Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

r5310305 Design of Machine Members I

Caricato da

sivabharathamurthy0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

112 visualizzazioni1 paginaThis document contains 8 questions related to the design of machine members for a mechanical engineering exam. The questions cover topics like assumptions in deriving the torsion equation, Soderberg's equation, design of riveted joints, bolt design, knuckle joint design, line shaft design, cast iron flange coupling design, and helical spring design. Dimensions, stresses, and other parameters are to be determined for various mechanical components and systems based on the given power, forces, speeds, materials and other specifications in each multi-part question.

Descrizione originale:

Titolo originale

r5310305 Design of Machine Members i

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document contains 8 questions related to the design of machine members for a mechanical engineering exam. The questions cover topics like assumptions in deriving the torsion equation, Soderberg's equation, design of riveted joints, bolt design, knuckle joint design, line shaft design, cast iron flange coupling design, and helical spring design. Dimensions, stresses, and other parameters are to be determined for various mechanical components and systems based on the given power, forces, speeds, materials and other specifications in each multi-part question.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

112 visualizzazioni1 paginar5310305 Design of Machine Members I

Caricato da

sivabharathamurthyThis document contains 8 questions related to the design of machine members for a mechanical engineering exam. The questions cover topics like assumptions in deriving the torsion equation, Soderberg's equation, design of riveted joints, bolt design, knuckle joint design, line shaft design, cast iron flange coupling design, and helical spring design. Dimensions, stresses, and other parameters are to be determined for various mechanical components and systems based on the given power, forces, speeds, materials and other specifications in each multi-part question.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

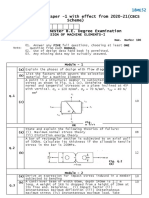

Code No: R5310305 R5

III B.Tech I Semester(R05) Supplementary Examinations, November 2010

DESIGN OF MACHINE MEMBERS-I

(Mechanical Engineering)

Time: 3 hours Max Marks: 80

Answer any FIVE Questions

All Questions carry equal marks

?????

1. (a) What are the assumptions made in deriving torsion equation.

(b) A cast Iron pulley transmits 15 kw at 600 rpm. The diameter of the pulley is 1.2 metre and it

has four straight arms of elliptical cross section, in which the major axis is twice the minor axis.

Determine the dimensions of the arms, if the allowable bending stress is 15Mpa. [4+12]

2. (a) Write Soderberg’s equation and state its application to different type of loadings.

(b) Determine the diameter of a circular rod made of ductile material with a fatigue strength.

σe =265Mpa and a tensile yield strength of 350 Mpa. The member is subjected to a varying

axial load from Wmin =-300 kN to Wmax =700 kN and has a stress concentration factor=1.8. Use

factor of safty as 2.0. [6+10]

3. (a) Sketch various types of riveted joints.

(b) A double riveted lap joint with zig-zag riveting is to be designed for 13mm thick plates.

Assume σt = 80MPa, τ = 60 Mpa and σc = 120 MPa. [6+10]

4. (a) Define the following terms with necessary sketch.

i. Major diameter

ii. Minor diameter

iii. Pitch

iv. Lead.

(b) Derive an expression for the maxim load in a bolt. When a bracket with a circular base is bolted

to a wall by means of four bolts. [8+8]

5. (a) How is the slipping of the cotter avoided? Explain by two methods.

(b) Design a knuckle joint to transmit 120 kN, with permissible stresses in tension; shear and com-

pression are 75 Mpa; 60 Mpa and 150 Mpa respectively. [4+12]

6. Design a line shaft transmitting power to two machine tools. The power received by the shaft is 30kW

at 300 rpm. The power absorbed by pulley P1 is 12 kW and the remaining power is absorbed by pulley

P2 . The diameter of pulley P1 is 300mm and its mass is 40Kg. the diameter and mass of pulley P2

are 600mm and 75Kg respectively. Assume the belt tension ratio of 2 for both pulleys and the shaft

material as 30C8 steel with Km = 2 and Kt = 1.5. Draw the B.M and torque diagram’s. Assuming

maximum shear stress theory. [16]

7. Design a cast iron protective type flange coupling to transmit 15kW at 900rpm from an electric motor

to a compressor. The service factor may be assumed as 1.35. The following permissible stresses may

be used :

Shear stress for shaft, bolt and key material=40MPa

Crushing stress for bolt and key=80MPa

Shear stress for cast iron =8MPa

Draw a neat sketch of the coupling. [16]

8. (a) What requirements must be satisfied by a spring?

(b) A weight of 800N is to drop on the center of a planet from a height of 30cm. The planet is

supported on four helical spring. Assuming that deflection allowed for each spring is 6cm, spring

index of 5 and maximum allowable stress equal to 4000kg/cm2 ; determine the diameter of wire,

outside diameter of the coils and the number of active coils. [4+12]

?????

Potrebbero piacerti anche

- R5310305-Design of Machine Members - IDocumento4 pagineR5310305-Design of Machine Members - IsivabharathamurthyNessuna valutazione finora

- Design of Machine Elements Oct 2017Documento3 pagineDesign of Machine Elements Oct 2017Kalpesh JadhavNessuna valutazione finora

- Mech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsDocumento5 pagineMech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsARIGARAN SNessuna valutazione finora

- PMD ModelDocumento8 paginePMD ModelDamodara SatyaDeva MadhukarNessuna valutazione finora

- Rr310305 Design of Machine Members IDocumento8 pagineRr310305 Design of Machine Members ISrinivasa Rao GNessuna valutazione finora

- 4363 111 Machine Design IDocumento6 pagine4363 111 Machine Design Iyogesh_b_k100% (2)

- Design of Machine Members I July 2023Documento2 pagineDesign of Machine Members I July 2023gunas4767Nessuna valutazione finora

- Dmm1 Mar2007Documento8 pagineDmm1 Mar2007prk74Nessuna valutazione finora

- rr312404 Design of Machine ElementsDocumento8 paginerr312404 Design of Machine ElementsSRINIVASA RAO GANTANessuna valutazione finora

- r05320305 Design of Machine Members IIDocumento9 paginer05320305 Design of Machine Members IISRINIVASA RAO GANTANessuna valutazione finora

- Dmm1 Mar2006Documento8 pagineDmm1 Mar2006prk74Nessuna valutazione finora

- DESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperDocumento8 pagineDESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperelimelekNessuna valutazione finora

- 08 r05310305 Design of Machine Members IDocumento9 pagine08 r05310305 Design of Machine Members IKrupanandareddyYarragudiNessuna valutazione finora

- 3-1 DMM1 (Nov 2009 Regular)Documento9 pagine3-1 DMM1 (Nov 2009 Regular)micmechNessuna valutazione finora

- rr320305 Design of Machine Members IIDocumento8 paginerr320305 Design of Machine Members IISrinivasa Rao GNessuna valutazione finora

- r5100305 Engineering MechanicsDocumento4 paginer5100305 Engineering Mechanicssivabharathamurthy100% (1)

- Dmm2 Mar2006Documento8 pagineDmm2 Mar2006Abdul Saleem MohammedNessuna valutazione finora

- rr10302 Engineering MechanicsDocumento12 paginerr10302 Engineering MechanicsSRINIVASA RAO GANTANessuna valutazione finora

- Gujarat Technological University: InstructionsDocumento2 pagineGujarat Technological University: InstructionsRenieNessuna valutazione finora

- Model Question Paper - 1 With Effect From 2020-21 (CBCS Scheme) Fifth Semester B.E. Degree ExaminationDocumento10 pagineModel Question Paper - 1 With Effect From 2020-21 (CBCS Scheme) Fifth Semester B.E. Degree ExaminationSharath KotegarNessuna valutazione finora

- R7310305-Design of Machine Members-I2Documento4 pagineR7310305-Design of Machine Members-I2slv_prasaad100% (1)

- rr320305 Design of Machine Members IIDocumento8 paginerr320305 Design of Machine Members IISRINIVASA RAO GANTANessuna valutazione finora

- DomeDocumento3 pagineDomevikaskumar1986Nessuna valutazione finora

- DME Model QuesDocumento3 pagineDME Model QuesSiva RamanNessuna valutazione finora

- Me8593 - Dme - Model QPDocumento3 pagineMe8593 - Dme - Model QPChandrasekhar PrabhakaranNessuna valutazione finora

- WWW - Manaresults.co - In: (Mechanical Engineering)Documento2 pagineWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNessuna valutazione finora

- 07a6ec05 Designofmachinemembers IIDocumento11 pagine07a6ec05 Designofmachinemembers IIzahid_polyNessuna valutazione finora

- dmm1 PDFDocumento9 paginedmm1 PDFmohan_rapaka6095Nessuna valutazione finora

- DME 30MKS Aug15Documento3 pagineDME 30MKS Aug15palashNessuna valutazione finora

- Question PapersDocumento89 pagineQuestion PapersDreamer ChavanNessuna valutazione finora

- Prelim 2022 SMDocumento4 paginePrelim 2022 SMARJUNANessuna valutazione finora

- Gujarat Technological UniversityDocumento3 pagineGujarat Technological UniversityHarshit PatelNessuna valutazione finora

- r05312401 Design of Machine ElementsDocumento8 paginer05312401 Design of Machine ElementsSrinivasa Rao GNessuna valutazione finora

- 15A03602 Design of Machine Members - IIDocumento2 pagine15A03602 Design of Machine Members - IIJagannath CherkuNessuna valutazione finora

- r05320305 Design of Machine Members IIDocumento11 paginer05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- Dme 2 QP CombinedDocumento9 pagineDme 2 QP CombinedPrasinNessuna valutazione finora

- IFS Mechanical Engineering 2015 Part 1Documento4 pagineIFS Mechanical Engineering 2015 Part 1Saurabh BhardwajNessuna valutazione finora

- Docs MEDMMIAssignments2013 PDFDocumento13 pagineDocs MEDMMIAssignments2013 PDFHafiz Mahar28Nessuna valutazione finora

- MDDocumento2 pagineMDAbhijeet PramanikNessuna valutazione finora

- WWW - Manaresults.co - In: Board Diploma Examination, (C-16) JUNE-2019 Dme-First Year ExaminationDocumento4 pagineWWW - Manaresults.co - In: Board Diploma Examination, (C-16) JUNE-2019 Dme-First Year ExaminationGod deva123Nessuna valutazione finora

- Dynamics of Machinery r10 May-2016Documento20 pagineDynamics of Machinery r10 May-2016Srimanthula SrikanthNessuna valutazione finora

- 2017 AS (Summer) Sem VII Mech Engg Machine Design N Drawing IIDocumento4 pagine2017 AS (Summer) Sem VII Mech Engg Machine Design N Drawing IIMayur DhanokarNessuna valutazione finora

- rr321401 Principles of Machine DesignDocumento8 paginerr321401 Principles of Machine DesignSRINIVASA RAO GANTANessuna valutazione finora

- Design of Machine Elements 2 Jan 2014Documento2 pagineDesign of Machine Elements 2 Jan 2014Prasad C M100% (1)

- Dme Model QPDocumento3 pagineDme Model QPCody LeeNessuna valutazione finora

- nr321401 Principles of Machine DesignDocumento2 paginenr321401 Principles of Machine DesignSRINIVASA RAO GANTANessuna valutazione finora

- 21751-6838-Principles of Machine DesignDocumento8 pagine21751-6838-Principles of Machine DesignMacasaet Al-awnNessuna valutazione finora

- Snist Dom Previous PaperDocumento9 pagineSnist Dom Previous PaperKapil Siddhant DevulapalliNessuna valutazione finora

- Dts Model Que Type B 2018-19Documento2 pagineDts Model Que Type B 2018-19rammit2007Nessuna valutazione finora

- Question Paper Code:: Reg. No.Documento3 pagineQuestion Paper Code:: Reg. No.lavanya babuNessuna valutazione finora

- Mechanics of SolidsDocumento8 pagineMechanics of SolidsKhaista RahmanNessuna valutazione finora

- O level Physics Questions And Answer Practice Papers 2Da EverandO level Physics Questions And Answer Practice Papers 2Valutazione: 5 su 5 stelle5/5 (1)

- O level Physics Questions And Answer Practice Papers 1Da EverandO level Physics Questions And Answer Practice Papers 1Valutazione: 3.5 su 5 stelle3.5/5 (4)

- O level Physics Questions And Answer Practice Papers 3Da EverandO level Physics Questions And Answer Practice Papers 3Valutazione: 3 su 5 stelle3/5 (1)

- Solution Manual for 100 Genesys Design Examples: Second EditionDa EverandSolution Manual for 100 Genesys Design Examples: Second EditionNessuna valutazione finora

- From Microstructure Investigations to Multiscale Modeling: Bridging the GapDa EverandFrom Microstructure Investigations to Multiscale Modeling: Bridging the GapDelphine BrancherieNessuna valutazione finora

- Characteristic Modes: Theory and Applications in Antenna EngineeringDa EverandCharacteristic Modes: Theory and Applications in Antenna EngineeringNessuna valutazione finora

- 07A4EC01 Environmental StudiesDocumento1 pagina07A4EC01 Environmental StudiessivabharathamurthyNessuna valutazione finora

- R5410201 Neural Networks & Fuzzy LogicDocumento1 paginaR5410201 Neural Networks & Fuzzy LogicsivabharathamurthyNessuna valutazione finora

- SSC Social Textbook (AP)Documento100 pagineSSC Social Textbook (AP)sivabharathamurthyNessuna valutazione finora

- Control Systems (CS) Notes As Per JntuaDocumento203 pagineControl Systems (CS) Notes As Per Jntuasivabharathamurthy100% (3)

- R7410506 Mobile ComputingDocumento1 paginaR7410506 Mobile ComputingsivabharathamurthyNessuna valutazione finora

- R7312301 Transport Phenomena in BioprocessesDocumento1 paginaR7312301 Transport Phenomena in BioprocessessivabharathamurthyNessuna valutazione finora

- 9A05707 Software Project ManagementDocumento4 pagine9A05707 Software Project ManagementsivabharathamurthyNessuna valutazione finora

- 9A23501 Heat Transfer in BioprocessesDocumento4 pagine9A23501 Heat Transfer in BioprocessessivabharathamurthyNessuna valutazione finora

- 9A13701 Robotics and AutomationDocumento4 pagine9A13701 Robotics and AutomationsivabharathamurthyNessuna valutazione finora

- R7311506 Operating SystemsDocumento1 paginaR7311506 Operating SystemssivabharathamurthyNessuna valutazione finora

- Code: R7311306: (Electronics & Control Engineering)Documento1 paginaCode: R7311306: (Electronics & Control Engineering)sivabharathamurthyNessuna valutazione finora

- R7311006 Process Control InstrumentationDocumento1 paginaR7311006 Process Control InstrumentationsivabharathamurthyNessuna valutazione finora

- R7311205 Distributed DatabasesDocumento1 paginaR7311205 Distributed DatabasessivabharathamurthyNessuna valutazione finora

- R7310206 Linear Systems AnalysisDocumento1 paginaR7310206 Linear Systems AnalysissivabharathamurthyNessuna valutazione finora

- R7310406 Digital CommunicationsDocumento1 paginaR7310406 Digital CommunicationssivabharathamurthyNessuna valutazione finora

- R5310204 Power ElectronicsDocumento1 paginaR5310204 Power ElectronicssivabharathamurthyNessuna valutazione finora

- R7310106 Engineering GeologyDocumento1 paginaR7310106 Engineering GeologysivabharathamurthyNessuna valutazione finora

- 9A15502 Digital System DesignDocumento4 pagine9A15502 Digital System Designsivabharathamurthy100% (1)

- 9A04504 Digital IC ApplicationsDocumento4 pagine9A04504 Digital IC ApplicationssivabharathamurthyNessuna valutazione finora

- 9A21506 Mechanisms & Mechanical DesignDocumento8 pagine9A21506 Mechanisms & Mechanical DesignsivabharathamurthyNessuna valutazione finora

- R7412310 Nano BiotechnologyDocumento1 paginaR7412310 Nano BiotechnologysivabharathamurthyNessuna valutazione finora

- R7411307 Instrumentation & Control in Manufacturing SystemsDocumento1 paginaR7411307 Instrumentation & Control in Manufacturing SystemssivabharathamurthyNessuna valutazione finora

- 9A03505 Heat TransferDocumento4 pagine9A03505 Heat TransfersivabharathamurthyNessuna valutazione finora

- 9A14503 Principles of Machine DesignDocumento8 pagine9A14503 Principles of Machine DesignsivabharathamurthyNessuna valutazione finora

- 9A10505 Principles of CommunicationsDocumento4 pagine9A10505 Principles of CommunicationssivabharathamurthyNessuna valutazione finora

- R7411509 Distributed DatabasesDocumento1 paginaR7411509 Distributed DatabasessivabharathamurthyNessuna valutazione finora

- R7411510 Neural NetworksDocumento1 paginaR7411510 Neural NetworkssivabharathamurthyNessuna valutazione finora

- R7412311 Metabolic EngineeringDocumento1 paginaR7412311 Metabolic EngineeringsivabharathamurthyNessuna valutazione finora

- 9A02505 Electrical Machines-IIIDocumento4 pagine9A02505 Electrical Machines-IIIsivabharathamurthyNessuna valutazione finora

- R7411306 Robotics & AutomationDocumento1 paginaR7411306 Robotics & AutomationsivabharathamurthyNessuna valutazione finora

- 3 1 at The Proportional Limit A 12 InchDocumento34 pagine3 1 at The Proportional Limit A 12 InchAustin Duke100% (3)

- The Study of Bus Superstructure Strength Based On Rollover Test Using Body SectionsDocumento8 pagineThe Study of Bus Superstructure Strength Based On Rollover Test Using Body SectionsIvan ObandoNessuna valutazione finora

- Shear StrengthDocumento91 pagineShear StrengthBruce Lim100% (1)

- Motorised Hammer Project ReportDocumento35 pagineMotorised Hammer Project ReportRaja ManeNessuna valutazione finora

- Weldgroup Demo072 ASDDocumento11 pagineWeldgroup Demo072 ASDLivian TeddyNessuna valutazione finora

- A1007-15 Standard Specification For Carbon Steel Wire For Wire RopeDocumento10 pagineA1007-15 Standard Specification For Carbon Steel Wire For Wire Ropetjt4779Nessuna valutazione finora

- SMiRT 25 Numerical SimulationDocumento10 pagineSMiRT 25 Numerical SimulationEslam El-MawslyNessuna valutazione finora

- Reinforced Concrete BeamsDocumento11 pagineReinforced Concrete BeamsHaytham BouzidNessuna valutazione finora

- Strength SDocumento7 pagineStrength Sabdi dejeneNessuna valutazione finora

- Glulam Handbook-02 PDFDocumento90 pagineGlulam Handbook-02 PDFBanuta GabrielNessuna valutazione finora

- Astm B94 - 2013Documento6 pagineAstm B94 - 2013MarcinNessuna valutazione finora

- Article Vilebrequin F8L413Documento12 pagineArticle Vilebrequin F8L413Maarten BaanNessuna valutazione finora

- Design and Construction of Long-Span Composite Beam Specimens For Large Structural-Fire TestsDocumento13 pagineDesign and Construction of Long-Span Composite Beam Specimens For Large Structural-Fire TestsHoran HoranNessuna valutazione finora

- Esr 2583Documento19 pagineEsr 2583VaniaCuevaSotoNessuna valutazione finora

- Safety For Borrow PitDocumento12 pagineSafety For Borrow PitAmadu FarrowNessuna valutazione finora

- Experimental Investigation of Self Compacting Concrete by Partially Replacing Fine Aggregate With Quartz Sand With Use of Recron FibreDocumento6 pagineExperimental Investigation of Self Compacting Concrete by Partially Replacing Fine Aggregate With Quartz Sand With Use of Recron Fibreshivanand hippargaNessuna valutazione finora

- Jetting ConductorsDocumento10 pagineJetting Conductorszerocool2kNessuna valutazione finora

- DSS Notes Up To 21st January - 2019 PDFDocumento25 pagineDSS Notes Up To 21st January - 2019 PDFsanjana jainNessuna valutazione finora

- 2004 CFRPDocumento9 pagine2004 CFRPShashikant GaurNessuna valutazione finora

- Zone of Infulence For Tunnel Intersection1Documento32 pagineZone of Infulence For Tunnel Intersection1roshansm1978Nessuna valutazione finora

- Port Industrial Pavement Design With Concrete PaversDocumento110 paginePort Industrial Pavement Design With Concrete Paversadji100% (1)

- Environmental Behavior of Low Carbon Steel - Aço CarbonoDocumento13 pagineEnvironmental Behavior of Low Carbon Steel - Aço CarbonoGustavo de CastroNessuna valutazione finora

- DNV Os C201Documento190 pagineDNV Os C201Hari VelakaturiNessuna valutazione finora

- Bfc20903 Chapter 1 NewDocumento44 pagineBfc20903 Chapter 1 Newhamierul mohamadNessuna valutazione finora

- Helical Foundations What An Engineer Needs To KnowDocumento6 pagineHelical Foundations What An Engineer Needs To Knowameensderaj100% (1)

- Utilization of Avocado Seeds As Bioplastic Films FDocumento6 pagineUtilization of Avocado Seeds As Bioplastic Films FGessianyVictoriaNessuna valutazione finora

- A 732 - A732M - 02 Equivalencia Ic AstmDocumento8 pagineA 732 - A732M - 02 Equivalencia Ic AstmorivaldopenaNessuna valutazione finora

- H 01Documento59 pagineH 01Nadège ReyNessuna valutazione finora

- PHD Thesis On Aluminium AlloysDocumento7 paginePHD Thesis On Aluminium Alloysaflobjhcbakaiu100% (1)

- دورة التصميم الانشائي الكاملةDocumento249 pagineدورة التصميم الانشائي الكاملةAlsayed DiabNessuna valutazione finora