Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WRC Calculations

Caricato da

anu radhaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WRC Calculations

Caricato da

anu radhaCopyright:

Formati disponibili

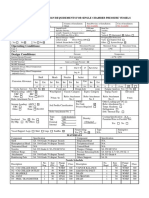

PV Elite 2019 1

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

Input, Nozzle Desc: N1 From: 20

Pressure for Reinforcement Calculations P 10.100 bars

Temperature for Internal Pressure Temp 78 °C

Shell Material SA-106 B

Shell Allowable Stress at Temperature Sv 117.90 N./mm²

Shell Allowable Stress At Ambient Sva 117.90 N./mm²

Inside Diameter of Cylindrical Shell D 303.23 mm.

Shell Finished (Minimum) Thickness t 9.0234 mm.

Shell Internal Corrosion Allowance c 0.0000 mm.

Shell External Corrosion Allowance co 0.0000 mm.

Distance from Bottom/Left Tangent 450.00 mm.

User Entered Minimum Design Metal Temperature 0.00 °C

Type of Element Connected to the Shell : Nozzle

Material SA-106 B

Material UNS Number K03006

Material Specification/Type Smls. pipe

Allowable Stress at Temperature Sn 117.90 N./mm²

Allowable Stress At Ambient Sna 117.90 N./mm²

Diameter Basis (for tr calc only) OD

Layout Angle 315.00 deg

Diameter 2.0000 in.

Size and Thickness Basis Minimum

Nominal Thickness tn 160

Flange Material SA-105

Flange Type Weld Neck Flange

Corrosion Allowance can 0.0000 mm.

Joint Efficiency of Shell Seam at Nozzle E1 1.00

Joint Efficiency of Nozzle Neck En 1.00

Outside Projection ho 150.0000 mm.

Weld leg size between Nozzle and Pad/Shell Wo 10.0000 mm.

Groove weld depth between Nozzle and Vessel Wgnv 9.0233 mm.

Inside Projection h 0.0000 mm.

Weld leg size, Inside Element to Shell Wi 0.0000 mm.

Class of attached Flange 150

Grade of attached Flange GR 1.1

The Pressure Design option was Design Pressure + static head.

Nozzle Sketch (may not represent actual weld type/configuration)

Insert/Set-in Nozzle No Pad, no Inside projection

PV Elite 2019 2

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

Reinforcement CALCULATION, Description: N1

ASME Code, Section VIII, Div. 1, 2017, UG-37 to UG-45

Actual Outside Diameter Used in Calculation 2.375 in.

Actual Thickness Used in Calculation 0.301 in.

Nozzle input data check completed without errors.

Reqd thk per UG-37(a) of Cylindrical Shell, Tr [Int. Press]

= (P*R)/(Sv*E-0.6*P) per UG-27 (c)(1)

= (10.1*151.6126)/(118*1.0-0.6*10.1)

= 1.3055 mm.

Reqd thk per UG-37(a) of Nozzle Wall, Trn [Int. Press]

= (P*Ro)/(Sn*E+0.4*P) per Appendix 1-1 (a)(1)

= (10.1*30.1625)/(118*1.0+0.4*10.1)

= 0.2575 mm.

UG-40, Limits of Reinforcement : [Internal Pressure]

Parallel to Vessel Wall (Diameter Limit) Dl 90.0684 mm.

Parallel to Vessel Wall, opening length d 45.0342 mm.

Normal to Vessel Wall (Thickness Limit), no pad Tlnp 19.1135 mm.

Weld Strength Reduction Factor [fr1]:

= min( 1, Sn/Sv )

= min( 1, 117.9/117.9 )

= 1.000

Weld Strength Reduction Factor [fr2]:

= min( 1, Sn/Sv )

= min( 1, 117.9/117.9 )

= 1.000

Weld Strength Reduction Factor [fr3]:

= min( fr2, fr4 )

= min( 1.0, 1.0 )

= 1.000

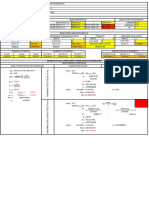

Results of Nozzle Reinforcement Area Calculations: (cm²)

AREA AVAILABLE, A1 to A5 | Design| External| Mapnc|

---------------------------------------------------------------

Area Required Ar | 0.588| NA| NA|

Area in Shell A1 | 3.476| NA| NA|

Area in Nozzle Wall A2 | 2.824| NA| NA|

Area in Inward Nozzle A3 | 0.000| NA| NA|

Area in Welds A41+A42+A43 | 1.000| NA| NA|

Area in Element A5 | 0.000| NA| NA|

TOTAL AREA AVAILABLE Atot | 7.300| NA| NA|

The Internal Pressure Case Governs the Analysis.

Nozzle Angle Used in Area Calculations 90.00 Degs.

The area available without a pad is Sufficient.

Area Required [A]:

= ( d * tr*F + 2 * tn * tr*F * (1-fr1) ) UG-37(c)

= (45.0342*1.3055*1.0+2*7.6454*1.3055*1.0*(1-1.0))

= 0.588 cm²

Reinforcement Areas per Figure UG-37.1

PV Elite 2019 3

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

Area Available in Shell [A1]:

= d( E1*t - F*tr ) - 2 * tn( E1*t - F*tr ) * ( 1 - fr1 )

= 45.034( 1.0 * 9.0234 - 1.0 * 1.306 ) - 2 * 7.645

( 1.0 * 9.0234 - 1.0 * 1.3055 ) * ( 1 - 1.0 )

= 3.476 cm²

Area Available in Nozzle Projecting Outward [A2]:

= ( 2 * tlnp )( tn - trn )fr2

= ( 2 * 19.11 )( 7.65 - 0.26 )1.0

= 2.824 cm²

Area Available in Inward Weld + Outward Weld [A41 + A43]:

= Wo² * fr2 + ( Wi-can/0.707 )² * fr2

= 10.0² * 1.0 + ( 0.0 )² * 1.0

= 1.000 cm²

UG-45 Minimum Nozzle Neck Thickness Requirement: [Int. Press.]

Wall Thickness for Internal/External pressures ta = 0.2575 mm.

Wall Thickness per UG16(b), tr16b = 1.5000 mm.

Wall Thickness, shell/head, internal pressure trb1 = 1.3055 mm.

Wall Thickness tb1 = max(trb1, tr16b) = 1.5000 mm.

Wall Thickness tb2 = max(trb2, tr16b) = 1.5000 mm.

Wall Thickness per table UG-45 tb3 = 3.4200 mm.

Determine Nozzle Thickness candidate [tb]:

= min[ tb3, max( tb1,tb2) ]

= min[ 3.42, max( 1.5, 1.5 ) ]

= 1.5000 mm.

Minimum Wall Thickness of Nozzle Necks [tUG-45]:

= max( ta, tb )

= max( 0.2575, 1.5 )

= 1.5000 mm.

Available Nozzle Neck Thickness = 7.6454 mm. --> OK

Stresses on Nozzle due to External and Pressure Loads per the ASME

B31.3 Piping Code (see 319.4.4 and 302.3.5):

Sustained : 33.2, Allowable : 117.9 N./mm² Passed

Expansion : 0.0, Allowable : 261.5 N./mm² Passed

Occasional : 1.3, Allowable : 156.8 N./mm² Passed

Shear : 25.3, Allowable : 82.5 N./mm² Passed

Note : The number of cycles on this nozzle was assumed to be 7000 or less for

the determination of the expansion stress allowable.

Nozzle Junction Minimum Design Metal Temperature (MDMT) Calculations:

Nozzle Neck to Flange Weld, Curve: B

----------------------------------------------------------------------

Govrn. thk, tg = 7.645, tr = 0.258, c = 0.0 mm., E* = 1.0

Thickness Ratio = tr * (E*)/(tg - c) = 0.034, Temp. Reduction = 78 °C

Min Metal Temp. w/o impact per UCS-66, Curve B -29 °C

Min Metal Temp. at Required thickness (UCS 66.1) -104 °C

Nozzle-Shell/Head Weld (UCS-66(a)1(b)), Curve: B

----------------------------------------------------------------------

Govrn. thk, tg = 7.645, tr = 0.258, c = 0.0 mm., E* = 1.0

Thickness Ratio = tr * (E*)/(tg - c) = 0.034, Temp. Reduction = 78 °C

Min Metal Temp. w/o impact per UCS-66, Curve B -29 °C

Min Metal Temp. at Required thickness (UCS 66.1) -104 °C

Governing MDMT of all the sub-joints of this Junction : -104 °C

PV Elite 2019 4

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

ANSI Flange MDMT including Temperature reduction per UCS-66.1:

Unadjusted MDMT of ANSI B16.5/47 flanges per UCS-66(c) -29 °C

Flange MDMT with Temp reduction per UCS-66(b)(1)(-b) -48 °C

Flange MDMT with Temp reduction per UCS-66(b)(1)(-c) -104 °C

Where the Stress Reduction Ratio per UCS-66(b)(1)(-b) is :

Design Pressure/Ambient Rating = 10.10/19.60 = 0.515

Note:

Using the min value from (b)(1)(-b) and (b)(1)(-c) above as the computed nozzle flange MDMT.

Weld Size Calculations, Description: N1

Intermediate Calc. for nozzle/shell Welds Tmin 7.6454 mm.

Results Per UW-16.1:

Required Thickness Actual Thickness

Nozzle Weld 5.3518 = 0.7 * tmin. 7.0700 = 0.7 * Wo mm.

Weld Strength and Weld Loads per UG-41.1, Sketch (a) or (b)

Weld Load [W]:

= max( 0, (A-A1+2*tn*fr1*(E1*t-tr))Sv)

= max( 0, ( 0.5879 - 3.4757 + 2 * 7.6454 * 1.0 *

(1.0 * 9.0234 - 1.3055 ) )118)

= max( 0, -2053.00) Kgf

Note: F is always set to 1.0 throughout the calculation.

Weld Load [W1]:

= (A2+A5+A4-(Wi-Can/.707)²*fr2)*Sv

= ( 2.8242 + 0.0 + 1. - 0.0 * 1.0 ) * 118

= 4597.68 Kgf

Weld Load [W2]:

= (A2 + A3 + A4 + (2 * tn * t * fr1)) * Sv

= ( 2.8242 + 0.0 + 1. + ( 1.3797 ) ) * 118

= 6256.50 Kgf

Weld Load [W3]:

= (A2+A3+A4+A5+(2*tn*t*fr1))*S

= ( 2.8242 + 0.0 + 1. + 0.0 + ( 1.3797 ) ) * 118

= 6256.50 Kgf

Strength of Connection Elements for Failure Path Analysis

Shear, Outward Nozzle Weld [Sonw]:

= (pi/2) * Dlo * Wo * 0.49 * Snw

= ( 3.1416/2.0 ) * 60.325 * 10.0 * 0.49 * 118

= 5582. Kgf

Shear, Nozzle Wall [Snw]:

= (pi *( Dlr + Dlo )/4 ) * ( Thk - Can ) * 0.7 * Sn

= (3.1416 * 26.3398) * ( 7.6454 - 0.0 ) * 0.7 * 118

= 5324. Kgf

Tension, Shell Groove Weld [Tngw]:

= (pi/2) * Dlo * (Wgnvi-Cas) * 0.74 * Sng

= ( 3.1416/2.0 ) * 60.325 * ( 9.0233 - 0.0 ) * 0.74 * 118

= 7607. Kgf

Strength of Failure Paths:

PATH11 = ( SONW + SNW ) = ( 5582 + 5324 ) = 10907 Kgf

PV Elite 2019 5

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

PATH22 = ( Sonw + Tpgw + Tngw + Sinw )

= ( 5582 + 0 + 7607 + 0 ) = 13189 Kgf

PATH33 = ( Sonw + Tngw + Sinw )

= ( 5582 + 7607 + 0 ) = 13189 Kgf

Summary of Failure Path Calculations:

Path 1-1 = 10906 Kgf, must exceed W = 0 Kgf or W1 = 4597 Kgf

Path 2-2 = 13189 Kgf, must exceed W = 0 Kgf or W2 = 6256 Kgf

Path 3-3 = 13189 Kgf, must exceed W = 0 Kgf or W3 = 6256 Kgf

Maximum Allowable Pressure for this Nozzle at this Location:

Converged Max. Allow. Pressure in Operating case 61.828 bars

The Drop for this Nozzle is : 3.0306 mm.

The Cut Length for this Nozzle is, Drop + Ho + H + T : 162.0540 mm.

Input Echo, WRC297 Item 1, Description: N1 :

Diameter Basis for Cylindrical Shell ID

Shell Corrosion Allowance 0.0000 mm.

Shell Diameter 303.225 mm.

Shell Thickness 9.0234 mm.

Shell Stress Concentration Factor 1.000

Vessel Material SA-106 B

Vessel Cold S.I. Allowable Smc 117.90 N./mm²

Vessel Hot S.I. Allowable Smh 117.90 N./mm²

Note:

Using 2 * Yield for Discontinuity Stress Allowable (Div 2, 4.1.6.3), Sps.

Make sure that material properties at this temperature are not

time-dependent for Material: SA-106 B

Diameter Basis for Nozzle OD

Nozzle Corrosion Allowance 0.0000 mm.

Nozzle Diameter 60.325 mm.

Nozzle Thickness 7.6454 mm.

Nozzle Stress Concentration Factor 1.000

Nozzle Material SA-106 B

Nozzle Cold S.I. Allowable SNmc 117.90 N./mm²

Nozzle Hot S.I. Allowable SNmh 117.90 N./mm²

Note:

Using 2 * Yield for Discontinuity Stress Allowable (Div 2, 4.1.6.3), Sps.

Make sure that material properties at this temperature are not

time-dependent for Material: SA-106 B

Note:

External Forces and Moments in WRC 107/537 Convention:

These loads are assumed to be SUStained loads.

Design Internal Pressure Dp 10.10 bars

Radial Load P -135.00 Kgf

Circumferential Shear Vc 200.00 Kgf

Longitudinal Shear Vl 200.00 Kgf

Circumferential Moment Mc 30.00 Kg-m.

Longitudinal Moment Ml 40.00 Kg-m.

Torsional Moment Mt 50.00 Kg-m.

Include Axial Pressure Thrust No

Include Pressure Stress Indices per Div. 2 No

Local Loads applied at end of Nozzle/Attachment No

PV Elite 2019 6

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

Stress Computations at the Edge of the Nozzle:

Stress Attenuation Diameter (for Insert Plates) per WRC 297:

= NozzleOD + 2 * 1.65 * sqrt( Rmean( t - ca ) )

= 60.325 + 2 * 1.65 * sqrt( 156.124( 9.023 - 0.0 ) )

= 184.186 mm.

WRC 297 Curve Access Parameters:

Vessel Mean Diameter (D) = 312.249 mm.

Nozzle Outside Diameter (d) = 60.325 mm.

Vessel Thickness used (T) = 9.023 mm.

Nozzle Thickness used (t) = 7.645 mm.

T / t = 1.180

d / t = 10.000

Lambda = [(d/D)* (D/T)1/2] = 1.136

Nr/P = 0.123

Mr/P = 0.164

M0/P = 0.060

N0/P = 0.123

MrD/Mc = 0.264

NrDL/Mc = 0.154

M0d/Mc = 0.113

N0DL/Mc = 0.040

MrD/Ml = 0.179

NrDL/Ml = 0.114

M0D/Ml = 0.076

N0DL/Ml = 0.131

Vessel Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stresses Normal to Top Top Bottom Bottom

longitudinal plane) Outside Inside Outside Inside

-----------------------------------------------------------

Outplane Membrane (P ) 1 1 1 1

Outplane Bending (P ) 5 -5 5 -5

Outplane Membrane (Mc) 0 0 0 0

Outplane Bending (Mc) 0 0 0 0

Outplane Membrane (ML) -10 -10 10 10

Outplane Bending (ML) -36 36 36 -36

Normal Pressure Stress 16 17 16 17

----------------------- -------- -------- -------- --------

Outplane Stress Summary -22 39 71 -12

Vessel Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stresses parallel to Top Top Bottom Bottom

longitudinal plane) Outside Inside Outside Inside

-----------------------------------------------------------

Inplane Membrane (P ) 1 1 1 1

Inplane Bending (P ) 16 -16 16 -16

Inplane Membrane (Mc) 0 0 0 0

Inplane Bending (Mc) 0 0 0 0

Inplane Membrane (ML) -9 -9 9 9

Inplane Bending (ML) -85 85 85 -85

Inplane Pressure Stress 8 8 8 8

----------------------- -------- -------- -------- --------

Inplane Stress Summary -68 70 121 -82

Vessel Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Shear stress normal to Top Top Bottom Bottom

longitudinal plane) Outside Inside Outside Inside

-----------------------------------------------------------

Outplane Shear (Vc) 2 2 -2 -2

PV Elite 2019 7

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

Outplane Shear (Vl) 0 0 0 0

Outplane Shear (Mt) 9 9 9 9

----------------------- -------- -------- -------- --------

Shear Stress Summary 11 11 7 7

Vessel Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stress Intensities Top Top Bottom Bottom

Outside Inside Outside Inside

-----------------------------------------------------------

Two * Max Shear Stress 71 74 122 83

Vessel Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stresses Normal to Left Left Right Right

circumferential plane) Outside Inside Outside Inside

-----------------------------------------------------------

Outplane Membrane (P ) 1 1 1 1

Outplane Bending (P ) 5 -5 5 -5

Outplane Membrane (Mc) -2 -2 2 2

Outplane Bending (Mc) -40 40 40 -40

Outplane Membrane (ML) 0 0 0 0

Outplane Bending (ML) 0 0 0 0

Normal Pressure Stress 8 8 8 8

----------------------- -------- -------- -------- --------

Outplane Stress Summary -26 42 59 -33

Vessel Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stresses parallel to Left Left Right Right

circumferential plane) Outside Inside Outside Inside

-----------------------------------------------------------

Inplane Membrane (P ) 1 1 1 1

Inplane Bending (P ) 16 -16 16 -16

Inplane Membrane (Mc) -9 -9 9 9

Inplane Bending (Mc) -95 95 95 -95

Inplane Membrane (ML) 0 0 0 0

Inplane Bending (ML) 0 0 0 0

Inplane Pressure Stress 16 17 16 17

----------------------- -------- -------- -------- --------

Inplane Stress Summary -69 89 138 -82

Vessel Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Shear stress normal to Left Left Right Right

circumferential plane) Outside Inside Outside Inside

-----------------------------------------------------------

Outplane Shear (Vc) 0 0 0 0

Outplane Shear (Vl) -2 -2 2 2

Torsional Shear (Mt) 9 9 9 9

----------------------- -------- -------- -------- --------

Shear Stress Summary 7 7 11 11

Vessel Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stress Intensities Left Left Right Right

Outside Inside Outside Inside

-----------------------------------------------------------

Two * Max Shear Stress 70 90 140 85

Nozzle Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stresses in the Top Top Bottom Bottom

hoop direction) Outside Inside Outside Inside

-----------------------------------------------------------

Hoop Membrane (P ) 1 1 1 1

PV Elite 2019 8

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

Hoop Bending (P ) 0 0 0 0

Hoop Membrane (Mc) 0 0 0 0

Hoop Bending (Mc) 0 0 0 0

Hoop Membrane (ML) -10 -10 10 10

Hoop Bending (ML) 0 0 0 0

Hoop Pressure Stress 3 4 3 4

----------------------- -------- -------- -------- --------

Hoop Stress Summary -5 -4 15 16

Nozzle Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stresses Normal to Top Top Bottom Bottom

pipe cross-section) Outside Inside Outside Inside

-----------------------------------------------------------

Axial Membrane (P ) 1 1 1 1

Axial Bending (P ) 13 -13 13 -13

Axial Membrane (Mc) 0 0 0 0

Axial Bending (Mc) 0 0 0 0

Axial Membrane (ML) -26 -26 26 26

Axial Bending (ML) -81 81 81 -81

Axial Pressure Stress 1 1 1 1

----------------------- -------- -------- -------- --------

Axial Stress Summary -91 43 124 -66

Nozzle Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Shear stress) Outside Inside Outside Inside

-----------------------------------------------------------

Shear due to (Vc) 2 2 -2 -2

Shear due to (Vl) 0 0 0 0

Shear due to Torsion 11 11 11 11

----------------------- -------- -------- -------- --------

Shear Stress Summary 13 13 8 8

Nozzle Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stress Intensities Outside Inside Outside Inside

-----------------------------------------------------------

Two * Max Shear Stress 93 55 125 85

Nozzle Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stresses in the Left Left Right Right

hoop direction) Outside Inside Outside Inside

-----------------------------------------------------------

Hoop Membrane (P ) 1 1 1 1

Hoop Bending (P ) 0 0 0 0

Hoop Membrane (Mc) -2 -2 2 2

Hoop Bending (Mc) 0 0 0 0

Hoop Membrane (ML) 0 0 0 0

Hoop Bending (ML) 0 0 0 0

Hoop Pressure Stress 3 4 3 4

----------------------- -------- -------- -------- --------

Hoop Stress Summary 2 3 7 8

Nozzle Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stresses Normal to Left Left Right Right

pipe cross-section) Outside Inside Outside Inside

-----------------------------------------------------------

Axial Membrane (P ) 1 1 1 1

Axial Bending (P ) 13 -13 13 -13

Axial Membrane (Mc) -19 -19 19 19

Axial Bending (Mc) -93 93 93 -93

Axial Membrane (ML) 0 0 0 0

Axial Bending (ML) 0 0 0 0

PV Elite 2019 9

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

Axial Pressure Stress 1 1 1 1

----------------------- -------- -------- -------- --------

Axial Stress Summary -97 62 130 -85

Nozzle Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Shear stress) Outside Inside Outside Inside

-----------------------------------------------------------

Shear due to (Vc) 0 0 0 0

Shear due to (Vl) -2 -2 2 2

Shear due to Torsion 11 11 11 11

----------------------- -------- -------- -------- --------

Shear Stress Summary 8 8 13 13

Nozzle Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stress Intensities Outside Inside Outside Inside

-----------------------------------------------------------

Two * Max Shear Stress 101 63 131 98

WRC 297 Stress Summations per ASME Sec. VIII Div. 2:

Vessel Stress Summation at Vessel-Nozzle Junction (N./mm²):

Type of | Stress Values at |

Stress Int. | |

Location | Au Al Bu Bl Cu Cl Du Dl |

-------------------------------------------------------------------------

Circ. Pm (SUS) | 16 17 16 17 16 17 16 17|

Circ. Pl (SUS) | -9 -9 11 11 -8 -8 10 10|

Circ. Q (SUS) | -31 31 41 -41 -79 79 111 -111|

-------------------------------------------------------------------------

Long. Pm (SUS) | 8 8 8 8 8 8 8 8|

Long. Pl (SUS) | -8 -8 10 10 -1 -1 3 3|

Long. Q (SUS) | -69 69 101 -101 -35 35 45 -45|

-------------------------------------------------------------------------

Shear Pm (SUS) | 0 0 0 0 0 0 0 0|

Shear Pl (SUS) | 2 2 -2 -2 -2 -2 2 2|

Shear Q (SUS) | 9 9 9 9 9 9 9 9|

Pm (SUS) | 16.0 17.0 16.0 17.0 16.0 17.0 16.0 17.0|

-------------------------------------------------------------------------

Pm+Pl (SUS) | 8.1 8.9 27.4 28.4 9.6 10.2 26.3 27.2|

-------------------------------------------------------------------------

Pm+Pl+Q (Total)| 71.5 72.6 119.9 83.7 72.1 89.0 138.5 86.3|

Vessel Stress Summation Comparison (N./mm²):

Type of | Max. S.I. S.I. Allowable | Result |

Stress Int. | | |

-------------------------------------------------------------------------

Pm (SUS) | 17.00 117.90 | Passed |

Pm+Pl (SUS) | 28.39 176.86 | Passed |

Pm+Pl+Q (TOTAL)| 138.47 353.71 | Passed |

Because only sustained loads were specified, the Pm+Pl+Q allowable was 3 * Smh.

WRC 297 Stress Summations per ASME Sec. VIII Div. 2:

Nozzle Stress Summation at Vessel-Nozzle Junction (N./mm²):

Type of | Stress Values at |

Stress Int. | |

Location | Au Al Bu Bl Cu Cl Du Dl |

-------------------------------------------------------------------------

PV Elite 2019 10

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N1

Circ. Pm (SUS) | 3 4 3 4 3 4 3 4|

Circ. Pl (SUS) | -9 -9 11 11 -1 -1 3 3|

Circ. Q (SUS) | 0 0 0 0 0 0 0 0|

-------------------------------------------------------------------------

Long. Pm (SUS) | 1 1 1 1 1 1 1 1|

Long. Pl (SUS) | -25 -25 27 27 -18 -18 20 20|

Long. Q (SUS) | -68 68 94 -94 -80 80 106 -106|

-------------------------------------------------------------------------

Shear Pm (SUS) | 0 0 0 0 0 0 0 0|

Shear Pl (SUS) | 2 2 -2 -2 -2 -2 2 2|

Shear Q (SUS) | 11 11 11 11 11 11 11 11|

Pm (SUS) | 3.0 4.0 3.0 4.0 3.0 4.0 3.0 4.0|

-------------------------------------------------------------------------

Pm+Pl (SUS) | 24.2 24.2 28.3 28.3 19.4 20.4 21.3 21.3|

-------------------------------------------------------------------------

Pm+Pl+Q (Total)| 93.9 55.5 122.7 83.0 100.6 64.3 128.4 95.6|

Nozzle Stress Summation Comparison (N./mm²):

Type of | Max. S.I. S.I. Allowable | Result |

Stress Int. | | |

-------------------------------------------------------------------------

Pm (SUS) | 4.00 117.90 | Passed |

Pm+Pl (SUS) | 28.30 176.86 | Passed |

Pm+Pl+Q (TOTAL)| 128.38 353.71 | Passed |

Because only sustained loads were specified, the Pm+Pl+Q allowable was 3 * Smh.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2019

PV Elite 2019 11

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

Input, Nozzle Desc: N2 From: 20

Pressure for Reinforcement Calculations P 10.100 bars

Temperature for Internal Pressure Temp 78 °C

Shell Material SA-106 B

Shell Allowable Stress at Temperature Sv 117.90 N./mm²

Shell Allowable Stress At Ambient Sva 117.90 N./mm²

Inside Diameter of Cylindrical Shell D 303.23 mm.

Shell Finished (Minimum) Thickness t 9.0234 mm.

Shell Internal Corrosion Allowance c 0.0000 mm.

Shell External Corrosion Allowance co 0.0000 mm.

Distance from Bottom/Left Tangent 770.00 mm.

User Entered Minimum Design Metal Temperature 0.00 °C

Type of Element Connected to the Shell : Nozzle

Material SA-106 B

Material UNS Number K03006

Material Specification/Type Smls. pipe

Allowable Stress at Temperature Sn 117.90 N./mm²

Allowable Stress At Ambient Sna 117.90 N./mm²

Diameter Basis (for tr calc only) OD

Layout Angle 180.00 deg

Diameter 2.0000 in.

Size and Thickness Basis Minimum

Nominal Thickness tn 160

Flange Material SA-105

Flange Type Weld Neck Flange

Corrosion Allowance can 0.0000 mm.

Joint Efficiency of Shell Seam at Nozzle E1 1.00

Joint Efficiency of Nozzle Neck En 1.00

Outside Projection ho 150.0000 mm.

Weld leg size between Nozzle and Pad/Shell Wo 10.0000 mm.

Groove weld depth between Nozzle and Vessel Wgnv 9.0233 mm.

Inside Projection h 0.0000 mm.

Weld leg size, Inside Element to Shell Wi 0.0000 mm.

Class of attached Flange 150

Grade of attached Flange GR 1.1

The Pressure Design option was Design Pressure + static head.

Nozzle Sketch (may not represent actual weld type/configuration)

Insert/Set-in Nozzle No Pad, no Inside projection

PV Elite 2019 12

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

Reinforcement CALCULATION, Description: N2

ASME Code, Section VIII, Div. 1, 2017, UG-37 to UG-45

Actual Outside Diameter Used in Calculation 2.375 in.

Actual Thickness Used in Calculation 0.301 in.

Nozzle input data check completed without errors.

Reqd thk per UG-37(a) of Cylindrical Shell, Tr [Int. Press]

= (P*R)/(Sv*E-0.6*P) per UG-27 (c)(1)

= (10.1*151.6126)/(118*1.0-0.6*10.1)

= 1.3055 mm.

Reqd thk per UG-37(a) of Nozzle Wall, Trn [Int. Press]

= (P*Ro)/(Sn*E+0.4*P) per Appendix 1-1 (a)(1)

= (10.1*30.1625)/(118*1.0+0.4*10.1)

= 0.2575 mm.

UG-40, Limits of Reinforcement : [Internal Pressure]

Parallel to Vessel Wall (Diameter Limit) Dl 90.0684 mm.

Parallel to Vessel Wall, opening length d 45.0342 mm.

Normal to Vessel Wall (Thickness Limit), no pad Tlnp 19.1135 mm.

Weld Strength Reduction Factor [fr1]:

= min( 1, Sn/Sv )

= min( 1, 117.9/117.9 )

= 1.000

Weld Strength Reduction Factor [fr2]:

= min( 1, Sn/Sv )

= min( 1, 117.9/117.9 )

= 1.000

Weld Strength Reduction Factor [fr3]:

= min( fr2, fr4 )

= min( 1.0, 1.0 )

= 1.000

Results of Nozzle Reinforcement Area Calculations: (cm²)

AREA AVAILABLE, A1 to A5 | Design| External| Mapnc|

---------------------------------------------------------------

Area Required Ar | 0.588| NA| NA|

Area in Shell A1 | 3.476| NA| NA|

Area in Nozzle Wall A2 | 2.824| NA| NA|

Area in Inward Nozzle A3 | 0.000| NA| NA|

Area in Welds A41+A42+A43 | 1.000| NA| NA|

Area in Element A5 | 0.000| NA| NA|

TOTAL AREA AVAILABLE Atot | 7.300| NA| NA|

The Internal Pressure Case Governs the Analysis.

Nozzle Angle Used in Area Calculations 90.00 Degs.

The area available without a pad is Sufficient.

Area Required [A]:

= ( d * tr*F + 2 * tn * tr*F * (1-fr1) ) UG-37(c)

= (45.0342*1.3055*1.0+2*7.6454*1.3055*1.0*(1-1.0))

= 0.588 cm²

Reinforcement Areas per Figure UG-37.1

PV Elite 2019 13

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

Area Available in Shell [A1]:

= d( E1*t - F*tr ) - 2 * tn( E1*t - F*tr ) * ( 1 - fr1 )

= 45.034( 1.0 * 9.0234 - 1.0 * 1.306 ) - 2 * 7.645

( 1.0 * 9.0234 - 1.0 * 1.3055 ) * ( 1 - 1.0 )

= 3.476 cm²

Area Available in Nozzle Projecting Outward [A2]:

= ( 2 * tlnp )( tn - trn )fr2

= ( 2 * 19.11 )( 7.65 - 0.26 )1.0

= 2.824 cm²

Area Available in Inward Weld + Outward Weld [A41 + A43]:

= Wo² * fr2 + ( Wi-can/0.707 )² * fr2

= 10.0² * 1.0 + ( 0.0 )² * 1.0

= 1.000 cm²

UG-45 Minimum Nozzle Neck Thickness Requirement: [Int. Press.]

Wall Thickness for Internal/External pressures ta = 0.2575 mm.

Wall Thickness per UG16(b), tr16b = 1.5000 mm.

Wall Thickness, shell/head, internal pressure trb1 = 1.3055 mm.

Wall Thickness tb1 = max(trb1, tr16b) = 1.5000 mm.

Wall Thickness tb2 = max(trb2, tr16b) = 1.5000 mm.

Wall Thickness per table UG-45 tb3 = 3.4200 mm.

Determine Nozzle Thickness candidate [tb]:

= min[ tb3, max( tb1,tb2) ]

= min[ 3.42, max( 1.5, 1.5 ) ]

= 1.5000 mm.

Minimum Wall Thickness of Nozzle Necks [tUG-45]:

= max( ta, tb )

= max( 0.2575, 1.5 )

= 1.5000 mm.

Available Nozzle Neck Thickness = 7.6454 mm. --> OK

Stresses on Nozzle due to External and Pressure Loads per the ASME

B31.3 Piping Code (see 319.4.4 and 302.3.5):

Sustained : 33.2, Allowable : 117.9 N./mm² Passed

Expansion : 0.0, Allowable : 261.5 N./mm² Passed

Occasional : 1.3, Allowable : 156.8 N./mm² Passed

Shear : 25.3, Allowable : 82.5 N./mm² Passed

Note : The number of cycles on this nozzle was assumed to be 7000 or less for

the determination of the expansion stress allowable.

Nozzle Junction Minimum Design Metal Temperature (MDMT) Calculations:

Nozzle Neck to Flange Weld, Curve: B

----------------------------------------------------------------------

Govrn. thk, tg = 7.645, tr = 0.258, c = 0.0 mm., E* = 1.0

Thickness Ratio = tr * (E*)/(tg - c) = 0.034, Temp. Reduction = 78 °C

Min Metal Temp. w/o impact per UCS-66, Curve B -29 °C

Min Metal Temp. at Required thickness (UCS 66.1) -104 °C

Nozzle-Shell/Head Weld (UCS-66(a)1(b)), Curve: B

----------------------------------------------------------------------

Govrn. thk, tg = 7.645, tr = 0.258, c = 0.0 mm., E* = 1.0

Thickness Ratio = tr * (E*)/(tg - c) = 0.034, Temp. Reduction = 78 °C

Min Metal Temp. w/o impact per UCS-66, Curve B -29 °C

Min Metal Temp. at Required thickness (UCS 66.1) -104 °C

Governing MDMT of all the sub-joints of this Junction : -104 °C

PV Elite 2019 14

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

ANSI Flange MDMT including Temperature reduction per UCS-66.1:

Unadjusted MDMT of ANSI B16.5/47 flanges per UCS-66(c) -29 °C

Flange MDMT with Temp reduction per UCS-66(b)(1)(-b) -48 °C

Flange MDMT with Temp reduction per UCS-66(b)(1)(-c) -104 °C

Where the Stress Reduction Ratio per UCS-66(b)(1)(-b) is :

Design Pressure/Ambient Rating = 10.10/19.60 = 0.515

Note:

Using the min value from (b)(1)(-b) and (b)(1)(-c) above as the computed nozzle flange MDMT.

Weld Size Calculations, Description: N2

Intermediate Calc. for nozzle/shell Welds Tmin 7.6454 mm.

Results Per UW-16.1:

Required Thickness Actual Thickness

Nozzle Weld 5.3518 = 0.7 * tmin. 7.0700 = 0.7 * Wo mm.

Weld Strength and Weld Loads per UG-41.1, Sketch (a) or (b)

Weld Load [W]:

= max( 0, (A-A1+2*tn*fr1*(E1*t-tr))Sv)

= max( 0, ( 0.5879 - 3.4757 + 2 * 7.6454 * 1.0 *

(1.0 * 9.0234 - 1.3055 ) )118)

= max( 0, -2053.00) Kgf

Note: F is always set to 1.0 throughout the calculation.

Weld Load [W1]:

= (A2+A5+A4-(Wi-Can/.707)²*fr2)*Sv

= ( 2.8242 + 0.0 + 1. - 0.0 * 1.0 ) * 118

= 4597.68 Kgf

Weld Load [W2]:

= (A2 + A3 + A4 + (2 * tn * t * fr1)) * Sv

= ( 2.8242 + 0.0 + 1. + ( 1.3797 ) ) * 118

= 6256.50 Kgf

Weld Load [W3]:

= (A2+A3+A4+A5+(2*tn*t*fr1))*S

= ( 2.8242 + 0.0 + 1. + 0.0 + ( 1.3797 ) ) * 118

= 6256.50 Kgf

Strength of Connection Elements for Failure Path Analysis

Shear, Outward Nozzle Weld [Sonw]:

= (pi/2) * Dlo * Wo * 0.49 * Snw

= ( 3.1416/2.0 ) * 60.325 * 10.0 * 0.49 * 118

= 5582. Kgf

Shear, Nozzle Wall [Snw]:

= (pi *( Dlr + Dlo )/4 ) * ( Thk - Can ) * 0.7 * Sn

= (3.1416 * 26.3398) * ( 7.6454 - 0.0 ) * 0.7 * 118

= 5324. Kgf

Tension, Shell Groove Weld [Tngw]:

= (pi/2) * Dlo * (Wgnvi-Cas) * 0.74 * Sng

= ( 3.1416/2.0 ) * 60.325 * ( 9.0233 - 0.0 ) * 0.74 * 118

= 7607. Kgf

Strength of Failure Paths:

PATH11 = ( SONW + SNW ) = ( 5582 + 5324 ) = 10907 Kgf

PV Elite 2019 15

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

PATH22 = ( Sonw + Tpgw + Tngw + Sinw )

= ( 5582 + 0 + 7607 + 0 ) = 13189 Kgf

PATH33 = ( Sonw + Tngw + Sinw )

= ( 5582 + 7607 + 0 ) = 13189 Kgf

Summary of Failure Path Calculations:

Path 1-1 = 10906 Kgf, must exceed W = 0 Kgf or W1 = 4597 Kgf

Path 2-2 = 13189 Kgf, must exceed W = 0 Kgf or W2 = 6256 Kgf

Path 3-3 = 13189 Kgf, must exceed W = 0 Kgf or W3 = 6256 Kgf

Maximum Allowable Pressure for this Nozzle at this Location:

Converged Max. Allow. Pressure in Operating case 61.828 bars

The Drop for this Nozzle is : 3.0306 mm.

The Cut Length for this Nozzle is, Drop + Ho + H + T : 162.0540 mm.

Input Echo, WRC297 Item 1, Description: N2 :

Diameter Basis for Cylindrical Shell ID

Shell Corrosion Allowance 0.0000 mm.

Shell Diameter 303.225 mm.

Shell Thickness 9.0234 mm.

Shell Stress Concentration Factor 1.000

Vessel Material SA-106 B

Vessel Cold S.I. Allowable Smc 117.90 N./mm²

Vessel Hot S.I. Allowable Smh 117.90 N./mm²

Note:

Using 2 * Yield for Discontinuity Stress Allowable (Div 2, 4.1.6.3), Sps.

Make sure that material properties at this temperature are not

time-dependent for Material: SA-106 B

Diameter Basis for Nozzle OD

Nozzle Corrosion Allowance 0.0000 mm.

Nozzle Diameter 60.325 mm.

Nozzle Thickness 7.6454 mm.

Nozzle Stress Concentration Factor 1.000

Nozzle Material SA-106 B

Nozzle Cold S.I. Allowable SNmc 117.90 N./mm²

Nozzle Hot S.I. Allowable SNmh 117.90 N./mm²

Note:

Using 2 * Yield for Discontinuity Stress Allowable (Div 2, 4.1.6.3), Sps.

Make sure that material properties at this temperature are not

time-dependent for Material: SA-106 B

Note:

External Forces and Moments in WRC 107/537 Convention:

These loads are assumed to be SUStained loads.

Design Internal Pressure Dp 10.10 bars

Radial Load P -135.00 Kgf

Circumferential Shear Vc 200.00 Kgf

Longitudinal Shear Vl 200.00 Kgf

Circumferential Moment Mc 30.00 Kg-m.

Longitudinal Moment Ml 40.00 Kg-m.

Torsional Moment Mt 50.00 Kg-m.

Include Axial Pressure Thrust No

Include Pressure Stress Indices per Div. 2 No

Local Loads applied at end of Nozzle/Attachment No

Stress Computations at the Edge of the Nozzle:

PV Elite 2019 16

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

Stress Attenuation Diameter (for Insert Plates) per WRC 297:

= NozzleOD + 2 * 1.65 * sqrt( Rmean( t - ca ) )

= 60.325 + 2 * 1.65 * sqrt( 156.124( 9.023 - 0.0 ) )

= 184.186 mm.

WRC 297 Curve Access Parameters:

Vessel Mean Diameter (D) = 312.249 mm.

Nozzle Outside Diameter (d) = 60.325 mm.

Vessel Thickness used (T) = 9.023 mm.

Nozzle Thickness used (t) = 7.645 mm.

T / t = 1.180

d / t = 10.000

Lambda = [(d/D)* (D/T)1/2] = 1.136

Nr/P = 0.123

Mr/P = 0.164

M0/P = 0.060

N0/P = 0.123

MrD/Mc = 0.264

NrDL/Mc = 0.154

M0d/Mc = 0.113

N0DL/Mc = 0.040

MrD/Ml = 0.179

NrDL/Ml = 0.114

M0D/Ml = 0.076

N0DL/Ml = 0.131

Vessel Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stresses Normal to Top Top Bottom Bottom

longitudinal plane) Outside Inside Outside Inside

-----------------------------------------------------------

Outplane Membrane (P ) 1 1 1 1

Outplane Bending (P ) 5 -5 5 -5

Outplane Membrane (Mc) 0 0 0 0

Outplane Bending (Mc) 0 0 0 0

Outplane Membrane (ML) -10 -10 10 10

Outplane Bending (ML) -36 36 36 -36

Normal Pressure Stress 16 17 16 17

----------------------- -------- -------- -------- --------

Outplane Stress Summary -22 39 71 -12

Vessel Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stresses parallel to Top Top Bottom Bottom

longitudinal plane) Outside Inside Outside Inside

-----------------------------------------------------------

Inplane Membrane (P ) 1 1 1 1

Inplane Bending (P ) 16 -16 16 -16

Inplane Membrane (Mc) 0 0 0 0

Inplane Bending (Mc) 0 0 0 0

Inplane Membrane (ML) -9 -9 9 9

Inplane Bending (ML) -85 85 85 -85

Inplane Pressure Stress 8 8 8 8

----------------------- -------- -------- -------- --------

Inplane Stress Summary -68 70 121 -82

Vessel Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Shear stress normal to Top Top Bottom Bottom

longitudinal plane) Outside Inside Outside Inside

-----------------------------------------------------------

Outplane Shear (Vc) 2 2 -2 -2

Outplane Shear (Vl) 0 0 0 0

Outplane Shear (Mt) 9 9 9 9

PV Elite 2019 17

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

----------------------- -------- -------- -------- --------

Shear Stress Summary 11 11 7 7

Vessel Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stress Intensities Top Top Bottom Bottom

Outside Inside Outside Inside

-----------------------------------------------------------

Two * Max Shear Stress 71 74 122 83

Vessel Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stresses Normal to Left Left Right Right

circumferential plane) Outside Inside Outside Inside

-----------------------------------------------------------

Outplane Membrane (P ) 1 1 1 1

Outplane Bending (P ) 5 -5 5 -5

Outplane Membrane (Mc) -2 -2 2 2

Outplane Bending (Mc) -40 40 40 -40

Outplane Membrane (ML) 0 0 0 0

Outplane Bending (ML) 0 0 0 0

Normal Pressure Stress 8 8 8 8

----------------------- -------- -------- -------- --------

Outplane Stress Summary -26 42 59 -33

Vessel Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stresses parallel to Left Left Right Right

circumferential plane) Outside Inside Outside Inside

-----------------------------------------------------------

Inplane Membrane (P ) 1 1 1 1

Inplane Bending (P ) 16 -16 16 -16

Inplane Membrane (Mc) -9 -9 9 9

Inplane Bending (Mc) -95 95 95 -95

Inplane Membrane (ML) 0 0 0 0

Inplane Bending (ML) 0 0 0 0

Inplane Pressure Stress 16 17 16 17

----------------------- -------- -------- -------- --------

Inplane Stress Summary -69 89 138 -82

Vessel Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Shear stress normal to Left Left Right Right

circumferential plane) Outside Inside Outside Inside

-----------------------------------------------------------

Outplane Shear (Vc) 0 0 0 0

Outplane Shear (Vl) -2 -2 2 2

Torsional Shear (Mt) 9 9 9 9

----------------------- -------- -------- -------- --------

Shear Stress Summary 7 7 11 11

Vessel Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stress Intensities Left Left Right Right

Outside Inside Outside Inside

-----------------------------------------------------------

Two * Max Shear Stress 70 90 140 85

Nozzle Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stresses in the Top Top Bottom Bottom

hoop direction) Outside Inside Outside Inside

-----------------------------------------------------------

Hoop Membrane (P ) 1 1 1 1

Hoop Bending (P ) 0 0 0 0

Hoop Membrane (Mc) 0 0 0 0

PV Elite 2019 18

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

Hoop Bending (Mc) 0 0 0 0

Hoop Membrane (ML) -10 -10 10 10

Hoop Bending (ML) 0 0 0 0

Hoop Pressure Stress 3 4 3 4

----------------------- -------- -------- -------- --------

Hoop Stress Summary -5 -4 15 16

Nozzle Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stresses Normal to Top Top Bottom Bottom

pipe cross-section) Outside Inside Outside Inside

-----------------------------------------------------------

Axial Membrane (P ) 1 1 1 1

Axial Bending (P ) 13 -13 13 -13

Axial Membrane (Mc) 0 0 0 0

Axial Bending (Mc) 0 0 0 0

Axial Membrane (ML) -26 -26 26 26

Axial Bending (ML) -81 81 81 -81

Axial Pressure Stress 1 1 1 1

----------------------- -------- -------- -------- --------

Axial Stress Summary -91 43 124 -66

Nozzle Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Shear stress) Outside Inside Outside Inside

-----------------------------------------------------------

Shear due to (Vc) 2 2 -2 -2

Shear due to (Vl) 0 0 0 0

Shear due to Torsion 11 11 11 11

----------------------- -------- -------- -------- --------

Shear Stress Summary 13 13 8 8

Nozzle Stresses (N./mm²):

LONGITUDINAL PLANE Au Al Bu Bl

(Stress Intensities Outside Inside Outside Inside

-----------------------------------------------------------

Two * Max Shear Stress 93 55 125 85

Nozzle Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stresses in the Left Left Right Right

hoop direction) Outside Inside Outside Inside

-----------------------------------------------------------

Hoop Membrane (P ) 1 1 1 1

Hoop Bending (P ) 0 0 0 0

Hoop Membrane (Mc) -2 -2 2 2

Hoop Bending (Mc) 0 0 0 0

Hoop Membrane (ML) 0 0 0 0

Hoop Bending (ML) 0 0 0 0

Hoop Pressure Stress 3 4 3 4

----------------------- -------- -------- -------- --------

Hoop Stress Summary 2 3 7 8

Nozzle Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stresses Normal to Left Left Right Right

pipe cross-section) Outside Inside Outside Inside

-----------------------------------------------------------

Axial Membrane (P ) 1 1 1 1

Axial Bending (P ) 13 -13 13 -13

Axial Membrane (Mc) -19 -19 19 19

Axial Bending (Mc) -93 93 93 -93

Axial Membrane (ML) 0 0 0 0

Axial Bending (ML) 0 0 0 0

Axial Pressure Stress 1 1 1 1

----------------------- -------- -------- -------- --------

PV Elite 2019 19

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

Axial Stress Summary -97 62 130 -85

Nozzle Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Shear stress) Outside Inside Outside Inside

-----------------------------------------------------------

Shear due to (Vc) 0 0 0 0

Shear due to (Vl) -2 -2 2 2

Shear due to Torsion 11 11 11 11

----------------------- -------- -------- -------- --------

Shear Stress Summary 8 8 13 13

Nozzle Stresses (N./mm²):

CIRCUMFERENTIAL PLANE Cu Cl Du Dl

(Stress Intensities Outside Inside Outside Inside

-----------------------------------------------------------

Two * Max Shear Stress 101 63 131 98

WRC 297 Stress Summations per ASME Sec. VIII Div. 2:

Vessel Stress Summation at Vessel-Nozzle Junction (N./mm²):

Type of | Stress Values at |

Stress Int. | |

Location | Au Al Bu Bl Cu Cl Du Dl |

-------------------------------------------------------------------------

Circ. Pm (SUS) | 16 17 16 17 16 17 16 17|

Circ. Pl (SUS) | -9 -9 11 11 -8 -8 10 10|

Circ. Q (SUS) | -31 31 41 -41 -79 79 111 -111|

-------------------------------------------------------------------------

Long. Pm (SUS) | 8 8 8 8 8 8 8 8|

Long. Pl (SUS) | -8 -8 10 10 -1 -1 3 3|

Long. Q (SUS) | -69 69 101 -101 -35 35 45 -45|

-------------------------------------------------------------------------

Shear Pm (SUS) | 0 0 0 0 0 0 0 0|

Shear Pl (SUS) | 2 2 -2 -2 -2 -2 2 2|

Shear Q (SUS) | 9 9 9 9 9 9 9 9|

Pm (SUS) | 16.0 17.0 16.0 17.0 16.0 17.0 16.0 17.0|

-------------------------------------------------------------------------

Pm+Pl (SUS) | 8.1 8.9 27.4 28.4 9.6 10.2 26.3 27.2|

-------------------------------------------------------------------------

Pm+Pl+Q (Total)| 71.5 72.6 119.9 83.7 72.1 89.0 138.5 86.3|

Vessel Stress Summation Comparison (N./mm²):

Type of | Max. S.I. S.I. Allowable | Result |

Stress Int. | | |

-------------------------------------------------------------------------

Pm (SUS) | 17.00 117.90 | Passed |

Pm+Pl (SUS) | 28.39 176.86 | Passed |

Pm+Pl+Q (TOTAL)| 138.47 353.71 | Passed |

Because only sustained loads were specified, the Pm+Pl+Q allowable was 3 * Smh.

WRC 297 Stress Summations per ASME Sec. VIII Div. 2:

Nozzle Stress Summation at Vessel-Nozzle Junction (N./mm²):

Type of | Stress Values at |

Stress Int. | |

Location | Au Al Bu Bl Cu Cl Du Dl |

-------------------------------------------------------------------------

Circ. Pm (SUS) | 3 4 3 4 3 4 3 4|

Circ. Pl (SUS) | -9 -9 11 11 -1 -1 3 3|

PV Elite 2019 20

FileName : SGK DEMO VESSEL

Nozzle Calcs.: N2

Circ. Q (SUS) | 0 0 0 0 0 0 0 0|

-------------------------------------------------------------------------

Long. Pm (SUS) | 1 1 1 1 1 1 1 1|

Long. Pl (SUS) | -25 -25 27 27 -18 -18 20 20|

Long. Q (SUS) | -68 68 94 -94 -80 80 106 -106|

-------------------------------------------------------------------------

Shear Pm (SUS) | 0 0 0 0 0 0 0 0|

Shear Pl (SUS) | 2 2 -2 -2 -2 -2 2 2|

Shear Q (SUS) | 11 11 11 11 11 11 11 11|

Pm (SUS) | 3.0 4.0 3.0 4.0 3.0 4.0 3.0 4.0|

-------------------------------------------------------------------------

Pm+Pl (SUS) | 24.2 24.2 28.3 28.3 19.4 20.4 21.3 21.3|

-------------------------------------------------------------------------

Pm+Pl+Q (Total)| 93.9 55.5 122.7 83.0 100.6 64.3 128.4 95.6|

Nozzle Stress Summation Comparison (N./mm²):

Type of | Max. S.I. S.I. Allowable | Result |

Stress Int. | | |

-------------------------------------------------------------------------

Pm (SUS) | 4.00 117.90 | Passed |

Pm+Pl (SUS) | 28.30 176.86 | Passed |

Pm+Pl+Q (TOTAL)| 128.38 353.71 | Passed |

Because only sustained loads were specified, the Pm+Pl+Q allowable was 3 * Smh.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2019

Potrebbero piacerti anche

- Nozzle Calculation - Primary Reformer Stack-R0Documento22 pagineNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Design Calculation Sheet: H2So4 Neutralization TankDocumento43 pagineDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNessuna valutazione finora

- Asme Sec 8 Div 1 - App 1-10Documento11 pagineAsme Sec 8 Div 1 - App 1-10BibinBabuNessuna valutazione finora

- Jeddah South Thermal Power Plant Stage-I: ProjectDocumento18 pagineJeddah South Thermal Power Plant Stage-I: ProjectAmr AbdeinNessuna valutazione finora

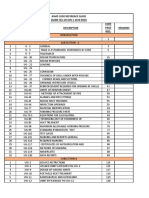

- Asme Code Reference Guide (Asme Sec - Viii Div.1 2019 Edn)Documento2 pagineAsme Code Reference Guide (Asme Sec - Viii Div.1 2019 Edn)anu radhaNessuna valutazione finora

- Dennis R Moss 4th EditionDocumento5 pagineDennis R Moss 4th Editionsenthil kumarNessuna valutazione finora

- Pressure Vessel DesignDocumento21 paginePressure Vessel Designscranderi100% (1)

- Tailing LugDocumento2 pagineTailing Lugjagannadha varmaNessuna valutazione finora

- U Stamp - KK Form - SampleDocumento5 pagineU Stamp - KK Form - SampleshazanNessuna valutazione finora

- Single Col - Tank-2013Documento35 pagineSingle Col - Tank-2013Hgagselim SelimNessuna valutazione finora

- Nozzle Calculations 01Documento32 pagineNozzle Calculations 01Rohith V VNessuna valutazione finora

- Nozzle Design CalculationDocumento1 paginaNozzle Design CalculationSachin55860% (1)

- SHELLDocumento6 pagineSHELLSalz EngineeringNessuna valutazione finora

- Storage Tank Alumnuim Roof - LatestDocumento22 pagineStorage Tank Alumnuim Roof - LatesthgagNessuna valutazione finora

- Piping Engineering - Tank Nozzle Loads 1Documento1 paginaPiping Engineering - Tank Nozzle Loads 1Nasrul AdliNessuna valutazione finora

- WRC 537 Cige Noz B Op 1Documento1 paginaWRC 537 Cige Noz B Op 1metroroadNessuna valutazione finora

- Calculation of Pipe Reinforcement ASME B31 3Documento5 pagineCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- Mechanical DesignDocumento11 pagineMechanical DesignVilas AndhaleNessuna valutazione finora

- Tailing LugDocumento2 pagineTailing Lugjagannadha varmaNessuna valutazione finora

- Etank Full ReportDocumento108 pagineEtank Full ReportFaizal SattuNessuna valutazione finora

- Compress EvaluateDocumento23 pagineCompress EvaluateVishalDhiman100% (1)

- WRC-107 Lifting Trunnions - Horz. LiftDocumento5 pagineWRC-107 Lifting Trunnions - Horz. LiftManoj MulikNessuna valutazione finora

- MecaStack MatindokDocumento59 pagineMecaStack MatindokmedyNessuna valutazione finora

- Air Eliminator Datasheet PDFDocumento2 pagineAir Eliminator Datasheet PDFbecpavanNessuna valutazione finora

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocumento25 paginePage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidNessuna valutazione finora

- Nozzle Repad Design SpreadsheetsDocumento2 pagineNozzle Repad Design SpreadsheetsArt G. EnziNessuna valutazione finora

- Storage Tank As Per API650 2007Documento27 pagineStorage Tank As Per API650 2007Santosh100% (1)

- Design Procedure For Aes He PDFDocumento30 pagineDesign Procedure For Aes He PDFRyan Goh Chuang HongNessuna valutazione finora

- New - Reinforcement of NozzleDocumento24 pagineNew - Reinforcement of NozzleVaniya GoelNessuna valutazione finora

- PV Elite Vessel Analysis Program HorizontalDocumento55 paginePV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNessuna valutazione finora

- Pressure Vessel Calculations ASME SectioDocumento11 paginePressure Vessel Calculations ASME Sectioivan chirinosNessuna valutazione finora

- SP-2069 Specification For Pressure VesselsDocumento68 pagineSP-2069 Specification For Pressure Vesselsarjunprasannan7Nessuna valutazione finora

- API 650 Tank Design 1Documento5 pagineAPI 650 Tank Design 1Nguyễn Thành Trung100% (1)

- Support Lug CalculationsDocumento26 pagineSupport Lug CalculationsDinesh ChouguleNessuna valutazione finora

- Saddle AnalysisDocumento17 pagineSaddle AnalysisPEJU0007Nessuna valutazione finora

- Design and Verification of Lifting LugsDocumento3 pagineDesign and Verification of Lifting LugsFabio Okamoto100% (1)

- plant pressure vessel training manual 6 of 6 권-2007 div.2-pd번역-1 (강도계산포함) -4-2-간력sampleDocumento36 pagineplant pressure vessel training manual 6 of 6 권-2007 div.2-pd번역-1 (강도계산포함) -4-2-간력samplekangrimNessuna valutazione finora

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDocumento10 pagineFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiNessuna valutazione finora

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocumento3 pagineForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssNessuna valutazione finora

- Saddle 3Documento3 pagineSaddle 3RUDHRA DHANASEKAR100% (1)

- Lifting Lug Calculation For Small Horizontal VesselDocumento2 pagineLifting Lug Calculation For Small Horizontal VesselshaishavNessuna valutazione finora

- Pvelite OutputDocumento44 paginePvelite OutputRam MurtyNessuna valutazione finora

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocumento1 paginaRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNessuna valutazione finora

- Compress CalculationDocumento106 pagineCompress CalculationKrupal Patel100% (1)

- Self Reinforced Forged Nozzle - 1500Documento1 paginaSelf Reinforced Forged Nozzle - 1500vincentNessuna valutazione finora

- API-650 Water Storage Tank TK-2Documento27 pagineAPI-650 Water Storage Tank TK-2Athira ZahraNessuna valutazione finora

- Sea Course - PG Diploma in Pressure Vessel Design Engg PDFDocumento10 pagineSea Course - PG Diploma in Pressure Vessel Design Engg PDFumeshNessuna valutazione finora

- Tank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeDocumento1 paginaTank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeABIDEEN BAMNENessuna valutazione finora

- Secondary Condensate B API650 Sloshing Impact RoofDocumento22 pagineSecondary Condensate B API650 Sloshing Impact RoofFrancisco OrtuzarNessuna valutazione finora

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocumento30 pagineWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersmishtinilNessuna valutazione finora

- PV Elite: User's GuideDocumento620 paginePV Elite: User's GuideSiva baalanNessuna valutazione finora

- Foundation Load Table.Documento1 paginaFoundation Load Table.Lcm TnlNessuna valutazione finora

- PVElite Design GuidelinesDocumento7 paginePVElite Design Guidelinesndrarly100% (2)

- Narrow Face Flange - Slip On Hub TypeDocumento17 pagineNarrow Face Flange - Slip On Hub TypeEng-CalculationsNessuna valutazione finora

- 25 Lifting Lug Design Per ASME BTH-1-2005Documento6 pagine25 Lifting Lug Design Per ASME BTH-1-2005luis nunezNessuna valutazione finora

- Pvelite PruebaDocumento6 paginePvelite PruebaLuis Cordova RamonNessuna valutazione finora

- InputDocumento5 pagineInputTrần Văn NhânNessuna valutazione finora

- Studding Outlet Calculation - PV Elite 2016Documento8 pagineStudding Outlet Calculation - PV Elite 2016Liu YangtzeNessuna valutazione finora

- WRC For NozzleDocumento43 pagineWRC For NozzleSachin55860% (1)

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Documento32 paginePV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNessuna valutazione finora

- Protelt1: of Project, Studenti de CimalsDocumento7 pagineProtelt1: of Project, Studenti de Cimalsanu radhaNessuna valutazione finora

- AOSS AccumulatorsDocumento7 pagineAOSS AccumulatorsPiero Fabrizzio Mendoza FuenteNessuna valutazione finora

- FormulaDocumento2 pagineFormulaanu radhaNessuna valutazione finora

- 8 Presentation - FairclothDocumento41 pagine8 Presentation - FairclothSıddık SarıcalarNessuna valutazione finora

- Calculo Placas de RefuerzoDocumento2 pagineCalculo Placas de RefuerzoPedro Luis Choque MamaniNessuna valutazione finora

- Nozzle List ETP ModulesDocumento6 pagineNozzle List ETP Modulesanu radhaNessuna valutazione finora

- TANKDocumento13 pagineTANKanu radhaNessuna valutazione finora

- New - Reinforcement of NozzleDocumento31 pagineNew - Reinforcement of NozzleChagar HarshpalNessuna valutazione finora

- New - Reinforcement of NozzleDocumento31 pagineNew - Reinforcement of NozzleChagar HarshpalNessuna valutazione finora

- Pressure Vessel Design Manual (Moss) 205Documento1 paginaPressure Vessel Design Manual (Moss) 205anu radha100% (1)

- New - Reinforcement of NozzleDocumento31 pagineNew - Reinforcement of NozzleChagar HarshpalNessuna valutazione finora

- Deliverable ListDocumento2 pagineDeliverable Listanu radhaNessuna valutazione finora

- DelugeDocumento2 pagineDelugeanu radhaNessuna valutazione finora

- FormulaDocumento2 pagineFormulaanu radhaNessuna valutazione finora

- Lifting Lug Calculations KodDocumento2 pagineLifting Lug Calculations Kodanu radhaNessuna valutazione finora

- Use of Liquefaction-Induced Features For Paleosesismic Analysis ObermeierDocumento76 pagineUse of Liquefaction-Induced Features For Paleosesismic Analysis ObermeierwilliamvargasmongeNessuna valutazione finora

- Soal Ujian: Panitia Ujian Tengah Semester TAHUN AJARAN 2017/2018 Fakultas TeknikDocumento2 pagineSoal Ujian: Panitia Ujian Tengah Semester TAHUN AJARAN 2017/2018 Fakultas TeknikMuhammad SupriyadiNessuna valutazione finora

- Composite Analysis PPT Vers 97 2003 PDFDocumento57 pagineComposite Analysis PPT Vers 97 2003 PDFDeva IsmayaNessuna valutazione finora

- Concrete 2014 PDFDocumento49 pagineConcrete 2014 PDFHarf Jucoy MirandaNessuna valutazione finora

- CoreBrace Brochure Dec 2011Documento8 pagineCoreBrace Brochure Dec 2011lcoraoNessuna valutazione finora

- Creep and Fatigue Damage During Boiler LifeDocumento9 pagineCreep and Fatigue Damage During Boiler Lifevikas2510100% (3)

- Materials Selection For High Temperature Metal RecuperatorsDocumento6 pagineMaterials Selection For High Temperature Metal RecuperatorsrezaNessuna valutazione finora

- Design Calculations (Singly-Reinforced Beam Design)Documento4 pagineDesign Calculations (Singly-Reinforced Beam Design)John Kevin CruzNessuna valutazione finora

- Design of Composite Beams Using Allowable Stress Design: Presented By: Dr. Sherine SwelemDocumento70 pagineDesign of Composite Beams Using Allowable Stress Design: Presented By: Dr. Sherine Swelemabdelrahman emadNessuna valutazione finora

- 1 s2.0 0308016191900719 MainDocumento17 pagine1 s2.0 0308016191900719 MainSaam SasanianNessuna valutazione finora

- Surface Vehicle Standard: Lattice Boom Cranes - Method of TestDocumento30 pagineSurface Vehicle Standard: Lattice Boom Cranes - Method of Test박재범Nessuna valutazione finora

- Cyclic Compressive Behavior of Hybrid FRP-Confined ConcreteDocumento12 pagineCyclic Compressive Behavior of Hybrid FRP-Confined ConcreteKorhan Deniz DALGICNessuna valutazione finora

- Week 09 MG Answer-FormatDocumento7 pagineWeek 09 MG Answer-FormatJohn Carlo BaralNessuna valutazione finora

- Group No.5 - MD1 - FinalCompilationto Print 1Documento42 pagineGroup No.5 - MD1 - FinalCompilationto Print 1Domingo Joshua Eduard C.Nessuna valutazione finora

- Glasses: An Fea ApproachDocumento28 pagineGlasses: An Fea Approachkgh4Nessuna valutazione finora

- Analisa Pak RaziDocumento7 pagineAnalisa Pak RaziBale GoNessuna valutazione finora

- Nataly Damaris Rodríguez Camacho 1914630: Find The Definition and Some Example or Figure of The Following TermsDocumento7 pagineNataly Damaris Rodríguez Camacho 1914630: Find The Definition and Some Example or Figure of The Following TermsNat RodríguezNessuna valutazione finora

- 1.105 Solid Mechanics Laboratory Fall 2003: Experiment 6 The Linear, Elastic Behavior of A BeamDocumento7 pagine1.105 Solid Mechanics Laboratory Fall 2003: Experiment 6 The Linear, Elastic Behavior of A Beamprieten20006936Nessuna valutazione finora

- Vane Shear Test: Dr. B. Munwar BashaDocumento17 pagineVane Shear Test: Dr. B. Munwar BashaArif AzizanNessuna valutazione finora

- Mae Theses - 19 PDFDocumento135 pagineMae Theses - 19 PDFShaun Raphael LeeNessuna valutazione finora

- Eurocode 2 Design of Concrete Structures BS en 1992-1-1 2023Documento408 pagineEurocode 2 Design of Concrete Structures BS en 1992-1-1 2023binhNessuna valutazione finora

- CVG 4184 - 6305 - Ch7 - Foundations On Rock PDFDocumento59 pagineCVG 4184 - 6305 - Ch7 - Foundations On Rock PDFStar998100% (2)

- Cheng Wang PaperDocumento13 pagineCheng Wang Paperm,narNessuna valutazione finora

- Shear Wall Moment-Curvature RelationshipDocumento16 pagineShear Wall Moment-Curvature RelationshipEric CastilloNessuna valutazione finora

- ETBX Stress-Life Fatigue Analysis ModuleDocumento12 pagineETBX Stress-Life Fatigue Analysis ModuleArdiyan Arezel ArdhyNessuna valutazione finora

- hw-7 Solutions-2014 PDFDocumento16 paginehw-7 Solutions-2014 PDFHeNessuna valutazione finora

- Paper No. 226: Rutting of Asphalt Concrete PavementsDocumento13 paginePaper No. 226: Rutting of Asphalt Concrete Pavementswaleedroomy100% (1)

- Design of Pile FoundationDocumento12 pagineDesign of Pile FoundationAbhijit Hazarika69% (13)

- Vindio 1.0 User's Manual PDFDocumento106 pagineVindio 1.0 User's Manual PDFRoberto LacalleNessuna valutazione finora

- 05 RCC - MDocumento46 pagine05 RCC - MSafikul HossainNessuna valutazione finora

- Marine Structural Design CalculationsDa EverandMarine Structural Design CalculationsValutazione: 4.5 su 5 stelle4.5/5 (13)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDa EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresValutazione: 1 su 5 stelle1/5 (2)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- Predicting Lifetime for Concrete StructureDa EverandPredicting Lifetime for Concrete StructureNessuna valutazione finora

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Advanced Modelling Techniques in Structural DesignDa EverandAdvanced Modelling Techniques in Structural DesignValutazione: 5 su 5 stelle5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (138)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDa EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNessuna valutazione finora

- Structural Cross Sections: Analysis and DesignDa EverandStructural Cross Sections: Analysis and DesignValutazione: 4.5 su 5 stelle4.5/5 (19)

- Pile Design and Construction Rules of ThumbDa EverandPile Design and Construction Rules of ThumbValutazione: 4.5 su 5 stelle4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDa EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNessuna valutazione finora

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesDa EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraValutazione: 4.5 su 5 stelle4.5/5 (4)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDa EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsValutazione: 4 su 5 stelle4/5 (16)

- Design and Construction of Soil Anchor PlatesDa EverandDesign and Construction of Soil Anchor PlatesValutazione: 5 su 5 stelle5/5 (1)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksDa EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksValutazione: 3 su 5 stelle3/5 (2)

- Modeling and Dimensioning of Structures: An IntroductionDa EverandModeling and Dimensioning of Structures: An IntroductionNessuna valutazione finora