Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Certificado Lote Er70s-6

Caricato da

willariasTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Certificado Lote Er70s-6

Caricato da

willariasCopyright:

Formati disponibili

The Lincoln Electric Company

22801 St. Clair Avenue

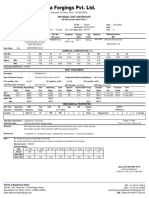

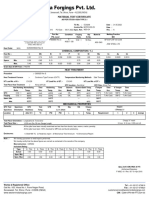

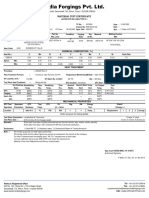

CERTIFICATE OF CONFORMANCE

Cleveland, Ohio 44117-1199 (APPLIES ONLY TO U.S. PRODUCTS)

Product: Lincoln® ER70S-6

Q1 Lot Number: 16116583

Classification: ER70S-6

Specification: AWS A5.18:2005, ASME SFA-5.18

Date May 09, 2013

This is to certify that the product named above and supplied on the referenced order number is of the same classification, manufacturing process, and material

requirements as the material which was used for the test that was concluded on the date shown, the results of which are shown below. All tests required by the

specifications shown for classification were performed at that time and the material tested met all requirements. It was manufactured and supplied according to

the Quality System Program of the Lincoln Electric Company, Cleveland, Ohio, U.S.A., which meets the requirements of ISO9001, NCA3800, AWS A5.01, and

other specification and Military requirements, as applicable. The Quality System Program has been approved by ASME, ABS, and VdTUV.

ER70S-6

Operating Settings Requirements RESULTS

Electrode Size 696 1/161inch

Polarity DC- DC-

Shielding Gas (per AWS A5.32) 100% Ar (I1-Ar-100) 100% Ar (I1-Ar-100)

Voltage, V 14

Current, A 200

Travel Speed, cm/min (in/min) (4 - 6) 13 (5)

Pass/Layers 18/8

Preheat Temperature, °C (°F) 135 (275)

Interpass Temperature, °C (°F) 150 (300)

Postweld Heat Treatment As-welded As-welded

Mechanical properties of weld deposits

Tensile Strength, MPa (ksi) (70 min.) 590 (85)

Yield Strength, 0.2% Offset, MPa (ksi) (58 min.) 470 (68)

Elongation % 22 min. 33

Average Impact Energy (20 min.) See Note

Joules @ -29 °C (ft-lbs @ -20 °F) 450,451,453 (332,333,334)

Average Hardness, HRB Not Required 90

Electrode composition (weight %) ER70S-6 1/16 Electrode

Requirements Results

C 696 0.06 - 0.15 1 0.08

Mn 1.40 - 1.85 1.47

Si 0.80 - 1.15 0.84

S 0.035 max. 0.007

P 0.025 max. 0.007

Cr 0.15 max. 0.02

Ni 0.15 max. 0.01

Mo 0.15 max. 0.00

V 0.03 max. 0.00

Total Cu 0.50 max. 0.16

NOTE: One or more of the reported impact values exceeds the machine capacity (542 J or 400 ft-lbs) or is greater than its 80% capacity (434 J or 320

ft-lbs). The values reported are approximate and should not be averaged, per ASTM E23.

1. This certificate complies with the requirements of EN 10204, Type 2.2.

2. All manufactured diameters will also meet these requirements.

3. Test assembly constructed of ASTM A36 steel.

4. Radiographic Inspection: Met requirements.

5. Results below the detection limits of the instrument or lower than the precision required by the specification are reported as zero. Strength values in SI

units are reported to the nearest 10 MPa converted from actual data. Preheat and interpass temperature values in SI units are reported to the nearest

5 degrees.

January 14, 2014 January 15, 2014

Toronto Cunningham, Certification Supervisor Date Dave Fink, Manager, Compliance Date

Engineering, Consumable R&D

Page 1 of 1 Cert. No. 9150

Potrebbero piacerti anche

- Q1 DisplayDocumento1 paginaQ1 DisplayOscar BasantesNessuna valutazione finora

- L-50 Lincolnweld 980Documento1 paginaL-50 Lincolnweld 980geloram66Nessuna valutazione finora

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Documento2 paginePipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazNessuna valutazione finora

- Lincolnweld 888 & LA-85Documento2 pagineLincolnweld 888 & LA-85Pablo PazNessuna valutazione finora

- Q1 Lot Number: 15888757: Certificate of ConformanceDocumento2 pagineQ1 Lot Number: 15888757: Certificate of ConformanceDesdeAquiHastaAllaNessuna valutazione finora

- Certificate of Conformance: Q1 Lot Number: 15163483Documento1 paginaCertificate of Conformance: Q1 Lot Number: 15163483interx00Nessuna valutazione finora

- Pipeliner 7P+: Conformances Key FeaturesDocumento2 paginePipeliner 7P+: Conformances Key FeaturesAnand GNessuna valutazione finora

- Lower Unit (85A Models) : Maintenance SpecificationDocumento1 paginaLower Unit (85A Models) : Maintenance SpecificationPHUONG NGUYENNessuna valutazione finora

- Excalibur 11018M MR CertDocumento2 pagineExcalibur 11018M MR CertAminNessuna valutazione finora

- Surface Mount PTC: AEC-Q CompliantDocumento4 pagineSurface Mount PTC: AEC-Q Compliantm3y54mNessuna valutazione finora

- Pinnacle Alloys E7018 E7018 1Documento2 paginePinnacle Alloys E7018 E7018 1BerniIrleNessuna valutazione finora

- 4.0X1500. 23920 E250a DoDocumento1 pagina4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Q1Display 15843280Documento3 pagineQ1Display 15843280Oscar BasantesNessuna valutazione finora

- 1466 - Ec0044Documento5 pagine1466 - Ec0044Deipak HoleNessuna valutazione finora

- Lincoln (Data Sheet) Murex E7024Documento2 pagineLincoln (Data Sheet) Murex E7024PubcrawlNessuna valutazione finora

- 1299 - Ec0176Documento4 pagine1299 - Ec0176Deipak HoleNessuna valutazione finora

- Ecolink Flood FL007 150 200wDocumento5 pagineEcolink Flood FL007 150 200wMohammad WildhanNessuna valutazione finora

- 1485 - Ec0231Documento6 pagine1485 - Ec0231Deepak HoleNessuna valutazione finora

- 1485 - Ec0216Documento6 pagine1485 - Ec0216Deepak HoleNessuna valutazione finora

- Material TCDocumento1 paginaMaterial TCgmbakshiNessuna valutazione finora

- 1900 - EC2157-signedDocumento4 pagine1900 - EC2157-signedDeepak HoleNessuna valutazione finora

- CertMaterialTestReport E6010 Fletweld SP 1-8Documento1 paginaCertMaterialTestReport E6010 Fletweld SP 1-8gerosuca800Nessuna valutazione finora

- 1485 - Ec0251Documento6 pagine1485 - Ec0251Deepak HoleNessuna valutazione finora

- Product Data Sheet - OK Tigrod 13.09 PDFDocumento2 pagineProduct Data Sheet - OK Tigrod 13.09 PDFarman pangestuNessuna valutazione finora

- Q1 Lot Number: 14997588: Certificate of ConformanceDocumento3 pagineQ1 Lot Number: 14997588: Certificate of ConformanceOscar BasantesNessuna valutazione finora

- AU - iPERL (Intl) Data SheetDocumento2 pagineAU - iPERL (Intl) Data SheetHC IngenierosNessuna valutazione finora

- Certificado Pipeliner 6P+Documento2 pagineCertificado Pipeliner 6P+Eric RamirezNessuna valutazione finora

- DatasheetDocumento2 pagineDatasheetStuxnetNessuna valutazione finora

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocumento2 pagineChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNessuna valutazione finora

- 1299 Ec1650Documento4 pagine1299 Ec1650Deepak HoleNessuna valutazione finora

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Documento2 pagineArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNessuna valutazione finora

- 1300 - Ec0313Documento5 pagine1300 - Ec0313Deepak HoleNessuna valutazione finora

- Material Test Certificate: TechnipfmcDocumento4 pagineMaterial Test Certificate: TechnipfmcDeipak HoleNessuna valutazione finora

- 1485 - Ec0208Documento5 pagine1485 - Ec0208Deepak HoleNessuna valutazione finora

- 1299 - Ec0583Documento5 pagine1299 - Ec0583Deipak HoleNessuna valutazione finora

- Unicima Nss23002 MTC 6534070332 of N.S. SteelDocumento12 pagineUnicima Nss23002 MTC 6534070332 of N.S. Steelchua weichengNessuna valutazione finora

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Documento2 pagineProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNessuna valutazione finora

- Material Search Results - COMPARISON REPORT: General Information MAT - ID 123 MAT - ID 212 MAT - ID 265Documento4 pagineMaterial Search Results - COMPARISON REPORT: General Information MAT - ID 123 MAT - ID 212 MAT - ID 265Muhammad DiazNessuna valutazione finora

- 1485 - Ec0234Documento5 pagine1485 - Ec0234Deepak HoleNessuna valutazione finora

- SDT S 105LMRDocumento2 pagineSDT S 105LMReaherreramNessuna valutazione finora

- 3343 (10) Prueba Final-200 HPDocumento5 pagine3343 (10) Prueba Final-200 HPMinoide De La Cruz OchoaNessuna valutazione finora

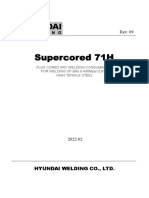

- Hyundai Supercored 71HDocumento9 pagineHyundai Supercored 71HPongwitt BoonayamaneeNessuna valutazione finora

- Ul Ag15a1 后乐Documento1 paginaUl Ag15a1 后乐karthikNessuna valutazione finora

- SteelDocumento5 pagineSteelManish DubeyNessuna valutazione finora

- ER80S Ni1Documento2 pagineER80S Ni1nilesh_erusNessuna valutazione finora

- ER80S Ni1 PDFDocumento2 pagineER80S Ni1 PDFebastien2Nessuna valutazione finora

- L1 10495 en Diamondspark 52 RC CU04110F 3375798 ENDocumento1 paginaL1 10495 en Diamondspark 52 RC CU04110F 3375798 ENRaviTeja BhamidiNessuna valutazione finora

- E6010 Data SheetDocumento2 pagineE6010 Data SheetKhaled A MarashliNessuna valutazione finora

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocumento1 paginaBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNessuna valutazione finora

- 1 - Primacore LW71 1.2 E208038900Documento1 pagina1 - Primacore LW71 1.2 E208038900Suli HartoNessuna valutazione finora

- Case Study BSES Rajdhani Power FinalDocumento4 pagineCase Study BSES Rajdhani Power FinalJonathan FerueloNessuna valutazione finora

- Technical Evaluation Sheet: Kishan Forge, RajkotDocumento3 pagineTechnical Evaluation Sheet: Kishan Forge, RajkotRajoo PrajapatiNessuna valutazione finora

- 1300 EC2192 SignedDocumento4 pagine1300 EC2192 SignedDeepak HoleNessuna valutazione finora

- Pinnacle Alloys E9018-M Code and Specification DataDocumento2 paginePinnacle Alloys E9018-M Code and Specification DataPutra Panca WardhanaNessuna valutazione finora

- 1299 EC2153 SignedDocumento5 pagine1299 EC2153 SignedDeepak HoleNessuna valutazione finora

- New Product: G5SBA20 and G5SBA60Documento2 pagineNew Product: G5SBA20 and G5SBA60CarlosNessuna valutazione finora

- Shanghai Huitian New Material Co LTD: Click To ContinueDocumento1 paginaShanghai Huitian New Material Co LTD: Click To ContinueAnimesh Kumar SinghNessuna valutazione finora

- B - Boehler EMK 6 - de - en - 5 PDFDocumento1 paginaB - Boehler EMK 6 - de - en - 5 PDFburakNessuna valutazione finora

- 3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetDocumento30 pagine3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetGiancarloRichardRivadeneyraMirandaNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Especificaciones de Proyecto para Soldadura PDFDocumento32 pagineEspecificaciones de Proyecto para Soldadura PDFwillariasNessuna valutazione finora

- Guy JollyDocumento24 pagineGuy JollyAndres Fitria FarrelNessuna valutazione finora

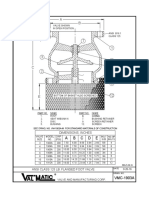

- VMC 1903aDocumento1 paginaVMC 1903awillariasNessuna valutazione finora

- MSS-SP-100 (1997) PDFDocumento7 pagineMSS-SP-100 (1997) PDFwillariasNessuna valutazione finora

- Trico Bond EpDocumento2 pagineTrico Bond EpBrandon TrocNessuna valutazione finora

- Listado Normas MSSPDocumento2 pagineListado Normas MSSPwillariasNessuna valutazione finora

- Trico Bond EpDocumento2 pagineTrico Bond EpBrandon TrocNessuna valutazione finora

- WELD Repair ProcedureDocumento5 pagineWELD Repair ProcedurewillariasNessuna valutazione finora

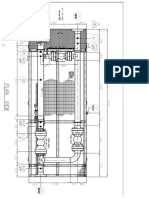

- Outlet DataDocumento7 pagineOutlet DatawillariasNessuna valutazione finora

- Guy JollyDocumento24 pagineGuy JollyAndres Fitria FarrelNessuna valutazione finora

- RP 5L9 - External Fusion Bounded Epoxy Coating of Line PipeDocumento1 paginaRP 5L9 - External Fusion Bounded Epoxy Coating of Line PipewillariasNessuna valutazione finora

- D4541Documento13 pagineD4541Danny SeeNessuna valutazione finora

- Bornemann PUMPS PDFDocumento72 pagineBornemann PUMPS PDFwillariasNessuna valutazione finora

- IPTC-22235-MS Foams To Control Slugging Issues in Pipeline - From Lab To SimulationDocumento9 pagineIPTC-22235-MS Foams To Control Slugging Issues in Pipeline - From Lab To SimulationLuky HendraningratNessuna valutazione finora

- Over Voltage ProtectionDocumento8 pagineOver Voltage ProtectionPKNessuna valutazione finora

- Reinforcement WorksheetionicbondingDocumento2 pagineReinforcement Worksheetionicbondingapi-24977735825% (4)

- QC Radiologic TechnologyDocumento20 pagineQC Radiologic TechnologyMa. Charlotte CabaleNessuna valutazione finora

- GCSE AQA Chemistry 8642 Paper 1Documento28 pagineGCSE AQA Chemistry 8642 Paper 1walidabdulrahman96Nessuna valutazione finora

- Fluid Properties LabDocumento18 pagineFluid Properties LabsilasNessuna valutazione finora

- 3.0 Plane Sailing Answers - FullDocumento16 pagine3.0 Plane Sailing Answers - FullUdhya Kumar50% (2)

- TCR Arabia Company ProfileDocumento120 pagineTCR Arabia Company Profilefatihkisa100% (1)

- Nex Flow: Frigid-X Panel CoolerDocumento17 pagineNex Flow: Frigid-X Panel CoolerrehanNessuna valutazione finora

- SADT HT-225A User Manual PDFDocumento20 pagineSADT HT-225A User Manual PDFDayane GomesNessuna valutazione finora

- AIATS First Step JEE (Main & Advanced) 2022-24 - Group 1Documento2 pagineAIATS First Step JEE (Main & Advanced) 2022-24 - Group 1Deepak LimbaNessuna valutazione finora

- Astm F 519-97 E98Documento12 pagineAstm F 519-97 E98Jorge ToribioNessuna valutazione finora

- Adge CompiledDocumento18 pagineAdge CompiledNovelyn LumboyNessuna valutazione finora

- TP07 Castillo PDFDocumento8 pagineTP07 Castillo PDFJefreyMatuanMondranoNessuna valutazione finora

- A Review On Durability of Fiber Reinforced Polymer (FRP) Bars ReinforcedDocumento18 pagineA Review On Durability of Fiber Reinforced Polymer (FRP) Bars Reinforcedsherif fodaNessuna valutazione finora

- BridgeDocumento20 pagineBridgebewketNessuna valutazione finora

- Chapter8 - Design Theory & Procedure PDFDocumento407 pagineChapter8 - Design Theory & Procedure PDFJunwhan KimNessuna valutazione finora

- D7425D7425M 13Documento3 pagineD7425D7425M 13diego rodriguez100% (1)

- UnitTest - D11 Feb 2024Documento3 pagineUnitTest - D11 Feb 2024muniharshit16Nessuna valutazione finora

- 高等材料力學2Documento20 pagine高等材料力學2吳鯰魚Nessuna valutazione finora

- Analisa Box Culvert Otiola 1Documento12 pagineAnalisa Box Culvert Otiola 1agussalim lammaseNessuna valutazione finora

- How To Calculate External Static Pressure in HVACDocumento4 pagineHow To Calculate External Static Pressure in HVACEntertain EveryoneNessuna valutazione finora

- Fiitjee: Solutions To Jee (Advanced) - 2020Documento29 pagineFiitjee: Solutions To Jee (Advanced) - 2020Vikash KumarNessuna valutazione finora

- Artemis E-Dyn® 96 Digital Displacement® Hydraulic Pump: EfficiencyDocumento3 pagineArtemis E-Dyn® 96 Digital Displacement® Hydraulic Pump: EfficiencyAshish NegiNessuna valutazione finora

- Lecture 3 Geometric Optics PDFDocumento36 pagineLecture 3 Geometric Optics PDFPuja KasmailenNessuna valutazione finora

- Thermal ConductivityDocumento5 pagineThermal ConductivitySiva Kumar SalumuriNessuna valutazione finora

- GantryDocumento7 pagineGantrysatydevsinghnegiNessuna valutazione finora

- Loc Corr SS Weldments SummaryDocumento52 pagineLoc Corr SS Weldments SummarySatheesh KumarNessuna valutazione finora

- Focus Stacking in LinuxDocumento7 pagineFocus Stacking in LinuxklladoNessuna valutazione finora