Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Engineering Short Course

Caricato da

rutuja0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

229 visualizzazioni7 paginecourse

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentocourse

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

229 visualizzazioni7 pagineProcess Engineering Short Course

Caricato da

rutujacourse

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

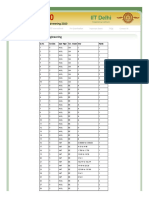

SUBJECT: Process Engineering Short Course Syllabus

1) Introduction to Various Types of Project Contracts (4 hours)

Meaning of Engineering Procurement and Construction (EPC)

Typical Organization Chart of EPC Company

Work Flow in EPC Companies

FEED Stage Work Flow

EPC Contract Types

Procurement Procedure

Types of Tenders

Tender Procurement Process Flow Chart

2) Basic Engineering Design Package (BEDP or FEED Package) (10 hours)

Scope and Title

Contents of BEDP

Contents of Table 1

General Design Data

Project Specifications

Manuals and Drawings

Contents of Table 2

General Design Data

Specifications & Data Sheets

Drawings

Developments of Table 1 Contents

General information

Basic Engineering Design Data

Complex/Plant material balance

Utility summary tables

Flare Load Summary Tables

Effluent summary tables

Winterizing & heat conservation and insulation data

Safety

Resins, Chemicals, Solvents and Catalysts

Hazardous area classification

Licensor’s Proprietary Items

Project Specifications

Different Types of Manuals

Developments of Table 2 Contents

General Information

Unit Design Basis

Equipment Item Index

Heat & material balance tables

Utility Summary Tables

Review of Detailed Design

Specifications & Data Sheets

Fired heaters

Storage tanks

Towers, reactors and vessels

Heat exchangers

Machinery

Instruments

Drawings

Preliminary unit plot plan

Piping & instrumentation diagrams (P&IDs)

Utility distribution flow diagrams (UDFDs)

Emergency shut-down block diagram and/or logic diagram.

Cause & effect tables/diagrams.

Single line diagrams.

3) Detail Design and Engineering (6 hours)

Scope

Work Sequence and Procedures

Process and Utilities Engineering

Piping Engineering

Mechanical Engineering

Instrumentation Engineering

Electrical Engineering

Civil and Structural Engineering

List of Softwares used During Detail Engineering (Name and Application)

4) Introduction to Key Process Engineering Deliverables (5 hours)

5) Preparation of Key Process Engineering Summaries (5 hours)

Fluid List- Sample

Line List-Sample

Line List- Preparation

Tie-in-Point List-Sample

Tie-in-Point List-Preparation

Catalyst Summary-Sample

Chemicals Summary-Sample

Catalyst & Chemical Summary-Preparation

Hazardous Source List-Sample

Hazardous Source List-Preparation

Equipment List- Sample

Equipment List- Preparation

Utility Consumption Summary – Sample

Utility Consumption Summary - Preparation

Preparation of Flare Load Summary

Effluent Summary-Sample

Effluent Summary-Preparation

6) Typical Oil and Gas Production Facilities (6 hours)

Oil Production Facilities

Artificial Lift

Crude Oil Treatment

Produced Water Treatment

Natural Gas Processing

Amine Process (Flow Diagram)

Dehydration using Glycol (Flow Diagram)

Dehydration using Solid Desiccants (Flow Diagram)

NGL Recovery

LNG Supply Chain

7) Introduction to Crude Oil Refinery Processes (6 hours)

Introduction

Typical Block Flow Diagram for Refinery

Various processes PFD.

Physical Processes

Thermal Processes

Catalytic Processes

Conversion of Heavy Residues

Treatment of Refinery Streams

Lube base stock preparation

Other processes (Common Facilities)

8) Guidelines for Preparation of Majors Process and Piping Drawings (6

hours)

Process Work Flow

Process Equipments Symbols for P&ID

Block Flow Diagram (BFD)

Process Flow Diagrams (PFD)

Piping and Instrumentation Diagrams (P&ID)

Process Control Diagrams (PCD)

Plot Plan

Guidelines for Preparation of Plot Plan

Elevation Drawings

Guidelines for Preparation of Equipment Layout

9) Fluid Flow and Line Sizing (5 hours)

Types of Fluid Flow

Equation of Continuity

Bernoulli's Equation

Friction Losses in Pipes

Minor Losses Calculation

Equivalent Length of Fittings

Pressure Drop Formula

Step Wise Procedure for Single Phase Pipeline Sizing

Line Sizing Criteria – Allowable Velocity & Pressure Drop

Line Sizing – Two Phase Flow

Types of Two Phase Flows

Flow Regimes

Pressure Drop Calculation Procedure

10) Pumps and Hydraulic Calculations (8 hours)

Part 1

Introduction

Types of Pumps

Positive Displacement Pumps

Positive Displacement Pumps (Strengths/Concerns)

Roto Dynamic Pumps

Roto Dynamic Pumps (Strengths/Concerns)

Head & Typical Performance Curves

Selection Guidelines

Centrifugal v/s Reciprocating Pumps

Capacity /Pressure

Pressure/Flow/ Fluid Handling

Cost

Affinity Laws

Part 2

Terminology in Hydraulics

NPSHA Calculations

Hydraulics Calculations Procedure

Solved Example

Hydraulic Calculations – Reciprocating Pump

Rule of Thumb for Pumps

Excel Calculation Sheet

11) Compressors (5 hours)

Introduction

Type of Compressors

Positive Displacement Compressors

Centrifugal Compressors

Compressors

Lubricating System

Lube Oil Cooling

Comparison

Basic Calculations – Head/Power/Discharge Temperature

Compressor Operation

Surge & Anti surge

Surge Controls

Thumb Rules for Compressors

Codes & Standards

12) Introduction to Process Vessel Design (4 hours)

Process Design Conditions

Codes and Standards

Low Temperature Requirements

Pressure Testing

Separators / Pressure Vessel Sizing

Vertical Separator Design

Separator Sizing

Horizontal Separator Sizing

Thumb Rules (Separators)

Thumb Rules (Storage Tanks)

13) Heat Exchangers and Thermal Design Procedure (12 hours)

Part 1

Classification of Exchangers

Exchangers Nomenclature

Types of Heat Exchangers

Double Pipe Heat Exchanger

Shell and Tube Exchanger

Major Components of Shell and Tube Heat Exchanger

Plate and Frame Exchanger

Spiral Plate Exchanger

Spiral Tube and Helical Flow Exchanger

Air Cooled Exchanger

Plate Fin Exchanger

Categories of Shell and Tube Exchanger

Fouling Factors

Log Mean Temperature Difference Correction Factor

Overall Heat Transfer Coefficients

Energy Balance and Heat duty

Pressure Drop Calculations

Data Required for Thermal Design

Thermal Design Procedure

Thermal Design Parameters

Thumb Rules for Heat Exchangers

Codes and Standards

Part 2

Shell and Tube Heat Exchanger

Allocation of Fluids

Flow Arrangements

Problem Statement

Design of Shell and Tube Heat Exchanger

General Design Steps

Thermal Design

Hydraulic Design

Part (A) - General Design Steps of Shell and Tube Heat Exchanger

Part (B) - Thermal Design of Shell and Tube Heat Exchanger

Physical Properties

How Should I Start

How to calculate heat duty of heat exchanger?

Calculating LMTD

Calculation Of Heat Transfer Area

Select A Suitable Size Tube

1 – 1 Pass Arrangement Calculation

1 – 4 Pass Arrangement Calculation

Read jH Factor from Graph-Tube

Summary of Tube Side Calculation...

Shell Side Calculations

Read jH Factor from Graph-Shell

Calculation Of Overall Heat Transfer Coefficient

Calculation of LMTD Correction Factor

Heat Transfer Area Verification

Part (C) – Hydraulic Design

Pressure Drop Calculations across Tube side…

Pressure Drop Calculations across shell side…

Single Phase Exchanger-Formulas

Codes & Standards

14) Pressure Safety Valves and Sizing / Calculation Procedures (6 hours)

Introduction

PSV Types

Chattering Problems

Sizing Calculations

Example and Procedures

Codes, Standards and Simulators

15) Control Valves and Sizing Calculations (5 hours)

Introduction

Features

Flow Characteristics

Cavitation

Flashing

Piping Influence & Choked Flow

Typical Control Valve Data Sheet

Construction Features

Classification & Types

Types of Actuators

Symbology in P&ID

Bonnet & Accessories

Major Vendors

Interface

Body & Trim Material

Codes & Standards

Sizing & Selection

16) Cost Estimation Methods (4 hours)

Fixed Capital Investment

Cost Estimate Types and Accuracy

Capital Cost Estimate Classifications

Capital Cost Estimate Definition

Cost Estimation Methods

Factors Affecting Capital Cost

Direct Project Expenses

Indirect Project Expenses

Contingency and Fee

Auxiliary Facilities

Pumps and Electric Motors

Fans

Blowers

Compressors

Heat Exchangers

Fired Heaters

Pressure Vessels

Distillation Columns

Packed Distillation Columns

17) HAZOP Analysis Fundamental (8 hours)

What is HAZOP?

Objective of HAZOP

How and Why HAZOP is used.

Purpose of HAZOP

HAZOP – Hazard and Operability Study

Features of HAZOP Study

HAZOP Phasing

HAZOP Study Procedure

HAZOP Study Flow Chart

Guidelines for division into Sections (Nodes)

Guide Words

HAZOP Study Form

HAZOP Study

Strength of HAZOP

Weakness of HAZOP

Planning for HAZOP

Documents to be kept ready

Team Characteristics

Responsibility of HAZOP Team Members

Sample Process Documents

Sample HAZOP Work Sheet

Sample HAZOP Close Out Report

Potrebbero piacerti anche

- Inspire Science Overview BrochureDocumento16 pagineInspire Science Overview BrochureJeffery Rafael Zeledon Tinoco0% (1)

- Oxygen Generation Plant For HospitalDocumento4 pagineOxygen Generation Plant For Hospitalrutuja100% (1)

- Deliverables and Estimated Man-Hours: Detail DesignDocumento10 pagineDeliverables and Estimated Man-Hours: Detail DesignkingNessuna valutazione finora

- Construction Schedule With S-CurveDocumento23 pagineConstruction Schedule With S-CurveJp Gallardo100% (2)

- EPC For ASAB Phase-II Stage-2-LatestDocumento2 pagineEPC For ASAB Phase-II Stage-2-LatestGokulprabhuNessuna valutazione finora

- P&ID ChecklistDocumento4 pagineP&ID ChecklistMeoNessuna valutazione finora

- Equipment Design BasisDocumento4 pagineEquipment Design BasisAnjani GantiNessuna valutazione finora

- PFD ChecklistDocumento1 paginaPFD ChecklistNguyen Anh TungNessuna valutazione finora

- Piping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDocumento5 paginePiping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDhiren PatelNessuna valutazione finora

- Column Piping: Study Layout, Nozzle Orientation & Platforms RequirementsDocumento23 pagineColumn Piping: Study Layout, Nozzle Orientation & Platforms Requirementsreach_arindomNessuna valutazione finora

- Rebar ArrangmentDocumento116 pagineRebar ArrangmentJesusBlasVitangcol100% (2)

- Guideline - Pump - System - Designers (Pump Fundamentals) PDFDocumento16 pagineGuideline - Pump - System - Designers (Pump Fundamentals) PDFyyukin1100% (1)

- P&ID Check ListDocumento3 pagineP&ID Check Listankur2061Nessuna valutazione finora

- Test Plan TemplateDocumento11 pagineTest Plan Templateapi-3806986100% (8)

- Geotechnical Manual For SlopesDocumento303 pagineGeotechnical Manual For SlopesMarcel Toruño Mendez100% (19)

- P&id PDFDocumento36 pagineP&id PDFSterling GordianNessuna valutazione finora

- en - O.1 - 8131 38Documento61 pagineen - O.1 - 8131 38yones83% (72)

- Pressure Safety ValvesDocumento11 paginePressure Safety Valveschianhho100% (1)

- Introduction To Engineering in Oil&Gas Facilitlities (For Distribution)Documento26 pagineIntroduction To Engineering in Oil&Gas Facilitlities (For Distribution)henryhh111100% (2)

- Process MaddahDocumento263 pagineProcess MaddahparykoochakNessuna valutazione finora

- Line SizingDocumento14 pagineLine SizingSaif MujawarNessuna valutazione finora

- PSV SizingDocumento18 paginePSV SizingGo IELTSNessuna valutazione finora

- General Deliverable of Piping Industry All DepartmentDocumento3 pagineGeneral Deliverable of Piping Industry All Departmentsujay Avati100% (1)

- Line Sizing CalculationsDocumento21 pagineLine Sizing Calculationsjabar sathikNessuna valutazione finora

- Chemical Engineering Plant Design (Che-441) : Dr. Imran HassanDocumento24 pagineChemical Engineering Plant Design (Che-441) : Dr. Imran HassanHassan KhalidNessuna valutazione finora

- Brief About Atlas CopcoDocumento17 pagineBrief About Atlas CopcorutujaNessuna valutazione finora

- Lecture 2 Process Engineering-1Documento95 pagineLecture 2 Process Engineering-1ahmed.ayoob.abdNessuna valutazione finora

- Flowsheet LectureDocumento23 pagineFlowsheet LectureAdolfo Perez MonteroNessuna valutazione finora

- MMP-CKL-0007 PID Check ListDocumento5 pagineMMP-CKL-0007 PID Check ListQWAS111Nessuna valutazione finora

- KIL3012 - WEEK 1 - 10.9.19 (Student Copy)Documento61 pagineKIL3012 - WEEK 1 - 10.9.19 (Student Copy)Ed100% (1)

- Flare Line Stress AnalysisDocumento7 pagineFlare Line Stress Analysisdhurjatibhutesh100% (1)

- Korf BrochureDocumento1 paginaKorf Brochurelhphong021191Nessuna valutazione finora

- Technology SelectionDocumento5 pagineTechnology SelectionrutujaNessuna valutazione finora

- Calculation of Relief Load On ColumnDocumento5 pagineCalculation of Relief Load On Columnnghiemta18Nessuna valutazione finora

- Computation of Dead LoadsDocumento10 pagineComputation of Dead LoadsSyrille Reyes75% (4)

- (SKP) PFD & P&idDocumento43 pagine(SKP) PFD & P&idSuresh Haldipur100% (1)

- Safety in OverpressureDocumento27 pagineSafety in OverpressurevrajakisoriDasiNessuna valutazione finora

- Basic Definitions of Overall Engineering PhasesDocumento12 pagineBasic Definitions of Overall Engineering PhasesTamka76100% (1)

- August 2012 IssueDocumento56 pagineAugust 2012 IssueGas, Oil & Mining Contractor Magazine100% (1)

- Industrial: Western European Energy Conservation Technologies For EvaporatorsDocumento33 pagineIndustrial: Western European Energy Conservation Technologies For EvaporatorsPhoe ChitNessuna valutazione finora

- Process Skid TrainingDocumento5 pagineProcess Skid TrainingrutujaNessuna valutazione finora

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferDocumento35 pagine6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalNessuna valutazione finora

- Process Design EngineeringDocumento3 pagineProcess Design EngineeringSHIVAM GUPTANessuna valutazione finora

- How Do You Carry Out Estimation? Ans: 1. Input From BidDocumento21 pagineHow Do You Carry Out Estimation? Ans: 1. Input From BidSunil ShaNessuna valutazione finora

- P&id SeminarDocumento30 pagineP&id SeminaryasirvazhikkadavuNessuna valutazione finora

- 10a - Pressure Relief SystemsDocumento3 pagine10a - Pressure Relief SystemsIslam SolimanNessuna valutazione finora

- Air Coolers Versus Shell-And-tube Water CoolersDocumento8 pagineAir Coolers Versus Shell-And-tube Water CoolersDefenceDog67% (3)

- Epcm Services For Installation of "Indresid " Demonstration Plant at PanipatDocumento19 pagineEpcm Services For Installation of "Indresid " Demonstration Plant at Panipatrutuja100% (2)

- Introducers Agreement O.I.L.Ahmedabad and AEC PuneDocumento4 pagineIntroducers Agreement O.I.L.Ahmedabad and AEC PunerutujaNessuna valutazione finora

- 01b. - Design Phases & InformationDocumento9 pagine01b. - Design Phases & InformationAna Carrasco MartínezNessuna valutazione finora

- Procurement of Piping SP Item PDFDocumento1 paginaProcurement of Piping SP Item PDFDinda Putri AmaliaNessuna valutazione finora

- Technology Selection For A Chemical Process GuidelinesDocumento9 pagineTechnology Selection For A Chemical Process GuidelinesrutujaNessuna valutazione finora

- Process Safeguarding - PSE02Documento2 pagineProcess Safeguarding - PSE02Sarfraz AliNessuna valutazione finora

- Eclipse HandbookDocumento118 pagineEclipse Handbook23Otter100% (1)

- Presentation For PSA Medical Oxygen GeneratorsDocumento10 paginePresentation For PSA Medical Oxygen GeneratorsrutujaNessuna valutazione finora

- Model Review Process X5axp5bsDocumento8 pagineModel Review Process X5axp5bsNadi Jothidan KLNessuna valutazione finora

- Equipment SizingDocumento5 pagineEquipment SizingPandu RockingNessuna valutazione finora

- Process Design Engineering Test-1Documento6 pagineProcess Design Engineering Test-1Vague FruitsNessuna valutazione finora

- Erification Omment Heet: ALPHA ECC-Dehydration Skids Package For Tien Hai Thai Binh ProjectDocumento2 pagineErification Omment Heet: ALPHA ECC-Dehydration Skids Package For Tien Hai Thai Binh ProjectLê Đức ThiệnNessuna valutazione finora

- Process Engineering Course by IfluidsDocumento81 pagineProcess Engineering Course by IfluidsirfichemNessuna valutazione finora

- Process EngineeringDocumento2 pagineProcess EngineeringSuvidya Institute of TechnologyNessuna valutazione finora

- Ammonia B PDFDocumento9 pagineAmmonia B PDFmehrdad_k_rNessuna valutazione finora

- Design of PipingDocumento51 pagineDesign of PipingLuisRiosQNessuna valutazione finora

- P&IDDocumento38 pagineP&IDHưng Luca100% (1)

- SAMSUNG SEM-9471E - Process Design Manual - Health and Design Safety Specification Rev0 2004Documento7 pagineSAMSUNG SEM-9471E - Process Design Manual - Health and Design Safety Specification Rev0 2004d_mazieroNessuna valutazione finora

- Automated Valves - GeneralDocumento19 pagineAutomated Valves - Generalhafizi07Nessuna valutazione finora

- 312013145817piping Design Engineering With PDMS Training CourseDocumento4 pagine312013145817piping Design Engineering With PDMS Training CourseAsan IbrahimNessuna valutazione finora

- Mechanical Design of Process EquipmentsDocumento2 pagineMechanical Design of Process EquipmentsSuvidya Institute of TechnologyNessuna valutazione finora

- General Arrangement Drawing: Pump DataDocumento1 paginaGeneral Arrangement Drawing: Pump DataJwardNessuna valutazione finora

- Junín Upgrader Hydrocracking Unit (14) Overall Material BalanceDocumento11 pagineJunín Upgrader Hydrocracking Unit (14) Overall Material BalancegarciahoNessuna valutazione finora

- BepDocumento4 pagineBepkashifwarsiNessuna valutazione finora

- Final PrintDocumento5 pagineFinal PrintMustafa AhsanNessuna valutazione finora

- Massive Open Online CourseDocumento44 pagineMassive Open Online CourseAdegunju Adedayo SulaimonNessuna valutazione finora

- Technical Audit Report (Sample)Documento4 pagineTechnical Audit Report (Sample)रविन्द्र मरघड़ेNessuna valutazione finora

- NSPR Ipp Ac 001Documento1 paginaNSPR Ipp Ac 001rutujaNessuna valutazione finora

- Comments On Equinox - BuHasa Project ScopeDocumento4 pagineComments On Equinox - BuHasa Project ScoperutujaNessuna valutazione finora

- Site Conditions Considered : (The Site Pressure and Pvs Values Are Taken From Vapour Pressure Chart)Documento1 paginaSite Conditions Considered : (The Site Pressure and Pvs Values Are Taken From Vapour Pressure Chart)rutujaNessuna valutazione finora

- Course Overview: Hazard and Operability (HAZOP) Studies For Supervisors-Team LeadersDocumento3 pagineCourse Overview: Hazard and Operability (HAZOP) Studies For Supervisors-Team LeadersrutujaNessuna valutazione finora

- SVN Process Capability Strength ListDocumento1 paginaSVN Process Capability Strength ListrutujaNessuna valutazione finora

- Enhanced-Gravity-Sizing PackDocumento1 paginaEnhanced-Gravity-Sizing PackrutujaNessuna valutazione finora

- Process Risk Assessment & Risk Management Outline: Course OverviewDocumento2 pagineProcess Risk Assessment & Risk Management Outline: Course OverviewrutujaNessuna valutazione finora

- HS 08 Working Safely Course OutlineDocumento2 pagineHS 08 Working Safely Course OutlinerutujaNessuna valutazione finora

- Enlistment Form For Engineering Sub-Contractor: L&T-ChiyodaDocumento3 pagineEnlistment Form For Engineering Sub-Contractor: L&T-ChiyodarutujaNessuna valutazione finora

- Sour Water Stripper 2Documento2 pagineSour Water Stripper 2rutujaNessuna valutazione finora

- Tech Clarification No.1 VaangdenDocumento1 paginaTech Clarification No.1 VaangdenrutujaNessuna valutazione finora

- Design, Fabrication, Supply & Commissioning of Stainless Steel Chemical SkidsDocumento2 pagineDesign, Fabrication, Supply & Commissioning of Stainless Steel Chemical SkidsrutujaNessuna valutazione finora

- Vaangden Pte LTD: MOU Strictly ConfidentialDocumento9 pagineVaangden Pte LTD: MOU Strictly ConfidentialrutujaNessuna valutazione finora

- Reply E-102 Bottoms Feed Heat ExchangerDocumento1 paginaReply E-102 Bottoms Feed Heat ExchangerrutujaNessuna valutazione finora

- SVN Commented 258A - Proposal - From FOCUS To SVNAIK - CRISIL REPORTDocumento6 pagineSVN Commented 258A - Proposal - From FOCUS To SVNAIK - CRISIL REPORTrutujaNessuna valutazione finora

- Typical PFD For Sour Water Stripper Column: Crude Oil Production Slug CatcherDocumento2 pagineTypical PFD For Sour Water Stripper Column: Crude Oil Production Slug CatcherrutujaNessuna valutazione finora

- Chapter 18 - Foundations and Retaining WallsDocumento32 pagineChapter 18 - Foundations and Retaining WallsShyamNessuna valutazione finora

- DEA GuidelinesDocumento2 pagineDEA GuidelinesKawsar AlamNessuna valutazione finora

- Slab With ReportsDocumento36 pagineSlab With ReportsER Manish MakhijaNessuna valutazione finora

- Gate Iitd Ac in EEKey PHPDocumento2 pagineGate Iitd Ac in EEKey PHPshagun gargNessuna valutazione finora

- High-Strength Concrete Structural Walls: Aci Structural Journal Technical PaperDocumento10 pagineHigh-Strength Concrete Structural Walls: Aci Structural Journal Technical PaperSiva GuruNessuna valutazione finora

- Abet Comm2 2015-2016 1Documento2 pagineAbet Comm2 2015-2016 1moneer1994Nessuna valutazione finora

- Residual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamageDocumento69 pagineResidual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamagemilindshettiNessuna valutazione finora

- Precast Piles For Route 40 Bridge in Virginia Using Concrete Filled FRP TubesDocumento14 paginePrecast Piles For Route 40 Bridge in Virginia Using Concrete Filled FRP TubesmarkicivanNessuna valutazione finora

- Attachment 01-Project Standards & Specifications-PearlDocumento8 pagineAttachment 01-Project Standards & Specifications-Pearlum erNessuna valutazione finora

- SBGH Corporate BrochureDocumento28 pagineSBGH Corporate Brochureomar14saifNessuna valutazione finora

- An Innovative RTM Providing Test Maintenance in An Automated Scripting New FrameworksDocumento5 pagineAn Innovative RTM Providing Test Maintenance in An Automated Scripting New FrameworksInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Fy 2018 Status of Contracts - Report For StakeholderDocumento266 pagineFy 2018 Status of Contracts - Report For StakeholderAngel MilitanteNessuna valutazione finora

- Cheemi SBWZ Temperature Transmitter PDFDocumento2 pagineCheemi SBWZ Temperature Transmitter PDFNguyen SonNessuna valutazione finora

- Introduction - Types of BuildingDocumento15 pagineIntroduction - Types of BuildingOmar SakibNessuna valutazione finora

- Design Development PlanDocumento1 paginaDesign Development PlanRajNessuna valutazione finora

- 123 Electrical InspectorDocumento2 pagine123 Electrical InspectorFahimuddin QureshiNessuna valutazione finora

- B.tech (CSE) Curriculum 2015 2016 Final - June 4Documento6 pagineB.tech (CSE) Curriculum 2015 2016 Final - June 4Soumyadeep SenguptaNessuna valutazione finora

- Compression and Capillary Pipe FittingsDocumento2 pagineCompression and Capillary Pipe FittingsstarykltNessuna valutazione finora

- Profile of Dr. Premanand ShenoyDocumento1 paginaProfile of Dr. Premanand ShenoyPremanand ShenoyNessuna valutazione finora

- AcharyaInstitute of Management VS Dayananda Sagar College of EngineeringDocumento7 pagineAcharyaInstitute of Management VS Dayananda Sagar College of EngineeringAdmission DetailsNessuna valutazione finora

- Ucu 3102Documento2 pagineUcu 3102Ishak IshakNessuna valutazione finora

- Design of UPS With Customer Load Management Function Ko, Jae HunDocumento82 pagineDesign of UPS With Customer Load Management Function Ko, Jae HunArmandinho CaveroNessuna valutazione finora

- Fem Analysis of Anchored Sheet Pile Quay Wall: A Case Study On The Failure of Wq-7 Berth of Visakhapatnam PortDocumento7 pagineFem Analysis of Anchored Sheet Pile Quay Wall: A Case Study On The Failure of Wq-7 Berth of Visakhapatnam Portbasum matNessuna valutazione finora