Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

05449493

Caricato da

Minhaj AkbarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

05449493

Caricato da

Minhaj AkbarCopyright:

Formati disponibili

Impact of Operating Parameters on Characteristics

of Effervescent Nozzle

2

Yunjing CUI1, Maojun YU2, Xingqi QIU3, Guangdong Development and Reform Committee

Peiyong MA1, Qizhao LIN1 3

Industry Department, Guangzhou, China

1

Department of Thermal Science and Energy Engineering College of Machinery and Electronic Engineering,

University of Science and Technology of China China University of Petroleum, Dongying, China

Hefei, China

cuiyj200@163.com

Abstract—An effervescent nozzle was designed to solve the investigation, experiments involving the influence of ALR and

combustion problems of the high viscosity oils. Experimental fluid pressures on the flow type and atomization characteristics

study on its atomization and flow characteristics about operation of the designed effervescent nozzle were conducted.

parameters was performed. It was found that the atomization

quality is better in the conditions that ALR (air-to-liquid mass

ratio) is 0.001~0.012 and the air to liquid pressure ratio is 1~1.1. II. EXPERIMENT SETUP

Empirical formulas of ALR and μ (flow coefficient of the nozzle Fig. 1 shows the structure of the designed nozzle. Table 1

exit), ALR and the liquid flow rate Ql were obtained by fitting shows the main structure and size of the effervescent nozzle.

the experimental data in different formats. The experimental To observe the flow type, the mixing chamber was made by

results have guiding significance for the nozzle design and its embeddable organic glass tubes.

field application.

As shown in Figs. 2 and 3, the experimental apparatus

Key words-effervescent atomizationl; ALR; SMD; APV/LDV includes water supply system, air supply system, control

system, spray system and measurement system. In this study,

I. INTRODUCTION water and compressed air were used as the working fluid. As

There are many problems including large consumption of shown in Fig. 4, the sum of the bubble’s surface tension and

fuel or atomization medium, incomplete combustion, easily the pressure differential inside and out of the bubbles at the

jam and coking existing in both the civil boiler and the large vent just before the explosion, which is about 0.5 MPa, far

industrial burners using high viscosity fuel such as heavy oil, outweighs that of the cohesive force between the molecules

residue and slurry oil[1]. According to GB13271-2001 "Boiler (With the temperature dropping, the viscosity drops) and the

air pollutant emission standard", the combustion equipments force of the atomization air. So the bubbles break into pieces

[8]

with these problems are territorially restricted. . For this reason the fuel’s viscosity were ignored and water

was used instead in experiments.

As effervescent atomization has many advantages,

especially being insensitive to oil viscosity and not clogging While a group of geometric parameters of effervescent

orifices easily, it is suitable for heavy oil and residue [2]. nozzle and air pressure were decided, we changed liquid

pressure to get the parameters such as ALR, Pa/Pl (air and

As is known, operational parameters such as air and liquid liquid pressure ratio), axial and radial velocities, droplet

pressures and ALR have great influence on the flow type, flow diameters and other information of the measuring points on

characteristics and atomization characteristics. L. s. Liu [3-7] has several horizontal radii. The measuring points were 3 mm at

done a great deal of research on effervescent atomization intervals on each measurement radius. As shown in Fig. 3, the

including the impact of ALR. Atomization characteristics are spray was measured by APV/LDV (Adaptive Phase-Doppler

different according to nozzle types and structures. To Laser Velocimetry) system.

accumulate information for nozzle design and atomization

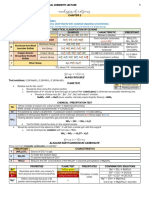

TABLE I. STRUCTURE DEMENSIONS OF THE DESIGNED EFFERVESCENT NOZZLE (MM)

Orifice Air/liquid Injection holes Mixing chamber

No. cone Slenderness of Air injection Liquid injection Injection area ratio

Orifice Slenderness

angle, ° orifice holes holes of air to liquid

1 φ3.0 120 1.53 10×φ1 6×φ1 1.67 1.6

2 φ2.5 120 1.6 10×φ1 6×φ2 0.42 2

3 φ1.5 120 1.93 16×φ1 6×φ1 2.67 2.67

4 φ2.5 90 1.6

978-1-4244-4813-5/10/$25.00 ©2010 IEEE

4

Figure 4. Stress on one bubble at the vent just before explosion[8]

1-Mixing chamber; 2-Orifice; 3-Bubble generator; 4-Liquid injection holes;

Figure 1. Schematic diagram of effervescent nozzle

80

70

SMD(μm)

60

L/ D=1.6

50 L/ D=2.0

L/ D=2.6 7

40

0.9 1 1.1 1.2

Pa /Pl

Figure 5. Impact of Pa/Pl on SMD with different mixing chamber

slenderness (z=150 mm, r=12 mm)

1-Air manometer; 2-Liquid manometer; 3- Manometer for the mixing

chamber; 4-Oattype flowmeter; 5-Water meter; 6- Nozzle;

7-Recirculation water meter; 8- Water box.9- Air vessels; 100

10- Air compressor;

80

Figure 2. A scheme of experiment

SM D(μm)

60

40

20

0 0.01 0 .02 0 .03

ALR

Figure 6. Impact of ALR on SMD (z=150 mm, r=12 mm, do=2.5 mm)

Figure 3. APV/LDV system[9]

Figure 7. Velocity distribution of the spray field (do=2.5 mm)

The inner pressure of effervescent nozzle influences its

atomization significantly because energy for bubbles expansion

2000 is related to Pm[11].

1600

Generally, in a certain pressure range the increase of Pa

Ql (kg/h) 1200 causes the rise of Pm. The increase of expansion energy of

800 bubbles helps to enhance atomization. The increases of Pa and

400 Pl improve the axial and radial velocities of spray droplets and

0 decrease the spray SMD (Sauter Mean Diameter).

0 0.01 0.02 0.03 Given Pa is fixed, decrease of Pl causes the fall of liquid

ALR flow rate Ql, rise of Pa/Pl and ALR and enhancement of the

shearing and entrainment actions of air on liquid. At the other

Figure 8. Relation between Ql and ALR (z=150 mm, r=12 mm) side, if Pm decreases, the burst energy reduces. So there is a

critical point at which atomization is best and SMD of droplets

is smallest in the course of ALR increasing and the Pm

0.8 decreasing. As shown in the Figs. 6 and 8, atomization effect is

good as ALR is between 0.001 and 0.012. When ALR is about

0.6 0.006, SMD of spray droplets is about 67 μm. It is evident in

0.4 Fig. 5 that SMD of spray droplets is smallest when Pa/Pl is

μ

between 1 and 1.1. If ALR continues to increase, the flow type

0.2 changes and the spray turn to be bad. Fig. 6 shows that SMD of

droplets are between 40 ~ 80 μm.

0

0 0.01 0.02 0.03 3) The impact of the operational parameters on the nozzle

ALR flow characteristics

Figure 9. Relation between ALR and μ (z=150mm, r=12mm) Fig. 7 shows the droplets velocity distribution on the six

horizontal measurement radii under one operating condition. r

is the measurement point on each radius. R is the radius length

III. RESULTS AND DISCUSSION at the distance of 400 mm downstream of the nozzle tip.

1) The impact of operating parameters on the flow type According to the symmetry characteristics of the spray field,

ALR is a significant operating parameter which influences spray velocity is bell-shaped distributed on each measurement

the atomization performance. While ALR increases from 0, the section. Velocities of droplets fall from spray center

flow rate of bubbles increases and the shearing action of air on horizontally to the edge and change little vertically downward

liquid enhances to break liquid films easily. But if ALR from the nozzle tip except the vent.

continues increasing, the bubble flow will turn to be slug flow Fig. 8 shows the relationship between Ql and ALR for

or annular flow, even pulse flow or air seal. For air pressure different nozzle structure with many operating parameters. For

inside the nozzle is so high that air flows into the liquid given Pa, with the increase of ALR, Ql decreases sharply first

injection holes and liquid is injected into the mixing chamber and then slowly. The reason is that air takes up more flow area

intermittently to form slug flow. When large air flows slowly, of the orifice with the increase of air flux or decrease of water

the bubbles are easy to gather and form annular flow. At high one. For given nozzle structure, the smaller ALR, the droplets

operating pressure, whistling occurs and atomization velocities and Ql are higher.

performance is improved a little. It is believed that air stream

inside the nozzle form cavitations and high-frequency As shown in the figure 9, the relationship between ALR

whistling. Both Air and liquid have injection pressure and μ is obtained by power format fitting the experimental

limitations. Once one reaches its limitation, air seal or liquid data.

seal will occur.

μ = 0.0308(ALR) -0.4587 (1)

The following phenomena found in experiments are

consistent with literatures [10] and [11]. There is a complex IV. CONCLUSIONS

inter-dependence relationship among the liquid flow rate Ql ,

air flow rate Qa , liquid pressure Pl , air pressure Pa and the

pressure in the mixing chamber Pm. It is difficult to control Ql, The following conclusions are deduced from experiments.

Qa and Pm by regulating Pl or Pa separately. In practice, special Special attention should be paid to the coordination of the

attention should be paid to the mutual coordination of the inter-dependently operating parameters in experiments.

various operating parameters. For a given nozzle structure, Pl,

Pa, and Pm are certain and the sequence of air and liquid In the conditions that ALR is between 0.001 and 0.012 and

flowing into the mixing chamber does not impact Pm which is Pa/Pl is between 1 and 1.1 the atomization performance is best.

affected more by Pa than by Pl. The flow characteristics of the designed effervescent nozzle are

shown as the following formula.

2) The impact of the operating parameters on SMD of

droplets μ = 0.0308(ALR) -0.4587.

If ALR continues to increase, bubble flow begins to change [6] L. S. Liu, J. X. Wu, Z. X. Han, H. Yang, “Investigation on the flow

the flow type. The critical conditions and relative atomization pattern in mixing-chamber and stability of spray of effervescent

atomizers,” Journal of Combustion Science and Technology, 8(4), pp.

performances should be ascertain in further study. 353-357, 2002.

[7] L. S. Liu, H.Yang, G. H. Heng, C. Du, C. H. Zhang, “Influences of

V. REFERENCES Air/Liquid Mass Flow Rate on Spray Combustion Produced by

Effervescent Atomizer”, Journal of Combustion Science and Technology,

[1] Zh. X. Han, “Experimental study of effervescent atomizer spraying 13(1), pp. 10-14, 2007.

horizontally,” [Master's thesis], Hebei University of Technology,

Tianjin, 2001. [8] Y. J. Cui, “Experiment study on characteristics of effervescent

emulsified oil atomizer,” [Master's thesis], China University of

[2] D. H. Wu, “Effervescent atomization and other advanced combustion Petroleum, Dongying, 2005.

technologies,” Energy Technology, 21(3), pp.156~157, 2001.

[9] TSI Incorporated, Instruction Manual. USA: TSI Inc., 1997, pp. 1~2.

[3] L. S. Liu, J. X. Wu, M. L. Fu, E. Y Wang., “Experimental studies on the

spray characteristics of effervescent atomizers,” Journal of Combustion [10] L. Sh. Liu, “Atomization performance of efervescent atomizer and

Science and Technology, 7(1), pp. 63-66, 2001. experimental and theoretical analysis on its two phase flow field,”

[Doctor’s thesis], Tianjin University, Tianjin, 2001.

[4] L. S. Liu, M. L. Fu, H. WANG, J. X. Wu, E. Y. Wang, B. H. Sun,

“Experimental studies on the flow rate characteristic of effervescent [11] Q. L. Li, “Performance evaluating and the design of tripropellant

atomizers,” Journal of Combustion Science and Technology, 5(3), pp. injector,” [Doctor’s thesis], University of Defense Technology,

297-303, 1999. Changsha, 2003.

[5] L. S. Liu, J. X. Wu, Z. X. Han, M. L. Fu, “Studies of effervescent [12] S. K. Chen, A. H. Lefebvre, “Influences of Ambient Air Pressure on

atomization at different physical properties of spray fluid,” Journal of Effervescent Atomization,” Journal of Propulsion and Power, 9(4), pp.

Thermal Science and Technology, 1(2), pp. 128-132, 2002. 10~14, 1993.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Lecture 4 - Stress-Life ApproachDocumento97 pagineLecture 4 - Stress-Life Approache pNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- MEL 417 Lubrication Lec 030211Documento37 pagineMEL 417 Lubrication Lec 030211Gamini SureshNessuna valutazione finora

- API 6X Design CalculationsDocumento14 pagineAPI 6X Design Calculationschau nguyenNessuna valutazione finora

- Modeling and Simulation of Shaped ChargesDocumento150 pagineModeling and Simulation of Shaped ChargesAlbet Straus100% (1)

- The Composite Catalog of Oilfield Equipment and ServicesDocumento333 pagineThe Composite Catalog of Oilfield Equipment and ServicesJosé Timaná100% (1)

- Bombardier Aerospace Learjet Suppliers Listing by NameDocumento1.420 pagineBombardier Aerospace Learjet Suppliers Listing by NameHari PrasadNessuna valutazione finora

- 5 HPHT API 6x - FowlerDocumento13 pagine5 HPHT API 6x - Fowlerchau nguyenNessuna valutazione finora

- Three Dimensional HLB: Dr. Z PresentsDocumento21 pagineThree Dimensional HLB: Dr. Z PresentshbordasmNessuna valutazione finora

- Activity1 - 7 ScienceDocumento4 pagineActivity1 - 7 ScienceLhyn DE Leon DumayaNessuna valutazione finora

- API 6A 21 Edition WG: API Subcommittee SC-6 DiscussionsDocumento9 pagineAPI 6A 21 Edition WG: API Subcommittee SC-6 DiscussionsMinhaj AkbarNessuna valutazione finora

- Guidelines For LPG Filling Station Inspection 20070508 eDocumento21 pagineGuidelines For LPG Filling Station Inspection 20070508 eWinson Liem80% (5)

- NaOH Lİme SodaDocumento6 pagineNaOH Lİme SodaallatcoolNessuna valutazione finora

- FarshchiTabrizi MASc F2013 PDFDocumento127 pagineFarshchiTabrizi MASc F2013 PDFMinhaj AkbarNessuna valutazione finora

- Dumouchel2008 PDFDocumento52 pagineDumouchel2008 PDFMinhaj AkbarNessuna valutazione finora

- 186broukal PDFDocumento6 pagine186broukal PDFMinhaj AkbarNessuna valutazione finora

- Rahman 2014Documento5 pagineRahman 2014Minhaj AkbarNessuna valutazione finora

- CFD Simulation of Bubbly Two-Phase Ow in Horizontal Pipes: Chemical Engineering JournalDocumento12 pagineCFD Simulation of Bubbly Two-Phase Ow in Horizontal Pipes: Chemical Engineering JournalReza KHNessuna valutazione finora

- HCLT Whitepaper: A New Approach in Control Valve Design With A New Hybrid Flow CharacteristicDocumento17 pagineHCLT Whitepaper: A New Approach in Control Valve Design With A New Hybrid Flow CharacteristicHCL TechnologiesNessuna valutazione finora

- 011HOHDocumento6 pagine011HOHbasharNessuna valutazione finora

- Design and Analysis of MIixedflow Centrifugal PumpDocumento7 pagineDesign and Analysis of MIixedflow Centrifugal PumpMinhaj AkbarNessuna valutazione finora

- Casing Hanger Calculation PDFDocumento3 pagineCasing Hanger Calculation PDFMinhaj AkbarNessuna valutazione finora

- Engineering TransactionsDocumento16 pagineEngineering TransactionsMinhaj AkbarNessuna valutazione finora

- F-102 Delta DaggerDocumento2 pagineF-102 Delta DaggerMinhaj AkbarNessuna valutazione finora

- Refund of Security-Revised FinalDocumento1 paginaRefund of Security-Revised FinalMinhaj AkbarNessuna valutazione finora

- 10 5923 J Textile 20120106 04 PDFDocumento6 pagine10 5923 J Textile 20120106 04 PDFAnonymous PR3k6Pl7nNessuna valutazione finora

- Iran CISG PaperDocumento8 pagineIran CISG PaperMinhaj AkbarNessuna valutazione finora

- F-117 Nighthawk SpecificationsDocumento3 pagineF-117 Nighthawk SpecificationsMinhaj AkbarNessuna valutazione finora

- Lockheed, Chengdu, or Sukhoi: Which 5th Gen Fighter Will Win More CustomersDocumento3 pagineLockheed, Chengdu, or Sukhoi: Which 5th Gen Fighter Will Win More CustomersMinhaj AkbarNessuna valutazione finora

- Lawrence Livermore National LaboratoryDocumento3 pagineLawrence Livermore National LaboratoryMinhaj AkbarNessuna valutazione finora

- Hyper SoarDocumento1 paginaHyper SoarMinhaj AkbarNessuna valutazione finora

- Hyper SoarDocumento1 paginaHyper SoarMinhaj AkbarNessuna valutazione finora

- F4D SkyrayDocumento2 pagineF4D SkyrayMinhaj AkbarNessuna valutazione finora

- F-15 EagleDocumento4 pagineF-15 EagleMinhaj AkbarNessuna valutazione finora

- Test 1 September 2020 SemesterDocumento3 pagineTest 1 September 2020 SemesterAhmed AlwaqediNessuna valutazione finora

- Electronic Structure Comprehensive Exam GuideDocumento4 pagineElectronic Structure Comprehensive Exam GuideMonyratanak LimNessuna valutazione finora

- 2013Documento11 pagine2013Nguyễn Bá LâmNessuna valutazione finora

- Cation Analysis GuideDocumento3 pagineCation Analysis GuideJan MezoNessuna valutazione finora

- Hasil Pengujian Triaxial Cu TP.3Documento7 pagineHasil Pengujian Triaxial Cu TP.3BobNessuna valutazione finora

- MCS & MPS Exam SyllabusDocumento165 pagineMCS & MPS Exam SyllabusMangeshNessuna valutazione finora

- Unsteady Flow AccelerationsDocumento117 pagineUnsteady Flow AccelerationsAbdur Rauf Ali89% (9)

- Physics Investogatory Project 2023Documento17 paginePhysics Investogatory Project 2023revNessuna valutazione finora

- 5070 w17 Ms 41 PDFDocumento6 pagine5070 w17 Ms 41 PDFSaad ArsalanNessuna valutazione finora

- An Integrated Converter With Reduced Components For Electric Vehicles Utilizing Solar and Grid Power SourcesDocumento14 pagineAn Integrated Converter With Reduced Components For Electric Vehicles Utilizing Solar and Grid Power SourcesManoj BadoniNessuna valutazione finora

- Determination of Wavelength of Light by Newton's Rings MethodDocumento2 pagineDetermination of Wavelength of Light by Newton's Rings MethodDipankar Mishra100% (1)

- Tutorial 4Documento2 pagineTutorial 4Nombulelo NgcoboNessuna valutazione finora

- 3 - Introduction - Physical Geology Practice 2020Documento24 pagine3 - Introduction - Physical Geology Practice 2020William LimNessuna valutazione finora

- Nssbio3e Sb1a Ch02 eDocumento44 pagineNssbio3e Sb1a Ch02 emyaleung1221Nessuna valutazione finora

- Energy and Chemical Change: Chemistry: The Molecular Nature of Matter, 7EDocumento47 pagineEnergy and Chemical Change: Chemistry: The Molecular Nature of Matter, 7EpopoojiNessuna valutazione finora

- Gel Filtration ColumnDocumento2 pagineGel Filtration ColumnkostrenarijekaNessuna valutazione finora

- Chapter Three Working Fluids (A) Ideal Gas (Perfect Gas) :: Statement No. (1)Documento16 pagineChapter Three Working Fluids (A) Ideal Gas (Perfect Gas) :: Statement No. (1)Bonifacio MifañaNessuna valutazione finora

- Differential Equations Mass PDFDocumento27 pagineDifferential Equations Mass PDFDiana Marcela Sierra Varela100% (1)

- Some Basic Concepts of ChemistryDocumento26 pagineSome Basic Concepts of ChemistryAnuj SharmaNessuna valutazione finora

- Redox Titration QuizDocumento1 paginaRedox Titration QuizChen Lit YangNessuna valutazione finora

- Bonite Bonite LDDocumento2 pagineBonite Bonite LDManoj ChitreNessuna valutazione finora

- ASETAZOLAMIDDocumento9 pagineASETAZOLAMIDfarmasiNessuna valutazione finora

- Revised - Isr - Star Co Super Chaina (Model-B) - CTM Exams Syllabus Clarification @20.05.23Documento5 pagineRevised - Isr - Star Co Super Chaina (Model-B) - CTM Exams Syllabus Clarification @20.05.23Sai PraneethNessuna valutazione finora

- Experiment 5 LipidsDocumento13 pagineExperiment 5 LipidsClemence Marie FuentesNessuna valutazione finora