Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Assignment 3 - Refrigeration

Caricato da

Pankaj KanatheDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Assignment 3 - Refrigeration

Caricato da

Pankaj KanatheCopyright:

Formati disponibili

MECH 390

Assignment #3 (Refrigeration)

Assignment date: Tuesday Jan 30, 2007

Due date: Tuesday Feb. 06, 2007

Problem 1:

Figure below shows a steam jet refrigeration system that produces chilled

water in a flash chamber. The chamber is maintained at a vacuum pressure by

the steam ejector, which removes the vapor generated by entraining it in the

low-pressure jet and discharging into the condenser. The vacuum pump

removes air and other non-condensable gases from the condenser shell. For

the conditions shown on the figure, determine the make-up water and cooling

water flow rates in kg/h.

Vacuum pump

Ejector nozzle

Sat. vapor at Steam jet

200 kPa

Sat. vapor

1 7

Cooling water in

Make-up water 6 @ 15 C

@ 15 C

5

Flash chamber 25 C

P = 4 kPa

water Condenser

4 5C 8

Cooling load

142 tons Condensate

2 return to drain

QL

25,000 kg/h

Pump

3

Note: 1 ton (of refrigeration) = 211 kJ/min.

M. Bahrami MECH 390 (W 07) Assignment #3 1

Problem 2:

The schematic diagram of a two evaporator refrigeration cycle is shown in the

figure below where refrigerant R-134a is used. The arrangement is used to

achieve refrigeration at two different temperatures with a single compressor

and a single condenser. The low-temperature evaporator operates at -18C with

saturated vapor at its exit and has a refrigerating capacity of 3 tons. The

higher-temperature evaporator produces saturated vapor at 3.2 bar at its exit

and has a refrigerating capacity of 2 tons. Compression is isentropic to the

condenser pressure of 10 bar. There are no significant pressure drops in the

flows through the condenser and the two evaporators, and the refrigerant

leaves the condenser as saturated liquid at 10 bar. Calculate:

1) the mass flow rate of refrigerant through each evaporator, in kg/min

2) the compressor power input, in kW

3) the rate of heat transfer from the refrigerant passing through the condenser,

in kW.

Qout

3 2

Condenser

Win

Expansion

valve Compressor

4 1

Evaporator 2 7 8

Expansion

valve

Qin, 2 = 2 tons

Expansion

valve

6

Evaporator 1

5 Qin, 1 = 3 tons

M. Bahrami MECH 390 (W 07) Assignment #3 2

Problem 1 Solution:

Assumptions:

1) each component is analyzed as a control volume at steady-state

2) the pump work is negligible

3) kinetic and potential energies effects are negligible

4) no heat transfer with the surroundings.

Analysis:

First we fix each state of the system.

State 1: sat. vapor, 200 kPa h1 = 2706.7 kJ/kg

State 2: sat. liquid, 5°C h2 = 20.98 kJ/kg

State 3: h3 h2 w

pump

m h2

2

0

State 4: Q load 142 ton 1.798 10 6 kJ / h

Q load 1.798 10 6

h4 h3

20.98 92.9kJ / kg

m 25,000

State 5: T5 = 15°C; h5 ≈ hf (T5) = 62.99 kJ/kg

State 6: sat. vapor, 5°C h6 = 2510.6 kJ/kg

State 7: sat. vapor, 4 kPa h7 = 2554.4 kJ/kg

State 8: sat. liquid, 4 kPa h8 = 121.46 kJ/kg

Now, consider a control volume enclosing the flash chamber:

m 4 h4 m 5 h5 m 2 h2 m 6 h6

m4 m2 m5 m6

thus

m 5 h5 h6 m 2 h2 h4

m 5 734.6 kg / h

Next, consider a control volume enclosing the steam jet ejector.

m1 h1 m 6 h6 m 7 h7

m 7 m1 m 6 or,

M. Bahrami MECH 390 (W 07) Assignment #3 3

m6 m6 m6

1 h1 h6 h7 0.7766

m7 m7 m7

m 7 945.9 kg / h

Finally, for the condenser

m 7 h7 h8 m cw hcw,out hcw,in

hcw,in = hf (15°C) = 62.99 kJ/kg and hcw,out = 104.89 kJ/kg

Thus,

m cw 54,920 kg / h

Problem 2 Solution:

Assumptions:

1) each component is analyzed as a control volume at steady-state

2) all processes are internally reversible, except for throttling through expansion valves

3) the compressor and exp. valves are adiabatic

4) potential and kinetic energies effects are negligible.

T 2

P = 10 bar

7

4 3.2 bar

8

-18 C 5

1

6 s

Analysis:

Fix each of the principal states:

State 3: P3 =10 bar, sat. liquid h3 = 105.29 kJ/kg

State 4: Throttling process h4 = h3 = 105.29 kJ/kg

State 5: Throttling process h5 = h4 = 105.29 kJ/kg

State 6: T6 = -18 °C, sat. vapor h6 = 236.53 kJ/kg

State 7: P7 = 3.2 bar, sat. vapor h7 = 248.66 kJ/kg

M. Bahrami MECH 390 (W 07) Assignment #3 4

State 8: Throttling process h8 = h7 = 248.66 kJ/kg

Fixing state 1 and 2 requires the mass flow rates through the evaporators. Thus:

Q in,1 m 6 h6 h5

Q in ,1 3tons 211kJ / min

m6 4.823kg / min

h6 h5 236.53 105.29 kJ / kg 1ton

and

Q in, 2 2tons 211kJ / min

m8 2.943kg / min

h7 h4 248.66 105.29 kJ / kg 1ton

State 1: Now, for adiabatic mixing streams 6 and 8 to form stream 1:

m 6 h6 m 8 h8 m 6 m 8 h1 0

m 6 h6 m 8 h8

h1

241.13kJ / kg

m 6 m8

Having the enthalpy and pressure of state 1, the specific entropy is found s 1 = 0.9493

kJ/kg.K.

State 2: P2 = 10 bar, s2 = s1 h2 = 282.3 kJ/kg

b) the compressor power is:

w c m 6 m 8 h2 h1 5.329 kW

For the condenser

Q out m 6 m 8 h2 h3 22.91 kW

M. Bahrami MECH 390 (W 07) Assignment #3 5

Potrebbero piacerti anche

- MECH 461 Assignment #3 (RefrigerationDocumento5 pagineMECH 461 Assignment #3 (Refrigerationshadow friendNessuna valutazione finora

- Assumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are NegligibleDocumento1 paginaAssumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are NegligibleRalph Bernard Dela RosaNessuna valutazione finora

- Refrigeration Systems Lecture Notes - Batch 7 Bsme-3ADocumento7 pagineRefrigeration Systems Lecture Notes - Batch 7 Bsme-3AkhinojidaNessuna valutazione finora

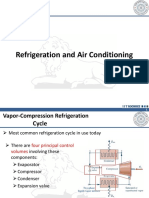

- Refrigeration and Air Conditioning Vapor Compression Cycle GuideDocumento24 pagineRefrigeration and Air Conditioning Vapor Compression Cycle GuideKevin PatelNessuna valutazione finora

- 2 - LEC 2 Refrigeration CyclesDocumento52 pagine2 - LEC 2 Refrigeration Cycleskolkolmohammed27Nessuna valutazione finora

- Refrigeration Cycles Study Guide in Powerpoint: To AccompanyDocumento20 pagineRefrigeration Cycles Study Guide in Powerpoint: To AccompanyDocumentos De Interés para IngenieríaNessuna valutazione finora

- Homework 1 &2Documento7 pagineHomework 1 &2mohamed.ahmed017Nessuna valutazione finora

- Chapter 9: Vapor and Combined Power Cycles: Heat Source T TDocumento21 pagineChapter 9: Vapor and Combined Power Cycles: Heat Source T TMadhurya BaruahNessuna valutazione finora

- Heat Source TDocumento24 pagineHeat Source TTemesgen ZelekeNessuna valutazione finora

- CH 02Documento112 pagineCH 02lastlanding50% (2)

- A FALL 2018 PET & Agric ENG THERMODYNAMICS EXAM I I CHE 304 CHE 212 Fall SOLUTIONDocumento3 pagineA FALL 2018 PET & Agric ENG THERMODYNAMICS EXAM I I CHE 304 CHE 212 Fall SOLUTIONfalmubaddelNessuna valutazione finora

- Refrigeration Cycles Study Guide in Powerpoint: To AccompanyDocumento20 pagineRefrigeration Cycles Study Guide in Powerpoint: To AccompanyMardian MardianNessuna valutazione finora

- Refrigeration Cycle Notes Lec9-1Documento20 pagineRefrigeration Cycle Notes Lec9-1mickey.102987Nessuna valutazione finora

- RefrigerationDocumento10 pagineRefrigerationrathore050587Nessuna valutazione finora

- Refrigeration Cycle: Key Components and ProcessesDocumento8 pagineRefrigeration Cycle: Key Components and ProcessesZain Ul AbideenNessuna valutazione finora

- Vapor-Compression Refrigeration SystemsDocumento28 pagineVapor-Compression Refrigeration Systemsm_alodat6144Nessuna valutazione finora

- Thermo LecDocumento18 pagineThermo LecOmer MoniemNessuna valutazione finora

- Lapres PendinginDocumento60 pagineLapres PendinginGiantcanaNessuna valutazione finora

- AmatrolDocumento9 pagineAmatrolGiyan Arpero ManiaNessuna valutazione finora

- Question 1. A Refrigerator Uses Refrigerant-134a As The Working Fluid and Operates On An IdealDocumento5 pagineQuestion 1. A Refrigerator Uses Refrigerant-134a As The Working Fluid and Operates On An Idealfivos_rgNessuna valutazione finora

- Boles Lecture Notes Thermodynamics Chapter 10Documento15 pagineBoles Lecture Notes Thermodynamics Chapter 10prince assiriNessuna valutazione finora

- Experiment On Refrigeration TutorDocumento11 pagineExperiment On Refrigeration TutorGgNessuna valutazione finora

- Amatrol Baru PDFDocumento6 pagineAmatrol Baru PDFGiyan Arpero ManiaNessuna valutazione finora

- C 10Documento107 pagineC 10نواف عبداللهNessuna valutazione finora

- Moran Shapiro Munson DeWitt - Introduction To Thermal Systems Engineering Cdrom Examples 7 - 3 7 - 7 7 - 12Documento7 pagineMoran Shapiro Munson DeWitt - Introduction To Thermal Systems Engineering Cdrom Examples 7 - 3 7 - 7 7 - 12Gabriel Victor SantanaNessuna valutazione finora

- Chapter 5 Refrigeration CondensersDocumento33 pagineChapter 5 Refrigeration CondensersRutaremwa VicentNessuna valutazione finora

- Refrigeration: Definitions and Useful InformationDocumento18 pagineRefrigeration: Definitions and Useful InformationJeffcaster ComelNessuna valutazione finora

- Module 2 (Refrigeration Lecture Manual)Documento45 pagineModule 2 (Refrigeration Lecture Manual)Shirley PelagioNessuna valutazione finora

- Refrigeration and AirconditioningDocumento107 pagineRefrigeration and Airconditioningadrian paul relayosaNessuna valutazione finora

- 15 RefrigerationDocumento10 pagine15 RefrigerationAsifur RumonNessuna valutazione finora

- Refrigeration and Heat Pump SystemsDocumento26 pagineRefrigeration and Heat Pump SystemsJojolasNessuna valutazione finora

- Tutorial 6sol2 PDFDocumento4 pagineTutorial 6sol2 PDFSohayb GattousNessuna valutazione finora

- Mmchapter 7 Steam Generator and AuxilliariesDocumento49 pagineMmchapter 7 Steam Generator and AuxilliariesKent Louie EyanaNessuna valutazione finora

- Thermodynamic Lab Experiment 8Documento6 pagineThermodynamic Lab Experiment 8Ronaldo UlisiNessuna valutazione finora

- Rankine cycle analysis and efficiency calculationsDocumento3 pagineRankine cycle analysis and efficiency calculationsSafaa Hameed Al NaseryNessuna valutazione finora

- Tutorial 21 Feedwater HeaterDocumento22 pagineTutorial 21 Feedwater HeaterSrashmiNessuna valutazione finora

- Chapter - 4 (Livro Com Exercícios Termodinâmica)Documento56 pagineChapter - 4 (Livro Com Exercícios Termodinâmica)Eder SoaresNessuna valutazione finora

- Solution Manual For Engineering and Chemical Thermodynamics 2nd Ed - Milo KoretskyDocumento20 pagineSolution Manual For Engineering and Chemical Thermodynamics 2nd Ed - Milo KoretskyAbolfazl29% (7)

- Reverse CarnotDocumento23 pagineReverse CarnotFlyNarutoFlyNessuna valutazione finora

- Ensc 461 Tutorial, Week#6 - Refrigeration Cycle: High Pressure Side P 700kpaDocumento6 pagineEnsc 461 Tutorial, Week#6 - Refrigeration Cycle: High Pressure Side P 700kpaArchie Gil DelamidaNessuna valutazione finora

- ICE PLANT TEST RIG PERFORMANCEDocumento9 pagineICE PLANT TEST RIG PERFORMANCEramniwas123Nessuna valutazione finora

- Absorption Refrigeration CycleDocumento50 pagineAbsorption Refrigeration CycleAndrew PantaleonNessuna valutazione finora

- Assignment 1 Soln PDFDocumento13 pagineAssignment 1 Soln PDFJawahar Khetan100% (1)

- Me 470 Refrigeration Cycles HW SolDocumento6 pagineMe 470 Refrigeration Cycles HW Solalagar krishna kumarNessuna valutazione finora

- Diesel engine power output at 2300 rpmDocumento3 pagineDiesel engine power output at 2300 rpmSohayb GattousNessuna valutazione finora

- MM321 Lab 3Documento5 pagineMM321 Lab 3Roshiv SharmaNessuna valutazione finora

- Ammonia Refrigeration Cycle AnalysisDocumento44 pagineAmmonia Refrigeration Cycle AnalysisAntonio Di FioreNessuna valutazione finora

- Heating VentilationDocumento20 pagineHeating VentilationAshan LiaqatNessuna valutazione finora

- Question 1. During An Experiment Conducted in A Room at 25Documento11 pagineQuestion 1. During An Experiment Conducted in A Room at 25fivos_rgNessuna valutazione finora

- Steam Power Plant LecturesDocumento36 pagineSteam Power Plant LecturesKariem Zaki100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Handbook of Heating, Ventilating and Air ConditioningDa EverandHandbook of Heating, Ventilating and Air ConditioningValutazione: 4 su 5 stelle4/5 (6)

- SDOF Forced VibrationsDocumento15 pagineSDOF Forced VibrationsSachin BharadwajNessuna valutazione finora

- Dynamic Measurements Instruments GuideDocumento10 pagineDynamic Measurements Instruments Guidekottapalli krishna chaitanyaNessuna valutazione finora

- Guideline FullDocumento281 pagineGuideline FullPankaj KanatheNessuna valutazione finora

- Chapter 5 Heat PDFDocumento39 pagineChapter 5 Heat PDFPankaj KanatheNessuna valutazione finora

- PrefaceDocumento44 paginePrefaceAravind SrinivasanNessuna valutazione finora

- Chapter 5 Heat PDFDocumento39 pagineChapter 5 Heat PDFPankaj KanatheNessuna valutazione finora

- ME 313 CH 9 Exaples and Solutions Fall 2017Documento14 pagineME 313 CH 9 Exaples and Solutions Fall 2017Pankaj KanatheNessuna valutazione finora

- ELIGIBILITY: ONLY Those Students Who Register On Tata Innoverse and Campus Commune Can ParticipateDocumento5 pagineELIGIBILITY: ONLY Those Students Who Register On Tata Innoverse and Campus Commune Can ParticipatePankaj KanatheNessuna valutazione finora

- Community Noise 2Documento18 pagineCommunity Noise 2interlude347Nessuna valutazione finora

- 322bookf ME PrelimsExam Cover Vol IDocumento2 pagine322bookf ME PrelimsExam Cover Vol IPankaj KanatheNessuna valutazione finora

- Chapter 7 - Work Study (Time and Motion Study)Documento8 pagineChapter 7 - Work Study (Time and Motion Study)Pankaj KanatheNessuna valutazione finora

- Work Study (Time and Motion Study)Documento34 pagineWork Study (Time and Motion Study)Ashween DOUTALNessuna valutazione finora

- 0 EDEM Applications MeDocumento16 pagine0 EDEM Applications MeRuben PurcaNessuna valutazione finora

- Admin Interview Questions and Answers - Robert HalfDocumento2 pagineAdmin Interview Questions and Answers - Robert HalfWaqqas AhmadNessuna valutazione finora

- Varco Manual ElevatorDocumento54 pagineVarco Manual ElevatorJohn Jairo Simanca Castillo100% (1)

- Understand Centrifugal CompressorDocumento16 pagineUnderstand Centrifugal Compressorramanathan72-1100% (2)

- YEZ-Conical Brake MotorDocumento3 pagineYEZ-Conical Brake MotorMech MallNessuna valutazione finora

- A1.2.3 Method Statement 4a Redacted Version2Documento98 pagineA1.2.3 Method Statement 4a Redacted Version2ChanelNessuna valutazione finora

- Chap1-Geometrical Optics - ExercisesDocumento3 pagineChap1-Geometrical Optics - ExercisesReema HlohNessuna valutazione finora

- Rob Thomas Digital Booklet - Cradle SongDocumento15 pagineRob Thomas Digital Booklet - Cradle SongAgnieszka ŁukowskaNessuna valutazione finora

- Prefabricated Structures ComponentsDocumento16 paginePrefabricated Structures ComponentsKrish KrishNessuna valutazione finora

- Mid Exam Odd Semester Academic Year 2021/2022 Study Program Management Faculty of Business Universitas Multimedia NusantaraDocumento9 pagineMid Exam Odd Semester Academic Year 2021/2022 Study Program Management Faculty of Business Universitas Multimedia NusantaraaekimNessuna valutazione finora

- CSE 390 Bash Command ReferenceDocumento3 pagineCSE 390 Bash Command Referencesam100% (1)

- Associating Numbers With Sets Having 51 Up To 100 Objects or ThingsDocumento4 pagineAssociating Numbers With Sets Having 51 Up To 100 Objects or ThingssweetienasexypaNessuna valutazione finora

- UCID Number Request FormDocumento1 paginaUCID Number Request FormOmar AwaleNessuna valutazione finora

- PLCDocumento16 paginePLCMohit Kinger100% (1)

- Tyre ManufacturingDocumento18 pagineTyre ManufacturingniteshkrisNessuna valutazione finora

- Gillette and The Men's Wet Shaving Market: Group 8 Section BDocumento12 pagineGillette and The Men's Wet Shaving Market: Group 8 Section BAmit Hemant JainNessuna valutazione finora

- 0.9PF PW 380v 3phase HF UPS10-120kvaDocumento8 pagine0.9PF PW 380v 3phase HF UPS10-120kvaArmandinho CaveroNessuna valutazione finora

- Selection ToolsDocumento13 pagineSelection ToolsDominador Gaduyon DadalNessuna valutazione finora

- Sample Lab ReportDocumento4 pagineSample Lab ReportHolley WrightNessuna valutazione finora

- DML Sro Karnal RMSDocumento5 pagineDML Sro Karnal RMSEr Rohit MehraNessuna valutazione finora

- AMG ActuatorsDocumento12 pagineAMG ActuatorsMohan ArumugavallalNessuna valutazione finora

- F1FR80 Series Quick-Response SprinklersDocumento6 pagineF1FR80 Series Quick-Response SprinklersAtila AmayaNessuna valutazione finora

- حل جميع المعادلات الكهربائيةDocumento60 pagineحل جميع المعادلات الكهربائيةGandhi HammoudNessuna valutazione finora

- Milenium BypassDocumento1 paginaMilenium BypassdinotecNessuna valutazione finora

- Raft Foundations - Design & Analysis With A Practical Approach PDFDocumento140 pagineRaft Foundations - Design & Analysis With A Practical Approach PDFemmanuel83% (6)

- Ficha Tecnica 750 GPMDocumento156 pagineFicha Tecnica 750 GPMByron Chele0% (2)

- Virginia Transformer - Developments in Traction TransformersDocumento10 pagineVirginia Transformer - Developments in Traction TransformersTshepo Sharky SebeNessuna valutazione finora

- Cybersecurity-Student-Book Res Eng 1014Documento38 pagineCybersecurity-Student-Book Res Eng 1014Nistor Andreea Maria100% (1)

- Auto BestBuys MAKATI CITY September ListingDocumento5 pagineAuto BestBuys MAKATI CITY September ListingWill GeronaNessuna valutazione finora

- Phase Locked LoopDocumento4 paginePhase Locked LoopsagarduttaNessuna valutazione finora