Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

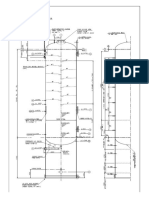

A133 086 16 46 DS 3019 - 2

Caricato da

Priyanka KumariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A133 086 16 46 DS 3019 - 2

Caricato da

Priyanka KumariCopyright:

Formati disponibili

NOZZLES AND CONNECTIONS GENERAL NOTES SPECIFICATIONS DESIGN DATA

MARK QTY

NOM.

SCH./THK

FLANGES PROJECTION PAD

SERVICE

UNLESS STATED OTHER WISE X DENOTES APPLICABLITY CODE ASME SEC. VIII DIV.1 2010+ ADDENDA 2011

DIA CLASS TYPE FACING 0 NOTE-4 WxT 1 ALL DIMENSIONS ARE IN MM UNLESS STATED OTHER WISE. WORKING PRESSURE (kg/cm g)

2

1.5

2 INT:

SEE 2 ALL ANCHOR BOLT HOLES TO STRADDLE N/S CENTRE LINE. DESIGN PRESSURE (kg/cm g) 6 EXT F.V.

1 1 600 12THK. 300 WN RF 230X12 MANHOLE + B.F.+DAVIT 0

TOP/

DWG. 3 NORTH DIRECTION WHEREVER SHOWN IS WITH RESPECT TO PLAN VIEW. WORKING TEMPERATURE ( C) 120-370

4 (A) FOR NOZZLES ON SHELL PROJECTIONS ARE REFERRED FROM VESSEL CENTER

JACOBS SPECIFICATIONS DESIGN TEMPERATURE

0

( C) 400

8 1 200 100 300 WN RF 1220 80X12 VENTILATION NOZZLE + BF LINE TO FLANGE CONTACT FACE.

X GENERAL SPECIFICATION FOR PRESSURE VESSELS 44NC-4600-0000-V.02.-0101-A4 MDMT ( C)

0

18

11 1 300 120 300 WN RF 1220

SEE

FEED FROM 86-R-01A/B $

4 (B) FOR NOZZLES ON HEAD PROJECTIONS ARE REFERRED FROM HEAD T.L TO X GENERAL SPECIFICATION FOR SHOP & FIELD PAINTING 44NC-4600-0000-V.02.-0111-A4 CORROSION ALLLOWANCE (MM) 6

2 DRG. FLANGE CONTACT FACE. GENERAL SPECIFICATION FOR INSULATION 44NC-4600-0000-V.02.-0112-A4 TYPE OF HEAD 2:1 ELLIPSOIDAL

SEE 5 THE INDICATED THICKNESS IS THE MINIMUM ACCEPTABLE AFTER GENERAL SPECIFICATION - MATERIAL SPECIFICATIONS 44NC-4600-0000-V.02.-0114-A4 JOINT EFFICIENCY SHELL 0.85 HEAD 1.0

16 1 350 24 THK 300 WN RF 1220 EQUALIZING LINE WITH 86-C-01$

2 DRG. CONSTRUCTION.

X STANDARD SPECIFICATION FOR BQ CS PLATES 44NC-4600-0000-V.02.-0117-A4 RADIOGRAPHY SHELL SPOT HEAD FULL

17 1 300 120 300 WN RF 1090

SEE

BOTTOM OUTLET TO 86-G-18A/B $

6 FLANGE GASKET FACE SHALL BE 125 AARH FINISH. X SUPPLEMENTARY SPECIFICATION FOR CS VESSELS 44NC-4600-0000-V.02.-0120-A4 POST WELD HEAT TREATMENT NIL

DRG. 7 DIMENSIONS OF FLANGES FOR NOZZLES UPTO 600NB SHALL BE AS PER ASME X JOB SPECIFICATION FOR VESSELS 44NC-4600-0000-V.02.-0141-A4 HEAT TREATMENT HEAD (AS PER SPEC.)

B16.5 AND FOR NOZZLE ABOVE 600NB SHALL BE AS PER ASME B16.47 OPERATING MEDIUM COKER CONDENSATE DRUM

31 1 100 160 300 WN RF 1040 55X12 DRAIN SERIES `B' UNLESS SPECIFIED OTHERWISE. JACOBS STANDARDS SP. GRAVITY 1.000

33 1 152.4 I/D _ 300 LWN RF 1220 _ SAFETY VALVE

8 ID OF WELD NECK FLANGES SHALL MATCH WITH CORRESPONDING ID OF X GENERAL TOLERANCES FOR PRESSURE VESSELS IND VSD 001 WIND SPECIFICATION IS 875

2 NOZZLE PIPE. X MANWAY DAVIT (FOR HORIZONTAL MANHOLE) IND VSD 003 SEISMIC IS 1893 & SITE SPECTRA

3

SEE 9 NOZZLES 50NB AND BELOW SHALL BE STIFFENED WITH 2 NOS. 40 x 6 THK DETAIL OF VESSEL/COLUMN TOP DAVIT IND VSD 004 CAPACITY (M ) 10.73

35 1 50 XXS 300 WN RF _ UTILITY CONNECTION 0

DWG. FLATS 90 APART. DETAIL OF SKIRT OPENING FOR VESSEL & COLUMN IND VSD 006 PAINTING/CLEANING AS PER PAINTING JOB SPEC.

_ 10 ALL INTERNALS SHALL BE SIZED TO PASS THROUGH NEAREST MANHOLE DETAIL OF SKIRT BASE FOR VESSEL & COLUMN IND VSD 007 INSULATION THICKNESS (mm) 115 HOT COLD

36 1 40 XXS 300 WN RF 1220 PRESSURE GAUGE EASILY. LEG SUPPORT FOR VERTICAL VESSEL (2 SHEETS) IND VSD 008 FIRE PROOFING YES NO

45

2 50 XXS 300 WN RF

SEE _ LEVEL GAUGE 11 2

VESSEL IS SUBJECTED TO STEAM OUT CONDITION OF 0.5 Kg/Cm (g) / FV X SADDLE SUPPORT FOR HORIZONTAL VESSEL(7 SHEETS) IND VSD 009 HYDROSTATIC TEST (kg/cm2g) HORIZONTAL / VERTICAL (AT TOP)

A-B DWG. MAGNETIC (SS) 0

AT 190 C 1 LUG SUPPORTS (2 SHEETS) IND VSD 010 PRESSURE (NEW & COLD) 10.328

46 SEE LEVEL TRANSMITTER 12 ALL NOZZLE FABRICATED FROM PLATE SHALL BE 100% RADIOGRAPHED. PIPE LEG SUPPORT IND VSD 011 INSPECTION BY EIL CIB X TPI

2 80 XXS 300 WN RF 55X12

A-B DWG. (DP-DS) 13 MOUNT 2" VENT NOZZLE ON THE BLIND FLANGE OF NOZZLE-8 X MINIMUM NOZZLE WALL THICKNESS IND VSD 012

MATERIAL OF CONSTRUCTION

47

2 80 XXS 300 WN RF

SEE

55X12

LEVEL TRANSMITTER 14 SURFACE PREPARATION AND PRIMER AND PAINTING SHALL BE AS PER JOB X REINFORCING PLATES FOR NOZZLES. (C.A. 3mm) IND VSD 018 (AS PER ASME / IS OR EQUIVALENT)

A-B DWG. (DP-DS) SPECIFICATION 44NC-4600-000-V-02-0111-A4.

X NAME PLATE BRACKET IND VSD 020

50 1 50 XXS 300 WN RF

SEE

_ VENT (NOTE-13)

15 ALSO REFER 44NC-4600-00/V.02/0164/A3 FOR OTHER APPLICABLE NOTES. X STANDARD NAME PLATE FOR VESSEL IND VSD 021 SHELL / INSERT PLATE SA 516 GR.70

DWG. 16 VENDOR SHALL INDICATE C.G OF EQUIPMENT IN FABRICATION DWGS. INSULATION SUPPORTS FOR VESSELS (HOT) IND VSD 022 REINFORCEMENT PAD SA 516 GR.70

17

MANDATORY & COMISSIONING SPARES SHALL BE SUPPLIED BY FABRICATOR.

X STANDARD NOZZLE PROJECTION IND VSD 024 HEADS SA 516 GR.70

LIFTING TRUNNIONS IND VSD 025 SHELL FLANGES -

18 WHENEVER FULL RADIOGRAPHY SPECIEFIED SHALL IMPLY 100% HANDHOLE WITH HINGED COVER IND VSD 029 NOZZLE FLANGES/LWN NOZZLES/B.F. SA 105

$ WITH INSERT PLATE RADIOGRAPHY OF ALL BUTT WELDS. STANDARD INTERNAL PLATE FLANGES NOZZLE NECK UPTO 300 NB SA 106 GR.B (SEAMLESS)

IND VSD 030

19 VACUUM STIFFENERS SHALL BE USED AS INSULATION SUPPORT RING. VORTEX BREAKERS (FLUSH TYPE NOZZLES) IND VSD 033 NOZZLE NECK ABOVE 300 NB SA 516 GR.70

STIFFENER RING SHALL BE MODIFIED WITH ADDITION OF GUSSET, NEOPRENE VORTEX BREAKERS (NOZZLE WITH INTERNAL PROJECTION) IND VSD 034 PIPE FITTINGS SA 234 GR. WPB

AND ALUMINIUM WASHERS, M6 G.I. BOLTS ETC. SO THAT SAME CAN BE USED

STANDARD DEMISTERS TYPE-I (VESSEL DIA<800mm) IND VSD 036 SPIRAL WOUND GASKET WITH SS 304 METAL

AS INSULATION SUPPORT RING.

STANDARD DEMISTERS TYPE-II(VESSEL DIA> 800mm) IND VSD 037 WINDINGS AND GRAPHITE FILLER MATERIAL

GASKET EXTERNAL

20 STIFFENER RING SHALL NOT BE WELDEDTO SHELL TILL ALL THE FOULING STANDARD DEMISTERS TYPE-III IND VSD 038 WITH SS 304 OUTER & INNER RING AS PER

W.R.T. THE PIPING AND STRUCTURAL CLIPS ARE CLEARED / RESOLVED. STANDARD DEMISTERS TYPE-IV IND VSD 039 ASME B16.20

X STANDARD BOLT HOLE ORIENTATION IND VSD 040 GASKET INTERNAL -

EARTHING BOSS IND VSD 041 EXTERNAL STUDS/BOLTS/NUTS SA 193 GR.B7 / SA 194 GR.2H

X LADDER RUNGS INSIDE VESSELS AND COLUMNS IND VSD 043 INTERNAL STUDS/BOLTS/NUTS SS 304

FOUNDATION TEMPLATE (2 SHEETS) IND VSD 044 SKIRT/ SUPPORT IS 2062 GR.B

SUPPORT FOR INTERNAL DISTRIBUTOR PIPES IND VSD 045 SKIRT/ SUPPORT BASE IS 2062 GR.B

SUPPORTS FOR INTERNAL FEED PIPE IND VSD 046/047 INTERNAL PARTS (WELDED) SA 516 GR.70

LIFTING LUG TOP HEAD TYPE IND VSD 048 INTERNAL PARTS (BOLTED) SA 516 GR.70

VISCOSITY

LIFTING LUG FOR HORIZONTAL VESSEL IND VSD 050 CLIPS & ATTACHMENTS ((EXT.) DIRECTLY WELDED SA 516 GR.70

X TYP. NOZZLE FLANGE TO NECK JOINT IND VSD 051 CLIPS & ATTACHMENTS (EXT.) WELDED OVER PAD IS 2062 GR.B

X RECOMMENDED WELD EDGE PREPARATION FOR BUTT WELDS IND VSD 052 PAD FOR EXTERNAL ATTACHMENTS SA 516 GR.70

ALLOY LINER DETAIL (2SHEETS) IND VSD 053 WRAPPER PLATE SA 516 GR.70

SUPPORT RING AND BOLTING BAR IND VSD 055 NAME PLATE SS 304

SUPPORT RING SIZES FOR PACKED TOWERS IND VSD 056 NAME PLATE BRACKET SA 516 GR.70

INSULATION SUPPORTS FOR VERTICAL VESSEL IND VSD 057

X INSULATION SUPPORTS FOR HORIZONTAL VESSEL IND VSD 058

FIRE PROOFING SUPPORT IND VSD 062 BRACKET SA 516 GR.70

MANWAY DAVIT

INLET DEFLECTOR BAFFLE IND VSD 064 ALL OTHER PARTS IS 2062 GR.B

X EARTHING LUG IND VSD 080

X NOZZLE ORIENTATIONS

PMC CONTROL CODE -V21 X LADDERS/PLATFORM CLEATS

PIPE SUPPORT CLEATS

DEMISTER DATA SHEET NA

MONKEY LADDER NA

APPROVAL

PMC REVIEW

RECORDS

STATUTORY REGULATIONS

LICENSORS SPECIFICATIONS

FOUNDATION LOADING DATA (OPERATING CONDITION) HOLD UPS 2

LICENSORS STANDARDS MAX MOMENT AT BASE (M) NOZZLE ORIENTATIONS SIZE OF NOZZLES

TYPE MAX. SHEAR FORCE AT BASE (H) (kg) APPROXIMATE WEIGHT (kgs)

X PIPE SUPPORT CLEATS

(kgm) (PER ITEM)

NOZZLE ELEVATIONS (AS MARKED)

FIXED/SLIDING SUPPORT LADDER/PLATFORM CLEATS

DBE _ _ DETAILS OF INTERNALS TRAY SUPPORT/BOLTING BARS

ERECTION 4100 OPERATING 15500

SEISMIC

PIPE DAVIT

MCE _ _ HYDROTEST(SHOP) 15700 HYDROTEST ( FIELD ) 16500

WIND _ _ NUMBER OF ITEMS : ONE

2 03.07.2014 REVISED AS MARKED 2 GCP SUU/PKP BBC DESIGN DATA

JOB NO: A133 1 01.02.2014 REVISED AS MARKED GCP SUU/PKP BBC

DRAWING NUMBER REV

0 26.12.2013 ISSUED FOR PURCHASE GCP PB/PKP BBC

CLIENT : B 19.09.2013 REVISED AND ISSUED FOR BIDS/ENGG. GCP SUU/PSV BBC

A 10.05.11 ISSUED FOR BIDS/ENGG. SBS AY/PP TG

PLANT : REV DATE REVISION BY CHECKED APPROVED

ITEM NO. 86-C-28

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- A133 086 16 46 DS 3017 - 2Documento1 paginaA133 086 16 46 DS 3017 - 2Priyanka KumariNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A133 086 16 46 DS 3021 - 2Documento1 paginaA133 086 16 46 DS 3021 - 2Priyanka KumariNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A133 086 16 46 DS 3017 - 2Documento1 paginaA133 086 16 46 DS 3017 - 2Priyanka KumariNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- E3d-Inst SelectionDocumento4 pagineE3d-Inst SelectionPriyanka KumariNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- A133 086 16 46 DS 3012 - 2Documento1 paginaA133 086 16 46 DS 3012 - 2Priyanka KumariNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- TM-1210 AVEVA Plant (12 Series) Multi-Discipline Supports Rev 3.0 PDFDocumento156 pagineTM-1210 AVEVA Plant (12 Series) Multi-Discipline Supports Rev 3.0 PDFnomurapreNessuna valutazione finora

- A133 086 16 46 DS 3011a2 - 1 PDFDocumento1 paginaA133 086 16 46 DS 3011a2 - 1 PDFPriyanka KumariNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A133 086 16 46 DS 3012 - 2Documento1 paginaA133 086 16 46 DS 3012 - 2Priyanka KumariNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- PSV and FlareDocumento116 paginePSV and FlareShanmuga Muthukumar100% (6)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- A133 086 16 46 DS 3016 - 2Documento1 paginaA133 086 16 46 DS 3016 - 2Priyanka KumariNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Is 2825Documento286 pagineIs 2825Biju P86% (7)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- A133 086 16 46 DS 3011a2 - 1 PDFDocumento1 paginaA133 086 16 46 DS 3011a2 - 1 PDFPriyanka KumariNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Excellence: His PublicationsDocumento2 pagineExcellence: His PublicationsPriyanka KumariNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- FPSO LayoutDocumento36 pagineFPSO LayoutPriyanka Kumari100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Smartmarine 3D: Samsung Heavy Industries Cosco Shipyard Group Keppel Offshore & Marine Grenland Group VietsovpetroDocumento64 pagineSmartmarine 3D: Samsung Heavy Industries Cosco Shipyard Group Keppel Offshore & Marine Grenland Group VietsovpetroPriyanka KumariNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- PDMS - Support Function DefinitionDocumento6 paginePDMS - Support Function DefinitionPriyanka KumariNessuna valutazione finora

- 6420-1S&9S-Line List-R9 - 02.04.19Documento111 pagine6420-1S&9S-Line List-R9 - 02.04.19Priyanka KumariNessuna valutazione finora

- 0468 Sid20 92DL 1202 001 0Documento1 pagina0468 Sid20 92DL 1202 001 0Priyanka KumariNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- D 100025 X 012Documento20 pagineD 100025 X 012ErnestoNessuna valutazione finora

- Making Carbon Black: Presented by Sid Richardson Carbon CoDocumento37 pagineMaking Carbon Black: Presented by Sid Richardson Carbon ColatshareNessuna valutazione finora

- Qty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DateDocumento5 pagineQty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DatePriyanka KumariNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Transmitter Instrument Without DiaphragmDocumento4 pagineTransmitter Instrument Without DiaphragmPriyanka KumariNessuna valutazione finora

- Pipe Module Equipments List 030419Documento1 paginaPipe Module Equipments List 030419Priyanka KumariNessuna valutazione finora

- Fisher 655 and 655R Actuators For Self Operated Control: FeaturesDocumento16 pagineFisher 655 and 655R Actuators For Self Operated Control: FeaturesPriyanka KumariNessuna valutazione finora

- Engineering Design Basis FOR Project: Client: Projec T: Job No.Documento11 pagineEngineering Design Basis FOR Project: Client: Projec T: Job No.Priyanka KumariNessuna valutazione finora

- Procon India Pvt. LTD.: Ph. +91-120-669 2000 Fax.: +91-120-669 2001Documento1 paginaProcon India Pvt. LTD.: Ph. +91-120-669 2000 Fax.: +91-120-669 2001Priyanka KumariNessuna valutazione finora

- Procon India Pvt. LTD.: Ph. +91-120-669 2000 Fax.: +91-120-669 2001Documento1 paginaProcon India Pvt. LTD.: Ph. +91-120-669 2000 Fax.: +91-120-669 2001Priyanka KumariNessuna valutazione finora

- 1139-ST-044 R0 Piping Material SpecificationDocumento19 pagine1139-ST-044 R0 Piping Material SpecificationPriyanka KumariNessuna valutazione finora

- After cooling pump installation documentationDocumento6 pagineAfter cooling pump installation documentationPriyanka KumariNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Repair Parts Catalog: FOR Sunnen Vertical Honing MachineDocumento48 pagineRepair Parts Catalog: FOR Sunnen Vertical Honing MachineLucas Isaias da Silva100% (1)

- 1 1 To Agartala (India) To Akhura (Bangladesh) : Dimension Details of Pile CapDocumento3 pagine1 1 To Agartala (India) To Akhura (Bangladesh) : Dimension Details of Pile CapNilay GandhiNessuna valutazione finora

- Shear Walls and Diaphragms PDFDocumento76 pagineShear Walls and Diaphragms PDFCharbel Saad SaadNessuna valutazione finora

- Fume Hood Wet ScrubberDocumento1 paginaFume Hood Wet ScrubberRedmi TigaesNessuna valutazione finora

- Understanding Wind Power TechnologyDocumento14 pagineUnderstanding Wind Power TechnologyDiego ZayasNessuna valutazione finora

- Allison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogDocumento6 pagineAllison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogMarcos LunaNessuna valutazione finora

- Washer - ISO 7093-1-2000Documento9 pagineWasher - ISO 7093-1-2000Corneliu VilcuNessuna valutazione finora

- Workshop Manual Freightliner M915a3Documento20 pagineWorkshop Manual Freightliner M915a3jennifer100% (50)

- Microsoft Word - Module 4-Steam Power Plant PDFDocumento51 pagineMicrosoft Word - Module 4-Steam Power Plant PDFJames Tnecniv AlborteNessuna valutazione finora

- Method Statement For PlumbingDocumento5 pagineMethod Statement For PlumbingParasNessuna valutazione finora

- 7 - Psy - Chart - XLS Cooling CoilDocumento28 pagine7 - Psy - Chart - XLS Cooling CoilRanu JanuarNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 1981 PitfallsDocumento44 pagine1981 Pitfallsengineer_atulNessuna valutazione finora

- Hydraulic Transmission, Installing: Información de ServicioDocumento5 pagineHydraulic Transmission, Installing: Información de ServicioFútbol y másNessuna valutazione finora

- 9ni 4coDocumento102 pagine9ni 4cosunsirNessuna valutazione finora

- Node List & SIFDocumento2 pagineNode List & SIFCandraNessuna valutazione finora

- Introduction of Control Systems and Basic TerminologyDocumento12 pagineIntroduction of Control Systems and Basic TerminologyShivaji ThubeNessuna valutazione finora

- Comparison of Effective Width Method, Pigeaud's Theory and Westergaad's Method With SAP2000 Fem ModelDocumento14 pagineComparison of Effective Width Method, Pigeaud's Theory and Westergaad's Method With SAP2000 Fem ModelAkarshGowdaNessuna valutazione finora

- 0 - Geotechnical Site Classification and Croatian National Annex For Eurocode 8 - P.kvasnicka, Leo Matesic and K.ivandic - 2011 - 8182Documento10 pagine0 - Geotechnical Site Classification and Croatian National Annex For Eurocode 8 - P.kvasnicka, Leo Matesic and K.ivandic - 2011 - 8182nebojsadj6411Nessuna valutazione finora

- Concrete and Composite Poles Construction and Design GuideDocumento18 pagineConcrete and Composite Poles Construction and Design GuideJayabalan R KNessuna valutazione finora

- Motor effect concepts and applicationsDocumento2 pagineMotor effect concepts and applicationsIntiser RahmanNessuna valutazione finora

- Agma 908-B89-1999Documento79 pagineAgma 908-B89-1999Alex OliveiraNessuna valutazione finora

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocumento7 pagineDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- Properties of Matter: Extensive vs IntensiveDocumento16 pagineProperties of Matter: Extensive vs IntensiveCentener CalcetaNessuna valutazione finora

- ServiceManual UR3 en 3.1.3 PDFDocumento116 pagineServiceManual UR3 en 3.1.3 PDFEkeel PabloNessuna valutazione finora

- Necessity Of Gear Box In An AutomobileDocumento7 pagineNecessity Of Gear Box In An AutomobilekismuganNessuna valutazione finora

- Tank Installation RequirementsDocumento2 pagineTank Installation Requirementsmarkigldmm918Nessuna valutazione finora

- Portal FrameDocumento11 paginePortal FrameRaJ ShlrzvesteRNessuna valutazione finora

- Manual MisiaDocumento60 pagineManual MisiaErc Nunez VNessuna valutazione finora

- Application Data Sheet: General InformationDocumento5 pagineApplication Data Sheet: General InformationAugusto PenessiNessuna valutazione finora