Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Putsch High Performance Candle Filters PDF

Caricato da

Tung Bui ThanhTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Putsch High Performance Candle Filters PDF

Caricato da

Tung Bui ThanhCopyright:

Formati disponibili

GROUP

High Performance Candle Filters

GROUP

Putsch® candle filters have been

standard equipment in the sugar

industry worldwide for decades.

Filtrate

Level measurement

The filters are used successfully in

sugar beet factories as well as in

sugar refineries. Application in sugar

cane factories is also possible.

These low pressure filter systems are

particularly suitable for thickening of

slurries with low to moderate solid Return

contents, for safety filtration and for

syrup filtration.

Putsch® High Performance Candle Carbonated Carbonated mud

Filters (HKF) are discontinuously mud juice juice concentrate

working filters with back flush.

Acid cleaning in place Acid

Areas of Application: Pre-filtrate

In beet sugar factories:

· for filtration of carbonated Filtration and cleaning schematic of high performance candle filters

juice after the first and the (HKF) for carbonated mud juice 2 filtration and safety filtration.

second carbonation

· as safety filters for thin juice

· for fine filtration of syrups with

the addition of filter aids

In refineries:

· for thickening of carbonated The special space saving Putsch® All electrical equipment is

clarified liquor filter cover construction allows the conceptualized and realized by

economical, quick and safe stacking Putsch®. Therefore, individual

Advantages of candle filters: of the filter covers on top of nearby customer requests can be taken into

· programmable control ensures filters. account.

fully automated operation

· thickening rate is individually Putsch® uses different materials Putsch® filters are fully automated.

adjustable (depending on and weave patterns with various A programmable controller controls

application up to 650 g/l) permeabilities for the filter cloths the operation sequence. Depending

· no additional energy depending on the slurries to be on site conditions, several filters

required for cleaning filtered. can be controlled from one control

· durable equipment cabinet. Additional control units

· sturdy filter elements The necessary back flush filtrate is can also be installed on each filter,

· high specific throughput rate available in a separate head tank. depending on the distance between

because of short cycle times the control cabinet and the filters.

· quick exchange of complete Cleaning of the filter material can be

intermediate bottom complete supported by applying air pressure To monitor the process, the filter

with filter candles if needed or steam for difficult filtration control can be integrated in a central

· CIP (cleaning in place) of processes. factory control system with the

filter cloths in closed candle option of switching from automatic to

filter to extend cycle times manual operation.

before exchange (option).

7

13

Cleaning in place

In Putsch® HKF clogged filter cloths

can be cleaned directly inside the 3

filter with the help of acid. This will be 1

carried out automatically without any

additional assembly work.

Function and Construction of 10

Putsch® High Performance

Candle Filter (HKF) 5

Putsch High Performance Candle

®

Filter HKF is a further developed candle 6

filter. The goal of this development is to

offer sugar factories a high performance

filter type HKF, which will meet the 8

raised expectations of filtration using

proven and new components.

12

Main features of the Putsch® High

Performance Candle Filters include: 11

· a higher specific filter performance

· high solid contents in carbonated

mud juice concentrate Candle filters (HKF) consist of the filter 1 = Vessel

· reliable cleaning of filter cloths vessel (1), the intermediate bottom (2) 2 = Intermediate bottom

through back flush filtrate with filter candles (3) and the filter cover 3 = Filter candle

· clear filtrate (4). Up to 291 filter candles are installed 4 = Filter cover

· filtration in the low pressure range in the pressurized filter vessel. 5 = Filter cloth

· quick and easy exchange 6 = Central inlet

of filter candles The constructional features of the 7 = Filtrate outlet

· cost efficient design Putsch® High Performance Candle 8 = Conical shaped bottom

Filters (HKF) are: 9 = Lifting eyes for filter cover

The material to be filtered is · The conical bottom is 10 = Sealing ring

introduced through a central inlet (6) constructed at a 45° angle. 11 = Mud concentrate outlet

into the filter vessel (1). The solids · Introduction of slurry occurs 12 = Acid resistent coating

collect on the filter candles (3), centrally up to 8” below the 13 = Level measurement for cleaning in place

which are covered with filter cloths intermediate bottom.

(5). The filtrate flows through the filter · If a clearance of 2” between

candles into the filtrate area to the candles is selected, filter areas With the improved construction

head tank through a pipe (7). of 1130 sq.ft. or 2150 sq.ft. are and operation features we

available. A clearance of 2” can achieve significantly higher filter

Mud concentrate is removed through be utilized because this process performances.

the conical bottom of the vessel (8). forms thinner filter cake.

· During the filter cycle, partial Short filtration times result in thin

The main dimensions of the new cleaning can be accomplished. filter cake on the filter candles. This

High Performance Candle Filter · Cleaning of the filter candles ensures that filtration always takes

(HKF) are basically the same, occurs with filtrate back place in the high throughput range

allowing for easy replacement of old flush from an head tank. of the filtration curve but with low

Candle Filters with the new type. · An acid-resistance coating filtration pressure.

allowes cleaning in place.

GROUP

Process Control The filtrate outlet pipe (7) extends Filtration is completed when:

An adapted filter control system into the dome of the vessel cover · the preset slurry volume is filtered

ensures that a high solid content (4) to improve the filtrate quality. The · the monitoring time has elapsed

in carbonated mud concentrate air contained in the filtrate is thus · the maximum filtration

is reached and prevents clogging compressed in the dome of the filter. pressure has been reached

of the Putsch® High Performance Pressure surges can thereby be

Candle Filters. equalized. At the end of the cycle the mud

concentrate in the conical bottom

Monitoring of the filtration pressure To achieve the highest filtrate quality, (8) is emptied aided by back flush

ensures technical and technological the High Performance Candle Filter filtrate.

optimum filtration. (HKF) is equipped with a cloudy

filtrate return. Subsequently the filter control will

automatically switch to cleaning,

ensuring the filters’ full capacity

performance again.

Please contact us for additional information and spare part inquiries:

Putsch® & Company, Inc.

Asheville, NC 28813-5128 Fax 828.684.4894

Phone 828.684.0671 Email info@putschusa.com

Toll free 800.847.8427 www.putschusa.com

Potrebbero piacerti anche

- Sugar Industry ReportDocumento47 pagineSugar Industry ReportTung Bui ThanhNessuna valutazione finora

- Condenser ManualDocumento4 pagineCondenser ManualTung Bui ThanhNessuna valutazione finora

- 2016 Tascon OverviewCrystallizationinColombianSugarMillsDocumento16 pagine2016 Tascon OverviewCrystallizationinColombianSugarMillsTung Bui ThanhNessuna valutazione finora

- Fdocuments - in Sugar Cane CrusherDocumento25 pagineFdocuments - in Sugar Cane CrusherTung Bui ThanhNessuna valutazione finora

- VR505ADocumento3 pagineVR505ATung Bui ThanhNessuna valutazione finora

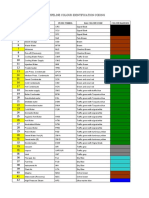

- Pipeline Colour Identification CodingDocumento2 paginePipeline Colour Identification CodingTung Bui ThanhNessuna valutazione finora

- Molasses Conditioning: Additional Heating SurfaceDocumento1 paginaMolasses Conditioning: Additional Heating SurfaceTung Bui ThanhNessuna valutazione finora

- VIVI Trash Plate Heel Session - 2. - KP - Singh - 210318044122 - 2Documento55 pagineVIVI Trash Plate Heel Session - 2. - KP - Singh - 210318044122 - 2Tung Bui ThanhNessuna valutazione finora

- A MK 1800 TCD Pump InquiryDocumento4 pagineA MK 1800 TCD Pump InquiryTung Bui ThanhNessuna valutazione finora

- Mill Training CourseDocumento27 pagineMill Training CourseTung Bui ThanhNessuna valutazione finora

- Recent Trends in Extraction TechnologyDocumento5 pagineRecent Trends in Extraction TechnologyTung Bui ThanhNessuna valutazione finora

- Tinh May EpDocumento10 pagineTinh May EpTung Bui ThanhNessuna valutazione finora

- DG Series Boiler Water Suppl Y PumpDocumento40 pagineDG Series Boiler Water Suppl Y PumpTung Bui ThanhNessuna valutazione finora

- Modern Extraction Technology: List of ContentsDocumento14 pagineModern Extraction Technology: List of ContentsTung Bui ThanhNessuna valutazione finora

- Ign Schematic Block Diagram of Sugar ProcessingDocumento1 paginaIgn Schematic Block Diagram of Sugar ProcessingTung Bui ThanhNessuna valutazione finora

- Efficiency of Juice Clarifier (Atif Sattar)Documento15 pagineEfficiency of Juice Clarifier (Atif Sattar)Tung Bui ThanhNessuna valutazione finora

- Importance of In-Line Colour Measurement of Sugar For Product Quality and Factory PerformanceDocumento46 pagineImportance of In-Line Colour Measurement of Sugar For Product Quality and Factory PerformanceTung Bui ThanhNessuna valutazione finora

- Beet Sugar: Alfacaus AlfaaddDocumento9 pagineBeet Sugar: Alfacaus AlfaaddTung Bui ThanhNessuna valutazione finora

- Pressure Plate Frame Plate Frame Plate Pressure PlateDocumento6 paginePressure Plate Frame Plate Frame Plate Pressure PlateTung Bui ThanhNessuna valutazione finora

- Boiler CI KartiDocumento127 pagineBoiler CI KartibaluNessuna valutazione finora

- Mill Misc ABSTRACTDocumento21 pagineMill Misc ABSTRACTTung Bui ThanhNessuna valutazione finora

- 2001 Kent The Distribution of Torque in A Three Roll MillDocumento6 pagine2001 Kent The Distribution of Torque in A Three Roll MillTung Bui ThanhNessuna valutazione finora

- Sugar boiling-MA-CVDocumento8 pagineSugar boiling-MA-CVTung Bui ThanhNessuna valutazione finora

- ND Mill Setting 2500 - 13FDocumento1 paginaND Mill Setting 2500 - 13FTung Bui ThanhNessuna valutazione finora

- Cargill Liquid SucroseDocumento1 paginaCargill Liquid SucroseTung Bui ThanhNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- DAC AnalysisDocumento19 pagineDAC Analysisమురళీధర్ ఆది ఆంధ్రుడుNessuna valutazione finora

- Breuer - Sun & Shadow (Inglés) PDFDocumento18 pagineBreuer - Sun & Shadow (Inglés) PDFccorrea74Nessuna valutazione finora

- Microsoft PowerPoint - Sesi 2-Communication Skills - PPT (Comp PDFDocumento21 pagineMicrosoft PowerPoint - Sesi 2-Communication Skills - PPT (Comp PDFSarah Eddiah0% (1)

- TA-Modulator EN LowDocumento16 pagineTA-Modulator EN Lowkap4enijNessuna valutazione finora

- Wind Tunnel Technique Notes For Aeronautical Engineers TP 2Documento6 pagineWind Tunnel Technique Notes For Aeronautical Engineers TP 2Ramji VeerappanNessuna valutazione finora

- Assignment 9 Nomor 1Documento2 pagineAssignment 9 Nomor 1Alexander Steven ThemasNessuna valutazione finora

- International Journal of Agricultural ExtensionDocumento6 pagineInternational Journal of Agricultural Extensionacasushi ginzagaNessuna valutazione finora

- Prose 2 - Lost Spring - Important QADocumento5 pagineProse 2 - Lost Spring - Important QADangerous GamingNessuna valutazione finora

- Industrial ReactorsDocumento10 pagineIndustrial ReactorssarahNessuna valutazione finora

- Merged DocumentDocumento28 pagineMerged DocumentJamirah Maha ShahinurNessuna valutazione finora

- Esinex: R Resinated Lignite Is Designed ToDocumento2 pagineEsinex: R Resinated Lignite Is Designed ToWaleed Barakat MariaNessuna valutazione finora

- The Child's Learning of English Morphology: WORDDocumento29 pagineThe Child's Learning of English Morphology: WORDCatnis TomNessuna valutazione finora

- Toyota Motor Manufacturing (TMM)Documento20 pagineToyota Motor Manufacturing (TMM)Lekha ShahNessuna valutazione finora

- PE1 Introduction To MovementsDocumento4 paginePE1 Introduction To MovementsDaniela AnsayNessuna valutazione finora

- Bollard Pull Calculations For Towing OperationsDocumento8 pagineBollard Pull Calculations For Towing OperationsDiegoNessuna valutazione finora

- C-L-X® Type MC-HL (XHHW-2)Documento3 pagineC-L-X® Type MC-HL (XHHW-2)Xin LiNessuna valutazione finora

- Getting Good Grades in School Is What Kids Are Supposed To Be Doing.Documento6 pagineGetting Good Grades in School Is What Kids Are Supposed To Be Doing.The QUEENNessuna valutazione finora

- Cloud Computing 101 TutorialDocumento203 pagineCloud Computing 101 TutorialYunis Iklil100% (1)

- Present Simple Present ContinuousDocumento3 paginePresent Simple Present ContinuousFernando SabinoNessuna valutazione finora

- Flotech Corporate FlyerDocumento6 pagineFlotech Corporate FlyerPrasetyo PNPNessuna valutazione finora

- CES Wrong Answer SummaryDocumento2 pagineCES Wrong Answer SummaryВладислав КомаровNessuna valutazione finora

- Lecture Note On Photovoltaic CellDocumento1 paginaLecture Note On Photovoltaic CellHaseeb NawazNessuna valutazione finora

- ENG-116: Branches of Linguistics: Books) .Farmer, A. K Demers, R. A. A Linguistics WorkbookDocumento6 pagineENG-116: Branches of Linguistics: Books) .Farmer, A. K Demers, R. A. A Linguistics WorkbookBILAL ZAFARNessuna valutazione finora

- 5 Levels of Leadership AnswersDocumento4 pagine5 Levels of Leadership Answersk98hk8wnnbNessuna valutazione finora

- KrautKramer DM4E DM4DL - ManualDocumento38 pagineKrautKramer DM4E DM4DL - ManualfdsgfdgNessuna valutazione finora

- Methley Railway Station: A Proposal To The Department For Transport.Documento38 pagineMethley Railway Station: A Proposal To The Department For Transport.Rt Hon. Alec Shelbrooke, M.P.0% (1)

- 3PM - Project Management Method - Sales MessagingDocumento5 pagine3PM - Project Management Method - Sales Messagingberuang kutubNessuna valutazione finora

- Operator'S Manual AND Set-Up Instructions For The: WDL-2070-FADocumento49 pagineOperator'S Manual AND Set-Up Instructions For The: WDL-2070-FAМаксим ЛитвинNessuna valutazione finora

- MMC 16101 - Positive Displacement Pump - 01Documento19 pagineMMC 16101 - Positive Displacement Pump - 01HET DEDHIANessuna valutazione finora

- Laundry Center Dryer Tech Data Sheet: NO - Normally Open NTC - NTC Thermistor MCF - Machine Configuration FileDocumento40 pagineLaundry Center Dryer Tech Data Sheet: NO - Normally Open NTC - NTC Thermistor MCF - Machine Configuration FilePedro IsmaelNessuna valutazione finora