Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A133 086 16 46 DS 3012 - 2

Caricato da

Priyanka KumariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A133 086 16 46 DS 3012 - 2

Caricato da

Priyanka KumariCopyright:

Formati disponibili

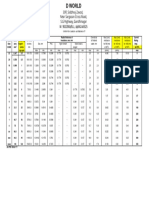

NOZZLES AND CONNECTIONS GENERAL NOTES SPECIFICATIONS DESIGN DATA

MARK QTY

NOM.

SCH./THK

FLANGES PROJECTION PAD

SERVICE

UNLESS STATED OTHER WISE X DENOTES APPLICABLITY CODE ASME SEC. VIII DIV.1 2010+ADDENDA 2011

DIA CLASS TYPE FACING NOTE-4 WxT 1 ALL DIMENSIONS ARE IN MM UNLESS OTHERWISE STATED. WORKING PRESSURE (kg/cm g)

2

TOP 1.5 BOT _

2 INT:

SEE 2 ALL ANCHOR BOLT HOLES TO STRADDLE N/S CENTRE LINE. DESIGN PRESSURE (kg/cm g) 7 EXT F.V. AT 190°C

1 1 600 16THK. 150 WN RF 250X16 MANHOLE + B.F.+DAVIT 0

TOP/

DWG. 3 NORTH DIRECTION WHEREVER SHOWN IS WITH RESPECT TO PLAN VIEW. WORKING TEMPERATURE ( C) TOP 193 BOT _

0

4 (A) FOR NOZZLES ON SHELL PROJECTIONS ARE REFERRED FROM VESSEL CENTER DESIGN TEMPERATURE ( C) 250

7 1 80 160 150 WN RF 2300 55X16 VAPOR OUTLET TO BALANCE LINE LINE TO FLANGE CONTACT FACE.

X GENERAL SPECIFICATION FOR PRESSURE VESSELS 44NC-4600-0000-V.02.-0101-A4 MDMT ( C)

0

18

8 1 200 80 150 WN RF 2300 85X16 VENTILATION NOZZLE +BF

4 (B) FOR NOZZLES ON HEAD PROJECTIONS ARE REFERRED FROM HEAD T.L TO X GENERAL SPECIFICATION FOR SHOP & FIELD PAINTING 44NC-4600-0000-V.02.-0111-A4 CORROSION ALLLOWANCE (MM) 3

FLANGE CONTACT FACE.

X GENERAL SPECIFICATION FOR INSULATION 44NC-4600-0000-V.02.-0112-A4 TYPE OF HEAD 2:1 ELLIPSOIDAL

5 THE INDICATED THICKNESS IS THE MINIMUM ACCEPTABLE AFTER GENERAL SPECIFICATION - MATERIAL SPECIFICATIONS 44NC-4600-0000-V.02.-0114-A4 JOINT EFFICIENCY SHELL 0.85 HEAD 1.0

11 1 350 16THK. 150 WN RF 2300 140X16 FEED FROM OSBL CONSTRUCTION.

X STANDARD SPECIFICATION FOR BQ CS PLATES 44NC-4600-0000-V.02.-0117-A4 RADIOGRAPHY (NOTE-17) SHELL SPOT HEAD FULL

17 1 350 16THK. 150 WN RF 2050 140X16 BOTTOM OUTLET TO 86-G-02A/B

6 FLANGE GASKET FACE SHALL BE 125 AARH FINISH. X SUPPLEMENTARY SPECIFICATION FOR CS VESSELS 44NC-4600-0000-V.02.-0120-A4 POST WELD HEAT TREATMENT NO

7 DIMENSIONS OF FLANGES FOR NOZZLES UPTO 600NB SHALL BE AS PER ASME X JOB SPEC. FOR VESSELS 44NC-4600-0000-V.02.-0141-A4 HEAT TREATMENT HEAD (AS PER SPEC.)

B16.5 AND FOR NOZZLE ABOVE 600NB SHALL BE AS PER ASME B16.47 SERIES OPERATING MEDIUM COKER UNIT FEED SURGE DRUM

20 1 200 80 150 WN RF 2300 85X16 RETURN FROM 86-G-02A/B `B' UNLESS SPECIFIED OTHERWISE.

SP. GRAVITY 0.930

31 1 80 160 150 WN RF 1970 55X16 DRAIN

8 ID OF WELD NECK FLANGES SHALL MATCH WITH CORRESPONDING ID OF X GENERAL TOLERANCES FOR PRESSURE VESSELS IND VSD 001 WIND SPECIFICATION IS 875

NOZZLE PIPE. X MANWAY DAVIT (FOR VERTICAL/HORIZOTAL MANHOLE) IND VSD 002/003 SEISMIC IS 1893 & SITE SPECTRA

3

9 a) NOZZLES 50NB AND BELOW SHALL BE STIFFENED WITH 4 NOS. 40 x 6 THK DETAIL OF VESSEL/COLUMN TOP DAVIT IND VSD 004 CAPACITY (M ) 122.2

33 1 254 I/D _ 150 LWN RF 2300 _ SAFETY VALVE 0

FLATS 90 APART. 2 NOS. SHALL BE LOCATED AT 200MM AWAY FROM SHELL DETAIL OF SKIRT OPENING FOR VESSEL & COLUMN IND VSD 006 PAINTING/CLEANING AS PER PAINTING SPEC.

AND OTHER TWO NOS SHALL BE LOCATED CLOSE TO FLANGE / PIPE WELD.

SEE _ DETAIL OF SKIRT BASE FOR VESSEL & COLUMN IND VSD 007 INSULATION THICKNESS (mm) 45 HOT COLD

35 1 50 XXS 150 WN RF UTILITY CONNECTION

DWG. 9 b) NOZZLES 80NB SHALL BE STIFFENED WITH 2 NOS. 40 x 6 THK FLATS AT 90

0 LEG SUPPORT FOR VERTICAL VESSEL (2 SHEETS) IND VSD 008 FIRE PROOFING YES NO

36 1 40 160 300 WN RF 2300

_

PRESSURE GAUGE

APART LOCATED CLOSE TO FLANGE / PIPE WELD. X SADDLE SUPPORT FOR HORIZONTAL VESSEL(7 SHEETS) IND VSD 009 HYDROSTATIC TEST (kg/cm2g) HORIZONTAL / VERTICAL (AT TOP)

10 ALSO REFER 44NC-4600-0000-V02-0164 A3 FOR OTHER APPLICABLE NOTES. LUG SUPPORTS (2 SHEETS) IND VSD 010 PRESSURE (NEW & COLD) 9.1

45 PIPE LEG SUPPORT IND VSD 011 INSPECTION BY EIL CIB X TPI

2 50 XXS 300 WN RF 2000 _ STAND PIPE

A-B 11 2

VESSEL IS SUBJECTED TO STEAM OUT CONDITION OF 0.5 Kg/Cm (g) AT 190 C

0

X MINIMUM NOZZLE WALL THICKNESS IND VSD 012

MATERIAL OF CONSTRUCTION

47

2 80 160 300 WN RF 2000 55X16 LEVEL CONTROLLER X REINFORCING PLATES FOR NOZZLES. (C.A. 3mm) IND VSD 018 (AS PER ASME / IS OR EQUIVALENT)

A-B 12 ALL NOZZLE FABRICATED FROM PLATES SHALL BE FULLY RADIOGRAPHED. X NAME PLATE BRACKET IND VSD 020

49

6 80 160 300 WN RF 2000 55X16 LEVEL TRANSMITER

13 SURFACE PREPARATION AND PRIMER AND PRIMER SHALL BE AS PER JOB X STANDARD NAME PLATE FOR VESSEL IND VSD 021 SHELL SA 516 GR.70

A-F SPECIFICATION 44NC-4600-000-V-02-0111-A4.

X INSULATION SUPPORTS FOR VESSELS (HOT) IND VSD 022 REINFORCEMENT PAD/INSERT PLATE SA 516 GR.70

50 1 50 160 150 WN RF

SEE _

VENT NOZZLE (NOTE-18)

14 VENDOR SHALL INDIDATE C.G OF EQUIPMENT IN EACH FABRICATION X STANDARD NOZZLE PROJECTION IND VSD 024 HEADS SA 516 GR.70

1 DWG. DRAWING. LIFTING TRUNNIONS IND VSD 025 SHELL FLANGES -

15 MANDATORY AND COMMISIONNING SPARES SHALL BE SUPPLIED BY HANDHOLE WITH HINGED COVER IND VSD 029 NOZZLE FLANGES/LWN NOZZLES/B.F. SA 105

FABRICATOR. STANDARD INTERNAL PLATE FLANGES IND VSD 030 NOZZLE NECK UPTO 300 NB SA 106 GR.B (SEAMLESS)

16 PIPE TO PIPE, PIPE TO FLANGE PIPE TO FITTING & FITTING TO FLANGE JOINT X VORTEX BREAKERS (FLUSH TYPE NOZZLES) IND VSD 033 NOZZLE NECK ABOVE 300 NB SA 516 GR.70

SHALL BE WELDED WITH SAME TECHNIQUE USED FOR MAIN EQUIPMENT VORTEX BREAKERS (NOZZLE WITH INTERNAL PROJECTION) IND VSD 034 PIPE FITTINGS SA 234 GR. WPB

WELDING.

STANDARD DEMISTERS TYPE-I (VESSEL DIA<800mm) IND VSD 036 SPIRAL WOUND GASKET WITH SS 304 METAL

17 WHEREVER FULL RADIOGRAPHY IS SPECIFIED SHALL IMPLY 100% STANDARD DEMISTERS TYPE-II(VESSEL DIA> 800mm) IND VSD 037 WINDINGS AND GRAFOIL FILLER MATERIAL

GASKET EXTERNAL

RADIOGRAPHY OF ALL BUTT WELDS. STANDARD DEMISTERS TYPE-III IND VSD 038 WITH SS 304 INNER & OUTER RING AS PER

18 STANDARD DEMISTERS TYPE-IV IND VSD 039 ASME B16.20

VENT NOZZLE `50' SHALL BE MOUNTED ON BLIND FLANGE OF VENTILATION

NOZZLE `8'. X STANDARD BOLT HOLE ORIENTATION IND VSD 040 GASKET INTERNAL -

19 CENTER LINE OF NOZZLE 45A/B, 47A/B & 49A/B/C/D IS PARALLEL TO EARTHING BOSS IND VSD 041 EXTERNAL STUDS/BOLTS/NUTS SA 193 GR.B7 / SA 194 GR.2H

HORIZONTAL CENTER LINE OF VESSEL. X LADDER RUNGS INSIDE VESSELS AND COLUMNS IND VSD 043 INTERNAL STUDS/BOLTS/NUTS SS 304L

FOUNDATION TEMPLATE (2 SHEETS) IND VSD 044 SKIRT/ SUPPORT IS 2062 Gr.B

SUPPORT FOR INTERNAL DISTRIBUTOR PIPES IND VSD 045 SKIRT/ SUPPORT BASE IS 2062 Gr.B

SUPPORTS FOR INTERNAL FEED PIPE IND VSD 046/047 INTERNAL PARTS (WELDED) SA 516 GR.70

LIFTING LUG TOP HEAD TYPE IND VSD 048 INTERNAL PARTS (BOLTED) SA 516 GR.70

X LIFTING LUG FOR HORIZONTAL VESSEL IND VSD 050 CLIPS & ATTACHMENTS ((EXT.) DIRECTLY WELDED SA 516 GR.70

X TYP. NOZZLE FLANGE TO NECK JOINT IND VSD 051 CLIPS & ATTACHMENTS (EXT.) WELDED OVER PAD IS 2062 Gr.B

X RECOMMENDED WELD EDGE PREPARATION FOR BUTT WELDS IND VSD 052 PAD FOR EXTERNAL CLIPS ATTACHMENTS SA 516 GR.70

ALLOY LINER DETAIL (2SHEETS) IND VSD 053 DEMISTER/GRID -

SUPPORT RING AND BOLTING BAR IND VSD 055 PIPE DAVIT -

SUPPORT RING SIZES FOR PACKED TOWERS IND VSD 056 WRAPPER PLATE SA 516 GR.70

INSULATION SUPPORTS FOR VERTICAL VESSEL IND VSD 057

X INSULATION SUPPORTS FOR HORIZONTAL VESSEL IND VSD 058

MANWAY DAVIT

BRACKET SA 516 GR.70

FIRE PROOFING SUPPORT IND VSD 062 ALL OTHER PARTS IS 2062 Gr.B

INLET DEFLECTOR BAFFLE IND VSD 064 SHELL STIFFENER RING SA 516 GR.70

X EARTHING LUG IND VSD 080 NAME PLATE SS 304

NAME PLATE BRACKET SA 516 GR.70

EIL REFERENCE DRAWINGS 1 EARTHING LUGS IS 2062 Gr.B

X NOZZLE ORIENTATIONS A133-086-16-43-NZ-C021 LIFTING LUGS IS 2062 Gr.B

PMC CONTROL CODE -V21 X LADDERS/PLATFORM CLEATS A133-086-16-48-10751

X PIPE SUPPORT CLEATS

DEMISTER DATA SHEET

APPROVAL

PMC REVIEW

RECORDS

STATUTORY REGULATIONS

LICENSORS SPECIFICATIONS INDIAN BOILER REGULATIONS (IBR)

FOUNDATION LOADING DATA (OPERATING CONDITION) HOLD UPS 1

LICENSORS STANDARDS MAX MOMENT AT BASE (M) NOZZLE ORIENTATIONS SIZE OF NOZZLES

TYPE

(kgm)

MAX. SHEAR FORCE AT BASE (H) (kg)

NOZZLE ELEVATIONS PIPE SUPPORT CLEATS

APPROXIMATE WEIGHT (kgs) (PER ITEM)

FIXED/SLIDING SUPPORT LADDER/PLATFORM CLEATS

DBE _ _ DETAILS OF INTERNALS PIPE DAVIT

ERECTION 22,000 OPERATING 123,500

SEISMIC

MCE _ _ HYDROTEST(SHOP) 146,000 HYDROTEST ( FIELD ) 150,400

WIND _ _ NUMBER OF ITEMS : ONE

FILE NAME A133-086-16-46-DS-3012-1-1

DESIGN DATA fMtkbu MkVk

JOB NO: 1 GCP BBC

DRAWING NUMBER REV

1

CLIENT :

0 GCP BBC COKER UNIT FEED SURGE DRUM 1

B GCP BBC

A SBS TG

PLANT : REV DATE BY APPROVED

ITEM NO. SHEET 1 OF 2

Potrebbero piacerti anche

- PSV and FlareDocumento116 paginePSV and FlareShanmuga Muthukumar100% (6)

- Smartmarine 3D: Samsung Heavy Industries Cosco Shipyard Group Keppel Offshore & Marine Grenland Group VietsovpetroDocumento64 pagineSmartmarine 3D: Samsung Heavy Industries Cosco Shipyard Group Keppel Offshore & Marine Grenland Group VietsovpetroPriyanka KumariNessuna valutazione finora

- E3d-Inst SelectionDocumento4 pagineE3d-Inst SelectionPriyanka KumariNessuna valutazione finora

- Excellence: His PublicationsDocumento2 pagineExcellence: His PublicationsPriyanka KumariNessuna valutazione finora

- FPSO LayoutDocumento36 pagineFPSO LayoutPriyanka Kumari100% (1)

- PDMS - Support Function DefinitionDocumento6 paginePDMS - Support Function DefinitionPriyanka KumariNessuna valutazione finora

- Transmitter Instrument Without DiaphragmDocumento4 pagineTransmitter Instrument Without DiaphragmPriyanka KumariNessuna valutazione finora

- Pipe Module Equipments List 030419Documento1 paginaPipe Module Equipments List 030419Priyanka KumariNessuna valutazione finora

- Component: After Cooling Pump Type: Allweiler, NB 50-125/01/126 U32D W19 IEC 112-2 BEAS Part No.: 705783Documento6 pagineComponent: After Cooling Pump Type: Allweiler, NB 50-125/01/126 U32D W19 IEC 112-2 BEAS Part No.: 705783Priyanka KumariNessuna valutazione finora

- F132 60+iDocumento4 pagineF132 60+iPriyanka KumariNessuna valutazione finora

- Qty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DateDocumento5 pagineQty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DatePriyanka KumariNessuna valutazione finora

- Engineering Design Basis FOR Project: Client: Projec T: Job No.Documento11 pagineEngineering Design Basis FOR Project: Client: Projec T: Job No.Priyanka KumariNessuna valutazione finora

- Procon India Pvt. LTD.: Ph. +91-120-669 2000 Fax.: +91-120-669 2001Documento1 paginaProcon India Pvt. LTD.: Ph. +91-120-669 2000 Fax.: +91-120-669 2001Priyanka KumariNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- AT6501 (R-13) Notes PDFDocumento131 pagineAT6501 (R-13) Notes PDFAashiq NawinNessuna valutazione finora

- .Technical Detail of UNINYVIN CABLEDocumento1 pagina.Technical Detail of UNINYVIN CABLEJayNessuna valutazione finora

- FM62429 Serial Data Control Dual Electronic Volume: SpecificationDocumento10 pagineFM62429 Serial Data Control Dual Electronic Volume: Specificationfabio_sgNessuna valutazione finora

- B-64695en Fanuc 0i-Model F Plus Maintenance ManualDocumento814 pagineB-64695en Fanuc 0i-Model F Plus Maintenance ManualVladimirAgeev67% (3)

- 1 - Dongfeng KD Manufacture Project SolutionDocumento17 pagine1 - Dongfeng KD Manufacture Project Solutionkhairul alamNessuna valutazione finora

- RTV 900 WSM enDocumento31 pagineRTV 900 WSM enwireless303Nessuna valutazione finora

- EasyPact EZC EZC100F3080Documento5 pagineEasyPact EZC EZC100F3080Rizal PrasetyoNessuna valutazione finora

- MSP430C11x1, MSP430F11x1A Mixed Signal Microcontroller: DescriptionDocumento44 pagineMSP430C11x1, MSP430F11x1A Mixed Signal Microcontroller: DescriptionRueben Jeff SolisNessuna valutazione finora

- Canon IR2535 Trouble Error CodesDocumento36 pagineCanon IR2535 Trouble Error Codesnafees100% (4)

- Plansa Motopompa Caprari MEC-MG 80-4-3ADocumento2 paginePlansa Motopompa Caprari MEC-MG 80-4-3AAlex BancilaNessuna valutazione finora

- KMP Luna2014Documento225 pagineKMP Luna2014abrar nurtataNessuna valutazione finora

- SR5 Serial Protocol - Issue 1.6Documento14 pagineSR5 Serial Protocol - Issue 1.6siyakinNessuna valutazione finora

- Timberland RanchDocumento28 pagineTimberland Ranchrob_crowell_1Nessuna valutazione finora

- Ricoh Aficio 220 - 270 Manual PartesDocumento111 pagineRicoh Aficio 220 - 270 Manual PartesdesechableNessuna valutazione finora

- Bisun Duo XL 325 Duo enDocumento2 pagineBisun Duo XL 325 Duo enGökhan YüksekNessuna valutazione finora

- Dans Manual 1Documento19 pagineDans Manual 1Fabrii Magnus LodbrókNessuna valutazione finora

- EDP - DSP-90 - Air - NEXTDocumento2 pagineEDP - DSP-90 - Air - NEXTmongojerryNessuna valutazione finora

- SE-3000 - Schumacher ElectricDocumento3 pagineSE-3000 - Schumacher ElectricAlex RamirezNessuna valutazione finora

- TOA Vm3000 Operate eDocumento149 pagineTOA Vm3000 Operate eCristianLeotescuNessuna valutazione finora

- RU Emu ManualDocumento86 pagineRU Emu ManualEgor KaufmanNessuna valutazione finora

- Comet - Glands 2023 List PriceDocumento2 pagineComet - Glands 2023 List PriceNIRALI PRAJAPATINessuna valutazione finora

- Design & Verification of 16 Bit RISC ProcessorDocumento2 pagineDesign & Verification of 16 Bit RISC Processorravikanti.vinayNessuna valutazione finora

- IE EBM112 DLT1227 18 aEN 001Documento32 pagineIE EBM112 DLT1227 18 aEN 001Matias Van Balen BlankenNessuna valutazione finora

- Cat 980M 982M Wheel Loader BrochureDocumento36 pagineCat 980M 982M Wheel Loader BrochureAMNessuna valutazione finora

- Syegon Leaflet 2012Documento2 pagineSyegon Leaflet 2012kanteron6443Nessuna valutazione finora

- RT809F TutorialLlogic Board Gamma Chip BUF16821Documento7 pagineRT809F TutorialLlogic Board Gamma Chip BUF16821Sk WongNessuna valutazione finora

- Yaskawa L1000A Quick Start Guide TOEPC71061638Documento204 pagineYaskawa L1000A Quick Start Guide TOEPC71061638younesNessuna valutazione finora

- PM Power CatalogDocumento85 paginePM Power CatalogAlcides JNessuna valutazione finora

- Kuantitas Barang Per Gudang Jsbangunan 190626135041Documento88 pagineKuantitas Barang Per Gudang Jsbangunan 190626135041Arié WibowoNessuna valutazione finora

- SKODA - FABIA Estate - Brochure - DEC21Documento25 pagineSKODA - FABIA Estate - Brochure - DEC21controlorNessuna valutazione finora