Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

K034 - Daikoflux 940

Caricato da

cwiksjDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

K034 - Daikoflux 940

Caricato da

cwiksjCopyright:

Formati disponibili

SISTEMA DI GESTIONE

CERTIFICATO DA ICIM

UNI EN ISO 9001:2015

S.R.L.

Operative Site #1: Via Aquileia, 13-15 - 31048 Olmi di San Biagio di Callalta (Treviso) Italy - Ph. +39 0422 796367

Operative Site #2: Via Toscana, 3A-3B – 20056 Grezzago (MI) ITALY – ph. +39 02 9090477

technical@daikowelding.com www.daikowelding.com

DATA SHEET No. K034 DAIKOFLUX 940

ESW Cladding Flux

Description / Alloy type: Highly basic agglomerated flux especially designed for high speed

electroslag strip cladding with Nickel base welding strip such as alloy

625 (EQNiCrMo-3) and alloy 82 (EQNiCr-3).

Specifications: EN760

S A FB 2

Flux apparent density: 1.1 g/cm3

Basicity index: > 3 (according to BONISZEWSKI)

Packaging: 25-30 kg plastic bag or drum.

Re-drying: 300-350°C.

Typical chemical analysis of flux (%):

SiO2 Al2O3 TiO2 CaF2 Na2O+K2O others

8 20 4 65 2 <2

Typical chemical composition of overlay with Strip Daiko 625 60x0,5mm on carbon steel*, wt.%:

Ni C Mn Fe S P Si Cu Cr Nb Mo

1st layer (thick. 4 mm) 58.0 0.35 0.19 12.9 0.006 0.008 0.26 0.009 19.1 2.8 7.8

2nd layer (thick. 4 mm) 63.5 0.18 0.04 2.4 0.005 0.007 0.25 0.010 21.1 3.3 8.5

(*) = 1450A, 25V, 280 mm/min, 35 mm stick-out

Typical parameters:

Size [mm] 30x0.5 60x0.5 90x0.5

Current DCEP DCEP DCEP

Amperage [A] 400-900 800-1800 1200-2600

Voltage [V] 24-27 24-27 24-27

Travel Speed [mm/min] 120-350 120-350 120-350

Stick out [mm] 20-40 20-40 20-40

rev. 8/2018

Potrebbero piacerti anche

- Catalogue WP-SDC CCR CE (MID)Documento3 pagineCatalogue WP-SDC CCR CE (MID)control1y1segu-65318Nessuna valutazione finora

- SM Series: Aluminium Electrolytic CapacitorDocumento2 pagineSM Series: Aluminium Electrolytic CapacitorAlexanderViloriaMoranteNessuna valutazione finora

- Basic Linear G3 DatasheetDocumento10 pagineBasic Linear G3 Datasheetdavidroa05Nessuna valutazione finora

- MF60151V1 B00u A99 PDFDocumento14 pagineMF60151V1 B00u A99 PDFGustavo BorjaNessuna valutazione finora

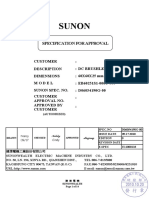

- Sunon: Specification For ApprovalDocumento16 pagineSunon: Specification For ApprovalManuelLentiNessuna valutazione finora

- TDS - Nimrod C276KSDocumento1 paginaTDS - Nimrod C276KSImmalatulhusnaNessuna valutazione finora

- TAC-F - v1.1-OmegaAir - EngDocumento12 pagineTAC-F - v1.1-OmegaAir - EngMột Lằn QuangNessuna valutazione finora

- Catalogue Al Jazeera OmanDocumento36 pagineCatalogue Al Jazeera OmankarthickNessuna valutazione finora

- Metcoloy 5 10-627Documento6 pagineMetcoloy 5 10-627Remco Van Den BergNessuna valutazione finora

- 3M Cold Shrink Silicone Rubber Termination QT-III: InstructionsDocumento16 pagine3M Cold Shrink Silicone Rubber Termination QT-III: InstructionsEliazer GonzalezNessuna valutazione finora

- SOLAR CABLE 0,6-1 KV PV1-F CharacteristicsDocumento2 pagineSOLAR CABLE 0,6-1 KV PV1-F CharacteristicswagnerengNessuna valutazione finora

- Specification VBMS380AJ09Documento7 pagineSpecification VBMS380AJ09NGOC CAONessuna valutazione finora

- Product CertificateDocumento1 paginaProduct CertificateMURSHID MUHAMMEDNessuna valutazione finora

- DS - Patchcord SM SX 3MM SCAPC LCAPC G657A1Documento2 pagineDS - Patchcord SM SX 3MM SCAPC LCAPC G657A1navin2617Nessuna valutazione finora

- THRUMAXX ZPL DoP 30551rev1 EngDocumento3 pagineTHRUMAXX ZPL DoP 30551rev1 EngRicardo MagalhãesNessuna valutazione finora

- Sunon: Specification For ApprovalDocumento14 pagineSunon: Specification For ApprovalVictor Mihai Oglinda ElivicNessuna valutazione finora

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocumento3 pagineE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNessuna valutazione finora

- SM Series: Aluminium Electrolytic CapacitorDocumento2 pagineSM Series: Aluminium Electrolytic CapacitorStuxnetNessuna valutazione finora

- Electromagnetic Water Meter CompressedDocumento4 pagineElectromagnetic Water Meter CompressedDavi RebouçasNessuna valutazione finora

- Hot Strip Mill Product TolerancesDocumento9 pagineHot Strip Mill Product TolerancesAyman Al AnsaryNessuna valutazione finora

- MMBD3004A/C/S: High Voltage Surface Mount Dual Switching DiodeDocumento5 pagineMMBD3004A/C/S: High Voltage Surface Mount Dual Switching DiodemrscribdNessuna valutazione finora

- LV TNB Aerial Bundle Cable ABC 1kvDocumento2 pagineLV TNB Aerial Bundle Cable ABC 1kvUntuk DiaNessuna valutazione finora

- Nicored 182 PDFDocumento1 paginaNicored 182 PDFDương Quang KhánhNessuna valutazione finora

- 8W DC-DC Regulated Single Output Converter: SeriesDocumento2 pagine8W DC-DC Regulated Single Output Converter: SerieskasiiiiiNessuna valutazione finora

- SUNON MF40201V1-1000U-G99 pg8Documento15 pagineSUNON MF40201V1-1000U-G99 pg8dkelicNessuna valutazione finora

- Nitrile Panel Leaf 032012Documento4 pagineNitrile Panel Leaf 032012Louis De KlerkNessuna valutazione finora

- Metco 470AW 10-632Documento8 pagineMetco 470AW 10-632JSH100Nessuna valutazione finora

- Ds Patchcord SX LCPC LCPC Om3Documento2 pagineDs Patchcord SX LCPC LCPC Om3navin2617Nessuna valutazione finora

- 1vap428831-Db SCBDocumento4 pagine1vap428831-Db SCBHoon MiewJieNessuna valutazione finora

- Sunon PF80251B1-0000-F99Documento14 pagineSunon PF80251B1-0000-F99Atharva Joshi.Nessuna valutazione finora

- G-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration NonwovensDocumento1 paginaG-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration Nonwovensfer17165Nessuna valutazione finora

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFDocumento6 pagineARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UNessuna valutazione finora

- Abb Spa COMEM Operating UnitDocumento8 pagineAbb Spa COMEM Operating UnitiamlpNessuna valutazione finora

- JazeeraDocumento38 pagineJazeeraaegon1510Nessuna valutazione finora

- Magnum  PE Corrugated Pipe SN8 DN-OD Outer DiametersDocumento3 pagineMagnum  PE Corrugated Pipe SN8 DN-OD Outer DiametersOsama sayedNessuna valutazione finora

- Catalogue WP-SDC Plus NewDocumento4 pagineCatalogue WP-SDC Plus NewMirko HTNessuna valutazione finora

- 2 Fcaw-AllDocumento51 pagine2 Fcaw-AllAhmad ShaheenNessuna valutazione finora

- S355G10 GBDocumento4 pagineS355G10 GBH41GAMINGNessuna valutazione finora

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocumento2 pagineTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373Nessuna valutazione finora

- 100 CR 62Documento4 pagine100 CR 62dadNessuna valutazione finora

- Turbine Flow MeterDocumento33 pagineTurbine Flow MeterPandeyNessuna valutazione finora

- Angle Bar 130x130x9mm Mill CertificateDocumento1 paginaAngle Bar 130x130x9mm Mill Certificatepstechnical_43312697100% (2)

- MF40101VX-1000U-A99 (Peltier Module 40x40 Fan)Documento15 pagineMF40101VX-1000U-A99 (Peltier Module 40x40 Fan)Mounica SNessuna valutazione finora

- 3.6.1 Busduct (Jis)Documento29 pagine3.6.1 Busduct (Jis)Kristine Grace LimatoNessuna valutazione finora

- A2L-A4L Data Sheet en 01Documento10 pagineA2L-A4L Data Sheet en 01zibbex555Nessuna valutazione finora

- Download: Ratings & CharacteristicsDocumento2 pagineDownload: Ratings & CharacteristicsaylinaykanNessuna valutazione finora

- Dokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfDocumento2 pagineDokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfraduonoNessuna valutazione finora

- It6427-0409 SMDocumento24 pagineIt6427-0409 SMavalente112100% (1)

- 3M Cold Shrink Silicone Rubber Outdoor Termination Kit QT-III 7600-S-3W SeriesDocumento12 pagine3M Cold Shrink Silicone Rubber Outdoor Termination Kit QT-III 7600-S-3W SeriesING CASTILLONessuna valutazione finora

- Metso Dust Hood DetailsDocumento9 pagineMetso Dust Hood DetailsmbaalaajeNessuna valutazione finora

- ENCHUFES CONECTORES 15kV AS - NZS-POWERMAXDocumento18 pagineENCHUFES CONECTORES 15kV AS - NZS-POWERMAXJuan AdrianzenNessuna valutazione finora

- MMDX SMMDX Series-1661233Documento12 pagineMMDX SMMDX Series-1661233Pușcă MartinNessuna valutazione finora

- Nickel Based ElectrodeDocumento1 paginaNickel Based Electrodewalter091011Nessuna valutazione finora

- NMS1217-Plus-neon SPI&DMX512) Specification-A02Documento10 pagineNMS1217-Plus-neon SPI&DMX512) Specification-A02SALV2049Nessuna valutazione finora

- 20NiMo9-7 - Liga MetálicaDocumento4 pagine20NiMo9-7 - Liga MetálicalutherblackNessuna valutazione finora

- RK0S RK0SPB - 25CrMo4 Nr.1.7218 25CrMoS4 Nr.1.7213 ENG PDFDocumento2 pagineRK0S RK0SPB - 25CrMo4 Nr.1.7218 25CrMoS4 Nr.1.7213 ENG PDFtosse atanasovNessuna valutazione finora

- CEWELD - 308LSi TIGDocumento1 paginaCEWELD - 308LSi TIGFilipe CordeiroNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDa EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNessuna valutazione finora

- Hardfacing Wood Chipper KnivesDocumento1 paginaHardfacing Wood Chipper KnivescwiksjNessuna valutazione finora

- N004 - Daiko Strip 625Documento1 paginaN004 - Daiko Strip 625cwiksjNessuna valutazione finora

- Specifications: Product TypeDocumento1 paginaSpecifications: Product TypecwiksjNessuna valutazione finora

- Specifications: Product TypeDocumento1 paginaSpecifications: Product TypecwiksjNessuna valutazione finora

- Carboklad Cr36 Data SheetDocumento1 paginaCarboklad Cr36 Data SheetcwiksjNessuna valutazione finora

- Robo TiPTiG Data Sheet FinalDocumento2 pagineRobo TiPTiG Data Sheet FinalcwiksjNessuna valutazione finora

- IN150 ProHeat 35 WaterCooled Induction System EnglishDocumento4 pagineIN150 ProHeat 35 WaterCooled Induction System EnglishCARLOSNessuna valutazione finora

- Meeting Minutes Roberts RulesDocumento1 paginaMeeting Minutes Roberts RulessaeedNessuna valutazione finora

- A Max WearplateDocumento1 paginaA Max WearplatecwiksjNessuna valutazione finora

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocumento3 pagineRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNessuna valutazione finora

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocumento3 pagineRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNessuna valutazione finora

- Wb2092e E7024Documento1 paginaWb2092e E7024cwiksjNessuna valutazione finora

- Utp 068 HHDocumento1 paginaUtp 068 HHRoberto_PrrNessuna valutazione finora

- Metrode WPS SuperduplexDocumento4 pagineMetrode WPS SuperduplexClaudia Mms100% (3)

- Wb2318e E9018-MDocumento1 paginaWb2318e E9018-McwiksjNessuna valutazione finora

- Wb1700e Enicu-BDocumento1 paginaWb1700e Enicu-BcwiksjNessuna valutazione finora

- Wb1700e Enicu-BDocumento1 paginaWb1700e Enicu-BcwiksjNessuna valutazione finora

- Wb2092e E7024Documento1 paginaWb2092e E7024cwiksjNessuna valutazione finora

- WB5525E ENiCrMo-5Documento1 paginaWB5525E ENiCrMo-5cwiksjNessuna valutazione finora

- WB4303EDocumento1 paginaWB4303EcwiksjNessuna valutazione finora

- Wb1700e Enicu-BDocumento1 paginaWb1700e Enicu-BcwiksjNessuna valutazione finora

- M.M.A. Welding ElectrodeDocumento1 paginaM.M.A. Welding ElectrodecwiksjNessuna valutazione finora

- Wb2092e E7024Documento1 paginaWb2092e E7024cwiksjNessuna valutazione finora

- Wb4606e E312-17Documento1 paginaWb4606e E312-17cwiksjNessuna valutazione finora

- Wb1500e Eni CiDocumento1 paginaWb1500e Eni CicwiksjNessuna valutazione finora

- Wb2092e E7024Documento1 paginaWb2092e E7024cwiksjNessuna valutazione finora

- Wb2092e E7024Documento1 paginaWb2092e E7024cwiksjNessuna valutazione finora

- Wb1500e Eni CiDocumento1 paginaWb1500e Eni CicwiksjNessuna valutazione finora

- Wb2000e E6013Documento1 paginaWb2000e E6013cwiksjNessuna valutazione finora

- Show Brazing AluminiumDocumento6 pagineShow Brazing Aluminiumneptuno97Nessuna valutazione finora

- Scanned Indian Standards List PDFDocumento30 pagineScanned Indian Standards List PDFJignesh Trivedi50% (2)

- Machine Design Examination 11Documento4 pagineMachine Design Examination 11SYBRELLE CRUZNessuna valutazione finora

- Esab Xpert 7018 Low Hydrogen ElectrodeDocumento1 paginaEsab Xpert 7018 Low Hydrogen ElectrodeAbu Anas M.SalaheldinNessuna valutazione finora

- 1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesDocumento2 pagine1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesaravindanNessuna valutazione finora

- Board To Board ConnectorsDocumento38 pagineBoard To Board Connectorsjagadees21Nessuna valutazione finora

- Astm A325 PDFDocumento8 pagineAstm A325 PDFRameez Bilwani100% (1)

- ME 303 (Manufacturing Engineering) - 08 - Machining IIDocumento38 pagineME 303 (Manufacturing Engineering) - 08 - Machining IITt OwnsqqNessuna valutazione finora

- TGN-M-04 Weld Procedure Comparison Struc SteelDocumento5 pagineTGN-M-04 Weld Procedure Comparison Struc Steelmanoj983@gmail.comNessuna valutazione finora

- Cswip 3.1Documento8 pagineCswip 3.1AnandNessuna valutazione finora

- Alloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDocumento6 pagineAlloy Steel Socket Button and Flat Countersunk Head Cap ScrewskrutikNessuna valutazione finora

- ARAMCO Interview 2015 PDFDocumento15 pagineARAMCO Interview 2015 PDFm.srinivasanNessuna valutazione finora

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-MoDocumento3 pagineMCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-Mobaskaran ayyapparajNessuna valutazione finora

- Global Overview of Ore-Based Metallics: Amm Dri & Mini-Mills Conference - November 2017Documento30 pagineGlobal Overview of Ore-Based Metallics: Amm Dri & Mini-Mills Conference - November 2017NtlNessuna valutazione finora

- 1233051969ct 109 Smelter ContractsDocumento4 pagine1233051969ct 109 Smelter ContractsZVIKOMBORERONessuna valutazione finora

- 15CrMo Alloy Steel TubeDocumento5 pagine15CrMo Alloy Steel TubeIbnu KhusnaNessuna valutazione finora

- Thyssenkrupp General Product Range Steel 2015 1Documento104 pagineThyssenkrupp General Product Range Steel 2015 1droessaert_stijnNessuna valutazione finora

- DRAFT Sample Welding Procedure GuidebookDocumento3 pagineDRAFT Sample Welding Procedure Guidebookahmad100% (1)

- Ma3022 Propeller Drydockingworks 1 Aug05Documento18 pagineMa3022 Propeller Drydockingworks 1 Aug05NAGENDRA KUMAR DNessuna valutazione finora

- E/Aod: According To en 10204Documento1 paginaE/Aod: According To en 10204agungNessuna valutazione finora

- Magnesium Alloys: Raw Material ProductionDocumento25 pagineMagnesium Alloys: Raw Material Productionmohamad hafizNessuna valutazione finora

- Science and Industry of Processes For Zinc-Based Coatings With Improved PropertiesDocumento34 pagineScience and Industry of Processes For Zinc-Based Coatings With Improved PropertiesAmirtharaaj VijayanNessuna valutazione finora

- Processing and Recycling in Mining andDocumento2 pagineProcessing and Recycling in Mining andHenockNessuna valutazione finora

- UNS Numbering SystemDocumento3 pagineUNS Numbering SystemorlomontNessuna valutazione finora

- Guide To Aluminium WeldingDocumento3 pagineGuide To Aluminium WeldingManish SharmaNessuna valutazione finora

- Huck Brochure enDocumento7 pagineHuck Brochure enLargyla Torres MendesNessuna valutazione finora

- Revised Draft Ammendment To IRS T29 MAR13Documento11 pagineRevised Draft Ammendment To IRS T29 MAR13Shipra MishraNessuna valutazione finora

- Filing, Marking, Cutting, Drilling, Taping, and Dyeing - Reprot - The FINAL ReportDocumento22 pagineFiling, Marking, Cutting, Drilling, Taping, and Dyeing - Reprot - The FINAL ReportBabong KobNessuna valutazione finora

- Alloy AllDocumento66 pagineAlloy AllBang OchimNessuna valutazione finora

- Steel Beams Astm A36Documento4 pagineSteel Beams Astm A36bat mananaNessuna valutazione finora