Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

03 Stress 01 Surface and Contact Forces

Caricato da

rohitTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

03 Stress 01 Surface and Contact Forces

Caricato da

rohitCopyright:

Formati disponibili

Section 3.

3.1 Surface and Contact Stress

The concept of the force is fundamental to mechanics and many important problems

can be cast in terms of forces only, for example the problems considered in Chapter 2.

However, more sophisticated problems require that the action of forces be described

in terms of stress, that is, force divided by area. For example, if one hangs an object

from a rope, it is not the weight of the object which determines whether the rope will

break, but the weight divided by the cross-sectional area of the rope, a fact noted by

Galileo in 1638.

3.1.1 Stress Distributions

As an introduction to the idea of stress, consider the situation shown in Fig. 3.1.1a: a

block of mass m and cross sectional area A sits on a bench. Following the

methodology of Chapter 2, an analysis of a free-body of the block shows that a force

equal to the weight mg acts upward on the block, Fig. 3.1.1b. Allowing for more

detail now, this force will actually be distributed over the surface of the block, as

indicated in Fig. 3.1.1c. Defining the stress to be force divided by area, the stress

acting on the block is

mg

(3.1.1)

A

The unit of stress is the Pascal (Pa): 1Pa is equivalent to a force of 1 Newton acting

over an area of 1 metre squared. Typical units used in engineering applications are

the kilopascal, kPa ( 10 3 Pa ), the megapascal, MPa ( 10 6 Pa ) and the gigapascal, GPa

( 10 9 Pa ).

mg mg

(a) (b) (c)

Figure 3.1.1: a block resting on a bench; (a) weight of the block, (b) reaction of

the bench on the block, (c) stress distribution acting on the block

The stress distribution of Fig. 3.1.1c acts on the block. By Newton’s third law, an

equal and opposite stress distribution is exerted by the block on the bench; one says

that the weight force of the block is transmitted to the underlying bench.

The stress distribution of Fig. 3.1.1 is uniform, i.e. constant everywhere over the

surface. In more complex and interesting situations in which materials contact, one is

more likely to obtain a non-uniform distribution of stress. For example, consider the

case of a metal ball being pushed into a similarly stiff object by a force F, as

Solid Mechanics Part I 31 Kelly

Section 3.1

illustrated in Fig. 3.1.2.1 Again, an equal force F acts on the underside of the ball,

Fig. 3.1.2b. As with the block, the force will actually be distributed over a contact

region. It will be shown in Part II that the ball (and the large object) will deform and

a circular contact region will arise where the ball and object meet2, and that the stress

is largest at the centre of the contact surface, dying away to zero at the edges of

contact, Fig. 3.1.2c ( 1 2 in Fig. 3.1.2c). In this case, we can consider a small

area of the contact region dA , Fig. 3.1.2d; the force on this region is dA . The total

force is

F dF dA (3.1.2)

A A

The stress varies from point to point over the surface but the sum (or integral) of the

stresses (times areas) equals the total force applied to the ball.

F F

contact Small

region region dA

F 2

1

(a) (b) (c) (d)

Figure 3.1.2: a ball being forced into a large object, (a) force applied to ball, (b)

reaction of object on ball, (c) a non-uniform stress distribution over the

contacting surface, (d) the stress acting on a small (infinitesimal) area

A given stress distribution gives rise to a resultant force, which is obtained by

integration, Eqn. 3.1.2. It will also give rise to a resultant moment. This is examined

in the following example.

Example

Consider the surface shown in Fig. 3.1.3, of length 2m and depth 2m (into the page).

The stress over the surface is given by x kPa, with x measured in m from the left-

hand side of the surface.

The force acting on an element of length dx at position x is (see Fig. 3.1.3b)

dF dA x kPa dx m 2 m

The resultant force is then, from Eqn. 3.1.2

1

the weight of the ball is neglected here

2

the radius of which depends on the force applied and the materials in contact

Solid Mechanics Part I 32 Kelly

Section 3.1

2

F dF 2 xdx kPa m 2 4 kN

A 0

The moment of the stress distribution is given by

M 0 dM l dA (3.1.3)

A A

where l is the length of the moment-arm from the chosen axis.

Taking the axis to be at x 0 , the moment-arm is l x , Fig. 3.1.3b, and

2

M x 0 dM 2 x x dx kPa m 3 16

3

kN m

A 0

Taking moments about the right-hand end, x 2 , one has

2

8

M x 2 dM 2 x 2 x dx kPa m 3 kN m

3

A 0

(x)

x (x)

x

2m dx

(a) (b)

Figure 3.1.3: a non-uniform stress acting over a surface; (a) the stress

distribution, (b) stress acting on an element of size dx

3.1.2 Equivalent Forces and Moments

Sometimes it is useful to replace a stress distribution with an equivalent force F,

i.e. a force equal to the resultant force of the distribution and one which also gives the

same moment about any axis as the distribution. Formulae for equivalent forces are

derived in what follows for triangular and arbitrary linear stress distributions.

Triangular Stress Distribution

Solid Mechanics Part I 33 Kelly

Section 3.1

Consider the triangular stress distribution shown in Fig. 3.1.4. The stress at the end is

0 , the length of the distribution is L and the thickness “into the page” is t. With

( x) 0 x / L , the equivalent force is, from Eqn. 3.1.2,

L

x 1

F t 0 dx 0 Lt (3.1.4)

0

L 2

which is just the average stress times the “area of the triangle”. The point of action of

this force should be such that the moment of the force is equivalent to the moment of

the stress distribution. Taking moments about the left hand end, for the distribution

one has, from 3.1.3,

L

1

M o t x ( x )dx 0 L2 t

0

3

Placing the force at position x xc , Fig. 3.1.4, the moment of the force is

M o 0 Lt / 2 xc . Equating these expressions leads to the position at which the

equivalent force acts, two-thirds the way along the triangle:

2

xc L. (3.1.5)

3

equivalent force

(x)

0

x

o xc

L

Figure 3.1.4: triangular stress distribution and equivalent force

Note that the moment about any axis is now the same for both the stress distribution

and the equivalent force.

■

Arbitrary Linear Stress Distribution

Consider the linear stress distribution shown in Fig. 3.1.5. The stress at the ends are

1 and 2 and this time the equivalent force is

L

F t 1 ( 2 1 )( x / L)dx Lt 1 2 / 2 (3.1.6)

0

Taking moments about the left hand end, for the distribution one has

Solid Mechanics Part I 34 Kelly

Section 3.1

L

M o t x ( x)dx L2 t 1 2 2 / 6 .

0

The moment of the force is M o Lt 1 2 xc / 2 . Equating these expressions leads

to

L 1 2 2

xc (3.1.7)

3 1 2

Eqn. 3.1.5 follows from 3.1.7 by setting 1 0 .

equivalent force

( x)

2

1

o xc

L

Figure 3.1.5: a non-uniform stress distribution and equivalent force

The Centroid

Generalising the above cases, the line of action of the equivalent force for any

arbitrary stress distribution (x) is

t x ( x)dx xdF

xc Centroid (3.1.8)

t ( x)dx F

This location is known as the centroid of the distribution.

Note that most of the discussion above is for two-dimensional cases, i.e. the stress is

assumed constant “into the page”. Three dimensional problems can be tackled in the

same way, only now one must integrate two-dimensionally over a surface rather than

one-dimensionally over a line.

Also, the forces considered thus far are normal forces, where the force acts

perpendicular to a surface, and they give rise to normal stresses. Normal stresses are

also called pressures when they are compressive as in Figs. 3.1.1-2.

Solid Mechanics Part I 35 Kelly

Section 3.1

3.1.3 Shear Stress

Consider now the case of shear forces, that is, forces which act tangentially to

surfaces.

A normal force F acts on the block of Fig. 3.1.6a. The block does not move and, to

maintain equilibrium, the force is resisted by a friction force F mg , where is

the coefficient of friction. A free body diagram of the block is shown in Fig. 3.1.6b.

Assuming a uniform distribution of stress, the stress and resultant force arising on the

surfaces of the block and underlying object are as shown. The stresses are in this case

called shear stresses.

F F

F

(a) (b)

Figure 3.1.6: shear stress; (a) a force acting on a block, (b) shear stresses arising

on the contacting surfaces

3.1.4 Combined Normal and Shear Stress

Forces acting inclined to a surface are most conveniently described by decomposing

the force into components normal and tangential to the surface. Then one has both

normal stress N and shear stress S , as in Fig. 3.1.7.

N

S

Figure 3.1.7: a force F giving rise to normal and shear stress over the contacting

surfaces

The stresses considered in this section are examples of surface stresses or contact

stresses. They arise when materials meet at a common surface. Other examples

would be sea-water pressurising a gas cylinder in deep water and the stress exerted by

a train wheel on a train track.

Solid Mechanics Part I 36 Kelly

Section 3.1

3.1.5 Problems

1. Consider the surface shown below, of length 4cm and unit depth (1cm into the

page). The stress over the surface is given by 2 x kPa, with x measured in

cm from the surface centre.

(a) Evaluate the resultant force acting on the surface (in Newtons).

(b) What is the moment about an axis (into the page) through the left-hand end of

the surface?

(c) What is the moment about an axis (into the page) through the centre of the

surface?

y x

( x)

2. Consider the surface shown below, of length 4mm and unit depth (1mm into the

page). The stress over the surface is given by x MPa, with x measured from

the surface centre, i.e. x mm corresponds to x MPa. What is the total force

acting on the surface, and the moment acting about the centre of the surface?

y

x

3. Find the reaction forces (per unit length) at the pin and roller for the following

beam, which is subjected to a varying pressure distribution, the maximum

pressure being ( x) 20 kPa (all lengths are in cm – give answer in N/m)

[Hint: first replace the stress distribution with three equivalent forces]

4 12 8

4 16 4

Solid Mechanics Part I 37 Kelly

Section 3.1

4. A block of material of width 10cm and length 1m is pushed into an underlying

substrate by a normal force of 100 N. It is found that a uniform triangular normal

stress distribution arises at the contacting surfaces, that is, the stress is maximum

at the centre and dies off linearly to zero at the block edges, as sketched below

right. What is the maximum pressure acting on the surface?

100 N typical cross-

section

1m

stress

10 cm distribution

Solid Mechanics Part I 38 Kelly

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

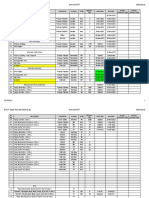

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Secret Codes The Formula of Mind Control-2015Documento136 pagineThe Secret Codes The Formula of Mind Control-2015Joe HinderbergenNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Triumph of Reason: The Thinking Man's HitlerDocumento122 pagineThe Triumph of Reason: The Thinking Man's HitlerDaniel MillerNessuna valutazione finora

- Jose Prager - Name & SignDocumento7 pagineJose Prager - Name & SignFreddie666100% (4)

- Islamic Palace Architecture in The Western Mediterranean - A HistoryDocumento385 pagineIslamic Palace Architecture in The Western Mediterranean - A HistoryJuan Antonio Franco100% (4)

- You, Me and Us Respectful Relationships Education Program: Training ManualDocumento257 pagineYou, Me and Us Respectful Relationships Education Program: Training ManualWomen's Health West100% (1)

- Mindfulness: Angel MeditationDocumento3 pagineMindfulness: Angel MeditationTereNessuna valutazione finora

- Using Games in Teaching English To Young LearnersDocumento30 pagineUsing Games in Teaching English To Young LearnersRatri Sudarno Putri82% (11)

- Glimmers of Hope, Prana Healing of Kundalini Yoga - HD 720Documento12 pagineGlimmers of Hope, Prana Healing of Kundalini Yoga - HD 720Krishna S KhalsaNessuna valutazione finora

- Violence in Football (Soccer) : Overview, Prevalence, and Risk FactorsDocumento12 pagineViolence in Football (Soccer) : Overview, Prevalence, and Risk FactorsDušan ČolovejićNessuna valutazione finora

- Sars-Cov-2 (Covid-19) Qualitative RT-PCR: Method: Real Time PCR (Qualitative), ICMR Reg No: STACDIABGDocumento2 pagineSars-Cov-2 (Covid-19) Qualitative RT-PCR: Method: Real Time PCR (Qualitative), ICMR Reg No: STACDIABGrohitNessuna valutazione finora

- Solutions 4 F14Documento5 pagineSolutions 4 F14nageshNessuna valutazione finora

- Equipment ErectionDocumento5 pagineEquipment ErectionrohitNessuna valutazione finora

- Main Tank Farm: Mass Excavation ExcavationDocumento17 pagineMain Tank Farm: Mass Excavation ExcavationrohitNessuna valutazione finora

- Overall Civil: Discipline UOM Total Scope Total Cumulative Achieved QtyDocumento1 paginaOverall Civil: Discipline UOM Total Scope Total Cumulative Achieved QtyrohitNessuna valutazione finora

- Technical Interview Mechanical Engineering Objective Book - by WWW - Learnengineering.in-1Documento138 pagineTechnical Interview Mechanical Engineering Objective Book - by WWW - Learnengineering.in-1rohitNessuna valutazione finora

- fpz3 A PDFDocumento265 paginefpz3 A PDFrohitNessuna valutazione finora

- Am PPDocumento2 pagineAm PProhitNessuna valutazione finora

- PlacementDocumento13 paginePlacementyaswanthNessuna valutazione finora

- Aavid Augmentated Heat SinksDocumento4 pagineAavid Augmentated Heat SinksrohitNessuna valutazione finora

- CH 4Documento22 pagineCH 4Manprita BasumataryNessuna valutazione finora

- HW2Documento1 paginaHW2Siyar JoyendaNessuna valutazione finora

- Box 8Documento2 pagineBox 8rohitNessuna valutazione finora

- Workshop TechDocumento3 pagineWorkshop TechrohitNessuna valutazione finora

- Zety Com PDFDocumento1 paginaZety Com PDFrohitNessuna valutazione finora

- Administrative ThinkersDocumento31 pagineAdministrative ThinkersRaj VeerNessuna valutazione finora

- 6a - Optimization-Introduction To DesignDocumento18 pagine6a - Optimization-Introduction To DesignAnonymous 6Zrsw5gNessuna valutazione finora

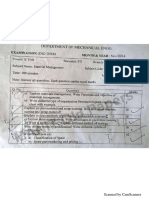

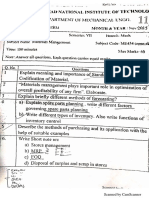

- ME6T2Documento3 pagineME6T2rohitNessuna valutazione finora

- 10 - Chapter 4Documento13 pagine10 - Chapter 4rohitNessuna valutazione finora

- PDF 2019 09 19 PDFDocumento17 paginePDF 2019 09 19 PDFrohitNessuna valutazione finora

- New Doc 2019-09-25 17.24.24 PDFDocumento4 pagineNew Doc 2019-09-25 17.24.24 PDFrohitNessuna valutazione finora

- New Doc 2019-11-18 22.02.17 PDFDocumento3 pagineNew Doc 2019-11-18 22.02.17 PDFrohitNessuna valutazione finora

- New Doc 2019-11-18 22.02.17 PDFDocumento3 pagineNew Doc 2019-11-18 22.02.17 PDFrohitNessuna valutazione finora

- Material Management Class NotesDocumento10 pagineMaterial Management Class NotesrohitNessuna valutazione finora

- New Doc 2019-09-25 17.24.24Documento4 pagineNew Doc 2019-09-25 17.24.24rohitNessuna valutazione finora

- Academic Calendar Dean Acad OfficeDocumento1 paginaAcademic Calendar Dean Acad OfficeNiteshNarukaNessuna valutazione finora

- RSCH g12 First Quarter Exam 2 PDF FreeDocumento54 pagineRSCH g12 First Quarter Exam 2 PDF FreeJoseph LapsoNessuna valutazione finora

- Ahmed Mohamed Sabry: Personal WebsitDocumento2 pagineAhmed Mohamed Sabry: Personal Websitapi-3698378Nessuna valutazione finora

- REPORT CARD (New Format G1 & 2) SY 2018-2019Documento2 pagineREPORT CARD (New Format G1 & 2) SY 2018-2019Goldine Barcelona EteNessuna valutazione finora

- Encouraging What Is Not Figural in The Gestalt GroupDocumento8 pagineEncouraging What Is Not Figural in The Gestalt GroupevgeniiNessuna valutazione finora

- Causes of Failure of Housing ProjectsDocumento7 pagineCauses of Failure of Housing Projectschill007Nessuna valutazione finora

- Identity-Protective Cognition ThesisDocumento37 pagineIdentity-Protective Cognition ThesisJohn BurkeNessuna valutazione finora

- Sped854 Szumlanski D m7 CasestudyreflectionDocumento3 pagineSped854 Szumlanski D m7 Casestudyreflectionapi-296328009Nessuna valutazione finora

- CS302 - Lab Manual - Week No PDFDocumento9 pagineCS302 - Lab Manual - Week No PDFattiqueNessuna valutazione finora

- QIYASDocumento28 pagineQIYASfamjNessuna valutazione finora

- Analysis and Comparison On Dynamic Characteristics of The BridgeDocumento10 pagineAnalysis and Comparison On Dynamic Characteristics of The BridgejayaramanrathnamNessuna valutazione finora

- Project Front Pages ModelDocumento6 pagineProject Front Pages ModelRam KumarNessuna valutazione finora

- Seeing Jesus in The PoorDocumento2 pagineSeeing Jesus in The PoorLadiesofCharityUSANessuna valutazione finora

- Situated Engineering Learning: Bridging Engineering Education Research and The Learning SciencesDocumento35 pagineSituated Engineering Learning: Bridging Engineering Education Research and The Learning Sciencesmerlin_fabricio90Nessuna valutazione finora

- Britannia Hotels Job Interview QuestionnaireDocumento5 pagineBritannia Hotels Job Interview QuestionnaireAnonymous jPAGqlNessuna valutazione finora

- Tembisa Aborn Final EssayDocumento14 pagineTembisa Aborn Final Essayapi-287299654Nessuna valutazione finora

- Critical Review of Roland Robertson's BEYOND THE DISCOURSE OF GLOBALIZATIONDocumento3 pagineCritical Review of Roland Robertson's BEYOND THE DISCOURSE OF GLOBALIZATIONAndrei ColteaNessuna valutazione finora

- Circular Motion ExperimentDocumento7 pagineCircular Motion ExperimentictStactsNessuna valutazione finora

- Journal 2007Documento110 pagineJournal 2007Mat KiNessuna valutazione finora

- Mental ToughnessDocumento10 pagineMental ToughnesscitisoloNessuna valutazione finora

- Volunteering and Health Literature ReviewDocumento38 pagineVolunteering and Health Literature ReviewNCVO100% (1)

- Study Guide of Key Ideas For Unit 3 KeyDocumento5 pagineStudy Guide of Key Ideas For Unit 3 Keyapi-236114955Nessuna valutazione finora