Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Satr J 6510

Caricato da

munnaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Satr J 6510

Caricato da

munnaCopyright:

Formati disponibili

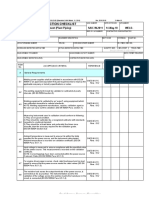

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.

Rev. 2018.03.00 31-Mar-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Instrument Loop Outputs - Relay / Contactor / Transducer

SATR-J-6510 14-May-18 INST

Operation and Trip Test

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

TEST PROCEDURE ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

A Dual Transducer Test Meter (Flow and Pressure)

Here we have discussed System Studies Transducer Test Meter

A1 (P/N9800-3600). Similar instructions are supplied with other product Vendor manual

to be followed.

It is also important to make sure the meter is zero adjusted before

A2 Vendor manual

taking readings and the battery does not show low battery indication

A3 Flow and pressure measurements must be made separately. Vendor manual

How to Test 4 to 20mA Monitoring Devices Using the Transducer Test Meter

1. Connect the meter’s red and black leads to the monitoring pair of

the device being measured. It is not important which leads are

A4 Vendor manual

connected to which conductor - unless you are testing devices on a

Selector Pair Saver™ device circuit

2. Evaluate the reading as indicated on the pressure or flow scale of

A5 the meter. For readings in the OPEN, 0, and SHORT scale regions, Vendor manual

see “Off-scale Readings.” [Attachment 1]

For pressure transducer output, use the values listed below the

curved scale on the gauge face. Reading increments are 0, 10, 20

and 30 PSI. Transducer output that falls between two indicated PSI

A6 values is estimated (Figure 3). Flow readings (numbers on top of Vendor manual

scale) are read as a fraction of the flow range listed on the Flow

Finder to which the transducer is connected. Flow Finder ranges are

0–95, 0–47.5, 0–19 and 0–9.5 SCFH.

A reading of “FS” (Full Scale), when testing a flow transducer

connected across a 47.5 SCFH Flow Finder, indicates a measured

flow of 47.5 SCFH; a scale reading of “1/2” indicates a flow of 23.75

A7 SCFH (0.5 X 47.5). System Studies’ monitoring devices are also Vendor manual

capable of reading up to twice the rated Flow Finder range. The

Transducer Test Meter will indicate extended ranges as either “1.5 X

FS ” or “2 X FS.”

Testing Selector Pair Saver Installations: System Studies’ Selector

A8 Pair Saver device (P/N 4990) makes it possible to read and monitor Vendor manual

two 4 to 20 mA transducers using only one device pair.

Procedures for testing both transducers at the Selector Pair Saver

A9 Vendor manual

are as follows: (A10 to A12)

1. Connect the meter’s red (positive) lead to the white (tip) conductor

Schedule Q

A10 of the Selector Pair Saver’s outgoing blue/white pair. Connect the

Att. IV

black (negative) lead to the blue (ring) conductor (Figure 4).

Saudi Aramco: Company General Use

2. To test the first transducer (the one connected to the orange/white

pair), move the polarity switch (bottom-right switch) to the “Device #1” Schedule Q

A11

(DOWN) position. To test the second transducer (green/white pair), Att. IV

move the switch to the “Device #2” (UP) position

Saudi Aramco: Company General Use

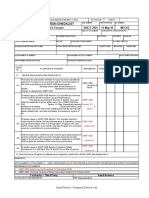

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.00 31-Mar-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Instrument Loop Outputs - Relay / Contactor / Transducer

SATR-J-6510 14-May-18 INST

Operation and Trip Test

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

3. Readings are evaluated as described in Step 2 of the Transducer Schedule Q

A12

Test Procedure (A4) Att. IV

Off-Scale Readings: “OPEN” Reading. OPEN readings indicate that

insufficient current is flowing in the device loop. Using the previous

test procedures as a reference, verify that the connections to both the Schedule Q

A13

meter and the device are correct. Also check to see that the battery is Att. IV

functioning properly. If all external connections are good, an OPEN

reading means the monitoring device could be faulty.

“0” Reading. A meter reading of 0 indicates a flow of zero, or

atmospheric pressure (0 PSIG). A properly functioning device with Schedule Q

A14

both pneumatic inputs disconnected (vented to atmosphere) will read Att. IV

in this region.

“SHORT” Reading. A SHORT reading indicates an over (excessive)

current condition in the device. If the meter reads SHORT, verify that Schedule Q

A15

the test meter or pair leads are not touching each other. If they are Att. IV

not, the device could be faulty.

Other Readings: A meter reading in the uncolored region between OPEN and 0 indicates one of the following conditions.

a) If both pneumatic inputs of the device are open to atmosphere, a reading on the left side of this region indicates a possible failed

device.

b) A reading toward the right of this region could indicate that the transducer has a low zero calibration. Low zero calibration can be

verified by placing a pressure transducer under pressure or creating a flow across a flow transducer (at the Flow Finder). If the reading

A16

increases, the transducer is functional but must be recalibrated.

c) If the device is connected to a Flow Finder in a pressurized system, a reading to the left side of the uncolored region can indicate a

reverse flow. Check the Flow Finder pneumatic connections to the transducer for proper orientation. This type of reading could also be

caused by cable pressure that is higher than air pipe pressure. Although this is rare, it is possible in an air-tight system. Test the

transducer with both pneumatic input ports vented to atmosphere to check for this condition

Testing the Battery

The Battery Test button and LED indicator on the front cover of the unit are used to verify that the battery charge is sufficient for proper

test meter operation. Simply press the button (with power on or off) to check the battery. If the LED illuminates, the battery charge is

A17

acceptable. Replace the batteries if it does not light (see replacement procedures below).

Note: The battery test is independent of the operating mode of the meter. It neither affects the readings, nor is it affected by being

connected to a transducer.

Zero Adjusting the Meter:

To verify that the meter is properly zeroed, turn the power switch on. If necessary, using a flat-blade screwdriver, turn the zero-adjust

A18 screw located on the gauge face in either direction until the meter’s needle lines up with the “meter zero” line. Because the meter is

slightly position sensitive, it is recommended that you both zero adjust and take readings holding the meter in the same orientation

(either vertical or horizontal).

B Test Equipment Serial Numbers: (a) Digital Multimeter

C General Test Routines

C1 Manufacturer's test routines to be followed and calibrations to be confirmed within tolerance limits

D Test Procedures

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.00 31-Mar-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Instrument Loop Outputs - Relay / Contactor / Transducer

SATR-J-6510 14-May-18 INST

Operation and Trip Test

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

1. Confirm the instrument tag of Relay/contactor/Transducer and that the devices are physically installed as per P & ID and wiring

drawing.

2. Verify proper wiring polarity and that the device is connected to the signal wiring.

3. Verify that the input or output signal is within the device's normal operating range.

4. Measure loop impedance by disconnecting the signal wiring at both the transmitter and rack room ends, shorting the signal wiring at

D1

the transmitter and measuring the loop resistance with an ohmmeter at the termination panel end.

5. With an ohmmeter, verify that there are no shorts to ground in the signal wiring by checking the wiring to ground while the wiring is

still disconnected.

6. Connect the device at the field location and have second technician in the rack room verify the status indication at DCS .

7. Reconnect the wiring to the in the field and the rack room.

E Results (The Table to be Modified Based on Requirements)

ITEM

PASS FAIL N/A RE-INSP DATE

No.

Measured Actual

% span Input Error

output output

0%

25%

50%

75%

100%

75%

25%

0%

F Conclusions

G Loop Continuity Check Sheet (Pre-Loop Check)

Unit No. System No. Loop No. Loop Drawing No

From To Checks per Section Name-sign/

Remarks and

Tag / Item no Area Cable Number Tag no Area Continuity Test Termination Date

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.00 31-Mar-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Instrument Loop Outputs - Relay / Contactor / Transducer

SATR-J-6510 14-May-18 INST

Operation and Trip Test

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), March 2006

2. Schedule Q - Quality Requirements (Pro Forma Contract), February 2008

3. SAES-J-700 - Control Valves, 1 January 2018

4. SAEP-16 - Project Execution Guide for Process Automation Systems, 14 March 2017

5. SAEP-1636 - Installation and Checkout Plan, 16 October 2017

6. SAEP-750- Testing Procedures for Process Automation Systems (PAS), 14 November 2016

7. 34-SAMSS-711 - Control Valves - General Services, 12 October 2017

8. 34-SAMSS-718 - Electric Motor Operated Valve Actuators, 12 February 2015

ATTACHMENTS:

1. Attachment 1: Transducer Test Meter - System Studies High Resolution Transducer

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose

listing states that the equipment, material or services either meets appropriate designated standards or has been tested and found suitable for

a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol or other identifying mark of an approved qualified

organization concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by

whose labeling the manufacturer indicates compliance with appropriate standards or performance in a specified manner.

5. Remarks:

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Name, Title, Department, Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Company, Initials and Name, Initials and Date:

Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.00 31-Mar-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Instrument Loop Outputs - Relay / Contactor / Transducer

SATR-J-6510 14-May-18 INST

Operation and Trip Test

Attachment 1: Transducer Test Meter - System Studies High Resolution Transducer

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- EPA07 Maxxforce 11, 13 Diagnostic Manual-1Documento190 pagineEPA07 Maxxforce 11, 13 Diagnostic Manual-1Manuel Alejandro Velez NavaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- HL510-HL 560 Technical ManualDocumento61 pagineHL510-HL 560 Technical ManualAJAYKUMAR PUND83% (6)

- Pre Welding ChecklistDocumento2 paginePre Welding Checklistmunna100% (3)

- CM20171017 08954 41228Documento93 pagineCM20171017 08954 41228valenciaNessuna valutazione finora

- Additional Requirements for Saudi Aramco ProjectDocumento27 pagineAdditional Requirements for Saudi Aramco Projectmunna100% (2)

- Sampleq Practice Exam d11 2002Documento22 pagineSampleq Practice Exam d11 2002Michael J Chandik0% (1)

- Citation Study GuideDocumento39 pagineCitation Study GuideJose Lara100% (4)

- Manual de Partes ST1010 - 369 PDFDocumento424 pagineManual de Partes ST1010 - 369 PDFCesar Chavez100% (2)

- Saep 42Documento11 pagineSaep 42munnaNessuna valutazione finora

- JCB 8080 Midi Excavator Service Repair Manual SN1024000 Onwards PDFDocumento17 pagineJCB 8080 Midi Excavator Service Repair Manual SN1024000 Onwards PDFhfjksekmmdm44% (9)

- Architectural Painting Works Ins ChecklistDocumento2 pagineArchitectural Painting Works Ins Checklistmunna100% (1)

- Jacquard Machines LX 1602 / LX 3202: TextileDocumento8 pagineJacquard Machines LX 1602 / LX 3202: TextileionutNessuna valutazione finora

- Saic W 2011Documento3 pagineSaic W 2011munnaNessuna valutazione finora

- Satr J 2001Documento1 paginaSatr J 2001munnaNessuna valutazione finora

- Saic P 3105Documento2 pagineSaic P 3105munnaNessuna valutazione finora

- Satip X 400 01Documento11 pagineSatip X 400 01munnaNessuna valutazione finora

- Saudi Aramco Foamed Asphalt Inspection PlanDocumento10 pagineSaudi Aramco Foamed Asphalt Inspection PlanmunnaNessuna valutazione finora

- Satip M 100 10Documento10 pagineSatip M 100 10munnaNessuna valutazione finora

- SAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONDocumento24 pagineSAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONmunnaNessuna valutazione finora

- Saic W 2090Documento2 pagineSaic W 2090munnaNessuna valutazione finora

- Satr P 3206Documento6 pagineSatr P 3206munnaNessuna valutazione finora

- Satip M 100 07Documento10 pagineSatip M 100 07munnaNessuna valutazione finora

- Saic RT 2009Documento3 pagineSaic RT 2009munnaNessuna valutazione finora

- Saic F 2025Documento8 pagineSaic F 2025munnaNessuna valutazione finora

- Saic RT 2007Documento9 pagineSaic RT 2007munnaNessuna valutazione finora

- Saudi Aramco Glass Inspection PlanDocumento10 pagineSaudi Aramco Glass Inspection PlanmunnaNessuna valutazione finora

- Saic P 3105Documento2 pagineSaic P 3105munnaNessuna valutazione finora

- Saic W 2090Documento2 pagineSaic W 2090munnaNessuna valutazione finora

- Schedule FDocumento5 pagineSchedule FmunnaNessuna valutazione finora

- Saic F 2024Documento2 pagineSaic F 2024munnaNessuna valutazione finora

- Schedule I Company Attachment IDocumento1 paginaSchedule I Company Attachment ImunnaNessuna valutazione finora

- Satip Q 001 03Documento10 pagineSatip Q 001 03munnaNessuna valutazione finora

- Schedule S Attachment IDocumento1 paginaSchedule S Attachment ImunnaNessuna valutazione finora

- Schedule C - Attachment 01Documento50 pagineSchedule C - Attachment 01munnaNessuna valutazione finora

- Saep 61 PDFDocumento21 pagineSaep 61 PDFmunnaNessuna valutazione finora

- Saep 55Documento12 pagineSaep 55munnaNessuna valutazione finora

- Equipment / Machinery Checklist: BlankDocumento3 pagineEquipment / Machinery Checklist: Blankyared admassuNessuna valutazione finora

- Bpac Leaflet PDFDocumento5 pagineBpac Leaflet PDFashishcnairNessuna valutazione finora

- App 1238 PDFDocumento3 pagineApp 1238 PDFIBRNessuna valutazione finora

- Virtual Amplification V-Amp 3: User ManualDocumento18 pagineVirtual Amplification V-Amp 3: User Manualoeqk25Nessuna valutazione finora

- Raychem t2 Red PDFDocumento2 pagineRaychem t2 Red PDFsenatNessuna valutazione finora

- Master Slave Flip FlopDocumento3 pagineMaster Slave Flip FloplakshmiraniNessuna valutazione finora

- Excavator Attachment Operation Manual - CompressedDocumento13 pagineExcavator Attachment Operation Manual - CompressedRobin Sanchez100% (1)

- Electronic Service Information System (ERWIN - ERWIN) 5Documento7 pagineElectronic Service Information System (ERWIN - ERWIN) 5Marius PopNessuna valutazione finora

- Oscillators RC, LC, Quartz Lecture 04 Services - Eng.uts - edu.Au-pmcl-DeDocumento5 pagineOscillators RC, LC, Quartz Lecture 04 Services - Eng.uts - edu.Au-pmcl-DeEnrik VillaNessuna valutazione finora

- Stepper Motor ControlDocumento5 pagineStepper Motor ControlSahilNessuna valutazione finora

- Alhambra 20V MotronicDocumento19 pagineAlhambra 20V MotronicMohd FairusNessuna valutazione finora

- Atlas-X1 Cat 6 U/UTP Cable, LSZH: Product Specifications UTP6Z-MxxDocumento2 pagineAtlas-X1 Cat 6 U/UTP Cable, LSZH: Product Specifications UTP6Z-MxxAdde JonNessuna valutazione finora

- Downloaded From Manuals Search EngineDocumento47 pagineDownloaded From Manuals Search EngineAan DharmawanNessuna valutazione finora

- 2016 MT03 Parts ListDocumento75 pagine2016 MT03 Parts ListDhK조커Nessuna valutazione finora

- Hvac LoadsDocumento99 pagineHvac LoadsYazNessuna valutazione finora

- BMW 318-Series 1991Documento9 pagineBMW 318-Series 1991Piotr JaworskiNessuna valutazione finora

- Garment Overview PBS SystemDocumento9 pagineGarment Overview PBS SystemMuskan AgarwalNessuna valutazione finora

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocumento3 pagineHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNessuna valutazione finora

- CNC Drilling and Dowel Inserting Machine DRILLTEQ C 100 NBS033Documento8 pagineCNC Drilling and Dowel Inserting Machine DRILLTEQ C 100 NBS033sufea saadNessuna valutazione finora

- 1.load Test On DC Shut MotorDocumento5 pagine1.load Test On DC Shut Motorg3v5Nessuna valutazione finora

- 12 Volt Bar-Mount Chain Saw Sharpener Owner'S Manual: Item # 141259Documento8 pagine12 Volt Bar-Mount Chain Saw Sharpener Owner'S Manual: Item # 141259Relyax ColiliNessuna valutazione finora

- 2015 K2500 ManualDocumento283 pagine2015 K2500 ManualRinto SilalahiNessuna valutazione finora

- Model 800: Applications IncludeDocumento2 pagineModel 800: Applications IncludeKikokNessuna valutazione finora