industry 4.0 Tech To FMGMTDocumento15 pagineRef11 - The Contribution of Industry 4.0 Tech To FMGMTMan HumanNessuna valutazione finora

- Questionnaire - Industry AssessmentDocumento24 pagineQuestionnaire - Industry AssessmentnaveedNessuna valutazione finora

- Implementing Industry 4.0 to Enhance Construction Project ManagementDocumento16 pagineImplementing Industry 4.0 to Enhance Construction Project ManagementDon PabloNessuna valutazione finora

- MBA4049 - Industry 4.O - CC - 22-23Documento5 pagineMBA4049 - Industry 4.O - CC - 22-23Prashantha G NNessuna valutazione finora

- SPM Unit-1Documento18 pagineSPM Unit-1Nageswara Rao AramandaNessuna valutazione finora

- Industry Revolution 4.0 Assignment 1Documento6 pagineIndustry Revolution 4.0 Assignment 1Thinesh SpadeNessuna valutazione finora

- Quiz 1 EE13 (MIRANDO)Documento3 pagineQuiz 1 EE13 (MIRANDO)Mirando Miguel Angel E.Nessuna valutazione finora

- Industry 4.0: An Overview: July 2018Documento7 pagineIndustry 4.0: An Overview: July 2018Romancing LoveNessuna valutazione finora

- Chapter 1: Introduction To Project ManagementDocumento9 pagineChapter 1: Introduction To Project ManagementJose SantosNessuna valutazione finora

- Key technologies for smart factory loyalty programsDocumento8 pagineKey technologies for smart factory loyalty programsLissette ObleaNessuna valutazione finora

- Digitaltransfpanel SummaryDocumento3 pagineDigitaltransfpanel SummaryAdel MohamedNessuna valutazione finora

- Industry 4.0: An Overview: July 2018Documento7 pagineIndustry 4.0: An Overview: July 2018Steve StevenNessuna valutazione finora

- An Empirical Framework For AssDocumento17 pagineAn Empirical Framework For AssMuhammad AfifNessuna valutazione finora

- Ebert 2016Documento2 pagineEbert 2016Lorraine FreitasNessuna valutazione finora

- Sjeat 810 244-248Documento5 pagineSjeat 810 244-248gowtham2436Nessuna valutazione finora

- Assignment 2 Final - UpdateDocumento14 pagineAssignment 2 Final - UpdateDon PabloNessuna valutazione finora

- Information Technology Project Management, Seventh EditionDocumento56 pagineInformation Technology Project Management, Seventh EditionVinson AlvindiNessuna valutazione finora

- CE - 403: Computer Engineering: Project ManagementDocumento60 pagineCE - 403: Computer Engineering: Project Managementnoman moinNessuna valutazione finora

- CH 1Documento28 pagineCH 1mostNessuna valutazione finora

- Key competencies needed for Industry 4.0 managersDocumento5 pagineKey competencies needed for Industry 4.0 managersGowthamNessuna valutazione finora

- Industry 4.0 OverviewDocumento14 pagineIndustry 4.0 OverviewThe YogiNessuna valutazione finora

- A Review On The Application of Blockchain To The Next Generation of Cybersecure Industry 4.0 Smart FactoriesDocumento18 pagineA Review On The Application of Blockchain To The Next Generation of Cybersecure Industry 4.0 Smart Factoriesrey_hadesNessuna valutazione finora

- Instability of Granular Materials at High Pressures.: January 1997Documento13 pagineInstability of Granular Materials at High Pressures.: January 1997Andius D. PutraNessuna valutazione finora

- Instability of Granular Materials at High Pressures.: January 1997Documento13 pagineInstability of Granular Materials at High Pressures.: January 1997Andius D. PutraNessuna valutazione finora

- 1 SMDocumento7 pagine1 SMAndius D. PutraNessuna valutazione finora

- Particle Breakage and The Critical State of SandDocumento11 pagineParticle Breakage and The Critical State of SandAndius D. PutraNessuna valutazione finora

- Effects of particle size and pressure on rockfill breakageDocumento11 pagineEffects of particle size and pressure on rockfill breakageAndius D. PutraNessuna valutazione finora

- Aerodrome Safety For Manouvering Area in Soekarno-Hatta International Airport CengkarengDocumento22 pagineAerodrome Safety For Manouvering Area in Soekarno-Hatta International Airport CengkarengAndius D. PutraNessuna valutazione finora

- The Role of Particle Breakage in The Mechanics of A Non-Plastic Silty SandDocumento14 pagineThe Role of Particle Breakage in The Mechanics of A Non-Plastic Silty SandAndius D. PutraNessuna valutazione finora

- ReinforcementDocumento1 paginaReinforcementAndius D. PutraNessuna valutazione finora

- 1 SMDocumento7 pagine1 SMAndius D. PutraNessuna valutazione finora

- Huang Chien Wen AbstractDocumento4 pagineHuang Chien Wen AbstractAndius D. PutraNessuna valutazione finora

- Human Resouces ManagementDocumento104 pagineHuman Resouces ManagementAftab RaniyaNessuna valutazione finora

- Open University of Mauritius MBA & CEMBA ProgrammesDocumento25 pagineOpen University of Mauritius MBA & CEMBA Programmesanon_406900448Nessuna valutazione finora

- Project Milestones - Simplicable PDFDocumento13 pagineProject Milestones - Simplicable PDFmoinahmed99Nessuna valutazione finora

- Intro to PM: Benefits, Definitions & Life CyclesDocumento10 pagineIntro to PM: Benefits, Definitions & Life CyclesTeererai KaguraNessuna valutazione finora

- Faster Construction Projects With CPM SchedulingDocumento1 paginaFaster Construction Projects With CPM SchedulingFia PutriNessuna valutazione finora

- Module ECM2415 (2013) Software EngineeringDocumento2 pagineModule ECM2415 (2013) Software EngineeringAseil BafaratNessuna valutazione finora

- Seven Tips On How To Build A Solid ScheduleDocumento2 pagineSeven Tips On How To Build A Solid Schedulekaiju85Nessuna valutazione finora

- PPMP20010 Assessment 2 - Marking SheetDocumento1 paginaPPMP20010 Assessment 2 - Marking SheetGanga RamNessuna valutazione finora

- Pert nOTESDocumento33 paginePert nOTESNeerupa Rajiv SisodiaNessuna valutazione finora

- ISP GovernanceDocumento12 pagineISP GovernanceFrancis Leo Gunseilan100% (1)

- Cost Management PlanDocumento7 pagineCost Management PlanHilmi HamdanNessuna valutazione finora

- Chapter 4 Software Poroject PlanningDocumento52 pagineChapter 4 Software Poroject Planningਅਮਰ ਪਾਲ ਸਿੰਘNessuna valutazione finora

- Qpb-2220053 Pd4 Ikk Project Electrical Wi & Eps - Siemens Tech Prop r0 20220815Documento45 pagineQpb-2220053 Pd4 Ikk Project Electrical Wi & Eps - Siemens Tech Prop r0 20220815kenthudNessuna valutazione finora

- Project Management: Total Property Solution Service OverviewDocumento12 pagineProject Management: Total Property Solution Service OverviewReverie InternationalNessuna valutazione finora

- Consultancy for Construction Supervision and Project ManagementDocumento205 pagineConsultancy for Construction Supervision and Project ManagementGaurav TanwerNessuna valutazione finora

- What Is A Terms of Reference in Project Management?Documento3 pagineWhat Is A Terms of Reference in Project Management?Jyoti ShresthaNessuna valutazione finora

- Construction Project Management Dissertation ExamplesDocumento6 pagineConstruction Project Management Dissertation ExamplesCustomCollegePaperCanadaNessuna valutazione finora

- SPPM UNIT 5Documento11 pagineSPPM UNIT 5Dance QueenNessuna valutazione finora

- PROJECT MANAGEMENT BLIND SPOTS V 1.0Documento15 paginePROJECT MANAGEMENT BLIND SPOTS V 1.0MANZA05Nessuna valutazione finora

- Electrical Report of IPDocumento11 pagineElectrical Report of IPBonaventure NzeyimanaNessuna valutazione finora

- Globex International Group Profile 4919Documento53 pagineGlobex International Group Profile 4919Hassan Safdar MalikNessuna valutazione finora

- Oracle-Primavera-Cloud - DataDocumento9 pagineOracle-Primavera-Cloud - DataPusala AnanthnagNessuna valutazione finora