Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

JH Step 1 Audit Sheet

Caricato da

Heena Gulati (Quality)0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

60 visualizzazioni2 pagineThis document appears to be an audit sheet for the first step of Jishu-Hozan, which is a method for autonomous maintenance, at the Ispat Industries plant. It evaluates 10 areas on a machine based on passing percentages for different audit levels. Area 1 assesses cleaning, area 2 checks for leaks, area 3 examines nuts and bolts, and so on, up to area 9 which reviews whether activity boards and processes are followed. Personnel are also evaluated on their understanding of autonomous maintenance and TPM concepts. The sheet is used by auditors to allocate marks in each area out of a total of 400 marks. Any deficiencies can result in a 25% reduction in marks for that area.

Descrizione originale:

Titolo originale

187348373-JH-Step-1-Audit-Sheet.xls

Copyright

© © All Rights Reserved

Formati disponibili

XLS, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document appears to be an audit sheet for the first step of Jishu-Hozan, which is a method for autonomous maintenance, at the Ispat Industries plant. It evaluates 10 areas on a machine based on passing percentages for different audit levels. Area 1 assesses cleaning, area 2 checks for leaks, area 3 examines nuts and bolts, and so on, up to area 9 which reviews whether activity boards and processes are followed. Personnel are also evaluated on their understanding of autonomous maintenance and TPM concepts. The sheet is used by auditors to allocate marks in each area out of a total of 400 marks. Any deficiencies can result in a 25% reduction in marks for that area.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

60 visualizzazioni2 pagineJH Step 1 Audit Sheet

Caricato da

Heena Gulati (Quality)This document appears to be an audit sheet for the first step of Jishu-Hozan, which is a method for autonomous maintenance, at the Ispat Industries plant. It evaluates 10 areas on a machine based on passing percentages for different audit levels. Area 1 assesses cleaning, area 2 checks for leaks, area 3 examines nuts and bolts, and so on, up to area 9 which reviews whether activity boards and processes are followed. Personnel are also evaluated on their understanding of autonomous maintenance and TPM concepts. The sheet is used by auditors to allocate marks in each area out of a total of 400 marks. Any deficiencies can result in a 25% reduction in marks for that area.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

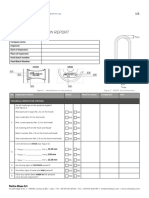

ISPAT INDUSTRIES

JISHU-HOZEN AUDIT SHEET(1st STEP)

DEPT: M/C:

Obtained % REMARKS

S.No Audit Levels Passing %

L1 L2 L3

1 L1 - Self Audit 90

2 L2 - Audit by Sectional Head 80

3 L3 - Audit by TPM Secretariat 80

Item Marks Allocated Marks Obtained

1 If the cleaning is through? 30

1.1 Floor below and around the machine. 15

1.2 Any other areas. 15

Any oil / air/ water leakages

2 50

observed?

Are nuts/bolts properly

3 provided? 50

3.1 Missing 10

3.2 Loose 10

3.3 Without Washer (Where Applicable) 10

3.4 Non standard 10

3.5 Of more than required length 10

4 Wire/cable/electrical 50

4.1 Any loose wires/cables 10

4.2 Loose wire/cable more than required length 10

4.3 Without glands (Where Applicable) 10

4.4 Wires/cables tied without clamps 10

4.5 Panels/covers not fully sealed/closed. 10

5 Items arround Machine 20

Any item arround machine without allocated

5.1 place 20

6 Unsafe conditions 60

6.1 Safety gaurds not available 15

Safety guard provided but may cause

6.2 15

accident

6.3 Floor around m/c with pits & projections 15

6.4 Sllipery areas around machine 15

7 Unaccessible areas identified 20

7.1 Hard to see 5

7.2 Hard to perform 5

7.3 Hard to clean 5

7.4 Hard to lubricate 5

If the personnel associated with the

8 m/c (claener/operator/ 60

supervisor/manager) clear about

TPM.

8.1 What is Autonomous Maintenance? 20

What is 1st step of Autonomous

8.2 Maintenance? 20

8.3 What are the defects and type of defects? 20

9 If Activity Board provided and 60

process followed?

9.1 Team Member. 7

Manager Model Machine marked with yellow

9.2 7

line.

9.3 Pre tentative Standards. 7

9.4 Attendance sheet. 7

9.5 Individual attendance. 7

9.6 Fugai(Defect sheet) 7

9.7 Classification defect 7

9.8 Gains & 1st step 11

TOTAL 400

TPM Secretariat JH 01/1/NOV02

ISPAT INDUSTRIES

* For every one incidence reduce 25% Marks Signature:

Auditor:

Audit Date:

TPM Secretariat JH 01/1/NOV02

Potrebbero piacerti anche

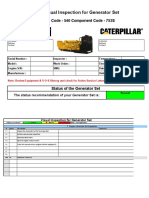

- TA1 English - Generator SetDocumento13 pagineTA1 English - Generator Setahmad adelNessuna valutazione finora

- Meditation For AddictionDocumento2 pagineMeditation For AddictionharryNessuna valutazione finora

- Contract of Lease (711) - AguilarDocumento7 pagineContract of Lease (711) - AguilarCoy Resurreccion Camarse100% (2)

- PsychometricsDocumento4 paginePsychometricsCor Villanueva33% (3)

- Information: Republic of The Philippines Regional Trial Court 8 Judicial Region Branch VIDocumento2 pagineInformation: Republic of The Philippines Regional Trial Court 8 Judicial Region Branch VIlossesaboundNessuna valutazione finora

- BOD2 - User Instructions - V3 - 2020 - 06Documento60 pagineBOD2 - User Instructions - V3 - 2020 - 06Julia Montelin Powers100% (1)

- The Permission Wheel Hawkes L PDFDocumento8 pagineThe Permission Wheel Hawkes L PDFNandita Asthana SankerNessuna valutazione finora

- Motorola p7382-p7389 Level3 SMDocumento58 pagineMotorola p7382-p7389 Level3 SMd.petiNessuna valutazione finora

- Fernau Dme 2020Documento60 pagineFernau Dme 2020srybsantosNessuna valutazione finora

- Progress Piping CLDocumento64 pagineProgress Piping CLAnggi Sepha PraditaNessuna valutazione finora

- Understanding and Servicing Alarm SystemsDa EverandUnderstanding and Servicing Alarm SystemsValutazione: 1 su 5 stelle1/5 (1)

- Land Building and MachineryDocumento26 pagineLand Building and MachineryNathalie Getino100% (1)

- Chapter 10 Recommended Practice For ESP Failure Analysis PDFDocumento64 pagineChapter 10 Recommended Practice For ESP Failure Analysis PDFedwinNessuna valutazione finora

- FmeaDocumento5 pagineFmeaBuiTrungNessuna valutazione finora

- Practical Industrial Data Networks: Design, Installation and TroubleshootingDa EverandPractical Industrial Data Networks: Design, Installation and TroubleshootingValutazione: 5 su 5 stelle5/5 (2)

- Inspeccion Ta1 Excavadora Caterpillar 320 DLDocumento21 pagineInspeccion Ta1 Excavadora Caterpillar 320 DLRAMON CALDERONNessuna valutazione finora

- Pea RubricDocumento4 paginePea Rubricapi-297637167Nessuna valutazione finora

- P54x en CommissioningDocumento126 pagineP54x en CommissioningChandra Dwi SaputraNessuna valutazione finora

- Mechanical Seal ReplacementDocumento4 pagineMechanical Seal ReplacementhussienkadhoemNessuna valutazione finora

- Introduction To Astronomical PhotometryDocumento452 pagineIntroduction To Astronomical PhotometrySergio Alejandro Fuentealba ZuñigaNessuna valutazione finora

- Rivertrace Manual 2015 - SseDocumento44 pagineRivertrace Manual 2015 - SseRomankoNessuna valutazione finora

- RWO Oily Water Separator PDFDocumento28 pagineRWO Oily Water Separator PDFИван БугаенкоNessuna valutazione finora

- JH Step 1 Audit SheetDocumento2 pagineJH Step 1 Audit SheetSwayambhar Majumder67% (3)

- Chapter 8.2-A Commissioning of The Micom P220 RelayDocumento22 pagineChapter 8.2-A Commissioning of The Micom P220 RelayGaurang PatelNessuna valutazione finora

- Manual SmartcellDocumento34 pagineManual Smartcelldwight ferrer100% (1)

- Gaggia Brera Service ManualDocumento42 pagineGaggia Brera Service ManualKanen Coffee, LLC.Nessuna valutazione finora

- HRB-4 KULLANIM KILAVUZU - Tr.enDocumento73 pagineHRB-4 KULLANIM KILAVUZU - Tr.enHaidar Sareeni0% (1)

- SRL CompressorsDocumento20 pagineSRL Compressorssthe03Nessuna valutazione finora

- 109080-x Smart Cell - Bilge - Manual High ResDocumento36 pagine109080-x Smart Cell - Bilge - Manual High ResDandy IkhwalNessuna valutazione finora

- Alfa Laval Seperator PDFDocumento316 pagineAlfa Laval Seperator PDFjohn kenneth vasquez vasquezNessuna valutazione finora

- Verb To Be ExerciseDocumento6 pagineVerb To Be Exercisejhon jairo tarapues cuaycalNessuna valutazione finora

- Commander 1000Documento6 pagineCommander 1000locoboeingNessuna valutazione finora

- Blue 7 TPM Part 2 of 2Documento14 pagineBlue 7 TPM Part 2 of 2shamelnaNessuna valutazione finora

- At1 - ExcavadoraDocumento14 pagineAt1 - ExcavadoraFREDDY NICOLAS ESCOBEDO LOZANONessuna valutazione finora

- English ForkliftDocumento2 pagineEnglish Forkliftwei heNessuna valutazione finora

- NGC - Asc OduDocumento90 pagineNGC - Asc OduSUNILNessuna valutazione finora

- Translation of The Original Operating Manual: Epg-Sprint XeDocumento100 pagineTranslation of The Original Operating Manual: Epg-Sprint XePatricio Exequiel Silva ColileoNessuna valutazione finora

- Documentatie Foamico R3 Uk - Mo 0122 - Mo 0122 D - Mo 0122 FD 22-11-2011Documento26 pagineDocumentatie Foamico R3 Uk - Mo 0122 - Mo 0122 D - Mo 0122 FD 22-11-2011Dascalu ValentinNessuna valutazione finora

- Capa 8DDocumento3 pagineCapa 8DVinod Kumar SharmaNessuna valutazione finora

- Hydrolux HL 500 Pro H2 1Documento30 pagineHydrolux HL 500 Pro H2 1muhammad adibNessuna valutazione finora

- Procedure: "Straight Beam/Angle Beam Manual Ultrasonic Testing"Documento21 pagineProcedure: "Straight Beam/Angle Beam Manual Ultrasonic Testing"mangalraj900Nessuna valutazione finora

- FSW10 Pallet Wrapping Machine Operation Manual: Machine Model Date IssueDocumento15 pagineFSW10 Pallet Wrapping Machine Operation Manual: Machine Model Date IssueEMRE KAAN USTANessuna valutazione finora

- Anant SPG MOM 7-08-18Documento4 pagineAnant SPG MOM 7-08-18Abhimanyu Singh ChundawatNessuna valutazione finora

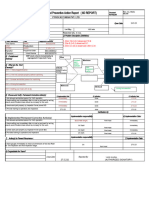

- Field Service Report: Table of ContentsDocumento5 pagineField Service Report: Table of Contentsrasyid alamNessuna valutazione finora

- WASPL - Yearly Inspection Report - enDocumento2 pagineWASPL - Yearly Inspection Report - enMayara WolffNessuna valutazione finora

- VS3 - Rework - Reject Loop 2Documento10 pagineVS3 - Rework - Reject Loop 2tozzitag7Nessuna valutazione finora

- Anirudh Acharya FA Exp 1Documento5 pagineAnirudh Acharya FA Exp 1Anirudh AcharyaNessuna valutazione finora

- PWH#3 No JOB ReasonDocumento12 paginePWH#3 No JOB ReasonAri WibowoNessuna valutazione finora

- Dishwasher Evo3: Service ManualDocumento54 pagineDishwasher Evo3: Service ManualGaborNessuna valutazione finora

- User Manual 80 - Pro - ENDocumento48 pagineUser Manual 80 - Pro - ENPathmanathan KandasamyNessuna valutazione finora

- Equipment System Equipment Tag / Name Working Contents Planned Date Progress Avaliable ScheduleDocumento1 paginaEquipment System Equipment Tag / Name Working Contents Planned Date Progress Avaliable ScheduleLim ChsNessuna valutazione finora

- Conv - 0039-384-R-100-R0 ODME manualAPPFDocumento141 pagineConv - 0039-384-R-100-R0 ODME manualAPPFTammy Jim TanjutcoNessuna valutazione finora

- Epgsprint XeDocumento100 pagineEpgsprint XeMartin ProbaNessuna valutazione finora

- E10 User Manual - V1.15 - E10 User ManualDocumento28 pagineE10 User Manual - V1.15 - E10 User ManualThiago Teixeira PiresNessuna valutazione finora

- Anant Corr. MOM 7-08-18Documento4 pagineAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNessuna valutazione finora

- Coal Mill Maintenance - UtkalDocumento3 pagineCoal Mill Maintenance - UtkalPankajNessuna valutazione finora

- Manual Inst Ows Amita 1Documento29 pagineManual Inst Ows Amita 1Shahrul ShafiqNessuna valutazione finora

- Service Report Monark: Dealer Process 9 1 1 5Documento4 pagineService Report Monark: Dealer Process 9 1 1 5Resa Ken BorresNessuna valutazione finora

- Edinburgh Airport vMATS 2020 08Documento42 pagineEdinburgh Airport vMATS 2020 08bob johnsomNessuna valutazione finora

- t1165 e Instructions For Use 2201Documento16 paginet1165 e Instructions For Use 2201Rico AndrianNessuna valutazione finora

- StupDocumento29 pagineStupNour BenNessuna valutazione finora

- ADV-PLUS Operator Manual - SO8816Documento39 pagineADV-PLUS Operator Manual - SO8816BiomedicaNessuna valutazione finora

- TA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753TDocumento22 pagineTA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753Tahmed el sayedNessuna valutazione finora

- Folien Berger Banerjee Final 2Documento27 pagineFolien Berger Banerjee Final 2biruk deribeNessuna valutazione finora

- TA1 English - Electric Rope Shovel - RopeCrowdv2 8.6.14Documento24 pagineTA1 English - Electric Rope Shovel - RopeCrowdv2 8.6.14cristian chuquicondor torresNessuna valutazione finora

- 4.5m Earth Station Antenna: Assembly, Installation, Operations, & Maintenance ManualDocumento29 pagine4.5m Earth Station Antenna: Assembly, Installation, Operations, & Maintenance ManualBobga DanjumaNessuna valutazione finora

- LIAG-LÄUFER International AG: DocumentationDocumento35 pagineLIAG-LÄUFER International AG: DocumentationFrancisco OchoaNessuna valutazione finora

- Technical Analysis 1 (TA1) Visual Inspection For Wheel LoadersDocumento18 pagineTechnical Analysis 1 (TA1) Visual Inspection For Wheel Loadershidekel crafort vinicioNessuna valutazione finora

- 230HB Petrol OM Manual English 1Documento66 pagine230HB Petrol OM Manual English 1flabberNessuna valutazione finora

- Model 9500 Dissolved Oxygen Meter Operating Manual: 950 050/REV A/04-03Documento5 pagineModel 9500 Dissolved Oxygen Meter Operating Manual: 950 050/REV A/04-03Sara ShNessuna valutazione finora

- Duterte Vs SandiganbayanDocumento17 pagineDuterte Vs SandiganbayanAnonymous KvztB3Nessuna valutazione finora

- What Is An Ethical Dilemma?: Decision-Making ProcessDocumento7 pagineWhat Is An Ethical Dilemma?: Decision-Making ProcessGauravsNessuna valutazione finora

- Allen F. y D. Gale. Comparative Financial SystemsDocumento80 pagineAllen F. y D. Gale. Comparative Financial SystemsCliffordTorresNessuna valutazione finora

- Elements of PoetryDocumento5 pagineElements of PoetryChristian ParkNessuna valutazione finora

- Curriculum Vitae: Personal InformationDocumento2 pagineCurriculum Vitae: Personal InformationtyasNessuna valutazione finora

- Name: Nur Hashikin Binti Ramly (2019170773) Course Code: Udm713 - Decision Making Methods and Analysis Assignment Title: Need Gap AnalysisDocumento2 pagineName: Nur Hashikin Binti Ramly (2019170773) Course Code: Udm713 - Decision Making Methods and Analysis Assignment Title: Need Gap AnalysisAhmad HafizNessuna valutazione finora

- Positive Accounting TheoryDocumento47 paginePositive Accounting TheoryAshraf Uz ZamanNessuna valutazione finora

- VIII and IXDocumento56 pagineVIII and IXTinn ApNessuna valutazione finora

- Img - Oriental Magic by Idries Shah ImageDocumento119 pagineImg - Oriental Magic by Idries Shah ImageCarolos Strangeness Eaves100% (2)

- Prof. Monzer KahfDocumento15 pagineProf. Monzer KahfAbdulNessuna valutazione finora

- Ra 7877Documento16 pagineRa 7877Anonymous FExJPnCNessuna valutazione finora

- Describe The Forms of Agency CompensationDocumento2 pagineDescribe The Forms of Agency CompensationFizza HassanNessuna valutazione finora

- Repair and Field Service BrochureDocumento4 pagineRepair and Field Service Brochurecorsini999Nessuna valutazione finora

- Taxation: Presented By: Gaurav Yadav Rishabh Sharma Sandeep SinghDocumento32 pagineTaxation: Presented By: Gaurav Yadav Rishabh Sharma Sandeep SinghjurdaNessuna valutazione finora

- CebuanoDocumento1 paginaCebuanoanon_58478535150% (2)

- Research PaperDocumento9 pagineResearch PaperMegha BoranaNessuna valutazione finora

- Cover Letter For Lettings Negotiator JobDocumento9 pagineCover Letter For Lettings Negotiator Jobsun1g0gujyp2100% (1)

- 1 Piling LaranganDocumento3 pagine1 Piling LaranganHannie Jane Salazar HerreraNessuna valutazione finora

- KB000120-MRK456-01-HR SamplingDocumento15 pagineKB000120-MRK456-01-HR SamplingMiguel Zuniga MarconiNessuna valutazione finora

- Designing HPE Server Solutions: Supporting ResourcesDocumento3 pagineDesigning HPE Server Solutions: Supporting ResourcesKARTHIK KARTHIKNessuna valutazione finora