Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Automig 70S-61

Caricato da

tarun kaushalTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Automig 70S-61

Caricato da

tarun kaushalCopyright:

Formati disponibili

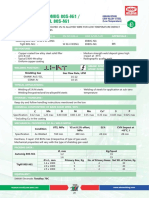

AUTOMIG 70S-6 GMAW/GTAW C-Mn Steel

COPPER COATED C-Mn STEEL GMAW FILLER WIRE FOR 500 MPA

TENSILE STRENGTH STEEL

CLASSIFICATION : EN ISO 14341-A AWS A/SFA 5.18 CSA W48 APPROVALS:

G 42 3 C G3Si1 ER70S-6 B-G 49A 3C1 S6 ABS/BV/DNV/IRS/IBR/LRA/NPCIL

G 46 3 M G3Si1 MND/RDSO/BHEL/CE/CWB

KEY FEATURES :

• C-Mn steel solid wire • Higher level of de-oxidizers makes it suitable

• Uniform copper coating for applications where dirt, rust or mill-scale

• Smooth wire feeding is present

• Can be use with 100% CO2, Ar+CO2 • Radiographic quality weld

WELDING POSITION : DCEP

Shielding Gas Gas Flow Rate, LPM Stickout, mm

CO2 12-18 10-20

80Ar+20CO2 17-22 10-20

TYPICAL APPLICATIONS :

• Construction and mining equipment • Thin sheet metal, Auto body

• Pressure vessels, LPG Cylinders • Farm implements, Steel casings

• Root pass pipe welding, Tanks, Structural steel • High-speed robotic, automatic and

components semi-automatic welding applications

• Railcar construction and repair, Frame fabrication • Shaft build up, General fabrication

STORAGE / HANDLING :

Keep dry and follow handling instructions mentioned on the box

CHEMICAL COMPOSITION OF BARE SOLID WIRE, Wt% :

C Mn Si S P Cu*

Specification 0.06-0.14 1.40-1.60 0.80-1.0 0.025 max 0.025 max 0.50 max

* Including Cu in the coating

MECHANICAL PROPERTIES OF ALL WELD METAL :

Shielding Gas UTS, MPa YS at 0.2% EL% CVN Impact

Condition

offset, MPa at -30°C, J

Specification As Welded 100% CO2 500-640 420 min 22 min 47 min

Specification As Welded 80Ar + 20CO2 530-680 460 min 24 min 47 min

Hardness, 3 Layer: 200 BHN max (irrespective of type of gas used) With mixed gas mechanical properties will be higher.

PARAMETERS - PACKING DATA :

Ø, mm Voltage, V Amperage, A Kg/Spool MIGPAC DRUM, Kg

0.8 17 - 27 80 - 250 15 / 18 100 / 250

1.0 18 – 30 100 - 350 15 / 18 100 / 250

1.2 20 – 34 120 - 400 15 / 18 100 / 250

1.6 24 – 36 150 - 450 15 / 18 100 / 250

Also sold as Automig 1

EQUIVALENT :

SMAW Electrode: Supabase X Plus FCAW Wire: Automig FC 71T-1, Automig FC 121

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

Potrebbero piacerti anche

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- CWC-BookletF1 10Documento1 paginaCWC-BookletF1 10satnamNessuna valutazione finora

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Documento1 paginaAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNessuna valutazione finora

- Automig FC 71 T1Documento1 paginaAutomig FC 71 T1Sushil BhansaliNessuna valutazione finora

- Automig 70S A1 - Tigfil 70S A1Documento1 paginaAutomig 70S A1 - Tigfil 70S A1Vaibhavi ganganeNessuna valutazione finora

- GBTDocumento1 paginaGBTRaviTeja BhamidiNessuna valutazione finora

- Supabase-X-Plus AdorDocumento1 paginaSupabase-X-Plus AdorJagan TnNessuna valutazione finora

- CWC-BookletF1 15Documento1 paginaCWC-BookletF1 15satnamNessuna valutazione finora

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 paginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNessuna valutazione finora

- Supabase X Plus 2Documento1 paginaSupabase X Plus 2Michael FortunaNessuna valutazione finora

- Electrode Booklet F Web 93Documento1 paginaElectrode Booklet F Web 93satnamNessuna valutazione finora

- CWC-BookletF1 12Documento1 paginaCWC-BookletF1 12satnamNessuna valutazione finora

- X Bond: Welding Electrode For Structural Welding ApplicationDocumento1 paginaX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNessuna valutazione finora

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Documento1 paginaAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNessuna valutazione finora

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Documento1 paginaAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- CSF-71T Technical Report EN - V2Documento7 pagineCSF-71T Technical Report EN - V2Miroslav ThôngNessuna valutazione finora

- Chromecore-430-G Er430Documento1 paginaChromecore-430-G Er430peymanNessuna valutazione finora

- Data Sheet A-10: Alloy TypeDocumento3 pagineData Sheet A-10: Alloy Typemohamed AdelNessuna valutazione finora

- 29102015000000B - Boehler DCMS-IG - SWDocumento1 pagina29102015000000B - Boehler DCMS-IG - SWErdinc BayatNessuna valutazione finora

- 29102015000000B - Boehler DCMS-IG - SWDocumento1 pagina29102015000000B - Boehler DCMS-IG - SWErdinc BayatNessuna valutazione finora

- CWC-BookletF1 24Documento1 paginaCWC-BookletF1 24Jagannath SahuNessuna valutazione finora

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62Nessuna valutazione finora

- Automig 80s G Tigfil 80s GDocumento1 paginaAutomig 80s G Tigfil 80s Gvijaysvm999Nessuna valutazione finora

- CWC-BookletF1 17Documento1 paginaCWC-BookletF1 17satnamNessuna valutazione finora

- Bronze C86300 SpecificationsDocumento2 pagineBronze C86300 SpecificationsDoss MartinNessuna valutazione finora

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDocumento1 paginaAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- Celwel - 60 (Adore Electrodes)Documento1 paginaCelwel - 60 (Adore Electrodes)Harish KandollaNessuna valutazione finora

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocumento1 paginaAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNessuna valutazione finora

- Ador - Auto Mig 720 E71t1Documento1 paginaAdor - Auto Mig 720 E71t1RaviTeja BhamidiNessuna valutazione finora

- Boehler CN 13 4-MC - SWDocumento1 paginaBoehler CN 13 4-MC - SWSebastian AcostaNessuna valutazione finora

- Idalloy: C MN Si CR Mo V P S CuDocumento1 paginaIdalloy: C MN Si CR Mo V P S CuiocephNessuna valutazione finora

- Miginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- Electrode Booklet F Web 100Documento1 paginaElectrode Booklet F Web 100satnamNessuna valutazione finora

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocumento2 pagineChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- Echnical Ulletin: Used For Joining in Large Vehicle and Crane ManufacturingDocumento1 paginaEchnical Ulletin: Used For Joining in Large Vehicle and Crane ManufacturingSungJun ParkNessuna valutazione finora

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocumento1 paginaBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNessuna valutazione finora

- Categorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBDocumento1 paginaCategorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBabhishekNessuna valutazione finora

- Automig FC 71T-1Documento1 paginaAutomig FC 71T-1Michael FortunaNessuna valutazione finora

- Electrode Booklet F Web 22Documento1 paginaElectrode Booklet F Web 22satnamNessuna valutazione finora

- Electrode Booklet F Web 97Documento1 paginaElectrode Booklet F Web 97satnamNessuna valutazione finora

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocumento1 paginaMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNessuna valutazione finora

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocumento9 pagineSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNessuna valutazione finora

- Technical Report (CSF-81TM)Documento5 pagineTechnical Report (CSF-81TM)matiasg.sanchezv95Nessuna valutazione finora

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Documento1 paginaAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNessuna valutazione finora

- 3dprint AM P22: Material TypeDocumento1 pagina3dprint AM P22: Material TypeKara WhiteNessuna valutazione finora

- Midalloy ER80S B6 EB6Documento1 paginaMidalloy ER80S B6 EB6joel cisnerosNessuna valutazione finora

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 paginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNessuna valutazione finora

- Automig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Documento1 paginaAutomig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- Boehler CM2-UPDocumento1 paginaBoehler CM2-UPdiahNessuna valutazione finora

- Merit RM-56: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit RM-56: Lincoln Electric China Gmaw Solid WirejuanchepeinNessuna valutazione finora

- Railrod: Data SheetDocumento1 paginaRailrod: Data Sheetmohamed AdelNessuna valutazione finora

- Electrode Booklet F Web 21Documento1 paginaElectrode Booklet F Web 21satnamNessuna valutazione finora

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Documento1 paginaAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNessuna valutazione finora

- Elgamatic 100Documento1 paginaElgamatic 100Milos StoisavljevicNessuna valutazione finora

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocumento1 paginaCovered (Stick) Electrodes (Smaw) Stainless Steel Electrodestarun kaushalNessuna valutazione finora

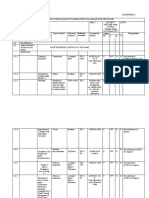

- Model QAP For Plates1Documento3 pagineModel QAP For Plates1tarun kaushalNessuna valutazione finora

- Punjab Govt. - BFUHS Recruitments PDFDocumento1 paginaPunjab Govt. - BFUHS Recruitments PDFtarun kaushalNessuna valutazione finora

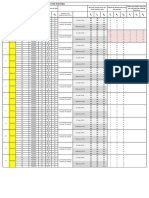

- MTCDocumento3 pagineMTCtarun kaushal100% (1)

- QAP Shear StudDocumento3 pagineQAP Shear Studtarun kaushalNessuna valutazione finora

- Bolt Tightening MethodologyDocumento6 pagineBolt Tightening Methodologytarun kaushalNessuna valutazione finora

- Apl Apollo Tubes LTD.: Manufacture Test Certificate For Steel Tubes For Structural PurposesDocumento1 paginaApl Apollo Tubes LTD.: Manufacture Test Certificate For Steel Tubes For Structural Purposestarun kaushal50% (4)

- Bearing Wedge Plate Comparision 05042018Documento3 pagineBearing Wedge Plate Comparision 05042018tarun kaushalNessuna valutazione finora

- Batch Test Certificate: For Berger Paints India LTDDocumento1 paginaBatch Test Certificate: For Berger Paints India LTDtarun kaushal100% (1)

- STATUS ABSTARCT Munirka Flyover: Dt-27.06.2018 SH-1/2Documento2 pagineSTATUS ABSTARCT Munirka Flyover: Dt-27.06.2018 SH-1/2tarun kaushalNessuna valutazione finora

- Welding Joint DetailDocumento1 paginaWelding Joint Detailtarun kaushalNessuna valutazione finora

- Batch Test Certificate: For Berger Paints India LTDDocumento1 paginaBatch Test Certificate: For Berger Paints India LTDtarun kaushal100% (1)

- WPS PQR As Per IsDocumento3 pagineWPS PQR As Per Istarun kaushalNessuna valutazione finora

- Tax Invoice: MR Tarun MR TarunDocumento1 paginaTax Invoice: MR Tarun MR Taruntarun kaushalNessuna valutazione finora

- ASNT L3 Exam ExperienceDocumento5 pagineASNT L3 Exam Experiencetarun kaushalNessuna valutazione finora

- Dfo LetterDocumento1 paginaDfo Lettertarun kaushalNessuna valutazione finora

- TriphosgeneDocumento9 pagineTriphosgeneJack TomarNessuna valutazione finora

- Air Entraining CementDocumento14 pagineAir Entraining CementBashairu WaseemNessuna valutazione finora

- Repsol Maker Hydroflux EP 32,46,68Documento1 paginaRepsol Maker Hydroflux EP 32,46,68ibrahim maulanaNessuna valutazione finora

- VernacularDocumento15 pagineVernacularsunil kumarNessuna valutazione finora

- Ultrafine High Performance Polyethylene FibersDocumento11 pagineUltrafine High Performance Polyethylene FibersUjjwal FinanceNessuna valutazione finora

- Heat StabilizersDocumento6 pagineHeat StabilizersXuan Giang NguyenNessuna valutazione finora

- Blends of Poly (Ethylene Terephthalate) and Poly (Butylene Terephthalate)Documento9 pagineBlends of Poly (Ethylene Terephthalate) and Poly (Butylene Terephthalate)NÄndo PelÄezNessuna valutazione finora

- ms1314-2004 - Compress 2Documento28 paginems1314-2004 - Compress 2Robbie LimbiNessuna valutazione finora

- Utilisation of Waste Derived Out of Mining: V.D. RajagopalDocumento37 pagineUtilisation of Waste Derived Out of Mining: V.D. RajagopalSanjay MurthyNessuna valutazione finora

- ME150MS HEAD SolutionsDocumento2 pagineME150MS HEAD SolutionsdiablomatiNessuna valutazione finora

- Progress in Additive Manufacturing On New Materials - A ReviewDocumento28 pagineProgress in Additive Manufacturing On New Materials - A ReviewRaistlin1Nessuna valutazione finora

- Litrax One Natural Bio BambooDocumento2 pagineLitrax One Natural Bio BambooRajdeep SinghNessuna valutazione finora

- Quality 11Smnpb37: Lucefin GroupDocumento1 paginaQuality 11Smnpb37: Lucefin GroupPaulo ZechinNessuna valutazione finora

- Formation of BakeliteDocumento4 pagineFormation of BakeliteMuhammad Bilal100% (2)

- Wagner's Pinkenba WharfDocumento43 pagineWagner's Pinkenba WharfH AnimeNessuna valutazione finora

- Compression Spring Material and FormulasDocumento23 pagineCompression Spring Material and FormulasVignesh T ShekarNessuna valutazione finora

- Plumbing For High Rise Building 08062KDocumento55 paginePlumbing For High Rise Building 08062Ktom stuartNessuna valutazione finora

- Guide To Epoxy Grouting 14000532Documento25 pagineGuide To Epoxy Grouting 14000532Chukwuma OgbonnaNessuna valutazione finora

- Epilux 155 SFDocumento2 pagineEpilux 155 SFMohamed NasifNessuna valutazione finora

- Sonotube® Commercial Concrete Forms PDFDocumento3 pagineSonotube® Commercial Concrete Forms PDFAnubhav MukherjeeNessuna valutazione finora

- Sokalan RO - Performance ChemicalsDocumento8 pagineSokalan RO - Performance ChemicalsshoyebNessuna valutazione finora

- Compound Wall Toilet Revised (4) - ModelDocumento1 paginaCompound Wall Toilet Revised (4) - ModelInfra SupportNessuna valutazione finora

- Boeing FastenersDocumento40 pagineBoeing Fastenersskynorth100% (16)

- Sample Electrical PlanDocumento1 paginaSample Electrical PlanMaeka Loraine GalvezNessuna valutazione finora

- Absorption Coefficient TableDocumento1 paginaAbsorption Coefficient TableMark bellie TeranteNessuna valutazione finora

- Elcometer 128 Pictorial Surface Standards Data SheetDocumento2 pagineElcometer 128 Pictorial Surface Standards Data SheetBalaji GuruNessuna valutazione finora

- Method For The Determination of CarotenesDocumento2 pagineMethod For The Determination of CarotenesNakibuuka Magdalein50% (2)

- Brochure MMB - CompressedDocumento8 pagineBrochure MMB - CompressedSvetlana ChiganovaNessuna valutazione finora

- 7-12-0036 Rev 4Documento4 pagine7-12-0036 Rev 4cynideNessuna valutazione finora

- 3 Recycle and Reuse of Textile WasteDocumento8 pagine3 Recycle and Reuse of Textile WastegunashekarkalluriNessuna valutazione finora