Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stainless Steel Needle Valve PN 400 F/F

Caricato da

OmarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stainless Steel Needle Valve PN 400 F/F

Caricato da

OmarCopyright:

Formati disponibili

REF.

481-487

STAINLESS STEEL NEEDLE VALVE PN 400 F/F

Certificate 3.1

Size : DN 1/4" to 1“

Ends : Female - Female BSP or NPT

Min Temperature : - 20°C

Max Temperature : + 180°C

Max Pressure : 400 Bars

Specifications : Rotating rising stem

1 piece type

Reduced bore

Materials : Stainless Steel EN 1.4408

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 05/19 Rev.08

Page 1 sur 6

Information provided as an indication and subject to possible modification

REF. 481-487

STAINLESS STEEL NEEDLE VALVE PN 400 F/F

SPECIFICATIONS :

Respect the flow direction ( indicated by the arrow )

Reduced bore

Rising rotating stem

1 piece type

Stainless steel type

6000 Psi type ( PN400 )

USE :

For common fluids of 2nd group

Min and max Temperature Ts : - 20°C to + 180°C

Max Pressure Ps : 400 bars ( see graph )

PRESSURE / TEMPERATURE GRAPH ( STEAM EXCLUDED ) :

FLOW COEFFICIENT Kvs ( m3 / h ) :

DN 1/4“ 3/8“ 1/2“ 3/4“ 1“

Kvs ( m3 / h ) 0.7 0.78 1.04 1.12 1.55

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 05/19 Rev.08

Page 2 sur 6

Information provided as an indication and subject to possible modification

REF. 481-487

STAINLESS STEEL NEEDLE VALVE PN 400 F/F

RANGE :

Stainless steel threaded female BSP cylindrical Ref. 481 from DN 1/4“ to DN 1“

Stainless steel threaded female NPT Ref. 487 from DN 1/4“ to DN 1“

MATERIALS :

Item Designation Materials

1 Body EN 1.4408

2 Bonnet ASTM A276-316

3 Packing PTFE

4 Packing nut AISI 304

5 Stem ASTM A276-316

6 Handle screw

AISI 304

7 Handle

8 O ring FKM

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 05/19 Rev.08

Page 3 sur 6

Information provided as an indication and subject to possible modification

REF. 481-487

STAINLESS STEEL NEEDLE VALVE PN 400 F/F

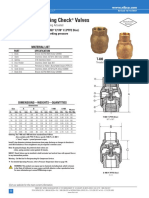

SIZE ( in mm ) :

Ref. DN 1/4" 3/8" 1/2" 3/4" 1"

L 45.5 59 65 70 80

L1 9.5 12 16.3 17 19

H ( closed ) 75 77 78 113 116

H ( opened ) 87.1 89.8 93.4 129.4 136.7

481/487 W on flat 22 25 30 35 45

ØD 5 5 6 8 8

Ø D1 6 6 6 8 8

ØP 5 6.3 8 10 12

Weight ( Kg ) 0.3 0.4 0.5 0.8 1.3

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 05/19 Rev.08

Page 4 sur 6

Information provided as an indication and subject to possible modification

REF. 481-487

STAINLESS STEEL NEEDLE VALVE PN 400 F/F

NUMBER OF TURNS TO CLOSE OR OPEN THE VALVE :

DN 1/4" 3/8" 1/2" 3/4" 1"

Nb of turns 8 9 11 8 12

STANDARDS :

Fabrication according to ISO 9001 : 2015

DIRECTIVE 2014/68/EU: Products excluded from directive (Article 4. § 3)

Certificate 3.1 on request

Pressure tests according to API 598, table 6

Threaded female BSP cylindrical ends according to ISO 7/1 Rp

Threaded female NPT ends according to AMSE B1.20.1

ATEX Group II Category 2 G/2D Zone 1 & 21 Zone 2 &22 ( optional marking ) according to directive

2014/34/EU

ADVICE : Our opinion and our advice are not guaranteed and SFERACO shall not be liable for the consequences of damages.

The customer must check the right choice of the products with the real service conditions.

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 05/19 Rev.08

Page 5 sur 6

Information provided as an indication and subject to possible modification

REF. 481-487

STAINLESS STEEL NEEDLE VALVE PN 400 F/F

INSTALLATION INSTRUCTIONS

GENERAL GUIDELINES :

Ensure that the valves to be used are appropriate for the conditions of the installation (type of

fluid,pressure and temperature).

Be sure to have enough valves to be able to isolate the sections of piping as well as the appropriate

equipment for maintenance and repair.

Ensure that the valves to be installed are of correct strenght to be able to support the capacity of their

usage.

Installation of all circuits should ensure that their function can be automatically tested on a regular

basis (at least two times a year).

INSTALLATION INSTRUCTIONS :

Before installing the valves,clean and remove any objects from the pipes (in particular bits of sealing

and metal) which could obstruct and block the valves.

Ensure that both connecting pipes either side of the valve (upstream and downstream) are aligned

(if they’re not,the valves may not work correctly).

Make sure that the two sections of the pipe (upstream and downstream) match,the valve unit will

not absorb any gaps.Any distortions in the pipes may affect the thightness of the connection,the

working of the valve and can even cause a rupture.To be sure,place the kit in position to ensure the

assembling will work.

The theoretical lengths given by ISO/R7 for the tapping are typically longer than required, the length of the

thread should be limited, and check that the end of the tube does not press right up to the head of the

thread.

Never use a vice to tighten the fixings of the valve.

If sections of piping do not have their final support in place,they should be temporarily fixed.This is

to avoid unnecessary strain on the valve.

It may be necessary to screw the packing gland during using according to the type of use.

Do not use a tool to shut the valve

Fluids in the valve must not contain solid objects ( it could damaged the seat ).

It’s recommended to operate the valve ( open and close ) 1 to 2 times per year

For an installation in ATEX area, check the conductivity between the valve, the upstream pipe and

the downstream pipe and make sure the pipe is connected to the earth.

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 05/19 Rev.08

Page 6 sur 6

Information provided as an indication and subject to possible modification

Potrebbero piacerti anche

- Zawor Iglicowy 488 Karta KatalogowaDocumento6 pagineZawor Iglicowy 488 Karta KatalogowacracoviamaszynaNessuna valutazione finora

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel BSP InitialDocumento6 pagineTechnical Datasheet 2 Pieces Ball Valve Stainless Steel BSP InitialBenny 37Nessuna valutazione finora

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Dry Cleaned Oxygen BSPDocumento6 pagineTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Dry Cleaned Oxygen BSPBenny 37Nessuna valutazione finora

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Male Female BSPDocumento6 pagineTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Male Female BSPBenny 37Nessuna valutazione finora

- Karta Katalogowa Zawor Kulowy 789Documento6 pagineKarta Katalogowa Zawor Kulowy 789Telmo EstrelaNessuna valutazione finora

- F L A N G e D S T A I N L e S S S T e e L S T R A I N e R P N 1 6Documento8 pagineF L A N G e D S T A I N L e S S S T e e L S T R A I N e R P N 1 6Miguel BentoNessuna valutazione finora

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Male Male BSPDocumento6 pagineTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Male Male BSPBenny 37Nessuna valutazione finora

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 BSPDocumento5 pagineTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 BSPBenny 37Nessuna valutazione finora

- TDS-765-Technical Datasheet 2 Pieces Splitbody Ball Valve Stainless Steel Dinf4-F5 pn16 40Documento12 pagineTDS-765-Technical Datasheet 2 Pieces Splitbody Ball Valve Stainless Steel Dinf4-F5 pn16 40ruiz sumarNessuna valutazione finora

- Ref.744 790 791 792 - enDocumento21 pagineRef.744 790 791 792 - enMikeNessuna valutazione finora

- CompressorwashingstrainerDocumento9 pagineCompressorwashingstraineraras aliNessuna valutazione finora

- Technical Datasheet 2 Pieces High Pressure Ball Valve Carbon Steel Female BSPDocumento8 pagineTechnical Datasheet 2 Pieces High Pressure Ball Valve Carbon Steel Female BSPBenny 37Nessuna valutazione finora

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTDocumento5 pagineTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTBenny 37Nessuna valutazione finora

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Solar High Temperature BSPDocumento6 pagineTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Solar High Temperature BSPBenny 37Nessuna valutazione finora

- Zawor 507 Karta-KatalogowaDocumento8 pagineZawor 507 Karta-KatalogowaKarolNessuna valutazione finora

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWDocumento5 pagineTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWBenny 37Nessuna valutazione finora

- Robinet Inox Cod 730Documento9 pagineRobinet Inox Cod 730RizzoRo1Nessuna valutazione finora

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 NPTDocumento5 pagineTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 NPTBenny 37Nessuna valutazione finora

- Fdez. Jove - Valvula 3 Vías - (SFERACO)Documento12 pagineFdez. Jove - Valvula 3 Vías - (SFERACO)Pedro VarelaNessuna valutazione finora

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel NPT Din m3Documento7 pagineTechnical Datasheet 2 Pieces Ball Valve Stainless Steel NPT Din m3Benny 37Nessuna valutazione finora

- 731 Technical - Datasheet - 3 - Pieces - Ball - Valve - Stainless - Steel - Flanged - pn40Documento8 pagine731 Technical - Datasheet - 3 - Pieces - Ball - Valve - Stainless - Steel - Flanged - pn40ruiz sumarNessuna valutazione finora

- Technical Datasheet Brass Ball Valve NF DVGW Green Handle BSPDocumento15 pagineTechnical Datasheet Brass Ball Valve NF DVGW Green Handle BSPBenny 37Nessuna valutazione finora

- Y-Strainer - Data SheetDocumento7 pagineY-Strainer - Data SheetŁukasz OlszewskiNessuna valutazione finora

- 2 Pieces Carbon Steel Ball Valve Pn63 Atex Din M3: Certificate 3.1Documento7 pagine2 Pieces Carbon Steel Ball Valve Pn63 Atex Din M3: Certificate 3.1LILA LAZARNessuna valutazione finora

- Technical Datasheet Gas Brass All Valve BSP NF RobgazDocumento5 pagineTechnical Datasheet Gas Brass All Valve BSP NF RobgazBenny 37Nessuna valutazione finora

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbsDocumento7 pagineTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbsBenny 37Nessuna valutazione finora

- 2 P I e C e S B A L L V A L V e C L A S S 8 0 0Documento6 pagine2 P I e C e S B A L L V A L V e C L A S S 8 0 0raulNessuna valutazione finora

- 494 - Stainless Steel Float ValvesDocumento6 pagine494 - Stainless Steel Float ValvesMohamed AldeebNessuna valutazione finora

- Technical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 800lbsDocumento7 pagineTechnical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 800lbsBenny 37Nessuna valutazione finora

- Technical Datasheet 2 Pieces Ball Valve Carbon Steel BSP Din m3Documento7 pagineTechnical Datasheet 2 Pieces Ball Valve Carbon Steel BSP Din m3Benny 37Nessuna valutazione finora

- Sorb Cu Clapeta 2Documento11 pagineSorb Cu Clapeta 2Cosmin BonghezNessuna valutazione finora

- Oetiker SC Serie eDocumento4 pagineOetiker SC Serie eHIDRAFLUIDNessuna valutazione finora

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWDocumento5 pagineTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWBenny 37Nessuna valutazione finora

- High Pressure Bar Stock Needle Valves: SHBNV SeriesDocumento2 pagineHigh Pressure Bar Stock Needle Valves: SHBNV SeriesToty DzNessuna valutazione finora

- Torcha Parker 400aDocumento1 paginaTorcha Parker 400aCristian Arias SepulvedaNessuna valutazione finora

- Integral Needle Valves SINV WebDocumento5 pagineIntegral Needle Valves SINV WebMEK MarineNessuna valutazione finora

- Oetiker SC Serie b1Documento5 pagineOetiker SC Serie b1HIDRAFLUIDNessuna valutazione finora

- Integral Bonnet Bar Stock Needle Valves: SBNV SeriesDocumento4 pagineIntegral Bonnet Bar Stock Needle Valves: SBNV SeriesToty DzNessuna valutazione finora

- Eng BD Fta731Documento19 pagineEng BD Fta731Lazar LilaNessuna valutazione finora

- Check Ranurado RH84X MechDocumento1 paginaCheck Ranurado RH84X MechFLOW INDUSTRIAL SACNessuna valutazione finora

- ART 1460 Rev1Documento1 paginaART 1460 Rev1mohdmmedniyaz786Nessuna valutazione finora

- Ptfe Flexible Joint: FeaturesDocumento5 paginePtfe Flexible Joint: FeaturesGatot NugrohoNessuna valutazione finora

- Series 45316 Flanged Globe ValveDocumento4 pagineSeries 45316 Flanged Globe ValveEmmanuelNessuna valutazione finora

- Series GBV100/101 - Stainless Steel: 1-pc Body Reduced Ball ValveDocumento1 paginaSeries GBV100/101 - Stainless Steel: 1-pc Body Reduced Ball ValveStan HonNessuna valutazione finora

- Howell H61 3pc SanitaryDocumento3 pagineHowell H61 3pc SanitaryyahsooyNessuna valutazione finora

- 783 784 785 786Documento8 pagine783 784 785 786lesonspkNessuna valutazione finora

- Material Identification: Part No. Description Material Q'ty Heat No. Cert NoDocumento4 pagineMaterial Identification: Part No. Description Material Q'ty Heat No. Cert Noคุณพ่อน้อง บิ๊กบอสNessuna valutazione finora

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbs Wedling EndsDocumento11 pagineTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbs Wedling EndsBenny 37Nessuna valutazione finora

- Valvulas SunDocumento1 paginaValvulas SunErickson AmpueroNessuna valutazione finora

- 4500 Series: Bellows Sealed Valves (0.156"/3.962 MM Orifice)Documento2 pagine4500 Series: Bellows Sealed Valves (0.156"/3.962 MM Orifice)dhaktodesatyajitNessuna valutazione finora

- VH86 Series High Pressure Multi Purpose Ball ValvesDocumento4 pagineVH86 Series High Pressure Multi Purpose Ball ValvesTran Duc DungNessuna valutazione finora

- TS480BIDocumento1 paginaTS480BITatiana Mejías SeguraNessuna valutazione finora

- BGS 20191103 PDFDocumento3 pagineBGS 20191103 PDFLuis AndrésNessuna valutazione finora

- I018 - Material Traceability Inspection Pipe SpoolDocumento24 pagineI018 - Material Traceability Inspection Pipe SpoolEka100% (1)

- Eng BD Fta301Documento9 pagineEng BD Fta301Lazar LilaNessuna valutazione finora

- Hose Type 4/2: Waterblast: HydraulicsDocumento4 pagineHose Type 4/2: Waterblast: HydraulicsClaudio AguirreNessuna valutazione finora

- Ball 2 PC Stainless Steel Cf8 (304) 2000 Psig Polyfill NPT: Design FeaturesDocumento1 paginaBall 2 PC Stainless Steel Cf8 (304) 2000 Psig Polyfill NPT: Design FeaturesJared D OminguezNessuna valutazione finora

- 1,000 Psi Full Port 3-Piece Ball Valve: DPV® Fig. 3F133SDocumento1 pagina1,000 Psi Full Port 3-Piece Ball Valve: DPV® Fig. 3F133SPradipta DwiNessuna valutazione finora

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Checklist Requirements Inthe Application MechanicalInstallation v2Documento1 paginaChecklist Requirements Inthe Application MechanicalInstallation v2Ges HuNessuna valutazione finora

- Rice FtirDocumento15 pagineRice FtirRavindra AgarwalNessuna valutazione finora

- Mechanical FailureDocumento52 pagineMechanical FailureDirkPons100% (5)

- Improving Solar Food DryersDocumento11 pagineImproving Solar Food Dryerspodbaydoor100% (1)

- BlackAndDeckerCircularSaw 7390Documento8 pagineBlackAndDeckerCircularSaw 7390wkinningcNessuna valutazione finora

- Composite Resin Layering and Placement TechniquesDocumento7 pagineComposite Resin Layering and Placement TechniquesenimaNessuna valutazione finora

- So Lubi LizerDocumento3 pagineSo Lubi LizerfushiersNessuna valutazione finora

- Advanced Lattice Support Structures For Metal Additive ManufacturingDocumento8 pagineAdvanced Lattice Support Structures For Metal Additive Manufacturinghadi32Nessuna valutazione finora

- China Display 2011 Kevin Long FINALDocumento29 pagineChina Display 2011 Kevin Long FINALPedro ReynosoNessuna valutazione finora

- Name of The Company: Columbia Wire and Cable Corporation Date of Tour: October 23, 2019 Overview of The CompanyDocumento3 pagineName of The Company: Columbia Wire and Cable Corporation Date of Tour: October 23, 2019 Overview of The CompanyJhun Michael LocusNessuna valutazione finora

- Chapter 4 - Plasticity of SoilDocumento15 pagineChapter 4 - Plasticity of SoilHussein EssaNessuna valutazione finora

- Wasca Disc Springs Catalogue 2014 PDFDocumento36 pagineWasca Disc Springs Catalogue 2014 PDFVahid ShNessuna valutazione finora

- ButylGlycol e 04 08Documento3 pagineButylGlycol e 04 08quimico10012812Nessuna valutazione finora

- Resists For Sub-20-Nm Electron Beam Lithography With A Focus On HSQ: State of The ArtDocumento32 pagineResists For Sub-20-Nm Electron Beam Lithography With A Focus On HSQ: State of The Artjake parkNessuna valutazione finora

- CR 828 Technical Data SheetDocumento1 paginaCR 828 Technical Data SheetHito Jimenez SalinasNessuna valutazione finora

- Support Details For ASHRAE Heat Load Calculation SheetDocumento8 pagineSupport Details For ASHRAE Heat Load Calculation SheetShravanNessuna valutazione finora

- Table of Contents-Heat Transfer Calculations-Myer KutzDocumento11 pagineTable of Contents-Heat Transfer Calculations-Myer Kutzpvr2k1100% (1)

- Laticrete 325 SW AdhesiveDocumento4 pagineLaticrete 325 SW AdhesiveAmeya MungaleNessuna valutazione finora

- Chapter 5 Steel and Metal Part 3Documento21 pagineChapter 5 Steel and Metal Part 3Joseph Cloyd LamberteNessuna valutazione finora

- A325n X SCDocumento1 paginaA325n X SCAnonymous ARMtmNKLNessuna valutazione finora

- b3850 Series Terminal Controllers: Andover ContinuumDocumento6 pagineb3850 Series Terminal Controllers: Andover ContinuumrbelduaNessuna valutazione finora

- Paraloid K 120ndDocumento7 pagineParaloid K 120ndkishanptlNessuna valutazione finora

- Taper Bushes: Instructions - Installation and RemovalDocumento2 pagineTaper Bushes: Instructions - Installation and RemovaldesetekNessuna valutazione finora

- 【Hail Netting】-Technical DATA SHEET - Raschel -TriangleDocumento1 pagina【Hail Netting】-Technical DATA SHEET - Raschel -TriangleVipul AgrawalNessuna valutazione finora

- Fillers in PVC - A Review of The Basics PDFDocumento4 pagineFillers in PVC - A Review of The Basics PDFN.B.PNessuna valutazione finora

- Charging SystemDocumento41 pagineCharging SystemazryNessuna valutazione finora

- Primal CM 219Documento7 paginePrimal CM 219Alaa Khaled MeetkeesNessuna valutazione finora

- Robitic WeldingDocumento23 pagineRobitic Weldingkhaled osmanNessuna valutazione finora

- Manual Electrolux LAVAMAT TURBO L 12720 VITDocumento52 pagineManual Electrolux LAVAMAT TURBO L 12720 VITGabriel LamartheeNessuna valutazione finora

- Chemistry of The Ironmaking by Blast Furnace Process - IspatguruDocumento7 pagineChemistry of The Ironmaking by Blast Furnace Process - IspatguruSanjeev Sahu100% (1)