Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

20040847

Caricato da

Marcelo GuarachiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

20040847

Caricato da

Marcelo GuarachiCopyright:

Formati disponibili

Books

Handbook of Industrial Mixing, pipeline mixing (including static mixers), rotor-stator mixers,

mechanical aspects of mixing and the role of the mixing

Science and Practice equipment vendor. Specialized equipment for powder blend-

E. L. Paul, V. A. Atiemo-Obeng and S. M. Kresta, Editors,

ing, pulp and paper, petroleum industry and high-viscosity

John Wiley & Sons, Hoboken, NJ, 1,377 pp., $160.00, 2003

mixing are discussed in the respective applications chapters.

Sponsored by the North American

The core mixing design topics of miscible liquid blend-

Mixing Forum (NAMF), the aim

ing, solid/liquid suspension, gas/liquid contacting,

of this Handbook is to provide

liquid/liquid mixing, mixing and chemical reaction, as well

mixing practitioners with a sum-

as heat transfer and mixing, are each covered in detail in one

mary of the current state of mixing

or more dedicated chapters. Liquid blending (which

knowledge, both in terms of funda-

involves mutually soluble streams) in pipeline systems,

mentals and from the perspective

stirred tanks and jet mixed tanks is also discussed in detail.

of industrial practice and experi-

The challenging non-Newtonian and laminar blending areas

ence. It has been written for the

are also covered in-line and in-tank. The solid/liquid suspen-

practicing engineer who needs to

sion chapters include design guidelines for off-bottom sus-

both identify and solve mixing

pension, achieving and maintaining uniform solids

problems. The Handbook compris-

concentration, mass transfer correlations for solids dissolu-

es a compilation of the experience

tion, maintaining discharge slurry composition and avoiding

and findings of industrialists and academics who have, over

nozzle plugging during drainage. The gas/liquid mixing

the last 30 years, been instrumental in the development of

chapter addresses the key objective of maximizing surface

mixing as a discipline. As well as describing the state-of-

area for mass transfer through effective dispersion.

the-art on traditional mixing topics, the Handbook presents

Liquid/liquid mixing is arguably the most difficult and least

methods for recognition of complex mixing problems and

understood mixing problem; its current state-of-art is dis-

alternative mixing designs for critical applications.

cussed with important guidelines emerging. The chapters on

Particular focus is on the scale-up of processes.

mixing and chemical reaction discuss in detail the effects of

The motivation for the Handbook and for the research

scaling-up mixing-sensitive reactions. Design correlations

efforts that it documents are revealed by the following eco-

for stirred-tank heat-transfer coefficients and key heat-trans-

nomic estimates. In 1989, the cost of poor mixing in the

fer concepts are provided in a specific chapter.

U.S. chemical industry was estimated at $1–$10 billion.

The section of the Handbook on industrial applications

Costs of poor mixing in the pharmaceutical industry due to

features chapters on solid/solid mixing fundamentals and

low yield, scale-up, process development and lost opportu-

practice, mixing of highly viscous fluids, polymers and

nity amount to $ 0.5–$1 billion/yr. Therefore, time spent

pastes, mixing in the fine chemicals and pharmaceuticals

improving the understanding of mixing and mixing equip-

industries, mixing in the fermentation and cell culture

ment design is potentially profitable.

industries, mixing in the petroleum industry, and mixing in

The Handbook is designed as a reference work, rather

the pulp and paper industries. The special requirements of

than one that should be read from beginning to end. In

mixing in water, wastewater and food industries are not

order to achieve this, it is well structured with copious

explicitly described in the Handbook.

cross-referencing and comprehensive references for sup-

The accompanying CD-ROM, Visual Mixing, assists in

porting literature at the close of each chapter. The

understanding specific mixing issues by using video clips of

Handbook is generally well written and easy to read, hav-

lab experiments or CFD simulations. The most informative

ing been written for the engineer new to mixing, rather than

sections cover circulation in a stirred tank, liquid blending,

the cognoscenti. Many calculation examples are given.

solids suspension and distribution, and droplet break-up.

The Handbook is divided into three broad sections —

In summary, effective mixing is of vital importance in

fundamentals, design and applications. The chapters on

a great many industrial processes. Getting the mixing

fundamental topics should be understood to address diffi-

right impacts the bottom line. This Handbook is the most

cult mixing problems. Three fundamental chapters cover

comprehensive, definitive and up-to-date treatise on

residence-time-distribution theory and modeling, turbulent

industrial mixing available anywhere. It is well written,

mixing theory and laminar mixing theory. Turbulent mix-

structured, illustrated and referenced. My colleagues and I

ing theory is concerned with the range of length and time

at BHR, have already found the Handbook to be our most

scales in the flow and the distribution of energy dissipation.

frequently used mixing reference. It is a “must buy” for

The principal tools used to investigate mixing problems are

all engineers whose work regularly involves mixing or

described in chapters on laboratory mixing experiments

mixing-related problems.

and computational fluid dynamics (CFD).

Dr. Michael Dawson,

Design of the wide range of mixing equipment now avail-

BHR Group Ltd., Cranfield, Bedford, U.K.

able is described in chapters on traditional stirred tanks

mdawson@bhrgroup.co.uk

(including baffling, impellers, internals and configurations),

CEP August 2004 www.cepmagazine.org 47

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Analisis y Simulacion de Procesos Himmelblau PDFDocumento4 pagineAnalisis y Simulacion de Procesos Himmelblau PDFMarcelo Guarachi0% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Analisis y Simulacion de Procesos Himmelblau PDFDocumento4 pagineAnalisis y Simulacion de Procesos Himmelblau PDFMarcelo Guarachi0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- WEB Lubricating Oil (Industrial Teresso 46) PDFDocumento2 pagineWEB Lubricating Oil (Industrial Teresso 46) PDFMarcelo GuarachiNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Lifter DesignDocumento6 pagineLifter DesignMarcelo GuarachiNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Secado NeumaticoDocumento8 pagineSecado NeumaticoMarcelo GuarachiNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Operating Instructions: Preparation For Start-UpDocumento8 pagineOperating Instructions: Preparation For Start-UpMiliani AhmedNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Chris Mills 2020Documento17 pagineChris Mills 2020AminNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 2347 Hydraulics and Fluid Power Control SystemsDocumento3 pagine2347 Hydraulics and Fluid Power Control SystemsKollikonda RameshNessuna valutazione finora

- Fluid05 ZBDocumento78 pagineFluid05 ZBZain MustafaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

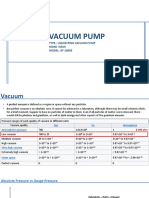

- Vacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EDocumento46 pagineVacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EAmit Balot100% (2)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- THE THE: Notes Meter Factor ForDocumento19 pagineTHE THE: Notes Meter Factor Forjgarcia388Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Santillan LBYME3B Laboratory Report 04Documento17 pagineSantillan LBYME3B Laboratory Report 04Nygel Gian SantillanNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Lpu Ca 02 01 ADocumento6 pagineLpu Ca 02 01 AFizan NaikNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- An Electrified Soap Bubble: Theoretical Competition: 12 July 2011Documento2 pagineAn Electrified Soap Bubble: Theoretical Competition: 12 July 2011Cretu NicolaeNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Fluid Mechanics With Lab Flumec1: School of Engineering and ArchitectureDocumento134 pagineFluid Mechanics With Lab Flumec1: School of Engineering and ArchitectureSamantha SamanthaNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- LP PDFDocumento8 pagineLP PDFEshanth RajNessuna valutazione finora

- Wells TurbineDocumento13 pagineWells TurbineSriram ChNessuna valutazione finora

- Strack 1976 A Single-Potential Solution For Regional Interface Problems in Coastal AquifersDocumento10 pagineStrack 1976 A Single-Potential Solution For Regional Interface Problems in Coastal AquifersMarie.NeigeNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Airlift Pump 2019Documento95 pagineAirlift Pump 2019Mo'taz MahmoudNessuna valutazione finora

- Domestik KAP.400M : Dosing Pump ExistingDocumento1 paginaDomestik KAP.400M : Dosing Pump ExistingHanum PravitasariNessuna valutazione finora

- GIW TDW - Tailings Dewatering Pump: For Illustrative Purposes Only. Images May Not Reflect Final DesignDocumento4 pagineGIW TDW - Tailings Dewatering Pump: For Illustrative Purposes Only. Images May Not Reflect Final DesignArhip GasanNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Centrifugal Fan Design MethodologiesDocumento10 pagineCentrifugal Fan Design MethodologiesMausam100% (2)

- 2 Irrigation Water Resources Engineering and Hydrology Questions and Answers - Preparation For EngineeringDocumento18 pagine2 Irrigation Water Resources Engineering and Hydrology Questions and Answers - Preparation For Engineeringahit1qNessuna valutazione finora

- IGV-Operation: Rev.: A Page: 1 / 8 Operation and Maintenance ManualDocumento7 pagineIGV-Operation: Rev.: A Page: 1 / 8 Operation and Maintenance ManualredwaneNessuna valutazione finora

- Model 4WG 100 - 800 HP Boilers: Table A3-13. Model 4WG Hot Water Relief Valve Outlet SizeDocumento4 pagineModel 4WG 100 - 800 HP Boilers: Table A3-13. Model 4WG Hot Water Relief Valve Outlet SizesebaversaNessuna valutazione finora

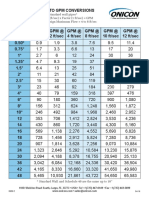

- 0868 5 Velocity To GPM Chart 2 Sided 04 18Documento2 pagine0868 5 Velocity To GPM Chart 2 Sided 04 18Abdul YaseenNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Lab 6Documento19 pagineLab 6IzzatiHazwaniNessuna valutazione finora

- Apag 20240319Documento33 pagineApag 20240319Евгений КондратенкоNessuna valutazione finora

- Nipro Surdial 55+ Dialysis Machine - Service Manual PDFDocumento456 pagineNipro Surdial 55+ Dialysis Machine - Service Manual PDFIvan Melendez Ortega93% (15)

- Advanced ECLIPSE Course: Saturation Functions and Endpoint ScalingDocumento42 pagineAdvanced ECLIPSE Course: Saturation Functions and Endpoint ScalingiskanderNessuna valutazione finora

- A Numerical Simulation of Vortex Shedding From An Oscillating Circular CylinderDocumento22 pagineA Numerical Simulation of Vortex Shedding From An Oscillating Circular CylinderAshish PawarNessuna valutazione finora

- Hydraulic Calculations Fire ProtectionDocumento16 pagineHydraulic Calculations Fire ProtectionGabriel LopezNessuna valutazione finora

- Simulation of Full-Bore Tube Rupture in Shell&Tube Heat ExchangerDocumento6 pagineSimulation of Full-Bore Tube Rupture in Shell&Tube Heat ExchangerMoca PhoenixNessuna valutazione finora

- NH L218 - Fluids & LubricantsDocumento4 pagineNH L218 - Fluids & LubricantsKristomiDerMarine-IngenieurNessuna valutazione finora

- Technical Information Data Sheet For Waste Water/Effluent Treatment Plant (Etp)Documento2 pagineTechnical Information Data Sheet For Waste Water/Effluent Treatment Plant (Etp)rashidulNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)