Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Saic F 2024

Caricato da

munnaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Saic F 2024

Caricato da

munnaCopyright:

Formati disponibili

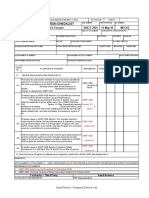

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.

Rev. 2018.03.00 31-Mar-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Lay-Up of Boiler Tubes & Drums SAIC-F-2024 14-May-18 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

A. Responsibilities for SAEP-1026 Boiler Lay-Up Procedures

Boiler lay up is per SAEP-1026, Boilers Lay-Up Procedures.

SAES-A-007,

A1 See Attachment 1 for SAEP-1026 in entirety. (5-

Para. 8.3.4

day rule)

Responsibilities for lay-up are met as follows (adequate):

A) Engineering: Recommends

the procedures to be used for the lay-up. Advises, and assists the

foreman of the boiler plant during lay-up activities involving the boiler,

and associated equipment. B) Inspection: SAEP-1026,

A2

1) Performs inspection before* & after lay-up. (*Chem/Steam Clean) Para. 5

2) Monitors lay-up effectiveness*.

3) Maintains Insp, Lab, & Engineering reports (permanent records).

*Includes cleanliness exam using remote fiber

scope & video associated with Cleaning per SAEP-1025

Inspectors involved in lay-up (water & fire sides) of Boiler Tubes &

Drums are experienced in lay-up methodology & understand the SAEP-1026,

A3

causes of corrosion relative to improper lay-up methods as outlined Section 6

in the SAEP-1026 Procedure (Section 4, Introduction).

Inspectors involved in lay-up (water & fire sides) of Boiler Tubes &

SAEP-1026,

A4 Drums understand Safety Precautions & they are Confined Space

Section 13

Entry trained as required. SAEP-1026 Procedure (Section 5, Safety)

Verify that the lay-up procedure selected met SAEP-1026 Reqmts:

A) Select steam lay-up if steam is available, and

rapid start up (< 24 hours), is required.

SAEP-1026,

A5 B) Select wet, or steam lay-up if the boiler is expected to be down for

Section 6

less than four weeks.

C) Select dry, wet, or steam lay-up if the boiler is expected to be

down for more than 12 weeks.

SAEP-1026,

A6 Wet Lay up & Maintenance/inspection Program meets SA reqmts.

Section 9

SAEP-1026,

A7 Dry Lay up & Maintenance/inspection Program meets SA reqmts.

Section 10

SAEP-1026,

A8 Steam Lay up & Maint/inspection Program meets SA reqmts.

Section 8

SAEP-1026,

A9 Fireside Lay up & Maint/inspection Program meets SA reqmts.

Section 12

REMARKS: Inspectors are required to read, understand and capable to perform Inspections in accordance to SAEP-1025, SAEP-

1026.

ATTACHMENTS:

REFERENCE DOCUMENTS: 1. SAEP-1026, Lay-Up and Preservation of Steam Generation Systems, (01 January 2018)

2. SAES-A-007, Hydrostatic Testing Fluids and Lay-Up Procedures,1 January 2018

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection:

T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved:

T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Potrebbero piacerti anche

- Saic P 3105Documento2 pagineSaic P 3105munnaNessuna valutazione finora

- Saic W 2090Documento2 pagineSaic W 2090munnaNessuna valutazione finora

- Satip X 400 01Documento11 pagineSatip X 400 01munnaNessuna valutazione finora

- Saic RT 2007Documento9 pagineSaic RT 2007munnaNessuna valutazione finora

- SAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONDocumento24 pagineSAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONmunnaNessuna valutazione finora

- Saic W 2011Documento3 pagineSaic W 2011munnaNessuna valutazione finora

- Satr P 3206Documento6 pagineSatr P 3206munnaNessuna valutazione finora

- Saudi Aramco Glass Inspection PlanDocumento10 pagineSaudi Aramco Glass Inspection PlanmunnaNessuna valutazione finora

- Satip Q 001 03Documento10 pagineSatip Q 001 03munnaNessuna valutazione finora

- Satip M 100 07Documento10 pagineSatip M 100 07munnaNessuna valutazione finora

- Saic RT 2009Documento3 pagineSaic RT 2009munnaNessuna valutazione finora

- Satr J 2001Documento1 paginaSatr J 2001munnaNessuna valutazione finora

- Saic P 3105Documento2 pagineSaic P 3105munnaNessuna valutazione finora

- Satip M 100 10Documento10 pagineSatip M 100 10munnaNessuna valutazione finora

- Saic W 2090Documento2 pagineSaic W 2090munnaNessuna valutazione finora

- Schedule FDocumento5 pagineSchedule FmunnaNessuna valutazione finora

- Satr J 6510Documento7 pagineSatr J 6510munnaNessuna valutazione finora

- Saudi Aramco Foamed Asphalt Inspection PlanDocumento10 pagineSaudi Aramco Foamed Asphalt Inspection PlanmunnaNessuna valutazione finora

- Sampleq Practice Exam d11 2002Documento22 pagineSampleq Practice Exam d11 2002Michael J Chandik0% (1)

- Saic F 2025Documento8 pagineSaic F 2025munnaNessuna valutazione finora

- Pre Welding ChecklistDocumento2 paginePre Welding Checklistmunna100% (3)

- Saep 55Documento12 pagineSaep 55munnaNessuna valutazione finora

- Schedule C - Attachment 01Documento50 pagineSchedule C - Attachment 01munnaNessuna valutazione finora

- Architectural Painting Works Ins ChecklistDocumento2 pagineArchitectural Painting Works Ins Checklistmunna100% (1)

- Schedule I Company Attachment IDocumento1 paginaSchedule I Company Attachment ImunnaNessuna valutazione finora

- Schedule S Attachment IDocumento1 paginaSchedule S Attachment ImunnaNessuna valutazione finora

- Additional Requirements for Saudi Aramco ProjectDocumento27 pagineAdditional Requirements for Saudi Aramco Projectmunna100% (2)

- Saep 42Documento11 pagineSaep 42munnaNessuna valutazione finora

- Saep 61 PDFDocumento21 pagineSaep 61 PDFmunnaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- History + Mission +SWOTDocumento2 pagineHistory + Mission +SWOThangchan_superchibiNessuna valutazione finora

- Dody Firmanda 2009 - KPIs RS Krakatau Medika 6 Agustus 2009Documento40 pagineDody Firmanda 2009 - KPIs RS Krakatau Medika 6 Agustus 2009Dody Firmanda100% (6)

- ERWIN STRAUS BibliographyDocumento7 pagineERWIN STRAUS BibliographyAndrea PinottiNessuna valutazione finora

- Physical Fitness TestDocumento8 paginePhysical Fitness Testalaskador03Nessuna valutazione finora

- Stretching - Anderson, Bob PDFDocumento194 pagineStretching - Anderson, Bob PDFxehupatl100% (6)

- BDMS Trauma Algorithm Version 2.0Documento32 pagineBDMS Trauma Algorithm Version 2.0Aungkhena Noomnim100% (2)

- WHO - Ammonia Chemical FactsheetDocumento4 pagineWHO - Ammonia Chemical FactsheetMark Joseph AbelleraNessuna valutazione finora

- Brochure Men - Ingrid Auer - Angel Essences To Help MenDocumento4 pagineBrochure Men - Ingrid Auer - Angel Essences To Help MenJoanne JacksonNessuna valutazione finora

- Chinese General Hospital Nursing College Functional Pattern GuideDocumento2 pagineChinese General Hospital Nursing College Functional Pattern GuideTin BernardezNessuna valutazione finora

- NEWCROSS Site Survey - Rev1Documento37 pagineNEWCROSS Site Survey - Rev1eke23Nessuna valutazione finora

- Hematology Sample QuestionsDocumento5 pagineHematology Sample QuestionsEarleen Del Rosario100% (1)

- Rhetorical Analysis Revision Final ProjectDocumento13 pagineRhetorical Analysis Revision Final Projectapi-371084574100% (1)

- Name: Jaanvi Mahajan Course: 2ballb Hons. REGISTRATION NO.: 22212033 Subject: Law and Medicine Submitted To: Mrs. Vijaishree Dubey PandeyDocumento9 pagineName: Jaanvi Mahajan Course: 2ballb Hons. REGISTRATION NO.: 22212033 Subject: Law and Medicine Submitted To: Mrs. Vijaishree Dubey Pandeyjaanvi mahajanNessuna valutazione finora

- BICOM Treatment of Chronic Fatigue and FibromyalgiaCFS ReportDocumento15 pagineBICOM Treatment of Chronic Fatigue and FibromyalgiaCFS ReportAnahata Fraydon100% (1)

- Vogt Koyanagi Harada SyndromeDocumento9 pagineVogt Koyanagi Harada SyndromeBianca PavelNessuna valutazione finora

- Full Download Test Bank For Pharmacology 9th Edition by Mccuistion PDF Full ChapterDocumento36 pagineFull Download Test Bank For Pharmacology 9th Edition by Mccuistion PDF Full Chapterpotshardmonied5cuc100% (19)

- Nitrogen PowerpointDocumento24 pagineNitrogen PowerpointArnis JapinsNessuna valutazione finora

- Eco-Friendly Fitness: 'Plogging' Sweeps the GlobeDocumento2 pagineEco-Friendly Fitness: 'Plogging' Sweeps the GlobecarlosNessuna valutazione finora

- NUR1204-RLE - Group 4 - Home Visit Activity (HTP and HVP)Documento16 pagineNUR1204-RLE - Group 4 - Home Visit Activity (HTP and HVP)Jayvee BillonesNessuna valutazione finora

- Toxicology Reports: Rekhadevi Perumalla Venkata, Rajagopal SubramanyamDocumento8 pagineToxicology Reports: Rekhadevi Perumalla Venkata, Rajagopal SubramanyamPoetri MarboenNessuna valutazione finora

- 1 PBDocumento6 pagine1 PBmutiakusumaNessuna valutazione finora

- Nclex Questions For Fundamentals of NursDocumento32 pagineNclex Questions For Fundamentals of NursJrBong SemaneroNessuna valutazione finora

- Patient Complaints About General PracticeDocumento9 paginePatient Complaints About General PracticesanaaNessuna valutazione finora

- Intelligent Dosing of RonozymeDocumento25 pagineIntelligent Dosing of RonozymeRaymundus Genty Laras100% (1)

- Exploratory Data Analysis of Electric Tricycle AsDocumento13 pagineExploratory Data Analysis of Electric Tricycle AsNiño E. EvangelioNessuna valutazione finora

- Mtendere Community Cholera Prevention OutreachDocumento2 pagineMtendere Community Cholera Prevention OutreachReal KezeeNessuna valutazione finora

- Alan Palmieri ArticlesDocumento9 pagineAlan Palmieri Articleschris_blair_1Nessuna valutazione finora

- BI Johor Paper1 (1) - SPMDocumento3 pagineBI Johor Paper1 (1) - SPMrajpus08Nessuna valutazione finora

- Good Will Hunting Report AnalysisDocumento8 pagineGood Will Hunting Report AnalysislylavanesNessuna valutazione finora

- National Green Tribunal Monthly Round Up For January 2019Documento5 pagineNational Green Tribunal Monthly Round Up For January 2019Shyanjali DattaNessuna valutazione finora