Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Abs Rules - 2844

Caricato da

rishabhk28995Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Abs Rules - 2844

Caricato da

rishabhk28995Copyright:

Formati disponibili

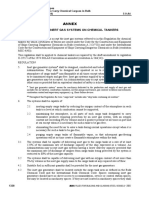

Part 5 Specific Vessel Types

Chapter 10 Vessels Intended to Carry Vehicles

Section 2 Vehicle Carrier 5-10-2

5.3 Strength

All cargo conditions are to be investigated on the basis of the following:

5.3.1

Cargo load due to static and dynamic forces based on a roll angle of 30 degrees and a period

of 10 seconds. Other values may be considered based on direct calculations.

5.3.2

Static sea pressure to the waterline in the heeled condition.

5.3.3

In general, the calculations are to be based on a 3D FEM analysis of the typical transverse

structure of the vessel between two main transverse bulkheads.

Where deck girders are arranged as indicated in 5-10-2/5.1, assessment of the transverse

strength of the structure at locations other than where the FEM analysis is carried out is to be

based on the results of the FEM analysis, particularly with reference to the effectiveness of

the longitudinal girders to evenly distribute the vehicle wheel loads onto the deck transverses.

5.3.4 Allowable Stresses

Henky-von Mises 0.80 of the minimum yield strength of the material

Shear stress 0.37 of the minimum yield strength of the material (*)

* Higher shear stress may be acceptable, provided that resultant Henky-von Mises stress is within the allowable

limit.

5.3.5

The effective width of deck plating to be used in determining the section modulus, and

moment of inertia of the deck transverses is to comply with 5-10-2/11.7.1.

7 Bottom Structure

Bottom structures are to be in accordance with Section 3-2-4.

9 Side Construction

9.1 General

The side shell up to the strength deck is generally to be longitudinally framed. The shell plating and

framing are to be in accordance with the following:

9.3 Shell Plating

Shell plating below the freeboard deck is to be in accordance with Section 3-2-2, where Ds is as given

in 3-2-2/3.

Side shell plating for 2.3 m (7.5 ft) above the freeboard deck is to be in accordance with 3-2-2/3.9,

however, 3-2-2/5.1 is not applicable. At the forward and after ends, the plating for 0.1L from each end

may be of the thickness obtained from 3-2-2/5.7 and 3-2-2/5.9 for forecastle and poop side plating,

respectively.

1342 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Marine InsightDocumento20 pagineMarine Insightshubham100% (4)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Silent Victory Rules (En)Documento28 pagineSilent Victory Rules (En)Frank MasonNessuna valutazione finora

- Discovery Topsail CutterDocumento5 pagineDiscovery Topsail CutterJim89% (19)

- This Study Resource Was: Cluster 4: Workplace AssignmentDocumento5 pagineThis Study Resource Was: Cluster 4: Workplace Assignmentrishabhk28995Nessuna valutazione finora

- Ship Design ConstructionDocumento23 pagineShip Design Constructionfarhan_8231% (16)

- Class 1 UK PDFDocumento7 pagineClass 1 UK PDFArun SNessuna valutazione finora

- The Docking Procedure: Duties of Ship's Master During Controlled Entry Into A DockDocumento5 pagineThe Docking Procedure: Duties of Ship's Master During Controlled Entry Into A DockBhupender RamchandaniNessuna valutazione finora

- Aba-Aba Mengemudi (Steering Order) : NO Command Meaning NoteDocumento7 pagineAba-Aba Mengemudi (Steering Order) : NO Command Meaning NoteMandaCinta100% (2)

- Ships Particulars Updated 2017Documento2 pagineShips Particulars Updated 2017Alex BelgraveNessuna valutazione finora

- This Study Resource Was: Cluster 4: Written AssignmentDocumento5 pagineThis Study Resource Was: Cluster 4: Written Assignmentrishabhk28995100% (1)

- Cluster 5: Written Assignment: Before Completing and Submitting This Assignment, Have You: What You Have To DoDocumento10 pagineCluster 5: Written Assignment: Before Completing and Submitting This Assignment, Have You: What You Have To Dorishabhk28995100% (1)

- Barrios v. Go Thong DigestDocumento1 paginaBarrios v. Go Thong DigestHershey Delos SantosNessuna valutazione finora

- Dana24 BrochureDocumento7 pagineDana24 BrochureCristiAnNessuna valutazione finora

- SI SurveyorDocumento1 paginaSI SurveyorPrasetyoWaskitoNessuna valutazione finora

- LA021088 WRTN Assn CHC43315 Cluster 2Documento3 pagineLA021088 WRTN Assn CHC43315 Cluster 2rishabhk28995Nessuna valutazione finora

- UntitledDocumento1 paginaUntitledrishabhk28995Nessuna valutazione finora

- Abs Rules - 2847Documento1 paginaAbs Rules - 2847rishabhk28995Nessuna valutazione finora

- Abs Rules - 2855Documento1 paginaAbs Rules - 2855rishabhk28995Nessuna valutazione finora

- FAST Conference 2013 Paper ID 61 - The Wageningen C - and D-Series Propellers - Final VersionDocumento10 pagineFAST Conference 2013 Paper ID 61 - The Wageningen C - and D-Series Propellers - Final Versionsk&jtNessuna valutazione finora

- Abs Rules - 2830Documento1 paginaAbs Rules - 2830rishabhk28995Nessuna valutazione finora

- Part 7 E-Sept14 020Documento1 paginaPart 7 E-Sept14 020rishabhk28995Nessuna valutazione finora

- 1 Conditions For Survey After Construction 1 General InformationDocumento1 pagina1 Conditions For Survey After Construction 1 General Informationrishabhk28995Nessuna valutazione finora

- AHTSV Anchor Handling Tug Supply Vessel With 5150 BHP / 60 Bollard PullDocumento8 pagineAHTSV Anchor Handling Tug Supply Vessel With 5150 BHP / 60 Bollard PullEdwien Arif WicaksonoNessuna valutazione finora

- Communications USADocumento51 pagineCommunications USAPierre BonivardNessuna valutazione finora

- STSDocumento2 pagineSTSAndi0% (1)

- FLOATEL SUPERIOR SPECIFICATION DetailsDocumento2 pagineFLOATEL SUPERIOR SPECIFICATION DetailsIsmail ZainolNessuna valutazione finora

- Administrative Organization of The Operating Forces of The USDocumento31 pagineAdministrative Organization of The Operating Forces of The USJulian AssangeNessuna valutazione finora

- Planiranje PutovanjaDocumento54 paginePlaniranje PutovanjaRoby VukelicNessuna valutazione finora

- Important Burden of ProofDocumento2 pagineImportant Burden of ProofElaine HanNessuna valutazione finora

- Seam 3 - Mod 16Documento20 pagineSeam 3 - Mod 16Jonalyn CordovaNessuna valutazione finora

- Lord FranklinDocumento4 pagineLord FranklinLuc Van HendeNessuna valutazione finora

- 14-Nt (09) /2008 Dated: 29Th January, 2009Documento2 pagine14-Nt (09) /2008 Dated: 29Th January, 2009sidadams2Nessuna valutazione finora

- Bagian-Bagian CraneDocumento4 pagineBagian-Bagian CraneAmrina Rosyada MaydiningrumNessuna valutazione finora

- Isps Latest Ms Notice 19 of 2011Documento1 paginaIsps Latest Ms Notice 19 of 2011virendra302Nessuna valutazione finora

- Iso 12217-1 Calculation Worksheet No. 7 Heel Due To Wind Action Design Categories C and D OnlyDocumento1 paginaIso 12217-1 Calculation Worksheet No. 7 Heel Due To Wind Action Design Categories C and D Onlyyunus ahmet ilhanNessuna valutazione finora

- Deck Opt C15Documento15 pagineDeck Opt C15rheaangelasinutoNessuna valutazione finora

- Enns-Class: Schiffswerft LinzDocumento2 pagineEnns-Class: Schiffswerft LinzJerome BrusasNessuna valutazione finora

- ERS 2009-2012 CompleteDocumento46 pagineERS 2009-2012 CompleteJuarez OliveiraNessuna valutazione finora

- Asia Lightrage and Shipping Inc Vs CA and Prudential Guaramtee and Assurance IncDocumento3 pagineAsia Lightrage and Shipping Inc Vs CA and Prudential Guaramtee and Assurance IncDanica BlancheNessuna valutazione finora

- Panama Canal, Disruption ChargesDocumento2 paginePanama Canal, Disruption Chargesreynold deepakNessuna valutazione finora

- Flying Colors RULES-2014 PDFDocumento24 pagineFlying Colors RULES-2014 PDFleonidas_the_iiiNessuna valutazione finora