Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MPS IE Mech

Caricato da

sitheeqCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MPS IE Mech

Caricato da

sitheeqCopyright:

Formati disponibili

---

---

---

---

---

---

---

In

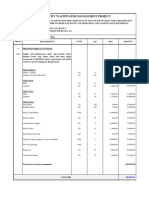

Shut Down

Jul-2019 Shut Down

Aug-2019 le

t

Date 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Remarks

C

Major schedule

Qty h

Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat a

if possible, permanent doors & windows fixing ---------------------Deo. Room Temple side------------------------- ----------------------------------------------Gen & Gate Room Temple side, & Entrance gate side---------------------------------------------------- m

Flowmeter (DI pipe) R ---------------------------WWTP PPB Flowmeter house----------------------------- b

& --- er

① Setting out F --- si

--- d

② Support Installation --- e-

--- ---

③ Pipe & Valve installation --- ---

--- ---

Inlet Gate (P-1) -- ---

R St -------------------Inlet gate Room------------------- ---

① Scaffolding & ee ---

1 lot F l ---

pl ---

② Gate installation w/FAB34 1 nos at

③ Ladder (Type 15) e

1 nos Pl

ug W

④ Ladder (Type 18) 1 nos s--

et

--- ru

Coarse Screen (P-2) R ---

-

-----Water Channel Flr.---- n

& ---

-

① Screen installation 2 nos F ---

-

---

-

② Ladder (Type 16) 2 nos ---

-

---

-

Grid Pump (P-3) -

R - ---------------------Water Channel Flr.----------------

① Pump installation 2 nos & B

F a

② Level Switch (LS-16) 2 nos ll

o

③ Pipe & Valve (DI DN80) n

9.8LM

④ Testing (DN80) P

9.8LM l W

u et

⑤ Ladder (Type 17) 2 nos g ru

s n

Odor Equipment & Pipes -

R - ---------------------Ground Flr. Deo. Room-------------------

-------------Basement Flr. ----------

① Installation (P-10 to 12) 3 nos & -

F - Better to install Ventilation equipment in advance

② Pipe at Ground Flr. -

-

③ Pipe at Basement Flr. W

et

MPS Fuel pump & tanks ru

R ---------MPS--------- n

① Fabrication (EP-2A&B) 2 nos &

F

② Tank Installation (EP-2A&B) 2 nos

③ Pump Installation (EP-2C&D) 2 nos

WWTP Fuel tanks

R ---------WWTP---------

① Fabrication (EW-2A&B) 2 nos &

F

② Tank Installation (EW-2A&B) 2 nos

FAB item & miscellaneous

R ------------------------------MPS----------------------------

① Grit Container (P-13) 8 nos &

F

② Pressure washer(P-9) 1 nos

③ Hatch cover(FAB-17) 37 nos

SUS Fuel pipe

R

① Pipe & Valve (25A-40A) &

F

② Fuel pipe cover(FAB64)

Hoist (P-4)

R ------Ground Flr.-----

① Hoist installation B&C 2 nos &

F

② Hoist installation A%D 2 nos

③ Hoist installation E,F&G 4 nos

Sewage Pump (P-7)

--------------Basement Flr. ------------ ---------------------------------------------------------------------------------Water Channel Flr. Pump pit----------------------------------------------------------------------------

① Setting out & Support R

&

② Pipe & Valve (DN600) 7.9LM F

③ Scaffolding for pump pit 2 lot

④ Pump installation 4 nos

⑤ Scaffolding for DI Pipe 1 lot

⑥ Pipe & Valve (DN300 w/P-8) 23.6LM

⑦ Testing DI Pipe (DN300) 23.6LM

⑧ Level Switch (LS-12&EP4) W

2 nos et

⑨ Ladder (Type 14) ru

2 nos n

Sluice Gate (P-6) R

& ---

① Gate installation w/FAB34 1 F ---

---

Mixer (P-5) R ----

& ----

① Mixer installation 2 F ----

----

Sanitary & Potable pipe --

R -

Ba

& -

① Pipelaying/testing F llo-

n--

Pl--

ug --

s-- --

--- --

--- --

--- --

--- --

--- --

B-

---

a-

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Essentials of o Ste 00 DaveDocumento112 pagineEssentials of o Ste 00 DaveGeki Iovan100% (1)

- C P P P: Rain'S Etrophysical Ocket ALDocumento54 pagineC P P P: Rain'S Etrophysical Ocket ALviya7100% (4)

- MPS Sub Measurement-01Documento56 pagineMPS Sub Measurement-01sitheeqNessuna valutazione finora

- MPS Sub Measurement-02Documento30 pagineMPS Sub Measurement-02sitheeqNessuna valutazione finora

- JFEEC-CDQ-Manpower Loading - RR & MPS Site - 19-07-2019Documento1 paginaJFEEC-CDQ-Manpower Loading - RR & MPS Site - 19-07-2019sitheeqNessuna valutazione finora

- 9500 MPR Wireless TransmissionDocumento46 pagine9500 MPR Wireless TransmissionMahdi AhmadiNessuna valutazione finora

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterDocumento14 pagineDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazNessuna valutazione finora

- Role of Packaging in Sales of FMCG Products and Its TrendsDocumento57 pagineRole of Packaging in Sales of FMCG Products and Its TrendsSaurabh0% (1)

- AjeerDocumento13 pagineAjeersitheeqNessuna valutazione finora

- Yazeed and Yousuf - October and Novermber - 201106Documento1 paginaYazeed and Yousuf - October and Novermber - 201106sitheeqNessuna valutazione finora

- Yazeed and Yousuf - October and Novermber - 201106Documento1 paginaYazeed and Yousuf - October and Novermber - 201106sitheeqNessuna valutazione finora

- GGHHDocumento4 pagineGGHHsitheeqNessuna valutazione finora

- Career Appraisal Guidance PDFDocumento11 pagineCareer Appraisal Guidance PDFManvendra NigamNessuna valutazione finora

- Brick Work in First Floor: 1.00 Description Times Length Width Area Unit Unit 01Documento8 pagineBrick Work in First Floor: 1.00 Description Times Length Width Area Unit Unit 01sitheeqNessuna valutazione finora

- Career Appraisal Application Form: About YouDocumento4 pagineCareer Appraisal Application Form: About YousitheeqNessuna valutazione finora

- House Rental 01Documento2 pagineHouse Rental 01sitheeqNessuna valutazione finora

- Task 01Documento58 pagineTask 01sitheeqNessuna valutazione finora

- Attribute Achievement FormDocumento14 pagineAttribute Achievement Formbatman12hkNessuna valutazione finora

- Kandy City Wastewater Management Project: Safety HelmetsDocumento1 paginaKandy City Wastewater Management Project: Safety HelmetssitheeqNessuna valutazione finora

- Tamil 14Documento2 pagineTamil 14sitheeqNessuna valutazione finora

- Other Equipments (Grinder, Drill,) (Welding Rod, Putty, Cutting Weel, Grinding Wheel)Documento1 paginaOther Equipments (Grinder, Drill,) (Welding Rod, Putty, Cutting Weel, Grinding Wheel)sitheeqNessuna valutazione finora

- Other Equipments (Grinder, Drill,) (Welding Rod, Putty, Cutting Weel, Grinding Wheel)Documento1 paginaOther Equipments (Grinder, Drill,) (Welding Rod, Putty, Cutting Weel, Grinding Wheel)sitheeqNessuna valutazione finora

- Redding: International SchoolDocumento3 pagineRedding: International SchoolsitheeqNessuna valutazione finora

- Redding: International SchoolDocumento2 pagineRedding: International SchoolsitheeqNessuna valutazione finora

- Redding: International SchoolDocumento3 pagineRedding: International SchoolsitheeqNessuna valutazione finora

- Redding: International SchoolDocumento3 pagineRedding: International SchoolsitheeqNessuna valutazione finora

- Redding: International SchoolDocumento2 pagineRedding: International SchoolsitheeqNessuna valutazione finora

- REMAINIG WORK NEW BOQ RR1 at SKRIDocumento4 pagineREMAINIG WORK NEW BOQ RR1 at SKRIsitheeqNessuna valutazione finora

- Redding: International SchoolDocumento2 pagineRedding: International SchoolsitheeqNessuna valutazione finora

- Redding: International SchoolDocumento2 pagineRedding: International SchoolsitheeqNessuna valutazione finora

- Designed Checked Job Code Project: Doc. No. Date Date Calculation ADocumento3 pagineDesigned Checked Job Code Project: Doc. No. Date Date Calculation AsitheeqNessuna valutazione finora

- Appendix 6 Two Week Look Ahead ScheduleDocumento15 pagineAppendix 6 Two Week Look Ahead SchedulesitheeqNessuna valutazione finora

- MPS Brick and PaintDocumento15 pagineMPS Brick and PaintsitheeqNessuna valutazione finora

- Appendix 6 Two Week Look Ahead ScheduleDocumento15 pagineAppendix 6 Two Week Look Ahead SchedulesitheeqNessuna valutazione finora

- Pre Post Tests For HPPDocumento3 paginePre Post Tests For HPPapi-434982019Nessuna valutazione finora

- A MCQ: Si - No Sub Topics NameDocumento2 pagineA MCQ: Si - No Sub Topics NameInzamamul Haque ShihabNessuna valutazione finora

- Review of Henry Vyverberg, Historical Pessimism in The French EnlightenmentDocumento4 pagineReview of Henry Vyverberg, Historical Pessimism in The French EnlightenmentRalph EllectualNessuna valutazione finora

- Rediscovery' Revised - The Cooperation of Erich and Armin Von Tschermak-Seysenegg in The Context of The Rediscovery' of Mendel's Laws in 1899-1901Documento7 pagineRediscovery' Revised - The Cooperation of Erich and Armin Von Tschermak-Seysenegg in The Context of The Rediscovery' of Mendel's Laws in 1899-1901lacisagNessuna valutazione finora

- TMJDocumento38 pagineTMJAnonymous 6kAmeZzINessuna valutazione finora

- Yu-Gi-Oh GX Duel Academy - Written ExamDocumento26 pagineYu-Gi-Oh GX Duel Academy - Written ExamisishamalielNessuna valutazione finora

- Esthetics and Shade Communication: A Practical Approach: Clinical ApplicationDocumento21 pagineEsthetics and Shade Communication: A Practical Approach: Clinical Applicationcatalin_adinaNessuna valutazione finora

- Middle East ManufacturerDocumento6 pagineMiddle East Manufacturerhsco rdNessuna valutazione finora

- A Guide To Maintenance Metrics-ProgramDocumento5 pagineA Guide To Maintenance Metrics-ProgramLy QuanNessuna valutazione finora

- Second Term English Exam: Level TCST June 2021Documento6 pagineSecond Term English Exam: Level TCST June 2021benfaresNessuna valutazione finora

- Tugas Topic 4 Devi PermatasariDocumento8 pagineTugas Topic 4 Devi PermatasariMartinaNessuna valutazione finora

- Prehistoric Art Notes XIDocumento6 paginePrehistoric Art Notes XIShalini Jha XI B1Nessuna valutazione finora

- A Very Old MachineDocumento20 pagineA Very Old MachineSwathi G. SalemNessuna valutazione finora

- Dense Ball PackingDocumento334 pagineDense Ball PackingLucas RibeiroNessuna valutazione finora

- Astro 429 Assignment 2 AlbertaDocumento2 pagineAstro 429 Assignment 2 AlbertatarakNessuna valutazione finora

- Whirlpool Adg 789Documento22 pagineWhirlpool Adg 789Laurentiu GramaNessuna valutazione finora

- Buk Uuuuuu UuuuuuuDocumento92 pagineBuk Uuuuuu UuuuuuuJanaliyaNessuna valutazione finora

- PTFE HZ-2 HoerbigerDocumento2 paginePTFE HZ-2 HoerbigerТатьяна ВасильеваNessuna valutazione finora

- Marcelo - GarciaDocumento6 pagineMarcelo - GarciaNancy FernandezNessuna valutazione finora

- Proposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Documento1 paginaProposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Jehan TangonanNessuna valutazione finora

- TP260SR Tier 3 TC002-1037Documento1 paginaTP260SR Tier 3 TC002-1037Jorge GalarceNessuna valutazione finora

- IMDB - ColaboratoryDocumento10 pagineIMDB - Colaboratory4416 LikhithaNessuna valutazione finora

- CHEM333 Syllabus 2020 2021Documento4 pagineCHEM333 Syllabus 2020 2021lina kwikNessuna valutazione finora

- Iso TR 16922 2013 (E)Documento18 pagineIso TR 16922 2013 (E)Freddy Santiago Cabarcas LandinezNessuna valutazione finora

- Field Dry Density Test Using Sand Replacement MethodDocumento29 pagineField Dry Density Test Using Sand Replacement MethodJassel Jalandoni100% (1)