Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Glo

Caricato da

kamranTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Glo

Caricato da

kamranCopyright:

Formati disponibili

SENIOR YEARS

General Learning Outcomes

GENERAL LEARNING OUTCOMES

In Industrial Arts Curricula in Manitoba the General Learning

Outcomes (GLOs) are grouped into three skill sets:

Drafting Design Electricity/Electronics

Fundamental Skills—the skills basic for study in Industrial

Technology Technology

I

Arts

I Personal Skills—the skills basic for personal effectiveness

and growth

I Production Skills—the skills basic for production and

fabrication

Fundamental Skills and Personal Skills contain General Metalwork

Graphic

Learning Outcomes that are common to all Industrial Arts Communication Technology

strands. Technology

Production Skills contain General Learning Outcomes that

are focused to each individual Industrial Arts strand.

Power Woodwork

Mechanics Technology

Technology

General Learning Outcomes 17

Fundamental Skills Personal Skills

(the skills basic for study in Industrial Arts—common to all (the skills basic for personal effectiveness and growth—

Industrial Arts strands) common to all Industrial Arts strands)

General Learning Outcomes General Learning Outcomes

GLO F1 Technical Communication: Communicate GLO P1 Time Management: Demonstrate responsibility

technical ideas and designs effectively and in time management, task completion, and in

appropriately. meeting project criteria. (Note: based on the

Conference Board of Canada’s Personal

GLO F2 Problem Solving: Apply effective decision- Management Skills)

making, problem-solving, and design strategies

to a project. (Refer to Appendix B for a sample GLO P2 Ethical Decision-Making: Make ethical decisions

design/problem-solving process.) concerning the impact of one’s activities and the

use of technology.

GLO F3 Information Management: Effectively manage

information. GLO P3 Career Planning: Develop an action plan relating

personal aptitudes and abilities to occupational

opportunities.

GLO P4 Safe Practices: Demonstrate safe practices with

tools, machines, materials, and related processes.

(Refer to: Keeping Your Facilities SAFE: A Support

Document for Industrial Arts Teachers, Manitoba

Education and Youth, 2003.)

GLO P5 Positive Attitude: Demonstrate positive attitudes

to learning in Industrial Arts facilities.

GLO P6 Teamwork: Adapt strategies to work effectively,

independently, or as a team member to complete

a project.

18 Senior Years Industrial Arts: Manitoba Curriculum Framework of Outcomes

Production Skills Electricity/Electronics Technology

GLO EE1 Tools and Equipment: Identify and demonstrate

(the skills basic for production and fabrication—focused to

proper use of tools, materials, and equipment

each individual Industrial Arts strand)

utilized in electricity/electronics.

General Learning Outcomes for Each Strand GLO EE2 Circuit Construction: Apply appropriate

Drafting Design Technology fabrication techniques to construct

electricity/electronics devices.

GLO DD1 Tools and Equipment: Identify and demonstrate

proper use of tools, materials, and equipment GLO EE3 Components: Demonstrate the function of

utilized in drafting design. electricity/electronics passive and active

components.

GLO DD2 Drawing Interpretation: Recognize and interpret

technical drawings. GLO EE4 Laws and Theory: Apply electricity/electronics

laws and theory.

GLO DD3 Technical Sketching: Employ technical sketching

as a way of visualizing ideas. GLO EE5 Circuits and Systems: Identify and analyze basic

electricity/electronics circuits.

GLO DD4 Geometric Application: Apply mathematics and

geometry in completing technical drawings. GLO EE6 Applications: Develop an understanding of

electricity/electronics applications.

GLO DD5 Production (Working) Drawings: Use the design

process and problem solving to create production GLO EE7 Current Innovation: Demonstrate an

drawings. understanding of current innovation in

electricity/electronics, processes, applications

GLO DD6 Applications: Develop an understanding of and emerging new technologies.

drafting applications and current workplace

practice.

GLO DD7 Current Innovation: Demonstrate an

understanding of current innovation in drafting

design processes, applications, and emerging

new technologies.

General Learning Outcomes 19

Graphic Communication Technology Metalwork Technology

GLO GC1 Image Acquisition: Demonstrate the principals GLO MW1 Metalurgy: Demonstrate an understanding of

and processes involved with image acquisition metallurgy—science and processes.

and creation.

GLO MW2 Measurement and Layout: Use metalworking

GLO GC2 Still Image Production: Apply knowledge and measurement and layout tools correctly and

practical skills to produce still image visual efficiently.

representations of ideas or abstract concepts.

GLO MW3 Separation: Apply separation processes to metal.

GLO GC3 Binding and Packaging: Demonstrate and apply

the knowledge and skills to finish a product for GLO MW4 Fastening: Apply fastening processes to metal.

distribution. GLO MW5 Forming and Casting: Apply forming and

GLO GC4 Animated Images: Apply knowledge and skills casting processes to metal.

to produce animated images of ideas or abstract GLO MW6 Finishing: Apply finishing processes to metal

concepts. considering their environmental impact.

GLO GC5 Video Editing: Create and edit video GLO MW7 Current Innovation: Demonstrate an

productions. understanding of current innovation in

GLO GC6 Current Innovation: Demonstrate an metalwork processes, applications, and emerging

understanding of current innovation in graphic new technologies.

communication processes, applications, and

emerging new technologies.

20 Senior Years Industrial Arts: Manitoba Curriculum Framework of Outcomes

Power Mechanics Technology Woodwork Technology

GLO PM1 Energy Conversion: Demonstrate an GLO WW1 Wood, Products, and Processes: Demonstrate an

understanding of the theory of internal understanding of woodwork— woods, wood

combustion and alternate energy converters. products, and processes.

GLO PM2 Engine Systems: Identify and analyze various GLO WW2 Measurement and Layout: Use woodworking

engine systems. measurement and layout tools, correctly and

efficiently.

GLO PM3 Electrical Systems: Understand the basic

electrical principles applied to power mechanics GLO WW3 Separation: Apply separation processes to wood.

systems.

GLO WW4 Fastening: Apply fastening processes and

GLO PM4 Mechanical Systems: Identify and analyze the specialty hardware to wood, correctly and

mechanical systems of an internal combustion efficiently.

engine.

GLO WW5 Wood Joints: Apply joints and joining techniques

GLO PM5 Chassis Systems: Identify and compare various to wood.

automotive chassis systems.

GLO WW6 Finishing: Apply finishing processes to wood

GLO PM6 Climate Control Systems: Identify and analyze considering their environmental impact.

the climate control systems in an automobile.

GLO WW7 Current Innovation: Demonstrate an

GLO PM7 Assembly/Disassembly Tools: Demonstrate the understanding of current innovation in

use of tools and equipment in assembly and woodwork processes, applications, and emerging

disassembly of mechanical components. new technologies.

GLO PM8 Diagnostic Tools: Use diagnostic tools and

methods to troubleshoot, diagnose, and repair

power mechanical systems.

GLO PM9 Environmental Impact and Current Innovation:

Demonstrate an understanding of current

innovation in automotive industry,

environmental impacts, and emerging new

technologies.

General Learning Outcomes 21

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Mitsubishi Meldas 2M Memoria FormatDocumento4 pagineMitsubishi Meldas 2M Memoria FormatangelNessuna valutazione finora

- Beml BH50 Electrical ManualDocumento33 pagineBeml BH50 Electrical ManualveereshNessuna valutazione finora

- Oxford University ArithmeticDocumento1 paginaOxford University ArithmetickamranNessuna valutazione finora

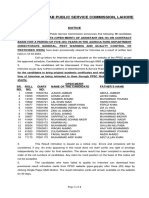

- Punjab Public Service Commission, Lahore: NoticeDocumento1 paginaPunjab Public Service Commission, Lahore: NoticekamranNessuna valutazione finora

- Punjab Public Service Commission, Lahore: NoticeDocumento2 paginePunjab Public Service Commission, Lahore: NoticekamranNessuna valutazione finora

- Essay and Its Types Mcqs PDFDocumento3 pagineEssay and Its Types Mcqs PDFkamran83% (18)

- Punjab Public Service Commission, Lahore: NoticeDocumento1 paginaPunjab Public Service Commission, Lahore: NoticekamranNessuna valutazione finora

- Second Test of EMT PDFDocumento3 pagineSecond Test of EMT PDFkamran100% (1)

- Communication Skill McqsDocumento11 pagineCommunication Skill McqsZafar Iqbal KhattakNessuna valutazione finora

- University of EducationDocumento5 pagineUniversity of EducationkamranNessuna valutazione finora

- Test Thermodynamics Ch#01 Punjab College ShakargarhDocumento2 pagineTest Thermodynamics Ch#01 Punjab College ShakargarhkamranNessuna valutazione finora

- CTM AssignmentDocumento10 pagineCTM AssignmentkamranNessuna valutazione finora

- Date SheetDocumento1 paginaDate SheetkamranNessuna valutazione finora

- Eco401 GDB 1 Idea SolutionDocumento1 paginaEco401 GDB 1 Idea Solutionkamran0% (2)

- Countis E43 Modbus 48503065 - Communication Table - 2019 09 - CMT201266 - MultiDocumento20 pagineCountis E43 Modbus 48503065 - Communication Table - 2019 09 - CMT201266 - Multitommy hariNessuna valutazione finora

- 1.1 APS - Basics E4Documento17 pagine1.1 APS - Basics E4christianxla100% (1)

- Ak56 Service ManualDocumento50 pagineAk56 Service Manualnita_alecsandru100% (1)

- Installation Planning and EstimatingDocumento26 pagineInstallation Planning and EstimatingNoob player Free Fire100% (2)

- Question Bank Unit 1Documento3 pagineQuestion Bank Unit 1vkjoshiNessuna valutazione finora

- SLD - Asam 180KWp ProjectDocumento3 pagineSLD - Asam 180KWp ProjectSwarnendu DebNessuna valutazione finora

- 19S800 7628 Philips TVDocumento67 pagine19S800 7628 Philips TVMauricio SolanoNessuna valutazione finora

- 02-2 Excitation CourseDocumento31 pagine02-2 Excitation CourseFulki Kautsar S100% (1)

- JASD Series AC Servo Drives Users ManualDocumento130 pagineJASD Series AC Servo Drives Users ManualsamadNessuna valutazione finora

- HBR4HF Transciever ManualDocumento7 pagineHBR4HF Transciever ManualPetrika Janeku100% (1)

- BiCMOS TechnologyDocumento17 pagineBiCMOS TechnologyJacob ChakoNessuna valutazione finora

- Fully Integrated LDO Linear Voltage RegulatorDocumento15 pagineFully Integrated LDO Linear Voltage RegulatorAram ShishmanyanNessuna valutazione finora

- Sunny Central Storage 1900 / 2200 / 2475 / 2900Documento4 pagineSunny Central Storage 1900 / 2200 / 2475 / 2900Dominic SantiagoNessuna valutazione finora

- Data Communication Media: Chapter - 2Documento4 pagineData Communication Media: Chapter - 2lvsaruNessuna valutazione finora

- A Dual-Feed Dual-Band L-Probe Patch AntennaDocumento3 pagineA Dual-Feed Dual-Band L-Probe Patch AntennaCRoberto Wah GonzalezNessuna valutazione finora

- E12686-0000-9002-01-09 Consumer List PDFDocumento67 pagineE12686-0000-9002-01-09 Consumer List PDFthanh100% (1)

- MAN SICAM P850 P855 7KG85xx V2.2 USDocumento302 pagineMAN SICAM P850 P855 7KG85xx V2.2 USIvanNessuna valutazione finora

- Ultra ConductorsDocumento28 pagineUltra ConductorsAnu Kp50% (8)

- OMD6068 Case Analysis - Call Drop ISSUE1.1Documento75 pagineOMD6068 Case Analysis - Call Drop ISSUE1.1Quốc Minh NguyễnNessuna valutazione finora

- Book - Capacitive Current Interruption With High Voltage Disconnector Switch - Yajing ChaiDocumento171 pagineBook - Capacitive Current Interruption With High Voltage Disconnector Switch - Yajing ChaiBalaji VenkatesanNessuna valutazione finora

- LAB 1-PE-LabDocumento10 pagineLAB 1-PE-LabLovely JuttNessuna valutazione finora

- Lab ReportDocumento26 pagineLab Reportsanjana972Nessuna valutazione finora

- v580 v580c HMM enDocumento114 paginev580 v580c HMM enmoment of powerNessuna valutazione finora

- TIP145 / TIP146 / TIP147 PNP Epitaxial Silicon Darlington TransistorDocumento5 pagineTIP145 / TIP146 / TIP147 PNP Epitaxial Silicon Darlington TransistorAndres UmarraNessuna valutazione finora

- Control Ningbo NBSL Nsfc01-01 Control System (4sw)Documento14 pagineControl Ningbo NBSL Nsfc01-01 Control System (4sw)Winderson Macauran89% (18)

- PF520 - User ManualDocumento244 paginePF520 - User ManualJonatan Zayas ValdezNessuna valutazione finora

- RX-F31S SCHDocumento22 pagineRX-F31S SCHjrm618Nessuna valutazione finora

- Connecteurs AMP SupersealDocumento28 pagineConnecteurs AMP SupersealADNessuna valutazione finora