Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Material Lab-13

Caricato da

Ahmad0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

10 visualizzazioni1 paginaTitolo originale

material lab-13

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

10 visualizzazioni1 paginaMaterial Lab-13

Caricato da

AhmadCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

MATERIALS LABORATORY 2006

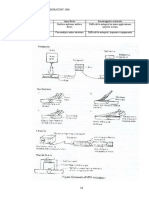

Table-I: Commonly used Rockwell hardness scales.

Scale Indenter Type Major Load

I Typical Applications

X (kgf)

A Diamond Brale 60 Tool Materials

D Diamond Brale 100 Cast Irons, Sheet Steels

C Diamond Brale 150 Hardened steels and cast irons, Ti

alloys

B 1/16" Diameter Ball 100 Annealed steels, Cu and Al

alloys

E 1/8" Diameter Ball 100 Al and Mg alloys, reinforced

polymers

F 1/16" Diameter Ball 60 Soft sintered products

M 1/4" Diameter Ball 100 Very soft metals, polymers

R 1/2" Diameter Ball 60 Very soft metals, polymers

Since the deformations caused by an indenter are of similar magnitude to

those occurring at the ultimate tensile strength in a tension test, some empirical

relationships have been established between hardness and engineering ultimate

tensile strength of metals and alloys. For example, for steels UTS can be roughly

estimated from Brinell hardness as follows:

UTS (in MPa) = 3.45 x BHN

Equipment

• Rockwell hardness tester

• Brinell hardness tester

• Microhardness (Vickers) tester

• Different test specimens

Procedure

1. Determine the proper Rockwell hardness scale,

2. calibrate the Rockwell hardness tester,

3. take five readings per specimen,

4. Perform Brinell hardness measurements on designated specimens (3

readings)

5. Using microhardness tester, determine the VHN at 0.20 mm distances

from the

surface to the center of case carburized specimen, until the hardness remains

unchanged.

6. Determine the core hardness of the carburized steel.

.

Analysis

Calculate the range and mean in hardness values for each test specimen which

will be considered in lab report.

14

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Material Lab-37Documento1 paginaMaterial Lab-37AhmadNessuna valutazione finora

- Material Lab-22Documento1 paginaMaterial Lab-22AhmadNessuna valutazione finora

- Mechanical Safety: Materials Laboratory 2006Documento1 paginaMechanical Safety: Materials Laboratory 2006AhmadNessuna valutazione finora

- Magnetic Particle:: The Following Steps Are Applied During The ExperimentDocumento1 paginaMagnetic Particle:: The Following Steps Are Applied During The ExperimentAhmadNessuna valutazione finora

- Jominy Hardenability Test: ObjectiveDocumento1 paginaJominy Hardenability Test: ObjectiveAhmadNessuna valutazione finora

- Tensile Testing of Metals: ObjectiveDocumento1 paginaTensile Testing of Metals: ObjectiveAhmadNessuna valutazione finora

- Ultrasonic Inspection:: The Following Steps Should Be Applied During The ExperimentDocumento1 paginaUltrasonic Inspection:: The Following Steps Should Be Applied During The ExperimentAhmadNessuna valutazione finora

- Material Lab-35Documento1 paginaMaterial Lab-35AhmadNessuna valutazione finora

- Material Lab-32Documento1 paginaMaterial Lab-32AhmadNessuna valutazione finora

- Material Lab-33 PDFDocumento1 paginaMaterial Lab-33 PDFAhmadNessuna valutazione finora

- Material Lab-33 PDFDocumento1 paginaMaterial Lab-33 PDFAhmadNessuna valutazione finora

- Visual Inspection:: Materials Laboratory 2006Documento1 paginaVisual Inspection:: Materials Laboratory 2006AhmadNessuna valutazione finora

- Material Lab-17Documento1 paginaMaterial Lab-17AhmadNessuna valutazione finora

- Material Lab-31Documento1 paginaMaterial Lab-31AhmadNessuna valutazione finora

- Material Lab-14Documento1 paginaMaterial Lab-14AhmadNessuna valutazione finora

- Material Lab-11Documento1 paginaMaterial Lab-11AhmadNessuna valutazione finora

- Material Lab-15Documento1 paginaMaterial Lab-15AhmadNessuna valutazione finora

- Material Lab-16 PDFDocumento1 paginaMaterial Lab-16 PDFAhmadNessuna valutazione finora

- Material Lab-16Documento1 paginaMaterial Lab-16AhmadNessuna valutazione finora

- Material Lab-12Documento1 paginaMaterial Lab-12AhmadNessuna valutazione finora

- Material Lab 7Documento1 paginaMaterial Lab 7AhmadNessuna valutazione finora

- Material Lab-5Documento1 paginaMaterial Lab-5AhmadNessuna valutazione finora

- Material Lab 4Documento1 paginaMaterial Lab 4AhmadNessuna valutazione finora

- Checklist For Tensile Report: Materials Laboratory 2006Documento1 paginaChecklist For Tensile Report: Materials Laboratory 2006AhmadNessuna valutazione finora

- Material Lab 4Documento1 paginaMaterial Lab 4AhmadNessuna valutazione finora

- Material Lab 9Documento1 paginaMaterial Lab 9AhmadNessuna valutazione finora

- Material Lab 3Documento1 paginaMaterial Lab 3AhmadNessuna valutazione finora

- Material Lab 2Documento1 paginaMaterial Lab 2AhmadNessuna valutazione finora

- Materials Laboratory Attendance: Experiment Group Date ApprovalDocumento1 paginaMaterials Laboratory Attendance: Experiment Group Date ApprovalAhmadNessuna valutazione finora